Article citation information:

Protsenko, V., Malashchenko, V., Nastasenko, V., Babiy, M., Voitovych, O. Elevator drum-pad brake mechanisms: redundant constraints and reliability rise opportunity. Scientific Journal of Silesian University of Technology. Series Transport. 2024, 125, 229-242. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2024.125.15.

Vladyslav PROTSENKO[1], Volodymyr MALASHCHENKO[2], Valentyn NASTASENKO[3], Mykhailo BABIY[4], Olha VOITOVYCH[5]

ELEVATOR

DRUM-PAD BRAKE MECHANISMS: REDUNDANT CONSTRAINTS AND RELIABILITY RISE

OPPORTUNITY

Summary. The article deals with

mechanical engineering, and transport machines, namely the elevator brake

mechanism structure. The article aims to study the number and location of

redundant constraints in elevator brake mechanisms and to depict their impact

on brake reliability and transportation safety. To study the structure of the

mentioned mechanisms, we used classical methods of applied mechanics plus the

circuit method of L. Reshetov. The structure of crane

disc brakes with short-stroke DC electromagnet and long-stroke AC electromagnet

mechanisms was analyzed and redundant constraints

were identified. It was shown that the presence of redundant constraints causes

friction torque oscillation and lead to load distribution unevenness between

brake elements. Based on the provided analysis,

construction improvement events should be implemented to remove the most

dangerous redundant constraints.

Keywords: drum-pad brake, redundant constraint; mechanism,

friction torque, reliability, self-alignment

1. INTRODUCTION

The reliability of the braking

system has a significant influence on transportation safety, which is vital for

automotive vehicles and other transport systems intended for transporting

people. The operational safety of an elevator directly depends on reliability

of the brake mechanism, especially considering the possibility of gearbox

self-braking loss. Disc-pad brakes are widespread in cars and lifting

equipment, and in heavy-loading systems, such as elevators, drum-type brakes

are also used. This explains the interest in studying ways to increase the

reliability of brake systems. In recent years, elevator accidents have often

occurred. The main factor of these accidents was the fault of brake mechanisms

[1]. The latest research has focused on identifying low-reliability elements in

brake systems using goal-oriented methodologies [2], investigation of safety

risks [3], brake capacity study [4], and identification of brakes noise and

vibration characteristics [5]. Nowadays, drum-pad type brakes are widespread in

cranes and elevators. Their characteristic drawback is overheating, which

determines a certain amount of modern scientific research in the field of their

dynamics [6], parts temperature distribution [7] and friction elements wear

features [8]. Based on new studies, new materials [9] and brake mechanisms

operation principles [10] are being proposed and researched.

Typically, in drum-pad brakes, to

increase safety, each pad can independently press the drum with the levers.

This reserve can be leveled by uneven loading of the pads due to driving or

brake parts dissymmetry. Therefore, increasing the reliability of brakes by

ensuring the possibility of pads self-aligning is a reserve for improving the

safety of the operation of elevators and other similar machines. One of the

main parts of elevator brakes are lever mechanisms, the accuracy of which

determines their operating parameters [11], namely the brake release response

time [12].

The presence of redundant

constraints in the mechanisms contributes to the increase in the unevenness of

the load distribution between the parts [13]. This can lead to the destruction

of parts, increased requirements for manufacturing and assembling accuracy

[14], and an increase in mechanical losses [15]. There are not many works

dedicated to the study of the structure and elimination of redundant

constraints in elevator brake mechanisms. For example, the lever mechanisms of

crane drum-pad brakes with electrohydraulic and electromagnetic actuators were

considered [16], but these elements themselves were not taken into account when

compiling the structural diagram of the brake, and the structure of elevator

brakes with independent pressing pads remains under-researched today.

2. METHODOLOGY

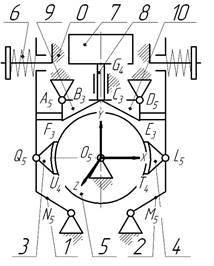

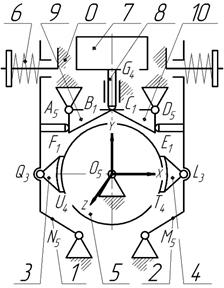

Currently, the two most widespread types

of drum-pad brakes in elevators are those with a short-stroke DC electromagnet

(Fig. 1) and those with long-stroke AC electromagnet (Fig. 2).

The brake mechanism in Fig. 1, b,

contains the left 1 and right 2 braking levers, hingedly

(with rotary joints M5

and N5)

connected to the base 0. Pads 3 and 4 are connected with rotary joints Q5 and

L5

to levers 1 and 2 and have the ability to cover drum 5 with their cylindrical

surfaces (T4,

U4).

When the brake pads 3 and 4 are closed against drum 5 pressure is provided by

springs 6. Brake opening is provided by a short-stroke DC electromagnet 7,

whose rod 8 can interact with rockers 9 and 10 (B3 and C3

connections) allowing axial and rotary slide relative to the base 0 (through G4

joint). Rockers 9 and 10 are connected to the base 0 with A5 and D5

rotary joints and are able to interact with braking levers 1 and 2 through

connections F3

and E3.

Drum 5 is fixed relatively to the base 0 with rotary joint O5.

|

|

|

|

|

a) |

b) |

|

|

Fig. 1. Elevator brake with short-stroke DC

electromagnet: general view (a) and structural diagram (b) |

||

|

|

|

|

|

a) |

b) |

|

|

Fig. 2. Elevator brake with long-stroke AC

electromagnet: general view (a) and structural diagram (b) |

||

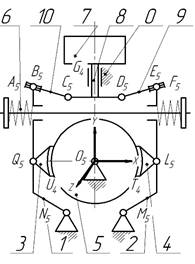

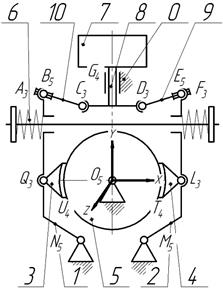

The brake mechanism shown in Fig. 2,

b, contains the left 1 and right 2 braking levers, which are hingedly (with rotary joints M5 and N5)

connected to the base 0. Pads 3 and 4 are connected with rotary joints Q5 and

L5

to levers 1 and 2 and they can cover drum 5 with their cylindrical surfaces (T4, U4).

When the brake pads 3 and 4 are closed against the drum 5 pressure is provided

by springs 6. Brake opening is provided by a long-stroke AC electromagnet 7,

whose rod 8 is connected with levers 1 and 2 through beams 9 and 10 using A5, B5, C5, D5, E5, F5

rotary joints. The drum 5 is fixed relative to the base 0 with rotary joint O5.

Firstly, we consider the structure

of the brake mechanism with a short-stroke DC electromagnet (Fig. 2, b). It

contains eight movable links (n = 8).

The number of 5-class kinematic pairs is P5 = 7 (А5, D5, L5, M5, N5, О5, Q5), the number of

4-class kinematic pairs is P4 = 3 (G4, T4, U4), the number of 3-class kinematic pairs is P3 = 4

(B3,

C3,

E3,

F3),

number of 2, and 1-class kinematic pairs is P2 = P1 =

0.

The total number of kinematic pairs

is:

|

P = P5 + P4 + P3 + P2 + P1 = 7 + 3 + 4 + 0 + 0 = 14 |

(1) |

The sum of kinematic pairs’ movabilities

[17]:

|

f = 1P5 + 2P4 + 3Pз + 4P2 + 5P1 = 1×7 + 2×3 + 3×4 + 4×0 + 5×0 = 25 |

(2) |

The number of independent locked circuits by Gohman formula [18]:

|

|

(3) |

Independent locked circuits are the following –

N5Q5U4О5N5;

M5L5T4О5M5;

N5F3A5N5;

M5E3D5M5;

A5B3G4A5;

D5C3G4D5.

Total mechanism mobility W = Wb + Wl = 1

+ 1 = 2,

where Wb = 1 – basic mechanism

mobility (drum 5 rotation);

Wl = 1 – local links

mobility (rod 8 around own axis rotation).

Then the number of redundant

constraints in basic variant by Somov and Malyshev formula:

|

|

(4) |

Redundant constraints number by Ozols formula

[19]:

|

|

(5) |

Thereby, the total redundant

constraints number in the analyzed mechanism q=qSM=qOZ=13.

Using the circuit method [20] confirms the

presented calculations (Table 1).

Tab. 1

Circuit method application to basic brake with

short-stroke

DC electromagnet mechanism (Fig. 1)

|

Circuit |

Planar movabilities fp |

Non-planar movabilities fn |

|

|

|

|||

|

N5Q5U4О5N5 |

|||

|

M5L5T4О5M5 |

|||

|

N5F3A5N5 |

|||

|

M5E3D5M5 |

|||

|

A5B3G4A5 |

|||

|

D5C3G4D5 |

|||

|

|

|||

The identified redundant constraints

prevent the self-installation of brake pads on the surface of the braking drum

and can lead to overloading of the mechanism’s link (Table 2).

Tab. 2

Redundant constraints presence in the basic

brake with short-stroke

DC electromagnet mechanism (Fig. 1) consequences

|

Redundant constraint |

Influence of Redundant constraint presence |

Practical way of redundant constraint

influence leveling |

Leveling absence consequences |

|

1 |

2 |

3 |

4 |

|

q1 |

Impossibility of braking pads self-aligning

along X axis ( |

Control and limitation radial and angular

misalignment of braking pads and drum along and around X and Y axes. This

leads to an increase in the labor-intensiveness of brake assembling and

maintenance. Radial gap in joints L

and Q increases. This leads to

delayed brake activation, strokes, and vibrations during the elevator start

process. |

Braking pads overlay uneven load and wear

among themselves. Braking levers and springs experience uneven load. |

|

q4 |

|||

|

q2 |

Impossibility of braking pads self-aligning

around X axis ( |

Braking pads overlay uneven load and wear

along their width. Additional loading of braking levers and shafts by bending

moment in the YZ plane. |

|

|

q5 |

|||

|

q3 |

Impossibility of braking pads self-aligning

around Y axis ( |

Braking pads overlay uneven load and wear

along their width. The additional load of braking levers by torque and shafts

by bending moment in the XZ plane. |

|

|

q6 |

|||

|

q7 |

Impossibility of rockers self-aligning along X axis ( |

Fitting of contact surfaces of kinematic

pairs E and F by scraping. This leads to an increase in the

labor-intensiveness of brake assembling and maintenance. |

Non-simultaneous withdrawal of braking pads

from the drum leads to strokes and vibrations during the elevator start

process. |

|

q9 |

|||

|

q8 |

Impossibility of rockers and braking levers

self-aligning around Y axis |

The additional load of braking levers by

torque in the XZ plane. |

|

|

q10 |

|||

|

q12 |

Impossibility of right rocker self-aligning

along Y axis ( |

Fitting of the contact surface of kinematic

pair C by scraping. This leads to

an increase in the labor-intensiveness of brake assembling and maintenance. |

Non-simultaneous withdrawal of braking pads from

the drum leads to strokes and vibrations during the elevator start process. |

|

q11 |

Impossibility of rockers self-aligning around

X axis ( |

Fitting of contact surfaces of kinematic pair

C and B by scraping. The radial gap in joints A and D increases. This

leads to the increase in the labor-intensiveness of brake assembling and

maintenance. |

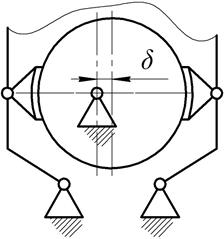

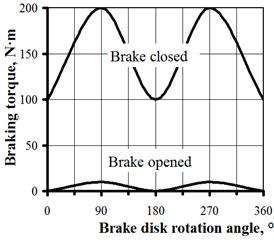

The most dangerous among the

identified redundant constraints belong to power circuits

q1…q6 which initiate the main disadvantage of the brake

mechanism (Fig. 1) – the impossibility of brake pads on drum self-alignment. In

addition to those listed in Table 1, this can lead to the creation of braking

forces even in an opened brake due to the presence of drum radial beating

and/or angular misalignment. Another disadvantage is the creation of a

cyclically variable friction moment by the closed brake in the presence of disk

radial beating (Fig. 3), which can lead to oscillations (Fig. 4) and a decrease

in the fatigue strength of the drive parts.

|

|

|

|

Fig. 3. Braking drum radial beating δ influence |

Fig. 4. Approximate influence of the drum

beating on the brake friction torque in redundant constraints presence |

The mechanism of the brake with a long-stroke

AC electromagnet (Fig. 2, b) contains eight movable links (n = 8). The number of 5-class kinematic pairs here is P5 = 11 (А5, B5, C5,

D5, E5, F5,

L5, M5, N5,

О5, Q5), number of 4-class kinematic pairs is P4 = 3 (G4, T4,

U4), number of 3, 2 and

1-class kinematic pairs is P3

= P2 = P1 = 0.

The total number of kinematic pairs is:

|

P = P5 + P4 + P3 + P2 + P1 = 11 + 3 + 0 + 0 + 0 = 14 |

(6) |

The sum of kinematic pairs’ movabilities:

|

f = 1P5 + 2P4 + 3Pз + 4P2 + 5P1 = 1×11 + 2×3 + 3×0 + 4×0 + 5×0 = 17 |

(7) |

Number of independent locked circuits by Gohman

formula:

|

|

(8) |

Independent

locked circuits are as follows – N5A5B5C5G4N5;

M5F5E5D5G4M5;

N5Q5U4О5N5;

M5L5T4О5M5;

M5E2D5M5;

O5U4Q5A5B5C5G4O5;

O5T4L5F5E5D5G4O5.

Total mechanism mobility W = Wb + Wl = 1

+ 0 = 1,

where Wb = 1 – basic mechanism

mobility (drum 5 rotation);

Wl = 0 – local links

mobilities.

Then the redundant constraints

number in the basic variant by Somov and Malyshev formula:

|

|

(9) |

Redundant constraints number by Ozols formula:

|

|

(10) |

The circuit method confirms the

presented calculations (Table 3). The influence of the identified redundant

constraints is described in Table 4.

Tab. 3

Circuit method application to basic brake with

long-stroke

AC electromagnet mechanism (Fig. 2)

|

Circuit |

Planar movabilities fp |

Non-planar movabilities fn |

|

|

|

|||

|

N5Q5U4О5N5 |

|||

|

M5L5T4О5M5 |

|||

|

N5A5B5C5G4N5 |

|||

|

M5F5E5D5G4M5 |

|||

|

O5U4Q5A5B5C5G4O5 |

|||

|

O5T4L5F5E5D5G4O5 |

|||

|

|

|||

Tab. 4

Concequences of Redundant constraints іn basic brake with long-stroke

AC electromagnet mechanism (Fig. 2)

|

Redundant constraint |

Influence of Redundant constraint presence |

Practical way of redundant constraint

influence leveling |

Leveling absence consequences |

|

1 |

2 |

3 |

4 |

|

q1 |

Impossibility of braking pads self-aligning

along X and Y axis |

Control and limitation of radial and angular

misalignment of braking pads and drum along and around X and Y axes. This

leads to an increase in the labor-intensiveness of brake assembling and

maintenance. Radial gap in joints L

and Q increases. This leads to

delayed brake activation, strokes, and vibrations during the elevator start

process. |

Braking pads overlay uneven load and wear

among themselves. Braking levers and springs experience uneven load. |

|

q2 |

|||

|

q5 |

|||

|

q3 |

Impossibility of braking pads self-aligning

around X axis ( |

Braking pads overlay uneven load and wear

along their width. Additional loading of braking levers and shafts by bending

moment in the YZ plane. |

|

|

q6 |

|||

|

q4 |

Impossibility

of braking pads self-aligning around Y

axis ( |

Braking

pads overlay uneven load and wear along their width. The additional load of

braking levers by torque and shafts by bending moment in the XZ plane. |

|

|

q7 |

|||

|

Impossibility

of circuits N5A5B5C5G4N5;

M5F5E5D5G4M5;

O5U4Q5A5B5C5G4O5;

O5T4L5F5E5D5G4O5

assembling without tension: |

|

|

|

|

q8, q12, q16, q20 |

- along Z axis ( |

Radial gap in joints A, B, C, D,

E, F increases. This leads to

delayed brake activation, strokes, and vibrations during the elevator start

process. |

Additional loads of braking levers and beams

during the brake opening period. |

|

q11, q15, q17, q19 |

- around Y axis ( |

||

|

q14, q18 |

- around X axis ( |

||

|

q10, q13, q17 |

- along Y axis ( |

||

|

q9 |

- along X axis ( |

||

As can be seen, the most dangerous

are also q1…q7 redundant constraints

which initiate the same effect as in previous construction with a DC

electromagnet because they belong to power circuits in both types of brakes.

Other constraints belong to control circuits and are not as harmful, especially

when using a variable frequency drive.

3. RESULTS AND DISCUSSION

The main way to eliminate the

detected redundant constraints without intentionally introducing errors into

the design or worsening brake performance is to add mobilities to the mechanism

circuits by increasing the classes of kinematic pairs. For both of brake types,

it is promising to implement spherical pairs L3 and Q3

instead of rotary ones (L5,

Q5). For brakes with a

short-stroke DC electromagnet, it is also useful to modify joints B, C,

E, F by making their tips spherical and turning these pairs class from

3-rd to 1-st "sphere-plane" pairs (Fig. 5). For brakes with

long-stroke AC-electromagnet, spherical joints can be applied in kinematic

pairs A, C, D, F turning their class from 5th to 3rd (Fig. 6).

|

|

|

|

Fig.

5. Modified mechanism for brake with DC short-stroke electromagnet |

Fig

6. Modified mechanism for brake with AC long-stroke electromagnet |

For the modified short-stroke

DC-electromagnet brake mechanism (Fig. 5), with an unchanged total number of

links, kinematic pairs and circuits, the number of kinematic pairs of the

5-class became P5 = 5 (А5, D5, M5,

N5, О5), number of 4-class kinematic pairs

P4 = 3 (U4, T4, G4),

3-class kinematic pairs is P3

= 2 (L3, Q3), 1-class kinematic pairs

number is P1 = 4 (B1, C1, E1,

F1), 2-class kinematic

pairs number is P1 = 0.

The sum of kinematic pairs’

movabilities:

|

f = 1P5 + 2P4 + 3Pз + 4P2 + 5P1 = 1×5 + 2×3 + 3×2 + 4×0 + 5×4 = 37 |

(11) |

Total mechanism mobility W = Wb

+ Wl

= 1 + 1 = 2,

where Wb

= 1 – basic mechanism mobility (disc 7 rotation);

Wl

= 1 – local links mobility (rod 8 around own axis rotation).

Then, the number of redundant

constraints in the basic variant by Somov and Malyshev formula:

|

|

(12) |

Redundant constraints number by Ozols formula:

|

|

(13) |

The application of the circuit

method for the described variant of structural diagram modification is shown in

the Table 5, confirming the obtained results.

Tab. 5

Circuit method application to a modified

mechanism for brake with

DC short-stroke electromagnet (Fig. 5)

|

Circuit |

Planar movabilities fp |

Non-planar movabilities fn |

|

|

|

|||

|

N5Q3U4О5N5 |

|||

|

M5L3T4О5M5 |

|||

|

N5F1A5N5 |

|||

|

M5E1D5M5 |

|||

|

A5B1G4A5 |

|||

|

D5C1G4D5 |

|||

|

|

|||

For the modified long-stroke

AC-electromagnet brake mechanism (Fig. 6), with an unchanged total number of

links, kinematic pairs and circuits, the number of kinematic pairs of the

5-class became P5 = 5 (B5, E5, M5,

N5, О5), number of 4-class kinematic pairs

is P4 = 3 (U4, T4, G4),

3-class kinematic pairs is P3

= 6 (A3, C3, D3, F3,

L3, Q3), 2-class and 1-class kinematic pairs number P2 = P1 = 0.

The sum of kinematic pairs’

movabilities:

|

f = 1P5 + 2P4 + 3Pз + 4P2 + 5P1 = 1×5 + 2×3 + 3×6 + 4×0 + 5×0 = 29 |

(14) |

Total mechanism mobility W = Wb

+ Wl

= 1 + 0 = 1,

where Wb

= 1 – basic mechanism mobility (disc 7 rotation);

Wl = 0 – local links

mobilities.

Then, the number of redundant

constraints in the basic variant by Somov and Malyshev formula:

|

|

(15) |

Redundant constraints number by Ozols formula:

|

|

(16) |

The application of the circuit method, as shown

in Table 6, confirms the obtained results.

Tab. 6.

Circuit method application to a modified

mechanism for brake with

AC long-stroke electromagnet (Fig. 6)

|

Circuit |

Planar movabilities fp |

Non-planar movabilities fn |

|

|

|

|||

|

N5Q3U4О5N5 |

|||

|

M5L3T4О5M5 |

|||

|

N5A3B5C3G4N5 |

|||

|

M5F3E5D3G4M5 |

|||

|

O5U4Q3A3B5C3G4O5 |

|||

|

O5T4L3F3E5D3G4O5 |

|||

|

|

|||

4. CONCLUSIONS

The structure of braking devices

mechanisms in transport vehicles and devices significantly affects their

reliability and safety of operation. This article proposes measures to improve

the structural integrity of elevator brakes, especially those intended for

transporting people. The structure of crane disc brakes with short-stroke DC

electromagnet and long-stroke AC electromagnet mechanisms is analyzed and

redundant constraints are identified. Based on this analysis, construction

improvement events are suggested to eliminate the most dangerous redundant

constraints.

The performed theoretical studies

made it possible to establish the following:

- structural analysis of the basic mechanisms of the

elevator drum-pad brakes showed that the mechanism of the brake with

short-stroke DC electromagnet contains q

= 13 and the mechanism of the brake with long-stroke AC electromagnet contains q = 20 redundant constraints;

- it is shown

that the most dangerous, among identified, redundant constraints are in power

circuits because they initiate the main disadvantages of brake mechanism – the

impossibility of brake pads self-aligning on the drum. This can lead to the

creation of braking forces even in an opened brake as a result of the presence

of the drum radial beating and/or angular misalignment or the creation of a

cyclically variable friction moment by a closed brake, which can lead to

oscillations and a decrease in the fatigue strength of the drive parts;

- compensation for the presence of redundant connections

is usually performed by increasing the gaps in the kinematic pairs, which leads

to delayed brake activation, strokes, and vibrations in the elevator start

process;

- possible variants for modifying the structure of the

mechanisms for both brake types are proposed, which will reduce the redundant

constraints from q = 13 to q = 1 for the short-stroke DC

electromagnet brake, and from q = 20

to q = 10 for the long-stroke AC

electromagnet brake;

- the developed

technical solutions can be implemented in production without significant

complications.

References

1.

Liang X. 2017. “Failure

Mechanism Analysis of Elevator Brake”. 4th

International Conference on Machinery, Materials and Computer (MACMC 2017):

405-409.

2.

Vu N.-T., L.-D. Phan,

V.-D. Nguyen, Q.-B. Vu. 2021. “Research of

Determining Low-Reliability Elements of Multiple-Flows Compressed Air Braking

System Based on Goal-Oriented (GO) Methodology”. International Journal of Automotive and Mechanical Engineering 18(2):

8814-8824. DOI: 10.15282/ijame.18.2.2021.19.0675.

3.

Ren Zh. 2022. “The

Performance Analysis of Elevator Brake”. Journal

of Physics: Conference Series 2463: 012047. DOI: 10.1088/1742-6596/2463/1/012047.

4.

Peng

Q., Zh. Li,

H. Yuan, G. Huang,

S. Li,

X. Sun.

2018. “A Model-Based Unloaded Test Method for Analysis of Braking Capacity of

Elevator Brake”. Advanced in Material Science

and Engineering 2018: 1-10. DOI:

10.1155/2018/8047490.

5.

Magaswaran K.,

A.S. Phuman Singh, M.Z. Hassan. 2022. “A New Method in the Identification of

Noise and Vibration Characteristics of Automotive Disk Brakes in the Low

Frequency Domain”. International Journal

of Automotive and Mechanical Engineering 9: 1564-1577. DOI:

10.15282/ijame.9.2013.7.0129.

6.

Slavchev Y., L.

Dimitrov, Y. Dimitrov. 2018. “3-D Computer research and comparative analysis of

dynamic aspects of drum brakes and caliper disc brakes”. Archive of Mechanical Engineering 2: 253-276. DOI: 10.24425/123024.

7.

Yevtushenko A., K. Topczewska, M. Kuciej. 2021. “Analytical determination of the brake

temperature mode during repetitive short-term braking”. Materials 14: 1912. DOI: 10.3390/ma14081912.

8.

Ungureanu

M., N. Medan,

S. Ungureanu,

K. Nadolny 2022. “Tribological Aspects

Concerning the Study of Overhead Crane Brakes”. Materials 15: 6549. DOI: 10.3390/ma15196549.

9.

Sahari B.B., M.M.

Shahzamanian, M. Bayat, Z.N. Ismarrubie, F. Mustapha. 2022. “Comparison of

Thermoelastic Results in Two Types of Functionally Graded Brake Discs”. Int. J. Automot. Mech. Eng. 5: 660-669. DOI: 10.15282/ijame.5.2012.12.0053.

10. Satyajit R.P., M.S. Suresh. 2022. “Experimental

Studies on Magnetorheological Brake for Automotive Application”. International Journal of Automotive and

Mechanical Engineering 15(1): 4893-4908. DOI: 10.15282/ijame.15.1.2018.2.0381.

11. Zalyubovskii M.G., I.V. Panasyuk. 2020. “On the Study

of the Basic Design Parameters of a Seven-Link Spatial Mechanism of a Part

Processing Machine”. International

Applied Mechanics 56: 54-64. DOI: 10.1007/s10778-020-00996-x.

12. Wang Bo. 2024. “Study on the Performance Test Method

of the Elevator Brake”. Mechatronics and

Automation Technology 46: 636-645. DOI: 10.3233/ATDE231158.

13. Zdanevich S.S., R.P. Pogrebnyak, S.V. Zdanevich. 2018.

“Structural analysis and rational design of mechanisms of cross-roll tube

straightening machines”. Science and

Transport Progress. Bulletin of Dnipropetrovs'k National University of Railway

Transport 5(77): 65-73. DOI:

10.15802/stp2018/147630.

14. Sydorenko I., E. Kravtsov, I. Prokopovych. 2019. “Reducing

the Reliability of Equipment as a result of the Reduction of the Culture of

Production”. Proceedings of Odessa

Polytechnic University 3: 5-13. DOI: 10.3390/ma15196549.

15. Pogrebnyak R.P. 2015. “Structural analysis and

rational design parallelogram arm gripping”. Metallurgy Theory and Practice 1-2: 123-125. DOI: 10.15802/stp2018/140547.

16. Smirnov G.F., P.I. Shtitsko, A.P. Ivanova. 2007. “Redundant

constraints in crane drum-pad brakes”. Lifting

and Transport Technique 2: 101-114.

17. Mata S.A., A.B. Torras, J.A. Cabrera et al. 2016. Fundamentals of

Machine Theory and Mechanisms. Cham:

Springer.

18. Kolovsky M.Z., A.N. Evgrafov, Yu.A. Semenov, et al.

2000. Advanced theory of mechanisms and

machines. Berlin: Springer.

19.

Ozols O.G. 1984. Theory of Mechanisms and Machines. Moscow:

Nauka.

20.

Reshetov L. 1986. Self-Aligning Mechanisms. Moscow:

Mir Publishers.

Received 01.08.2024; accepted in revised form 22.10.2024

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License