Article

citation information:

Tokarczyk,

J., Wójcicki, M., Wieczorek, A.N. Impact of load on the

contact surface of cooperating chain links of scraper conveyors. Scientific Journal of Silesian University of

Technology. Series Transport. 2025, 128,

283-294. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2025.128.16

Jarosław TOKARCZYK[1], Mateusz WÓJCICKI[2], Andrzej Norbert WIECZOREK[3]

IMPACT OF LOAD ON

THE CONTACT SURFACE OF COOPERATING CHAIN LINKS OF SCRAPER CONVEYORS

Summary. The article presents

the impact of load on the contact surface of cooperating chain links in scraper

conveyors. A finite element method (FEM) simulation was conducted for a chain

operating on a sprocket, based on which stress and strain maps were determined

for different load levels. The contact surface areas of the chain links and the

reaction forces were also calculated depending on the load, which allowed the

determination of surface pressures.

Keywords: transport, link chain, FEM, scraper conveyor

1. INTRODUCTION

Chain

drives are one of the oldest and most widely used solutions in transport

technology, which have been a reliable system for transmitting power between

machine and equipment components. Their versatility, durability, and simplicity

of design make them an integral component of many transport devices, from

typical equipment such as bicycles or motorcycles to advanced conveyor units

used in the mining, cement, and power industries.

The

most commonly used conveyor solution based on a chain drive is the scraper

conveyors. Mining scraper conveyors are classified as cable conveyors, where

the cable is a chain/chains driven by a chain wheel and moving along the

conveyor chute. Scrapers installed transversely to the direction of movement of

the chain (installed at equal intervals - with a constant pitch) are the

transporting components. Chains with scrapers create a closed loop (endless

chain) consisting of two branches. A closed loop can be both horizontal and

vertical (more often) [1, 2, 9-11] .

Fig. 1.

Schematic design of the scraper conveyor – view on the upper part of a chain

(V – direction of the material/run-of-mine transport)

The

principle of operation of the scraper conveyor is to generate torque on the

chain wheel (through the drive – a motor and a gear) and transmit it in the

form of a pulling force to the chain links with the scrapers. Both the scraper

chain and the scrapers are located inside the conveyor pan, which creates a

transport channel shielded on three sides. Movement of the chain and sliding of

the scrapers along the conveyor pans result in the removal of the excavated

material and its transport along the chain movement to the end point of

transport or the next means of transportation [1, 2, 9-11].

Cooperation

of chain links with the drum, cooperation between the links in the joint area,

and the extremely difficult and complex environmental conditions in hard coal

mining plants result in the complexity of the wear processes of link chains in

terms of friction, corrosion, and fatigue. The most important factors

increasing the degradation of chains and scraper conveyor assemblies are the

following:

·

stone and

coal dust in the cooperation zone of chain links (joints),

·

corrosive

effect of mine water from the spraying devices and from goafs,

·

dynamic

loads from conveyor drive starts and uneven loads,

·

frequent

overloading and blocking [3, 4, 6, 8].

Analysis

of contact between neighboring chain links that

articulate with each other while rolling through the drive or return wheel is

important regarding the chain degradation process. These links have a point

elastic contact on the torus inside of each cell. Theoretical basis for the

analysis of such zones includes, among others, the Hertz problem, which is the

foundation of the state-of-the-art theory of elastic contact. Described by

the German physicist Heinrich Hertz in 1882, this problem concerns the analysis

of stresses and strains arising in elastic bodies at their points of contact.

Hertz's theory is extremely important for understanding how materials behave

under contact loads, which has wide applications in the design of mechanical

components such as bearings, gears, shafts, and many other components exposed

to point or linear contact [5].

The

basic assumption of Hertz's theory is the analysis of contact between two

elastic surfaces in a situation where they do not undergo plastic deformation.

In practice, this means that materials behave according to Hooke's law, and

deformations are proportional to the applied forces. The Hertz problem allows

determining the distribution of stresses and strains in the contact area, which

allows assessing the durability and strength of the analyzed

components. Precise calculations enable predicting the extent to which surfaces

will deform and determine the maximum stresses, which are crucial to avoid

damage and premature wear.

Nowadays,

Hertz's theory is the foundation for many advanced computational methods, such

as the finite element method (FEM), which enables more complex and precise

contact analyses. This article presents deformation analyzes

and surface pressure analyzes of cooperating chain

links using computer methods. The cooperating links have point contacts of the

two internal parts of the tori, which is consistent with the described issues.

The analysis required using the special software based on the finite element method.

Hexagon software was used, i.e., Patran pre- and post-processor and Nastran

computational solver. Nonlinear static analysis was performed. Nonlinearities

resulted from simulating the contact and use of an elastic-plastic material

model.

2. GEOMETRIC

MODEL

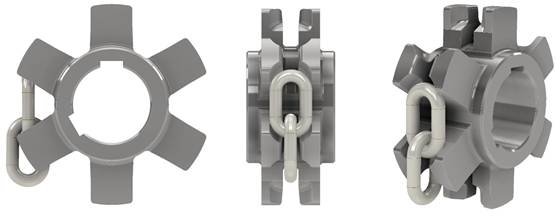

The

3D geometric model (Fig. 2) making the basis for creating the computational

model was designed using Autodesk Inventor software. It consists of a driving

star and one pair of links 14x50. The size of the actual conveyor chain was

selected according to PN-G-46701:1997 Standard - Mine link chains [7].

Fig. 2. 3D

geometric model of the driving star with a pair of cooperating links

3.

COMPUTATIONAL MODEL

3.1. Finite

elements mesh

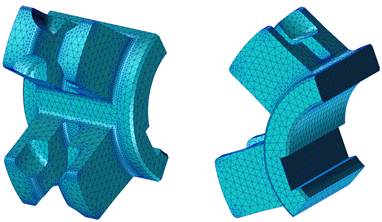

The

geometric model was moved to the Patran preprocessor environment. This model

was then discretized and a finite element mesh was created, consisting of the

following:

·

533

thousand nodes,

·

69

thousand finite elements TET10 – driving star represented by a section that is

1/3 of the geometric model (Fig. 3). The TET10 element is a ten-node

tetrahedral element used in numerical simulations. It consists of 10 nodes: 4

at the vertices and 6 at the midpoints of the tetrahedron's edges. It enables

modeling of complex geometries and stress fields with greater accuracy than

simpler elements due to quadratic shape functions. It is applied in analyses of

mechanics, thermodynamics, or fluid flow.

·

40.4

thousand finite elements HEX8 – two chain links. The HEX8 element is an

eight-node hexahedral element used in numerical simulations. It consists of 8

nodes located at the vertices of a cube. It enables modeling of regular

geometries and physical fields with good accuracy, using linear shape

functions. It is applied in analyses of mechanics, thermodynamics, or fluid

flow, particularly in regular structures. HEX8 elements are more efficient

because with a smaller number of nodes, they enable obtaining results of higher

quality than TET10 elements, especially in non-linear tasks, i.e. contacts and

large deformations, (Fig. 4),

·

number of

HEX8 elements has been increased in the contact zone (Fig. 5).

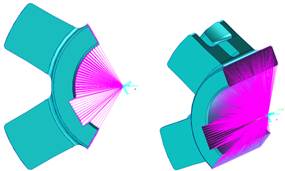

Fig. 3. Finite

elements mesh of a driving star (TET10 solid elements)

Fig. 4. Finite

elements mesh of collaborating links (HEX8 solid elements)

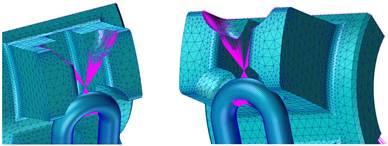

Fig. 5.

Increased number of finite elements in the contact zone between chain links

3.2. Finite

elements mesh

There

are the following assumptions and material parameters for numerical analysis:

·

driving

star – linear-elastic material:

Ø Young’s modulus – 205 GPa,

Ø Poisson’s number – 0.3,

·

chain

links – linear-elastic material with reinforcement C grade steel:

Ø Young’s modulus – 205 GPa,

Ø Poisson’s number – 0.3,

Ø conventional yield strength – 700 MPa,

Ø tensile strength – 850 MPa,

Ø relative elongation at a breaking load – 14%.

3.3. Boundary

conditions

For

the purposes of the calculations, the following boundary conditions were

assumed:

·

rotation

of the driving star around the axis of rotation, Fig. 6 - the rotation was

forced by a displacement corresponding to the relative elongation of the pair

of links at breaking load and was equal to 0.17 rad - a relative elongation of

14% corresponds to the elongation of the pair of links by 14 mm,

·

connection

of the drive star to the chain link - to force movement of the chain link

(upper link), in line with the moving drive star, MPC RBE2 type replacement

elements were used. MPC RBE2 (Multi-Point Constraint Rigid Body Element 2)

elements are a type of element used in numerical simulations, particularly in

finite element analysis (FEA). They are rigid elements that define a kinematic

relationship between one independent (master) node and one or more dependent

(slave) nodes. The motion of the independent node fully determines the motion

of the dependent nodes, with no relative displacement between them, imparting

infinite stiffness to the modeled region. RBE2 is used to represent rigid

connections, such as in modeling rigid structural components like beams or

welded joints, where deformation between nodes is negligible. Star nodes and

links are connected using these elements, Fig. 7,

·

contact

between the combined elements - spatial contact was used on the surface of the

links and the driving star, Fig. 8. Friction coefficient µ = 0.1 was

introduced,

·

fixation

of the lower link - to recreate cooperation of the link with subsequent links,

the MPC RBE2 substitute element was used to obtain support while simultaneously

monitoring the reaction value in one node, Fig. 8.

4.

DISPLACEMENT AND REDUCED STRESSES

The

simulation was carried out by generating the rotation of the driving star until

the chain links were extended by 14% - that is, until the moment that,

according to the catalogue, is the minimum at which the link breaks. All

published results of strength calculations use the SI system of units. Maps of

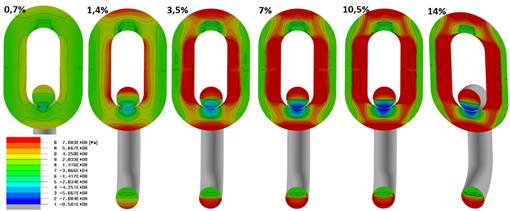

displacements and reduced stresses at 14% elongation are shown in Fig. 9-10.

Fig. 11 shows the change in the stress map for elongation of 0.7%, 1.4%, 3.5%,

7%, 10.5% and 14% (corresponding to 5, 10, 25, 50, 75 and 100% of maximum

elongation, respectively).

Fig. 6.

Rotation of the driving star around its axis of rotation. MPC RBE2

special numerical component

is used (purple color)

Fig. 7.

Connection of the link with a driving star. MPC RBE2

special numerical component is used to connect two separate components

Fig. 8.

Definition of contact on the surface of the links and the driving star (left),

fixation of the lower part of the link with the MPC RBE2 element (right)

Fig. 9. Map of

displacements (real deformation) on a dimensionless scale

Fig. 10. Map

of reduced stresses – on the left where red means a stress >700MPa,

and on the right >850MPa

Fig. 11. Map

of reduced stresses on the longitudinal cross-section of links pair

– tension zones are marked with yellow and red and compression zones with green

and blue – displacement 0.7-14%

5. CONTACT

BETWEEN THE LINKS

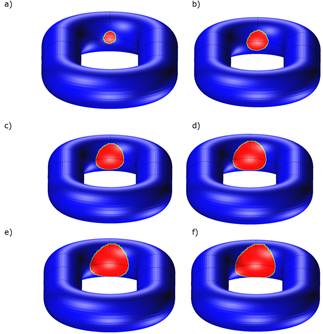

Fig.

12 and 13 present the contact surfaces between the links for each degree of

their elongation (according to Fig. 11).

Fig. 12.

Contact surfaces between the links for each degree of their elongation:

0,7% (a), 1,4% (b), 3,5% (c), 7% (d), 10,5% (e) and 14% (f)

The

surface areas of each contact for each degree of elongation are shown in Fig.

13 below.

Fig. 13. Area

of contact surfaces between the links for different levels of link elongation

The

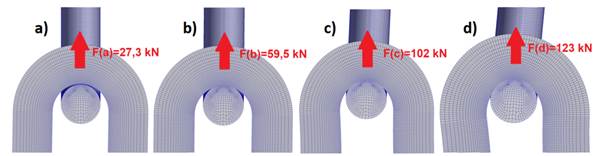

form of the deformation of the pair of links in the area of the contact zone

and the reaction value are shown in Fig. 14.

Fig. 14.

Deformation in the zone of links cooperation at the following links

elongations:

0.7% (a), 1,4% (b), 7% (c), and 14% (d)

Determining

the contact areas and the magnitude of the reaction allows for the estimation

of the surface pressures in the contact zone. These values are presented in the

Table 1 below.

Tab.

1

Determination of surface pressures

|

Link elongation |

Reaction [kN] |

Contact surface area [mm2] |

Surface pressure [MPa] |

|

0.7% |

27.3 |

19 |

1436 |

|

1.4% |

59.5 |

60 |

991 |

|

3.5% |

91.3 |

115 |

793 |

|

7% |

102 |

149 |

685 |

|

10.5% |

111 |

186 |

597 |

|

14% |

123 |

213 |

577 |

The

results regarding displacement maps, reduced stresses, main stresses,

identification of compression and tension zone,s and

the shape of the contact surface are presented for a chain link of real

dimensions and strength parameters in accordance with the PN-G-46701:1997

Standard.

Reaction

of 123 kN corresponds to the maximum link elongation

(14%) declared by the manufacturer for class C chain steel.

After

achieving the assumed elongation, the numerical simulation was stopped because

its further elongation may be a source of the following:

·

numerical

instabilities (increasing the error in the obtained results),

·

discrepancies

in the results obtained on the test stand (by the manufacturer), which are

related to the possibility of a random crack propagation (loss of material

continuity). This randomness is related to the manufacturing process of each

batch of links (e.g. the possibility of inclusions of contaminants inside the

material or its inhomogeneity).

6. CONCLUSIONS

The

results of the analysis described in this article, especially the determination

of the contact area of two links depending on the applied load (Fig. 12-13) and

the resulting surface pressures, allow forecasting the progress in chain wear.

As

expected, the contact area of chain links increases with elongation increase,

thus changing the point contact in the unloaded state with surface contact of

the loaded links. The growth rate of the links contact area decreases and is

the highest at the first stage of elongation and decreases with its increase.

Surface

pressure is the highest at the first stage of elongation and decreases as the

reaction increases below the yield stress value. Therefore, it can be concluded

that the cooperating loaded links adapt to each other at the first stage of

cooperation, creating the surface contact zone. Due to exceeding the yield

point, this zone does not return to the point contact state after the load is

removed.

This

analysis is part of broader research work related to the synergistic impact of

environmental factors on the wear of chain links depending on the combined

operating factors. In the presented work, the contact parameters of the

cooperating cells were determined for the needs of the mentioned research

work carried out using a dedicated test stand (description in [12]). These

guidelines enable determining the nominal parameters of the mentioned test

stand in terms of load and strength, in particular in the aspect of determining

the nominal force loading the chain links during tests, which will generate

degradation of the chain joint with the dominant tribological factor and

not as a result of decohesion or plastic deformations.

It

should be noted that there is a trend in which the frictional wear process in

cooperating parts is increasingly simulated using a coupling of two different

computational methods. As coal or rock are not continuous materials, they

are simulated in a software environment based on the Discrete Element Method

(DEM), in which it is possible to map the behavior of

these materials including simulating the wear process on the surfaces of the

wearing parts that are most exposed to loads. The deformations and stresses

that occur in metallic components, on the other hand, are calculated using the

finite element method [13, 14, 15]. This should be considered as a potential

direction for further research work.

The

obtained analysis results are of significant importance from the perspective of

broadly defined transport, particularly in the context of the operation and

design of scraper conveyor systems used in the mining, extraction, or energy

industries. Determining the contact parameters of interacting chain links and

understanding the relationship between load, contact area, and surface

pressures enables the optimization of chain design, enhancing their durability

and reliability. Precisely identifying the conditions under which the

transition from point contact to surface contact occurs facilitates better

prediction of tribological wear, which translates into reduced maintenance

costs and downtime for conveyors. Furthermore, these results support the design

of test rigs that reflect real operational conditions, which is crucial for

ensuring the safety and efficiency of bulk material transport in challenging

environmental conditions, such as mines or raw material processing plants.

References

1.

Antoniak Jerzy, Aleksander Lutyński. 2000. „Inteligentny system napędowy CST dla

ścianowych przenośników zgrzebłowych dużej mocy”. [In

Polish: “Intelligent CST drive system for high-power longwall scraper conveyors”].

Maszyny Górnicze

83. Publishing house: CMG KOMAG. ISSN: 0209-3693.

2.

Antoniak Jerzy, Józef Suchoń. 1983. Górnicze przenośniki zgrzebłowe. [In Polish: Mining

scraper conveyors]. Publishing house: Śląsk. ISBN:

8321603629.

3.

Celis Jean Pierre, Pierre Ponthiaux. 2011. Testing tribocorrosion

of passivating materials supporting research and industrial innovation.

European Federation Corrosion by Maney Publishing. ISBN: 978-1907975202.

4.

Dolipski Marian, Eryk Remiorz; Piotr Sobota. 2012. “Determination of dynamic loads of sprocket

drum teeth and seats by means of a mathematical model of the longwall conveyor”. Archives of Mining Sciences

57(4). ISSN: 0860-7001.

5.

Hertz Heinrich. 1982. “Ueber

die Berührung fester elastischer

Körper”. [In German: “On the Fixed Elastic Body Contact”]. Journal

für die Reine und Angewandte Mathematik

92. De Gruyter. ISBN: 978-3112342398.

6.

Mikuła Stanisław. 1978. Trwałość zmęczeniowa cięgien łańcuchowych górniczych maszyn

urabiających i transportowych. [In Polish: Fatigue life of

chains of mining and transport machines]. CMG KOMAG.

7.

PN-G-46701:1997 – Łańcuchy

ogniwowe górnicze. Warszawa: Polski Komitet Normalizacyjny.

[In Polish: Mining link chains. Warsaw: Polish

Committee of Standardization].

8.

Remiorz Eryk, Stanisław

Mikuła. 2017. „Podstawowe formy

degradacji własności użytkowych łańcuchów ogniwowych górniczych stosowanych w

maszynach ścianowych”. [In Polish: “Basic forms of

degradation of functional properties of mining link chains used in longwall

machines”]. Maszyny Górnicze

35(3). ITG KOMAG. ISSN: 2450-9442.

9.

Suchoń Józef. 2012. Górnicze

przenośniki zgrzebłowe: budowa i zastosowanie. [In Polish:

Mining scraper conveyors: construction and application]. ITG KOMAG. ISBN: 978-83-60708.

10.

Suchoń Józef. 2012. Górnicze

przenośniki zgrzebłowe: teoria, badania i eksploatacja. [In Polish:

Mining scraper conveyors: theory, research and operation]. ITG KOMAG.

ISBN 978-83-60708-69-9.

11.

Wieczorek Andrzej Norbert. 2018. Badania skojarzonego oddziaływania górniczych czynników środowiskowych

na degradację powierzchni bębnów chodnikowych przenośników zgrzebłowych. [In

Polish: Research on the combined impact of mining environmental factors on

the degradation of the surface of the roadway drums of scraper conveyors].

Publishing house of the Silesian University of Technology. ISBN:

978-83-7880-571-7.

12.

Wójcicki Mateusz, Andrzej Norbert Wieczorek, Grzegorz

Głuszek. 2021. “Concept

of the facility for testing the wear of chain links in the aspect of synergism

of environmental factors”. Mining Machines 39. ITG KOMAG. ISSN:

2719-3306. DOI: 10.32056/KOMAG2021.4.1.

13.

Xunan

Liu, Du Changqing, Fu Xin, Zhao Han, Zhang Jianzhuo, Yang Xinle. 2021. „Wear analysis and performance optimization of drum blade

in mining coal gangue with shearer”. Engineering

Failure Analysis 128. ISSN:

1350-6307. DOI: 10.1016/j.engfailanal.2021.105542.

14.

Yang Lu,

Hong Zhang, Ranhang Gao, Qian Feng. 2024. „Study on Contact Characteristics of Chain Track Interface

and Distribution Law of Coal Bulk Material of Short-distance Scraper Conveyor”. Mining, Metallurgy & Exploration 41. ISSN: 2524-3470. Available at: https://ui.adsabs.harvard.edu/link_gateway/2024MMExp.41.3257Y/doi:10.1007/s42461-024-01093-0.

15.

Yang

Xinwei, Dongxuan Wu, Hongyue Chen, Dong Wang. 2024. „Study on the force chain characteristics with coal dust

layer and the three-body contact stiffness”. Particuology 92. ISSN: 1674-2001. DOI: 10.1016/j.partic.2024.05.014.

Received 30.11.2024; accepted in revised form 05.03.2025

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License