Article

citation information:

Vu

Hai, Q., Tran Quang, T., Nguyen Anh, N., Le Hong, Q., Hoang Khai, H. Research on

the design and simulation of frontal collision assessment of a truck with

emergency vehicle suppression system. Scientific

Journal of Silesian University of Technology. Series Transport. 2025, 128, 295-309. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2025.128.17

Quan VU HAI[1], Tam TRAN QUANG[2], Ngoc NGUYEN ANH[3], Quan LE HONG[4], Hung HOANG KHAI5

RESEARCH ON THE

DESIGN AND SIMULATION OF FRONTAL COLLISION ASSESSMENT OF A TRUCK WITH EMERGENCY

VEHICLE SUPPRESSION SYSTEM

Summary. In response to the

growing threat of vehicle-ramming attacks targeting critical infrastructure

such as airports, government facilities, and public gathering spaces, this

study focuses on the design and simulation of a direct frontal collision

between a heavy truck and an emergency vehicle barrier using the Finite Element

Method (FEM). The simulation model is developed to replicate realistic impact

conditions, allowing detailed analysis of the barrier’s structural behavior under extreme loads, including deformation

patterns, stress distribution, and energy absorption capacity. Material

properties, contact interactions, and boundary constraints are carefully

defined to enhance simulation accuracy. The results reveal that an optimally

designed barrier with reinforced structures and effective energy-dissipating

features can significantly reduce damage and vehicle intrusion, thereby

improving overall protective performance. This confirms the crucial role of

FEM-based simulation in the early design phase of physical security systems,

offering a cost-effective and predictive approach to evaluating and optimizing

barrier effectiveness before real-world deployment.

Keywords: crash simulation, emergency vehicle barrier, chevrolet

silverado, energy absorption, front-end collision,

hyper radios

1. INTRODUCTION

The

growing population, rapid urbanization, and increasing global security

instability have significantly elevated the risk of vehicle-ramming attacks –

particularly those involving trucks, which are heavy, easily accessible, and

difficult to stop. According to the Global Terrorism Database, vehicle-based

attacks accounted for over 50% of terrorism-related deaths in Western countries

in 2016 alone [1]. Additional studies, such as "Democratization of

terrorism: an analysis of vehicle-based terrorist events" [2], recorded

257 vehicle-related terrorist incidents worldwide between 1970 and 2019,

resulting in 808 deaths and 1,715 injuries – 71% of which occurred in just the

last six years of the study period. Crowded public spaces, including festivals,

sporting events, and outdoor dining areas, continue to be vulnerable targets.

In

this context, emergency vehicle barriers play a critical role in safeguarding

vital locations such as airports, government buildings, and high-profile

events. Analyzing the direct impact of collisions

between trucks and such barriers is essential for optimizing structural design,

minimizing potential damage, and enhancing the overall effectiveness of

protective systems. Advanced simulation tools, particularly those based on

Computer-Aided Engineering (CAE), offer valuable insights into the performance

of barrier systems under realistic crash conditions.

In

Vietnam, ensuring the security of critical infrastructure has become

increasingly urgent, especially amid deeper international integration and

mounting regional instability. The protection of administrative centers, military zones, and airports is not only a

national priority but also a reflection of the country’s international

credibility. High-profile visits by world leaders in 2023-2024 – including the

Presidents of the United States, Germany, and Russia – further underscore the

importance of maintaining robust and reliable security systems.

Given

the rising threat of terrorism and illegal intrusions across Southeast Asia,

research into high-performance barrier systems is both timely and essential.

Such efforts significantly contribute to national security by enabling the

design of practical, efficient, and modern defense

solutions aimed at protecting both people and critical infrastructure.

2. THEORETICAL FOUNDATIONS OF AUTOMOTIVE COLLISIONS

2.1.

Finite element method

The Finite Element Method

(FEM) is a numerical technique used to obtain approximate solutions for

physical fields within a problem domain by discretizing the space into simple

elements connected by nodes. FEM is widely applied in various fields such as structural

mechanics, heat transfer, fluid mechanics, acoustics, and many other

engineering problems.

In nonlinear dynamic analysis,

the equation of motion is derived based on the principle of virtual work and is

expressed in matrix form as follows [3]:

![]() (1)

(1)

Where:

X is the nodal position vector;

![]() is the acceleration vector;

is the acceleration vector;

[M] is the mass matrix;

[K] is the stiffness matrix;

![]() represents external forces.

represents external forces.

Nonlinearity arises from contacts, material behavior, and geometric

effects, necessitating an advanced time integration scheme to handle

strong nonlinearities.

2.2. Calculating the energy of the

collision problem

When a collision

occurs between a vehicle and an emergency barrier, the initial velocity of the

vehicle is denoted as vo

(the velocity at the onset of impact), and v is the velocity after the

collision with the obstacle. In this case, v = 0 and v0

≠ 0 (the vehicle comes to a complete stop) [4, 5]. The kinetic

energy at the moment of impact is determined by the following equation:

![]() (2)

(2)

In the case of a

perfectly plastic (inelastic) collision [6], the entire kinetic energy is

converted into deformation energy, which is calculated as:

![]() (3)

(3)

In there:

F – is

the instantaneous deformation force (N);

DX – is

the instantaneous deformation when the vehicle collides (m);

DV – is

the vehicle's deceleration (m/s);

DXmax – is the maximum

deformation of the front of the car when stopping (m);

m – is

the mass of the vehicle (kg).

The equation of

motion of the vehicle during the collision process is expressed as:

![]() (4)

(4)

3. MODEL

BUILDING

3.1.

Application of numerical simulation in collision problem analysis

This study employs HyperWorks

2020 with the Radioss solver for standardized model

analysis, ensuring consistency and accuracy. Design parameters are adjusted

across configurations to assess performance. The analysis follows a structured

workflow to ensure result reliability.

Fig. 1. Procedure for analyzing collision problems

3.2. Model

setup

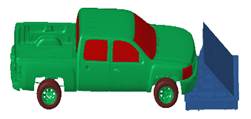

The researched vehicle, the

Chevrolet Silverado, is constructed using a body-on-frame design, similar to

that of heavy-duty vehicles like trucks and SUVs, rather than the unibody

construction commonly found in passenger cars. This type of construction is

typical in trucks, off-road vehicles, and heavy-duty applications due to its

high strength, durability, and ability to withstand rough terrain and heavy

loads.

Based on the 3D model of the Chevrolet Silverado

vehicle from the CCSA open database sponsored by NHTSA, using Hypermesh software with Radioss

solver for meshing, the number of elements divided is 730068 elements with mesh

sizes from 6 mm to 10 mm [7].

|

a) |

b) |

Fig. 2. Simulation

model: a) Chevrolet Silverado; b) setting up material for the model

Tab. 1

Chevrolet Silverado

vehicle specifications [7]

|

Type |

Chevrolet

Silverado version 3E |

|

Body

type |

4-door short cab pickup

truck |

|

Weight |

2,337

kg (5,152 lb) |

|

Engine

type |

4.8L

V8 |

|

Gear |

M30

4 Speed Automatic |

|

Tire

size |

P245/70R17 |

Then

create connections between the parts in the model, and create a rigid body to

create connections between the non-welded parts, and replace the missing parts.

Create materials and material properties for each part of the car.

Tab.

2

Material

specifications [8]

|

Material Parameter |

M36_PLAS_TAB (Case and chassis) |

M1_ELAST (Tire) |

M44_COWPER (Glasses) |

Unit |

|

Volumetric mass |

7.85e-09 |

7.86e-09 |

2.5e-09 |

Kg / m3 |

|

Young's modulus |

210000 |

200000 |

70000 |

MPa |

|

Poisson's ratio |

0.3 |

0.28 |

0.22 |

|

|

Yield stress |

|

|

30 |

MPa |

|

Plastic stiffness coefficient |

|

|

1000 |

MPa |

3.3. Set up interactions between components

The collision problem is a complex nonlinear problem,

with contact being one of the most important factors. Physically, contact

refers to the transfer of stress between two rigid bodies when they are in

contact. Numerically, contact is a nonlinear form due to its severe

discontinuity.

Modeling the contact between the parts is very

important to ensure accurate and realistic simulation results. We use the TYPE7

option to set up the interaction between the parts. The main advantage of the

TYPE7 interface is that the stiffness is constant and increases as the node

passes through the middle surface of the shell. This solves many problems with

poor contact (common when using TYPE3 or TYPE5 interfaces) [10].

There are three types of interactions that need to be

implemented. The first is the interaction among the finite elements of the

vehicle (Figure 3a), followed by the interaction among the finite elements of

the barrier (Figure 3b), and finally, the finite element interaction between

the vehicle and the barrier.

|

a) |

b) |

c) |

Fig. 3. Connection

setup: a) vehicle finite element connection; b) barrier finite element

connection; c) vehicle–barrier finite element connection

3.4. Set up road surface, wall and impact velocity

The

purpose of establishing interactions between the vehicle, and the road and the

wall is to avoid the occurrence of element penetration into the road or wall

during a collision. Then, the speed is assigned to all vehicle components; the

speed is selected as 40km/h based on the actual test speed when testing vehicle

collisions with walls, besides we will consider another case where the vehicle

hits the barrier at a speed of 60km/h (According to NHTSA).

Fig. 4. Infinitely

flat rigid walls after creation

4. RESULTS AND

DISCUSSION

4.1. Impact

energy

After analyzing the

conditions for collision and running the problem, we have energy lines such as

Internal Energy, Kinetic Energy, and Total Energy as shown in Figures 5 and 6.

Here we will have an energy balance to be able to evaluate the correctness of

the problem.

Fig. 5. Energy graph of the problem when the collision

occurs at a speed of 40km/h

Fig. 6. Energy graph of the problem when the collision

occurs at a speed of 60km/h

With a vehicle

mass of 1.378 tons and an initial speed of 40 km/h, the total theoretical

energy in this case is calculated as:

![]() J = 8.506

J = 8.506![]() 107 mJ (5)

107 mJ (5)

The

total energy from the simulation energy plot is 8,512.107 mJ. The result shows that the theoretical energy

and the simulation result are nearly identical, indicating that the simulation

model can be considered reliable.

With a

vehicle mass of 1.378 tons and an initial speed of 60 km/h, the total

theoretical energy in this case is:

![]() J =

J = ![]() mJ (6)

mJ (6)

The total energy from the energy plot is 1,915.108

mJ. The

close match between the theoretical calculation and simulation result again

demonstrates the reliability of the simulation model.

From the energy plots in Figure 5 and 6, it can be

seen that after the moment of impact (0.12 seconds), the total energy in the

system drops to 7,546. ![]() mJ (for 40 km/h) and 1,723.

mJ (for 40 km/h) and 1,723. ![]() mJ (for 60 km/h), corresponding

to an energy loss of approximately 11.3% and 10%, respectively. This lost

energy is not actually lost but is transformed into other forms such as

internal energy-reflecting structural deformation and interaction energy, which

represents hard-to-quantify forms like sound, heat due to friction, or

mechanical vibrations.

mJ (for 60 km/h), corresponding

to an energy loss of approximately 11.3% and 10%, respectively. This lost

energy is not actually lost but is transformed into other forms such as

internal energy-reflecting structural deformation and interaction energy, which

represents hard-to-quantify forms like sound, heat due to friction, or

mechanical vibrations.

Notably, the interaction energy in the two cases

reached 9,58. ![]() mJ (at 40 km/h) and

mJ (at 40 km/h) and

1,878. ![]() mJ (at 60 km/h), accounting for 99.17% and 97.8% of the total energy

dissipation, respectively. This indicates that most of the energy absorption

occurs in the contact and deformation zones, demonstrating the efficiency of

the emergency barrier in dissipating kinetic energy.

mJ (at 60 km/h), accounting for 99.17% and 97.8% of the total energy

dissipation, respectively. This indicates that most of the energy absorption

occurs in the contact and deformation zones, demonstrating the efficiency of

the emergency barrier in dissipating kinetic energy.

A portion of the energy loss may also be attributed

to numerical characteristics of the model, such as uneven mesh quality or

non-optimal boundary conditions. However, the close agreement between

theoretical values and simulation results confirms that the model accurately

reflects the energy transformation mechanism and can be used to predict the

safety performance of real-world damping solutions.

The energy analysis from the simulation clearly

demonstrates the system’s energy absorption and dissipation mechanisms during

collision, with the majority of the kinetic energy being converted into

internal and interaction energy-characteristic of plastic impact behavior. This forms an important foundation for assessing

the reliability of the model as well as its capability to protect passengers

and vehicles in real-world crash scenarios.

4.2. Vehicle safety

assessment during collision

Vehicle

timeline in process – Table 3.

Tab.

3

Timelines during the collision

|

|

|

At time 0

s |

|

|

|

At time 0.012 s |

|

|

|

At time

0.024 s |

|

|

|

At time

0.036 s |

|

|

|

At time

0.06 s |

|

|

|

At time

0.09 s |

|

|

|

At time

0.12 s |

When a vehicle collides with a rigid object such as

a barrier, the car’s frame structure suffers severe deformation, especially in

the front end and the area connecting the engine compartment and the passenger

cabin. A deformed front bumper can damage the engine and threaten driver safety

as the passenger compartment is intruded upon, reducing survival space.

To protect occupants, the cabin needs to be

reinforced with load-bearing beams at the doors, roof, and floor to limit

deformation during a collision. Analyzing the cabin

floor, particularly at the driver’s footrest area, helps assess intrusion

levels and propose design improvements.

According to IIHS standards [9], safety performance

is evaluated via crash simulations and the use of dummies to determine injury

severity. In numerical simulations, nodes on the vehicle floor are monitored to

measure displacement and intrusion into the passenger compartment. The results

are then compared with IIHS criteria to evaluate occupant protection and

suggest safer vehicle designs for the future.

Fig. 7. Measurement point for driver intrusion

The

research team measured the displacement of node 2039311 after the impact in two

velocity scenarios.

Fig. 8. Displacement graph of Node 2039311 along the X axis at

40 km/h

From

the displacement graph of Node 2039453 – representing the driver’s foot

location – it can be observed that from the moment of impact until

approximately 0.05 seconds, this point experienced significant continuous

deformation. The maximum displacement amplitude reached 316 mm, indicating a

strong direct impact that caused substantial movement in the vehicle floor.

After this moment, the displacement gradually decreased and stabilized around

0.12 seconds. While there was a slight recovery due to the material’s

elasticity, the deformation remained high and relatively unchanged post-impact.

According

to the Insurance Institute for Highway Safety (IIHS) [9], when floor

displacement exceeds 300 mm, the affected area is rated “Poor” – a serious

warning about the threat to the driver’s survival space. The displacement

exceeding this threshold at the footrest area indicates significant intrusion

into the cabin, potentially causing severe injuries to occupants, especially to

the legs and lower abdomen – vulnerable areas in frontal collisions.

From

these results, it can be concluded that the simulated Chevrolet vehicle

structure does not meet safety requirements for survival space in frontal

collisions with rigid objects at 40 km/h. This highlights the urgent need

to improve the design of load-bearing components at the front of the vehicle,

reinforce the cabin floor system, and optimize both the material and structural

geometry to better absorb and dissipate impact forces. Additionally, the

introduction of controlled crumple zones and reinforcements in the floor area

should be considered to reduce intrusion into the passenger cabin and enhance

occupant protection in severe crashes.

Fig. 9. Displacement graph of Node 2039311 along the X axis at

60 km/h

The

displacement graph of Node 2039311 at 60 km/h shows a peak displacement of

443.05 mm at 0.072 seconds, slightly decreasing to 427.76 mm at 0.12

seconds. Compared to the 40 km/h impact, the deformation reduces more slowly

due to the stronger force and insufficient material recovery time. The higher

impact speed leads to greater and longer-lasting deformation, causing more

severe structural damage to the vehicle.

According

to IIHS standards [9, 10, 11], a displacement exceeding 300 mm at the driver’s

foot area falls into the “red zone,” indicating a serious safety risk to the

passenger compartment. The results confirm that the vehicle fails to ensure

occupant survival space at both 40 km/h and 60 km/h, with a higher injury risk

at increased speeds.

Comparing

the two scenarios shows that increasing speed not only leads to greater

deformation but also reduces the structure’s recovery capability, emphasizing

the need for improved design to enhance safety across various collision speeds.

4.3. Barrier

Assessment

In

the crash simulation, the barrier is set in a fixed state, disallowing any

movement, to ensure that the resisting force is entirely concentrated on the

vehicle during the collision. This setup results in a sudden energy transfer

from the vehicle to the barrier, causing significant deformation to the

vehicle's frame structure and components such as the front bumper, engine

compartment, and body. Since the barrier does not move or deform significantly,

the collision energy is primarily absorbed by the vehicle.

In

reality, barriers have the capability to absorb collision energy through

deformation and displacement, which helps reduce the impact force on the

vehicle. Therefore, simulating a fixed barrier may limit the accuracy of

evaluating the energy absorption effectiveness of both sides. However, this

method simplifies the problem and provides a stable condition for collecting

data on displacement, deformation, and stress on the vehicle, even though it

does not fully reflect the actual interaction response between the vehicle and

the barrier under real-world conditions.

Tab.

4

Barrier model in two velocity cases

|

|

|

At time 0

s |

|

|

|

At time 0.024 s |

|

|

|

At time

0.12 s |

The crash simulation results show that the barrier

post experiences direct impact and significant deformation when the vehicle

crashes at a speed of 60 km/h. The strong impact force causes the post to bend

and fold right at the initial contact point; despite being reinforced, it still

undergoes considerable deformation. After the collision, the post’s cap and

base are pulled and displaced, leading to structural failure as the impact

force exceeds the load-bearing capacity of the barrier.

The post serves as the primary energy-absorbing

component of the barrier, thus undergoing the greatest deformation in the

entire system, including bending, breaking, or cracking, depending on the force

intensity and material properties. This deformation reflects the process of

converting collision energy into internal energy and the barrier’s ability to

dissipate force throughout the crash event.

Therefore, the post is the main load-bearing part

and the most severely damaged component of the barrier when the vehicle crashes

at high speed. This results in significant structural changes and

destabilization of the system's fixed points, reducing the overall protective

effectiveness of the barrier.

Fig. 10. Deformation of the strut at time 0.024 s in two cases

The greatest deformation during the collision

occurred at the connection point between the two support beams of the barrier,

where the vehicle’s impact force was directly applied. This location

concentrated the highest load, leading to significant structural deformation.

At a speed of 40 km/h, the maximum deformation at this point reached 104.2 mm,

indicating bending and shape change caused by the impact load.

When the speed increased to 60 km/h, deformation at

the same point rose noticeably to 127.5 mm. The stronger force over a

shorter period resulted in more kinetic energy being converted into internal

energy, leading to greater structural deformation.

The difference in deformation levels between the 40

km/h and 60 km/h crash scenarios clearly reflects the effect of collision speed

on the barrier’s structure. This also underscores the importance of designing

protective systems like barriers to withstand impact forces at various speed

levels. Barriers need to be optimized to absorb energy effectively without

sustaining severe damage in high-speed crash situations.

The stress distribution on the support beam is a

crucial indicator for evaluating the barrier's load-bearing capacity during a

collision. At a speed of 40 km/h, the maximum stress reaches 414.6 MPa, while

at 60 km/h, this value increases to 432.6 MPa due to the stronger impact force

and higher kinetic energy.

Although the stress remains within the material's

load-bearing limit – ensuring that the support beam does not fail immediately

and still performs its function of absorbing and dissipating energy – the

increase in stress can lead to plastic deformation or material fatigue over

time. This affects the support beam's ability to recover and its durability in

subsequent collisions, especially at higher speeds.

Fig. 11. Stress distribution of strut at time 0.024 s in two cases

Comparison between the two speed levels shows that

increased collision speed not only raises the impact stress but also

accelerates material degradation due to fatigue deformation. Therefore,

optimizing the material and design of the support beam is essential to ensure

both protective performance and long-term durability under various crash

conditions.

5. CONCLUSION

Amid the growing threat

of vehicle-based terrorist attacks targeting public areas and critical

infrastructure, the development of barrier systems capable of effective

interception and flexible deployment has become an urgent necessity. This study

developed a finite element model to simulate a frontal collision between a

heavy-duty truck and an emergency vehicle barrier system, thereby providing a

comprehensive assessment of the proposed system’s energy absorption capacity

and structural integrity.

Simulation results indicate that the proposed barrier structure is highly

effective in limiting cabin intrusion, maintaining displacement within safety

thresholds under both tested scenarios. To evaluate the level of intrusion into

the driver compartment, the research team employed the IIHS (Insurance

Institute for Highway Safety) standard. Energy analysis shows that most of the

vehicle’s kinetic energy was converted into internal and interaction energy,

confirming the system’s effective impact absorption capability and the

reliability of the simulation model. Additionally, the stress and deformation

distribution at major load-bearing areas provides a basis for structural

optimization to enhance post-impact durability.

Compared to conventional automatic bollard-type barriers, which require

fixed underground foundations and complex operating systems, the design

presented in this study demonstrates clear advantages in mobility, rapid

deployment, and adaptability to various terrain conditions. The system not only

fulfills the function of stopping unauthorized

vehicles but also improves occupant safety during impact scenarios.

In summary, this research has developed a reliable evaluation approach for

emergency barrier systems through high-fidelity numerical modeling,

integrating international safety standards and flexible structural design,

thereby offering a technically feasible solution for real-world application. In

the next phase, the authors will focus on fatigue analysis to assess the

operational lifespan of the system under repeated impact conditions, aiming to

ensure long-term performance and operational reliability.

References

1.

Bhugra D. 2017. „Violent radicalization”. International Review of Psychiatry 29. DOI: https://doi.org/10.1080/09540261.2017.1354516.

2.

Hoser R.S. „Democratization

of terrorism: an analysis of vehicle - based terrorist events”. Trauma

Surgery & Acute Care Open 7(1). DOI: https://doi.org/10.1136/tsaco-2022-000964.

3.

Liu G.R., S.S. Quek. 2003.

The

Finite Element Method: A Practical Course. Elsevier.

4.

Smith J., A. Brown. 2020. “Impact

behavior analysis of vehicle crash barriers under

dynamic loading”. International Journal of Crashworthiness 25(3):

215-227. DOI: https://doi.org/10.1080/13588265.2020.1712345.

5.

Zhang Y., L. Wang. 2021. “Energy

absorption characteristics of roadside safety barriers in vehicle impacts”. Engineering

Structures 236: 112045. DOI: https://doi.org/10.1016/j.engstruct.2021.112045.

6.

Lee K., H. Park, S. Kim. 2019. „Numerical simulation of vehicle collision with

safety barriers using finite element method”. Journal of Mechanical Science

and Technology 33(7): 3341-3350. DOI: https://doi.org/10.1007/s12206-019-0625-4.

7.

2014 Chevrolet Silverado 1500 Finite

Element Detailed Mesh Model Validation. DOI: https://doi.org/10.13021/f4yf-yd73.

8.

Brown Y.A., S. Windsor, A.P. Gaylard. 2010. “The

effect of base bleed and rear cavities on the drag of an SUV”. SAE Technical

Paper. No 2010-01-0512. DOI: https://doi.org/10.4271/2010-01-0512.

9.

IIHS. Insurance Institute for Highway Safety.

2024. Available at: https://www.iihs.org/.

10. Shao

B., D. Blass. 2020. “Case study: Implications of installing vehicle security

barriers in elevated structural slabs”. Structures Congress 2020: 11-23.

ISBN: 9780784482896. DOI: https://doi.org/10.1061/9780784482896.

Received 08.06.2025; accepted in revised form 02.08.2025

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License