Article citation information:

Mańka, A. Problems and good practices of measuring the railway wheel rolling diameter. Scientific Journal of Silesian University of Technology. Series Transport. 2024, 125, 167-176. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2024.125.11.

Adam MAŃKA[1]

PROBLEMS

AND GOOD PRACTICES OF MEASURING

THE RAILWAY WHEEL ROLLING DIAMETER

Summary. The article describes

the results of research on the influence of the methods used to measure

the rolling diameter of a railway wheel "D" and measuring instruments

on the accuracy of the obtained results. The differences in the results

obtained using five different measuring instruments are presented. In particular,

the difficulty of meeting the repair criterion |D-D'| was pointed out using the

current measurement method. The article also illustrates the original

measurement method proposed by author, which is a reference measurement for

currently used methods, along with its limitations.

Keywords: railway wheel, wheelset, diameter of railway

wheel, diameter difference, parameter |D-D'|, diameter measurement method,

new measurement method

1. INTRODUCTION

To enable the operation of railway vehicles, it

is necessary to ensure their required technical condition. As part of periodic

tests of the technical condition of the vehicle, measurements are taken of

those values that indicate the state of wear of elements that are important for

the technical safety of the vehicles. Taking measurements and comparing

them with the limit values contained in the maintenance manual system (MMS)

allows for an unambiguous engineering assessment of the vehicle's

condition and the approval or withdrawal of the vehicle from operation. The

railway wheel set, as an element particularly responsible for safety, is

subject to a rigorous maintenance process. This process is described in detail

in each documentation of the MMS of railway vehicles and includes a measurement

card. An important element of this measurement card is the indication of the

values that are to be measured together with the provision of reference values,

which are the basis for the engineer to make decisions on the further operation

of this element. Reference values, like other elements of the MMS, are

indicated as mandatory in [1 - (§13.2 c)], i.e.: design values, post-repair

values and limit values.

2. ANALYSIS OF NORMATIVE REQUIREMENTS IN TERMS

OF THE |D-D’| CRITERION

Requirements concerning the method

of measurement, maintenance process, measured values and reference values are

also the subject of Journals of Laws, Railway Instructions, standards and

Technical Specifications for Interoperability (TSI) among others in

publications [2÷12]. Currently, a significant part of the above-mentioned

documents is not obligatory due to the lack of reference in higher-level legal

acts (act, directive, regulation, including TSI, announcement). This leaves ECM

(Entity in Charge of Maintenance) units without superior guidelines and the

need to rely on good industry practices. It is important to emphasize the fact

that each new edition of TSI, standards or other industry requirements may

introduce the standards indicated below and then the provisions contained

therein become mandatory. This is another premise for constant monitoring of

railway regulations in the field of vehicle maintenance, introducing changes

and continuous improvement of MMS.

For the analysis of the requirements

of the selected value |D-D’| characterizing the railway wheel set, 12 normative

and legal sources [1÷12] were taken into account. Considering the maintenance

process, the analysis of legal requirements was started with the regulation

[1]. This regulation is a current mandatory legal act, but it does not define

precise requirements or values in the scope of the parameter |D-D’|. The

analysed TSI Loc&Pas [2] is a current and mandatory document. TSI

Loc&Pas [2] does not state this criterion directly but indicates the need

to maintain compliance with EN14363 standards and to apply EN 13979-1:2003+A2:2011

standards, however, within the scope of points 7.2.1, 7.2.2, 7.2.3 and 7.3 and

6 of this standard. TSI Loc&Pas also refers to EN 13260:2009 +A1:2010

(3.2.1). It should be noted that this standard has already been updated, but

due to the indication of a specific edition in the TSI, it is still legally

required. TSI [2] itself in Tables 1 and 2 contains requirements for SR, Sd, Sh

and qr, but without |D-D’|. From the standards listed in the TSI, the EN

14363+A2:2023-01 [3] and 13979-1:2020-12 [4] standards are up to date, but they

do not directly define the values of the post-repair geometric parameters of

the railway wheel. It is important that the TSI [2] refers to the EN

13260:2021-02 [5] standard as mandatory, but only indicates its point 3.2.1,

which means that although this standard precisely defines the geometric

parameters of railway wheels, including |D-D’| £0.3 mm and £0.5 mm, depending on the speed of movement for

V £120 km/h and over 200 km/h,

respectively, these elements are not mandatory, but only the elements included

in point 3.2.1 of the publication [5]. EN 15313 [6] is current and defines the

parameter |D-D’|, similarly to the above 0.3 and 0.5 mm for V£120 km/h and V>120 km/h,

respectively, but as a value after reprofiling and not as a decision

criterion for reprofiling.

EN 13715 [7] was also analysed due

to the subject of the standard "Running surface outline" included

even in the title. This standard is current, but it also does not indicate the repair

values of the measured geometric parameters of the wheel outline. The railway

standard PN-92/K-91056 [8], which is the prototype of the above standard, also

does not include permissible values for the geometric dimensions of the wheel.

The same applies to EN 15302 [8] and EN 14363 [10] as well as EN 17095

[11].

Only the PN-K-91045 [12] standard

from 2002 defines the outline of wheel sets and the parameters |D-D’| <

0.5 mm, however, this standard has been withdrawn from use. It is also worth

noting that this standard required a value below, but not equal to 0.5 mm

(important symbol) for all vehicles with an operating speed V below 200 km/h.

It can therefore be seen that the currently selected standards indicate

permissible values, but these requirements are not mandatory. Therefore, when

verifying the railway instructions of several carriers, a significant

discrepancy can be seen in the scope of this criterion, i.e. |D-D’| from £ 0.3 mm through < 0.5 mm to £ 1 mm. This is not a favourable

situation both from the point of view of the safety of the railway system and

the arguments for the values adopted by individual railway entities in the DSU.

This situation is also not conducive to the development of uniform requirements

for the maintenance of rail vehicles, which at the current stage of railway

development in the EU is becoming an expected and justified element from the

point of view of economics and ensuring safety.

3. ACCURACY OF MEASUREMENTS OF PARAMETERS

DESCRIBING A RAILWAY WHEEL SET AND WHEEL PROFILE

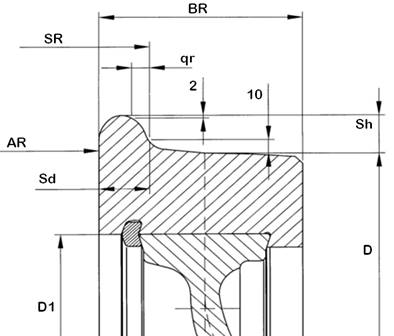

The most important parameters that

constitute the basis for determining the technical condition of railway wheel

sets include: qr, Az (AR), Ez (SR), Ow (Sh), Og (Sd), b (BR) and D and |D-D’|.

Based on current measurement experience and control, measurement and research

equipment used in the industry, these parameters are measured with the

following accuracies (measurement uncertainty / resolution):

•

qr,

rim steepness, (1 mm / 1 mm);

•

AR,

distance between the inner surfaces of the rims or wheel rims in wheel sets

without load (1 mm / 1 mm);

•

SR,

guide width (indirect measurement based on AR);

•

Sh

[h], rim height, (0.1 mm / 0.1÷0.01 mm);

•

Sd

[e], rim thickness, (0.1 mm / 0.1÷0.01 mm);

•

BR,

rim width, (0.1÷0.05 mm / 0.1÷0.05 mm);

•

D

[d], rolling circle diameter, (0.1÷0.2 (0.08*) mm/0.1÷0.01 mm);

•

|D-D’|,

difference in rolling diameter of a wheel for one wheel set, (indirect

measurement based on D);

•

|Dmax-Dmin|

difference in wheel diameters between drive and rolling bogie sets, between

drive bogie sets, between rolling bogie sets, between rolling and driving bogie

sets, (indirect measurement based on D).

It can therefore be seen that the measurement of the wheel rolling

diameter D mm, and even more so the differences |D-D’| and the series

|Dmax-Dmin| determined multiple times on this basis, are burdened with

measurement uncertainty, which is of significant importance for maintaining the

decision criterion.

Fig. 1. Designations of the wheel rolling

profile elements, wheel cross-section and

wheel set geometry [13, 14]

4. RESEARCH METHODOLOGY

To identify possible problems and differences in the measurement of the

|D-D’| parameter, a series of measurements of the rolling diameter of the

railway wheel D were performed using several measuring devices, including:

•

3

devices – three-point diameter gauges of various types and manufacturers;

•

1

optical device;

•

1

vernier calliper with a range of 1000 mm and accuracy of ±0.02 mm equipped with

designed and manufactured measurement bases (designation in the study SN).

To verify measurement errors, a single, untied wheel of the 22WE type

vehicle made of ER8 material and a nominal diameter of 850 mm was tested. The

wheel was measured dismantled from the wheel set in the repair hall. The

nominal diameter of the new wheel of the tested type is 850 mm. The tested

wheel comes from a vehicle designed to travel at a maximum speed of 160

km/h. Before measurements, the wheel was cleaned of oxides and degreased with

CX80. One section was left raw for further verification of the effect of

cleaning on measurement accuracy.

5. THE COURSE OF THE RESEARCH AND THE OBTAINED

RESULTS

The AA type measuring device (AA, BB, CC - authors' designations) was

used to perform 95 measurements of the same railway wheel. The manufacturer of

the AA device declares measurement accuracy of ±0.1 mm and resolution of 0.1 mm

or 0.01 mm.

The first series of measurements (34 measurements) was performed within

5 minutes of the device being delivered to the hall, which did not guarantee

that the temperature of the measuring device would be established. The

measurements were performed in November at an outside temperature of approx. 100C

and an inside temperature of approx. 190C. The results obtained

unequivocally confirmed the significance of the manufacturer's recommendation

that to obtain correct measurement results, the measurement should be performed

only after the temperature of the device has been established and taking into

account the recommendations to hold the device in designated places (heating at

the temperature measurement points).

The average (maximum) value of the differences in the measured parameter

D for a single point was:

•

for

the first series of measurements: 0.47 mm (0.7 mm);

•

for

the second series of measurements: 0.13 mm (0.3 mm).

Based on the measurements performed,

it is therefore clear that failure to consider the need to establish and

equalize the temperature of the device with the temperature of the measured

object may result in obtaining an average difference value D more than 3.6

times greater than in the steady-state conditions. Therefore, only the second

measurement series and measurements with other devices performed after the

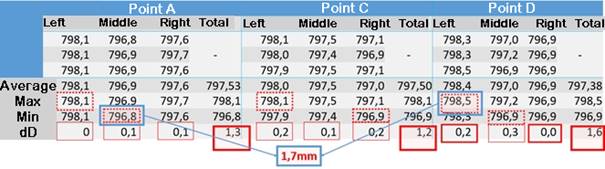

temperature had stabilized are considered for further tests. Analysing the

detailed measurement results presented in Fig. 2, it can be stated that

the average value of the wheel diameter was DmeanAA=797.47 mm with a spread

between the maximum and minimum value of as much as dDAA=1.6 mm.

Significant differences in the measurement values between individual points may

indicate ovalisation of the wheel or imperfections of the measurement method

for the three-point method.

Significant differences in the measurement values were also obtained

between the left, right and center / point sides. This is obtained for all

points, i.e. A, B and C: dDA=1.3 mm; dDC=1.2 mm; dDD=1.6

mm. It can be seen that changing the position of the measuring point by only

about ±120 mm around the circumference of the wheel (which is described as the

left or right side) results in a measurement result that differs by as much as

1.6 mm (with very good repeatability in a single point). This indicates that

the measuring device indicates repeatable results, while the place of

application of the measuring base on the wheel or its rolling diameter shows

significant deviations from the average value. Such a significant dispersion of

results depending on the measurement location makes it difficult to make a

clear decision on meeting the requirements in terms of the |D-D’| or |Dmax-Dmin|

criterion. i.e. both in the range of <0.5 mm after turning (repair

dimension)), requirements indicated in the MMS for the vehicle (limit dimension

|D-D’| <1 mm. Having the above measurement results available and the

unambiguous confirmation of very good repeatability of measurement results at

one point, proving the quality of the measuring device, it was necessary to

analyse whether the cause of these discrepancies is not caused by wheel ovality

or unevenness on its rolling surface. For this purpose, a parametric model of

the measuring system was introduced (Fig. 2), for which the influence of

unevenness at the point of contact between the measuring head and the wheel on

the obtained rolling diameter of the wheel D was simulated.

In Fig. 3, the red arrows represent two measurement bases, and the green

colour represents the measurement location with the measuring head (micrometre

sensor) of the three-point inside diameter gauge. The results obtained based on

this simulation clearly show that even the smallest local defects of the wheel

cause very large, often unacceptable changes in the measurement result. This

means that the measurement performed using this method depends on local defects

on the railway wheel surface. To minimize the impact of this dependence, this indication

should be taken into account when selecting the measurement location and,

if possible, avoid measuring at places with local unevenness of the wheel

surface (although of course this is not always possible).

Fig. 2. Summary of the results of measurements

with an AA diameter gauge

Fig. 3. Parametric model of the three-point

diameter measuring system

(the distance of supports was intentionally changed)

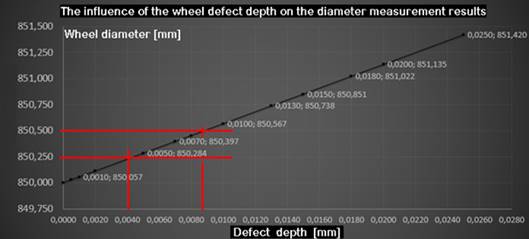

Based on this model, wheel defects

of different depths were intentionally introduced to illustrate the effect of

these local defects on the measurement result of the wheel rolling diameter D.

The selected measuring device was also used to measure the wheel

diameter in 23 places every 15.70. This measurement was aimed at determining

the wheel ovality. The results obtained are shown in Fig. 5. Despite the

relatively high repeatability of measurements at individual points, a

significant difference was obtained between the maximum and minimum measured

diameter D. In places where extreme values were obtained, the measurement was

repeated three times and very good repeatability was obtained. The maximum

difference in wheel diameters D measured at 23 points on the circumference is

dD23=2.25 mm.

Such a significant difference in diameters may indicate ovality of the

wheel or inaccuracy of the applied measurement method (Fig. 4). The obtained

average value of the diameter D is Dśr23=797.47 mm. In the

comparison of Dśr23 with the average value obtained using a vernier

calliper (VC), i.e. DVC=769.68 mm, a difference of 0.79 mm is

obtained. This measurement also indicates that averaging the results of 23

measurements does not guarantee obtaining correct measurement results that

could be compared with the criterion |D-D’|.

Fig. 4. Graph of changes in the

indications of the rolling diameter D resulting from

the local wheel irregularity

Fig. 5. Visualization of the measurement

results of the diameter D [mm] in 23 places on

the circumference of the wheel made with a three-point diameter gauge

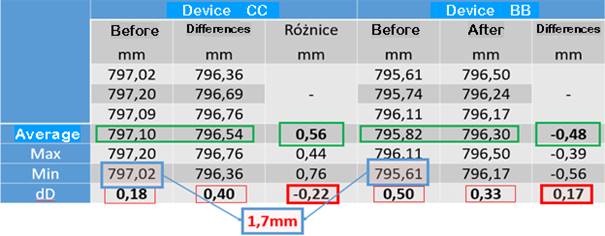

In the further part of the work, measurements were performed using other

measuring devices, including an optical device. The influence of cleaning the

surface before measurement was also verified – Fig. 6. The obtained results

indicate that the measurement performed with the optical device (marked in Fig.

6 as CC) before cleaning had a smaller scatter of results, i.e. dD=0.18 mm than

after cleaning (shiny surface) dD=0.40 mm. After cleaning, the diameter DmeanCC=796.54

mm was obtained, i.e. 0.56 mm smaller than for the measurement without

cleaning. It can therefore be seen that both measurement methods are sensitive

to contamination of the measuring surface, however, in the tested case, the CC

device overestimated the measurement by 0.56 mm and the result obtained

from the three-point diameter gauge marked in Fig. 6 as BB was lower by 0.48 mm

in the case of cleaning the wheel surface.

Fig. 6. Summary of measurement

results before and after cleaning the surface of the railway wheel

It should be noted that for both the CC and BB devices, the results most

similar to the VC vernier calliper are obtained in the case of measurement on a

cleaned surface. Taking the average value of DVCmean=796.68 mm,

the difference in relation to the CC measurement on the cleaned surface is dDVC-CC=0.14

mm and in relation to the BB measurement is

dDVC-BB=0.38 mm and in relation to the uncleaned surface,

respectively

dDVC-CC=(-0.42) mm and dDVC-BB=0.86 mm. The test

shows that cleaning the measurement site for both the CC and BB devices

significantly brings the measurement result closer to the reference value

(VC). It is also worth noting that surface contamination in the case of the CC

device always overestimated the measurement result and the BB device always

underestimated the measurement result in relation to the value obtained after

cleaning.

Fig. 7. View of the vernier calliper

measurement with measurement bases

To determine the reference value, it was proposed to measure using

specially designed measurement bases and a vernier calliper (VC) with a

measuring range of 1000 mm and an accuracy of ±0.02 mm – Fig. 7.

6. CONCLUSIONS AND DIRECTIONS FOR

FURTHER WORK

Based on the conducted research, it

was found that:

•

there

is an urgent need to standardize the requirements for the maintenance criteria

for wheel set geometry, in particular in the |D-D’| and |Dmax-Dmin| criteria,

and the need to standardize maintenance procedures throughout the European

Union along the lines of the introduced TSIs (to increase safety and reduce

maintenance costs);

•

the

tested methods and measuring instruments marked AA, BB, CC, EE showed

significant differences in the rolling diameter D. The rolling diameter values

obtained ranged from 796.17 mm to 798.50 mm, which gives a difference of 2.33

mm (on one and the same wheel);

•

even

minimal differences in the measurement performance compared to the measuring

instrument manufacturer's recommendations resulted in several times greater

differences in the measurement results at a single point (temperature, accuracy

of application to bases, calibration, surface cleaning);

•

such

significant differences in results using different measurement methods exclude

the simultaneous use of different measuring instruments for the purpose of

determining

|D-D’| for the vehicle;

•

in

all categories, the best parameters were shown by the vernier calliper, for

which the average dispersion at one point was 0.03 mm (14 times smaller

compared to CC (0.43 mm) and 4 times smaller compared to AA (0.13 mm));

•

an

obvious disadvantage of the method using a vernier calliper and measuring bases

is the possibility of measuring on a dismantled wheel set;

•

in

the example implemented, no clear advantage of any measuring device was

indicated (except for the vernier calliper);

•

significant

differences in the diameter were obtained depending on whether the surface was

measured in an operational state or cleaned, i.e. on average by -0.56 mm

("the diameter decreased" after cleaning) for the optical device

and by 0.48 mm ("the diameter increased" after cleaning) for the

internal diameter gauge.

Based on the measurements performed, it can be stated that despite the

considerable technical advancement of measuring instruments, the measurement

methods used so far without removing the wheel sets from the vehicle are

burdened with measurement uncertainty, which is significant in relation to the

maintenance criterion |D-D’| < 1 mm. It is advisable to support the

measurements performed with another method with higher measurement accuracy,

which in the case of obtaining the limit value will allow for unambiguous

verification of the difference in the diameter of the wheels in the railway

wheel set. It is obvious that the measured parameter is of great importance for

the safety of the railway system, as well as a significant impact on

operating costs, therefore increasing the accuracy and repeatability of

the measurement is particularly justified in this case.

References

1.

Announcement of the Minister of Infrastructure and

Construction of 27 January 2016 on the announcement of the uniform text of the

regulation of the Minister of Infrastructure on the general technical

conditions for the operation of railway vehicles. Dz.U. 2016 poz. 226 (replacing Dz.U. 2005 nr 212 poz.

1771). [In Polish: Obwieszczenie

Ministra Infrastruktury i Budownictwa z dnia 27 stycznia 2016 r. w sprawie

ogłoszenia jednolitego tekstu rozporządzenia Ministra Infrastruktury w sprawie

ogólnych warunków technicznych eksploatacji pojazdów kolejowych].

2.

Commission regulation (EU) No 1302/2014 of 18 November

2014 concerning a technical specification for interoperability relating to the

‘rolling stock - locomotives and passenger rolling stock’ subsystem of the rail

system in the European Union. Official Journal of the European Union,

2024. TSI Loc&Pas.

3.

EN 14363+A2:2023-01 Railway applications – Model tests

and simulations of the dynamic properties of rail vehicles before being

put into service – Running behaviour tests and stationary tests.

4.

EN 13979-1:2020-12 Railway applications – Wheelsets

and bogies – Monoblock wheels – Technical approval procedure – Part 1: Forged

and rolled wheels.

5.

EN 13260:2021-02 Railway applications – Wheelsets and

bogies – Wheelsets – Product requirements.

6.

EN 15313:2016-05E Railways – Performance requirements

for wheel set maintenance – Maintenance of wheel sets of vehicles in service

and out of service.

7.

EN 13715:2020-12 Railway applications –

Wheelsets and bogies – Wheels – Tread profile.

8.

PN-92/K-91056 Railway rolling stock – External outline

of rims and wheel rims of rimless wheel sets.

9.

EN 15302:2022-03 Railways – Parameters of wheel-rail

contact geometry – Definitions and evaluation methods.

10.

EN 14363+A2:2023-01 Railway applications – Model tests

and simulations of the dynamic properties of rail vehicles before being

put into service – Running behaviour tests and stationary tests.

11.

EN 17095:2019-05 Railway applications – Rolling stock

maintenance – Maintenance records.

12.

PN-K-91045:2002 Railway rolling stock – Wheel sets –

Requirements and test methods.

13. Instructions for

measuring and technical evaluation of traction vehicle wheel sets.

Bt-11. PKP Intercity, 2010.

14.

Młynarski, S., R.

Pilch, M. Smolnik, J. Szybka, G. Wiązania. 2019. “A simulation model for

regenerated objects with multiparameter evaluation of technical condition

reliability estimation”. Journal of

KONBiN 49(2). DOI: 10.2478/jok-2019-0023.

Received

29.09.2024; accepted in revised form 10.11.2024

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License