Article

citation information:

Grega,

M., Brezinová, J. Causes of stress-relief cracks in forged differential gear. Scientific Journal of Silesian University of

Technology. Series Transport. 2025, 128,

83-94. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2025.128.5

Marek GREGA[1], Janette BREZINOVÁ[2]

CAUSES OF

STRESS-RELIEF CRACKS IN FORGED DIFFERENTIAL GEAR

Summary. The article

investigates the formation of stress-relief cracking and lamellar cracking in

steel forgings used for differential gears for transport components. The

forging and heat treatment processes, conducted under consistent technological

conditions, revealed the occurrence of carburizing annealing cracks caused by

plasticity depletion during stress relaxation. Additionally, stress-relief

cracks were microstructurally analyzed, and the

primary cause of the disturbance of the equilibrium state, which resulted in

the formation of these cracks, was sought. Die-tool wear and damage during

forging were identified as key contributors to the formation of non-metallic

oxide inclusion, transferring surface defects and creating lamellar propagation

during subsequent heat treatment. The findings underscore the influence of

tooling conditions and process parameters on the quality and reliability of

steel forgings.

Keywords: stress-relief cracking, lamellar crack, forging, differential gear

1. INTRODUCTION

The increasing demands

for transmitting greater torque forces through differential gears bring many

challenges to the designers of individual components. Even proven processes for

producing precision drop forgings can ultimately introduce errors into subsequent

progressive methods of increasing the mechanical properties of steel, which can

ultimately be counterproductive due to material failure.

The production of a gear

wheel made of alloyed stainless steel for an axel - differential, represents a

technologically demanding process, wherein strict adherence to defined

manufacturing procedures is essential for ensuring the required quality of the final

product. The resulting properties of the components are significantly affected

not only by the applied technological operations but also by the precise

chemical composition and microstructural characteristics of the input material.

In conventional

industrial practice, the identification of latent defects during processing

remains a considerable challenge. In many cases, such defects become apparent

only during special processes, or final inspection and quality control

procedures. This necessitates detailed post-process analysis aimed at

identifying the root causes of the observed nonconformities.

Effective detection and

classification of defects in forged components require a systematic and

comprehensive approach to their typology. Among various defect types,

crack-like discontinuities are particularly problematic due to the complex and

multifactorial nature of their origin, which may involve thermal, mechanical,

or metallurgical influences throughout the entire manufacturing cycle.

A fundamental

classification of surface crack types is described in the EN 1011-2 standard

[5]. While this standard primarily addresses cracks arising during welding, it

is not limited to those occurring in welds but also includes cracks in the

heat-affected zones of parent metal. According to this standard, base materials

include not only sheets but also pipes and forgings. Categorized cracks based

on their temperature of origin during forging and their type—taking into

account orientation relative to the forging axis, location on the forged part,

and the forging method used [6,7].

Researchers Viňáš, Brezinová, Maňková, and Brezina [3] as well as researcher Brziak [4] adopted the basic classification of cracks from

the EN 1011-2 standard and further refined it into four primary groups, each

with subcategories. These groups include hot cracks, such as solidification,

liquation, and polygonization cracks. Cold cracks are a broad category without

subdivisions. Lamellar cracks are divided into exogenous and endogenous types

and annealing cracks, and have been a subject of study for many researchers.

Researchers Ito and Nawrocki investigated the mechanism of crack formation due

to stress relief [8, 13, 14].

Although the basic

mechanisms of stress-relieving annealing cracking are generally known and

extensively documented in the literature, the details of crack initiation and

the factors influencing them remain a matter of debate [10]. In general,

stress-relief cracking occurs when the stresses during annealing exceed the

local deformation capacity of the material [15].

The following mechanisms

are generally necessary for crack initiation:

- almost complete dissolution of carbides and carbonitrides in the

coarse-grained heat-affected zone;

- partial supersaturation of carbide-forming elements due to rapid cooling;

-

precipitation of

dissolved elements and formation of carbides in the matrix during subsequent

heat treatment.

The formation of these

cracks is associated with high-stress states in the carburizing zone during

phase transformations when cooling the materials above the heating temperature

Ms - 180°C. The temperature of heat treatment and holding time depend on the

chemical composition and especially on the material thickness. In cases where

the mechanical stresses are already too high, it can be necessary to perform a

so-called intermediate stress relief heat treatment [2, 10, 12].

Numerous research

results on precipitation behavior and carbide

development in low-alloy steels have been published in the last 60 years. While

there is agreement in the literature that crack initiation takes place during

the heating phase of the heat treatment, there are widely differing statements

on the critical temperature range of crack formation, from which a very broad

range between 315 and 705°C can be derived [11]. While the time-temperature behavior of carbide formation is documented in detail, the

influence of the forging process has so far received little attention.

All defects introduced

into the forgings during the forging process present a significant challenge in

the production of steel forgings, as defects can drastically affect the quality

and mechanical properties of the forged components. Such defects may lead to

product failure in applications subjected to high mechanical or thermal loads.

The paper presents the

results of research aimed at determining the causes of lamellar stress-relief

cracks in carburizing forgings.

2. MATERIALS

AND METHODS

Experimental observations of

defect occurrences were conducted on the product "gear wheell,"

designed for axle-differential applications for LKW and heavy-duty machinery.

The product features a simple geometric shape - a rotational disk with a central

hole and a non-uniform cross-section.

The product dimensions are as

follows: outer diameter - Ø 315 mm, inner diameter of the central hole -

Ø 658 mm, height - 60 mm, thickness - 30 mm, weight of the forging is

approximately 16 kg.

The forging is manufactured from

18CrNiMo7-6 steel, classified according to EN 10084:2008. Highly stressed

machine parts with a cemented surface. After heat treatment, the cemented layer

reaches a surface hardness of 62 up to 64 HRC, while the core of the cemented

part is quite tough even with relatively high strength.

This products from 18CrNiMo7-6

steel after forging are recrystallization heat treatment to achieve a

ferritic-pearlitic microstructure. Subsequently, they are subjected to

machining, hardening with cementation, and grinding to achieve the desired

roughness.

The technological and production

operations for the forging of the bearing ring are summarized in Figure 1. The heating of the billet is

performed in a gas furnace at a temperature range of 1150 to 1280°C.

The forging of the "gear

wheel" is carried out on a mechanical forging air hammer with a maximum

working force of 17 500 kN. The forging tools for this operation are designed

to combine two phases:

- pre-forging (open die): this phase involves reducing the

billet to the desired height of the preform and shaping it to prepare for the

next phase;

- final forging (closed die): this phase involves filling the

forging cavity to achieve the desired shape of the forging. The result includes

a slug for the central hole and flash along the edges of the forging.

Fig. 1. Final product – gear wheel

Subsequently, on a separate

machine – a mechanical press with a maximum working force of 15000 kN - the

forging undergoes flash and slug removal.

Tab. 1.

Technology operations overview

|

Working operation |

Material |

Working temperature [°C] |

|

Heating |

18CrNiMo6-7

+ U |

1150-1280 |

|

Forging |

18CrNiMo6-7 |

900-1150 |

|

Annealing |

18CrNiMo6-7 |

710-750 |

|

Tempering |

18CrNiMo6-7+FP |

550-690 |

|

Machining |

18CrNiMo6-7+FP |

20-30 |

|

Carburizing |

18CrNiMo6-7

+ gas |

930 – 940 |

|

Cooling |

18CrNiMo6-7

+ oil |

25-35 |

|

Quenching |

18CrNiMo6-7 |

830-840 |

|

Cooling |

18CrNiMo6-7

+ oil |

25-35 |

|

Tempering |

18CrNiMo6-7 |

180 |

|

Griding |

18CrNiMo6-7 |

20-30 |

After the forging process, the product undergoes heat

treatment, beginning with recrystallization annealing in continuous gas

furnaces equipped with electronically controlled temperature regulation

systems, in accordance with the DIN 17052-1 standard (Requirements for

temperature uniformity). The treatment is carried out at a temperature of

750 °C with a holding time of 200 minutes.

Following controlled cooling, the forgings are

subjected to shot blasting to remove surface contaminants and prepare them for

final quality inspection. Non-destructive testing is then performed,

specifically visual inspection in accordance with the EN 13018 standard.

Subsequently, the forgings undergo machining operations, including turning and

milling.

The next stage of heat treatment involves gas

carburizing. The components are placed in a furnace and exposed to a controlled

carbon monoxide atmosphere. The furnace is heated to a temperature range of

930–940 °C, corresponding to the austenitic phase region of the steel.

The carbon potential of the atmosphere is precisely regulated to achieve a

target surface carbon concentration of approximately 0.5%. The required

effective case depth of carburizing is in the range of 1,1-1.5 mm.

Following carburization, the parts are rapidly cooled

by oil quenching, transforming austenite into martensite and thereby increasing

surface hardness. The quenched components are then quenched and tempered at a

lower temperature (e.g., 180 °C) to relieve internal stresses and improve

toughness.

The subsequent processing step is grinding, which

ensures the desired surface finish and dimensional accuracy. The final process

is non-destructive testing (NDT) - a visual inspection of the pieces to detect

any defects.

To evaluate the mechanical properties, chemical

composition, and microstructural characteristics, a cross-sectional specimen

was prepared for analysis. The chemical composition was determined using

optical emission spectroscopy. The results, presented in Table 2, confirm that

the elemental composition of the material falls within the specified limits for

18CrNiMo7-6 steel and for the carburization layer of this steel.

The obtained measurement results fall within the

specified tolerance limits, confirming compliance with the prescribed quality

criteria. The applied technological procedures led to the achievement of the

required mechanical and structural properties in both the base material and the

cemented surface layer. Detailed results are presented in Table 2 and 3. The

base material, prior to mechanical processing, exhibited the prescribed

microstructure, hardness, and chemical composition. Subsequent heat treatment processes

resulted in the formation of a martensitic cementation layer on the material

surface, with a depth of approximately 1.5 mm, as required.

Tab.

2.

Chemical analysis of two different zone (wt.%, Fe balance)

|

Chemical element |

Core material

[wt.%] |

Carburized layer

[wt%] |

|

C |

0.17 |

0.46 |

|

Si |

0.27 |

0.27 |

|

Mn |

0.56 |

0.55 |

|

P |

0.010 |

0.009 |

|

S |

0.009 |

0.009 |

|

Cr |

1.63 |

1.61 |

|

Mo |

0.276 |

0.275 |

|

Ni |

1.58 |

1.55 |

The aim of the research is to verify the primary cause

of cracks in cemented forgings, based on empirical observation using laboratory

microstructural and other analyses. The Brinell hardness test was conducted in

accordance with EN ISO 6506-1 method HBW 2,5/1850/10. The microstructure

materials were observed under an optical microscope at 500x zoom, on an etched

sample with 5% Nital taken directly from the crack location. The microstructure

of the crack was observed under optical microscope at 200x zoom. Final quality

control was performed using Non-Destructive Testing (NDT) - Visual Testing (VT)

was according to EN 13018.

Tab. 3

Test results

|

|

Core material

|

Border zone |

Carburized layer

|

|

HBW |

361 |

428 |

570 |

|

Type of microstructure |

Ferit-perlite |

Upper bainite |

Tempered martensite |

|

Thickness of layer [mm] |

0-30 |

0.1-0.2 |

1.1-1.5 |

3. RESULT

An VT analysis was conducted of 293 pieces. The number of defective

forgings after each inspection phase were 21 pc, that is 7,17% scrap forgings.

|

|

|

|

(a) |

(b) |

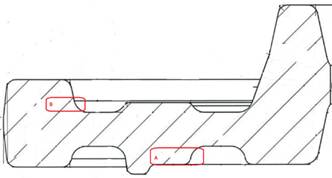

Fig. 2. Inspected forging in visual testing (VT): a) Location of cracks on

forging;

b) Location of cracks on forging in section

The cracks are localized on the bottom and upper sides

of the forging (Figure 3, zones A and B). The length of the cracks ranged from

40 to 120 mm (Figure 2a,b). The depth of this crack ranges from 0 to15 mm.

These cracks were observed only in special zone with radius R6 mm in part of

its perimeter. The start of the crack (Figure 2a) is on surface R6, and

progression is lamellar toward the outer side (Figure 2b) of the forging.

Fig. 3. Localized

crack after VT only in two zones, A and B (red color

on section scheme)

Fig. 4. Length

crack in zones A

The direction of the cracks is parallel to the surface

of the hardened layer. On macroscopic

observation of the crack – Fig. no. 4 and 5, an oxide layer is clearly visible

along its entire length. The crack starts in the martensitic structure and runs

and ends in the bainite microstructure - boundary zone. The start of the cracks

is on the surface at a radius of R6, on the forgings.

Fig. 5. Macroscopic observation of the steel structure

The crack is bounded along its entire length by an

oxide layer (Figure 5 up), beneath which a gradual intergranular breakdown of

the bainitic structure is observed.

The observed

microstructure differs depending on which part of the forging layer it is

located.

-

The Core – Ferrite and Pearlite (Figure 6a)

is the core microstructure of the steel, which remains unaffected by the

carburizing and hardening treatments. It consists of a fine-grained

ferrite-pearlite structure with evenly distributed phases. The light-colored

ferrite matrix is interspersed with dark, lamellar pearlite colonies. This

microstructure offers good toughness and machinability, although it has

relatively low hardness compared to the surface.

-

Surface Layer – Tempered Martensite (Figure

6b), which is a fine, needle-like structure typical of tempered martensite,

which dominates the carburized and quenched surface layer. The structure

appears uniform and relatively dense, with possible traces of retained

austenite in certain regions. The martensitic needles are tempered, indicating

that the sample underwent a post-quenching tempering process. This

microstructure is associated with high surface hardness and wear resistance,

which is essential for the functional performance of case-hardened components.

|

|

|

|

(a) |

(b) |

Fig. 6. Microscopic structure (200x zoom):

(a) ferrite-perlite structure; (b) tempered martensite structure

- Border

zone – Upper

Bainite (Figure 7) is the transition region between the hard case and the

softer core. The microstructure consists primarily of columnar and equiaxed

bainitic laths, which nucleate intragranular due to the presence of

non-metallic inclusions. These grains are randomly oriented, providing

isotropic mechanical properties. The lath-like morphology is characteristic of

transition zones cooled at moderate rates, which prevents the formation of

coarse pearlite or martensite. This gradient zone results from decreasing

carbon content and a reduced cooling rate with depth. It exhibits a mixed

microstructure comprising:

• upper bainite, which appears darker and more compact;

• acicular ferrite with minor polygonal ferrite;

• in this zone oxide inclusion are observed.

Fig. 7. Microscopic observation of the borderline structure – bainite

The combination of different microstructures across the case depth – tempered

martensite at the surface, a martensite-bainite transition zone, and a

ferrite-pearlite core – demonstrates the effectiveness of the applied

thermochemical treatment in tailoring the performance of 18CrNiMo6-7 steel.

Fig. 8. Microscopic observation of the zone microstructure

To evaluate the heat

treatment process and separate microstructure zones a hardness test was

performed on a cross-section of the forging. The individual measurement values

are presented in Table 3. Based on this measurement, the depth of individual

microstructural zones was determined, as well as the depth of the crack in the

forging.

4. DISCUSSION

Based on the evaluation of the test results and

laboratory analyses of the location, direction, and size of the cracks, it can

be concluded that this type of crack propagated in the material during heating

during steel carburization. Since oxide inclusions are present on both sides of

the crack, it initiated in the heat-affected zone of the carburization zone of the steel. The main

cause of the growth of these cracks is the loss of plasticity in the critical

zone of the heat-affected zone during the carburization process, namely during

the relaxation of residual stresses [2].

A detailed visual examination of the crack (Figure 9a,

b) on the surface of the forging revealed that it was formed by sharp notches

that penetrated the surface layer at radius R6 and thus disrupted its

integrity. The inclusion material consisted of oxide scale residues that had

entered the layer of the base material during forging. The shape of the oxide

scale is flaky, and when mixed into the surface of the steel forging, a surface

groove is created. The oxide scale was removed from the surface of the forging

during the blasting operation, but traces remained in the form of notches and

grooves.

|

|

|

|

(a) |

(b) |

Fig. 9. Detail from a visual inspection

of initial cracks on the surface:

(a) oxide scale in radius R6; (b) sharp notches on the surface

It is important to note that these stress-relieving

cracks are only a consequence of the introduction of oxide inclusions into the

surface of the forging and thus the creation of a notch concentrator of excess

stress during the forging process in the austenitic phase [9]. The places of

introduction of oxide inclusions are defined in two specific zones of the

forging in local radii on the upper and lower parts of the forging. It should

be noted that the material flow in the forging process causes abrasive wear of

the dies, which, if not properly maintained, can cause a reduction in the

radius of the radii and thus the formation of a place where oxide inclusions

occur more frequently. Oxide inclusions are subsequently transferred from the

die to the forging when the material in the austenitic phase does not flow

properly. Mold failure in hot forging is complicated by various types of

influencing variables, such as mold material, mold design, mold manufacturing,

and forging operations [1]. Structural disharmony together with the notch

effect on the surface of the forging leads to the formation of microcracks,

which act as precursors to crack formation in the following heat treatment.

5. CONCLUSIONS

Stress-relief cracking is widely recognized as a

phenomenon primarily induced by the synergistic effects of residual stresses,

microstructural transformations along grain boundaries, and suboptimal thermal

cycles during heat treatment. In the batch production of carburized forgings,

even when technological parameters are correctly set, external and

process-related variables can lead to significant quality issues and economic

losses due to defect formation and product nonconformity.

The borderline bainitic microstructure is

intentionally developed to withstand residual stress accumulation after the

heat treatment of forgings between martensite and ferrite-perlite structures.

Nevertheless, the integrity of this structure can be compromised by the

presence of non-metallic oxide inclusions at the surface, which disrupt the

structural continuity. These inclusions act as initiation sites for lamellar

cracking, particularly at the interface between the carburized surface layer

and the core material exactly in bainite structure.

The root cause of this degradation mechanism lies in

the wear of the forging die, especially in regions with defined radii. During

hot forging, steel is plastically deformed to its final geometry by filling the

die cavities at elevated temperatures. The combined effects of thermal

exposure, repeated mechanical impacts, and abrasive action result in the

progressive deterioration of the die surface, leading to the formation of

oxidized scale zones.

This degradation subsequently facilitates the

entrapment of oxide scale within the surface layer of the forging and promotes

the formation of stress concentrators such as notches. During subsequent heat

treatment, these surface discontinuities serve as preferential sites for crack

initiation and propagation. The presence of such defects significantly

compromises the structural integrity of the forgings, adversely affecting their

functional reliability in service conditions.

Funding

This

research is the result of the project supported by the Slovak Research and

Development Agency, the Scientific Grant Agency “Possibilities of application

of laser additive technologies in restoration of functional surfaces”

(1/0597/23), the Cultural and Educational Grant Agency “Hybrid student

education for current automotive industry needs” (024TUKE-4/2025) and

"Innovative approaches in the restoration of functional surfaces by laser

surfacing" (APVV-20-0303).

References

1.

Bílik, J. 2027. Teoretické A Technologické

Aspekty Mechanického Spevňovania Povrchových Vrstiev. AlumniPress, STU, Trnava, Slovakia. ISBN:

978-80-8096-020-9. [In Slovak: The Theoretical and Technological Aspects

of Surface Layers Mechanical Strenghtening].

2.

Bentley K.P. 1964. Precipitation

during stress relief of welds in Cr - Mo - V steels. Br Weld J. P. 507-515.

3.

Brezinová J., J. Viňáš, D. Draganovská, A. Guzanová. 2020. Základy materiálového inžinierstva. Study

literature edition. Košice, Slovakia. ISBN:

978-80-553-3745-6. P. 256-273. [In Slovak: Fundamentals

of Materials Engineering].

4.

Brziak P., et al. 2020. Materiály a ich správanie sa

pri zváraní. Welding Research Institute

- Industrial Institute of the Slovak Republic, Bratislava Slovakia. ISBN: 978-80-96933-09-9. [In Slovak: Materials and their behavior

during welding].

5.

ČSN EN 1011-2:2002/A1. Svařování - Doporučení pro svařování

kovových materiálů - Část 2: Obloukové svařování feritických ocelí. Praha: Czech Norms Institute.

[In Czech: Welding - Recommendations

for welding of metallic materials - Part 2: Arc welding of ferritic steels].

6.

George E. Dieter. 1993.

“Material Factors Affecting Workability”. ASM Handbook Forming and Forging

14: 782-794.

7.

George E. Dieter. 1993.

“Forging Defects”. ASM Handbook Forming and Forging 14: 834-841.

8.

Ito Y., K. Bessyo K. 1968. “Cracking parameter of high strength steels

related to heat affected zone cracking”. Journal of the Japan Welding

Society 37(9): 983-991. DOI: 10.2207/qjjws1943.37.983.

9.

Kotecki D.J. 2016. “Fourth

round robin report-trace elements in Cr-Mo-V steel weld metal”. Weld World

60(4): 639-643.

10. Kromm Arne, Thomas Lausch, Dirk Schroepfer, Michael Rhode,

Thomas Kannengiesser. 2020. “Influence of welding stresses on relief cracking

during heat treatment of a creep-resistant 13CrMoV steel Part II: mechanisms of

stress relief cracking during post weld heat treatment”. Welding in

the World 64: 819-829. DOI: 10.1007/s40194-020-00881-8.

11. Kroupa A., A. Výrostková, M.

Svoboda, J. Janovec. 1998. “Carbide reactions and phase equilibria in low-alloy

Cr–Mo–V steels tempered at 773–993 K. Part II: theoretical calculations”.

Acta Materialia 46(1): 39-49. DOI: 10.1016/S1359-6454(97)00239-5.

12. Nakamura N., T.

Wnjo, Y. Kikuchi. 1992. „Effects of heat-affected zone microstructure on

reheat cracking susceptibility of Cr-Mo steels”. Weld Int 6(6): 436-442.

13. Nawrocki J.G., J.N. DuPont, C.V. Robino, J.D. Puskar, A.

Marder. 2003. “The mechanism of stress-relief cracking in a ferritic alloy

steel”. Welding Journal (Miami, Fla) 82. 25/S-35/S.

14. Nawrocki J.G. 2002. “Stress-relief cracking of a

ferritic alloy steel”. Welding Research Abroad 48: 16-23.

15. Tamaki K., J. Suzuki. 1983. “Reheat cracking test on

high strength steels by a modified implant test – (Study of reheat cracking of

Cr-Mo steels, Report I)”. Trans Jpn Weld Soc Bd

14(2): 33-38.

Received 11.06.2025; accepted in revised form 10.08.2025

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License