Article citation information:

Łukasik, Z., Kuśmińska-Fijałkowska, A., Olszańska-Wesoły, S. Strategy of improvement of the logistical processes in an enterprise. Scientific Journal of Silesian University of Technology. Series Transport. 2024, 125, 145-166. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2024.125.10.

Zbigniew

ŁUKASIK[1], Aldona KUŚMIŃSKA-FIJAŁKOWSKA[2],

Sylwia OLSZAŃSKA-WESOŁY[3]

STRATEGY

OF IMPROVEMENT OF THE LOGISTICAL PROCESSES IN AN ENTERPRISE

Summary. The e-commerce industry

is growing in strength year by year due to the growth in the number of

consumers using this solution. The market of e-commerce industry allows

reaching to a broader group of customers and reduction of costs. In order to

gain a competitive advantage, any enterprise must work out an appropriate plan,

action strategy within the scope of distribution. A basis for decision about

strategy of distribution actions, or aiming at improvement of executed

processes, is a proper identification and analysis of external and internal

factors. Rationalization of conduct result in high quality of customer service

in the aspect of promptness of delivery, and also affects planning of actions

in the long term. The goal of the article was to analyze the logistics

distribution of the enterprise acting within the scope of e-commerce and to

propose a strategy to improve the execution of the process of completion. A

model has been developed and simulation has been made.

Keywords: distribution logistics, customer service,

quality of processes

1. INTRODUCTION

In the e-commerce industry, execution of large

number of orders and finding the best method to deliver ordered goods brings

many challenges [6, 7]. Above all, the main goal of any strategy is to gain a

competitive advantage. Proper strategy allows defining the direction of

development, working out the scope of long-term actions and also to adjust to

the changing environment through earlier preparation for expectations of

contractors [8, 19]. Therefore, while selecting appropriate actions, not only

internal factors must be considered because logistics distribution joins

participants of the whole supply chain [12]. Therefore, strategy must also

consider customer service, which is focused on a key element, that is, time of

delivery [9, 17, 21, 22, 27]. Therefore, enterprise in its actions should work

on minimization of duration of performance of all actions, that is, preparation

of an order, preparation of goods for shipment and hands over to supplier

[24-26]. If enterprise in its actions treats these factors as a priority, then

it can expect long-lasting success. What is more, the action strategy of the

enterprise is largely affected by the distribution channel, and correct

selection of a channel is a big challenge, and therefore, it should include

precise determination of width and vertical and horizontal organization [11,

15, 18]. While planning the best distribution channel, we should pay attention

to the degree of intensity that should be predicted in the event of the

specific enterprise. Usefulness of a channel based on the degree that tasks

must be done in the aspect of meeting expectations in a given segment of

purchasers must also be taken into account [10, 13, 14]. Because in the event

of usefulness, customers expect fast execution of an order, reliable delivery

and additional after-sales services [16, 20]. This article also includes an

analysis within the scope of processes of supply of goods and distribution

illustrated with an example of an enterprise from e-commerce industry and

strategy of improvement of executed processes in the aspect of completion route

in the warehouse of analyzed enterprise has been developed.

2. LOGISTICAL

MODELS IN LOGISTICS DISTRIBUTION

In the e-commerce industry, in the

event of functioning of an enterprise, proper management of assortment,

reserves, and transport of goods are key factors. While selection of a

logistical solution in an enterprise, we refer to the amount and type of

offered goods and goods that are physically in the warehouse. An extreme

approach is outsourcing of logistical tasks. The total opposite of outsourcing

is having only its own warehouse and offering only what can be found there.

However, the most popular model is an indirect model, in which an enterprise

has its own warehouse with only part of the offered assortment. Such a solution

allows offering a large number of goods in assortment [1]. If an enterprise

chooses logistical outsourcing, then an external company takes over some of the

processes connected with logistics, that is, controlling of deliveries,

execution of the orders, or monitoring of stock levels. In the event of

outsourcing within the scope of storage, the external enterprise makes infrastructure

necessary for storage of goods available and is responsible for execution of

the orders.

Most commonly used logistical models

for selection of an action strategy of an enterprise:

–

Own warehouse – a model, in

which an enterprise has its own warehouse space where goods are stored, which

gives the possibility of purchasing larger amount of goods, and also affects

better purchasing conditions (Fig. 1.). The application of this model has

impact on reduction of duration of execution of an order, which results in

increased satisfaction of the customers. The disadvantages of this solution are

costs generated by maintenance of the warehouse. Another cost of such method of

functioning is the necessity to purchase goods to this warehouse, which usually

requires a lot of financial resources and poses a risk that invested resources

may not be recovered because goods will deteriorate, past their sell-by date,

or there will be no demand for them [5].

Fig. 1. Own warehouse model

–

Dropshipping – a model of logistical outsourcing, in which the process of execution

of an order is transferred from an e-commerce enterprise to the supplier

(producer, wholesaler) (Fig. 2.). In this model, there are two elements, an

online shop and an enterprise executing at least completion, packing, and

shipment. This model can be applied by an enterprise that wants to increase

retail sale and deals with execution of the orders collected by an external

enterprise, that is, an online shop. Another method of functioning is

entrusting online shops with full sale process, by for example, producer of

goods and such shops take marketing actions by collecting orders. Two types of

dropshipping can be distinguished: pure dropshipping, that is, an action model,

in which an e-commerce enterprise has no own warehouse, and its activity is

entirely based on external subcontractors, or partial dropshipping, that is,

the case when an e-commerce enterprise has its own warehouse but commissions an

external enterprise to execute parts of orders, for example, assortment with

small demand being only supplement of the whole offer. Implementation of

dropshipping in an e-commerce enterprise requires developing appropriate

standards in the flow of information, packing, payments and returns. Communication

between warehouse systems and online shop system is important so that

information about the availability of goods in the warehouse was constantly

visible on the shop website [1].

Fig.

2. Dropshipping model

The

advantages of dropshipping include fast and easy change of an offer, which

results from shortages of previously purchased goods, located in the warehouse.

To change an offer, we only have to find a new supplier and change an offer of

goods on the website of an enterprise. Another advantage similar to change of

an offer is the possibility of testing the market, that is, creating new offer

on the e-commerce enterprise website, and depending on the interest of the customers, ordering from the supplier, or when

demand is low, it can be easily closed without the risk of leaving the

goods in the warehouse. Dropshipping also brings financial benefits because, to

start an activity in this model, an enterprise only needs a website allowing to

reach the customers and place orders.

Therefore, starting such an activity does not require practically initial

capital, which gives the possibility of development for small

enterprises. The disadvantages of dropshipping include becoming dependent on

the supplier of offered assortment, lower credibility of an enterprise because

e-commerce enterprise not having its own warehouse becomes the customer’ agent.

It has also impact on lower revenues caused by agreement conditions of the

supplier. In the event of dropshipping, the problem is also lack of detailed

information about product features from an e-commerce enterprise because there

is no physical contact [1].

–

Fulfillment - a model, in which an external company provides logistical services

for an enterprise running an online shop (Fig. 3.). In the event of adopting

the strategy of fulfillment, an e-commerce enterprise has no warehouse,

whereas, purchased goods are stored in the warehouse owned by an external

company, which also deals with goods service and further shipment. The

advantages of this solution include avoiding execution of any processes

connected with goods and often lower prices of shipments in the event of larger

orders. The disadvantages of this solution are the lack of full supervision of

goods, the lack of quality control of goods and high costs of such functioning

[3].

Fig. 3. Fulfillment model

–

Pseudo-Just-in-Time - a model that is very frequently applied by the enterprises in the

e-commerce industry. It includes agency of e-commerce enterprise between

customer and supplier (Fig. 4.). The shop places assortment on its website and

marks a delivery date. Only when a customer places an order on the website, an

enterprise places an order in a supplier. An advantage of this solution is the

possibility of offering a wide range of assortments with simultaneous minimal initial capital. Warehouse

storage space, which affects the reduction of costs of functioning, is also not required. The biggest problem in

such a solution is extended time of delivery to the customer and the

occurrence of various mistakes. A disadvantage is also the lack of accurate

information about stock level of a supplier, which can make time of execution

of an order extended, and as a consequence, decrease satisfaction of the

customers [3].

Fig. 4.

Pseudo-Just-in-Time model

–

Extended shopping – a model, in which e-commerce enterprise is fully serviced by external

enterprises within the scope of storage, settlements, return service (Fig. 5.).

E-commerce enterprise must only enlarge the customer base, suppliers do the rest.

The advantages of this solution are low market entry threshold, an option of

offering a wide range of assortments, high flexibility, fast execution of the

orders, no need for customer service. Whereas, the disadvantages include

shortages of goods and deliveries, as well as errors and no impact on the

quality of customer service [4].

–

Commodity brokering - a

model, in which even supplier has no all goods in its warehouse, whereas, in

the event that an e-commerce enterprise places an order, supplier must place an

order in its supplier (Fig. 6.). Such a way of functioning allows to order

larger batches of goods and results in lower prices. The advantages include

simplified logistics and unlimited assortment. The disadvantages include long

duration of execution of the orders and potential goods shortages that

e-commerce enterprise has no impact on [4].

Apart from getting goods in the

event of some models, e-commerce enterprises, to function efficiently, must

decide about acceptance of the forms of delivery of goods to the customer. The

most popular forms of delivery of ordered goods include: courier services and

own transport when goods require specialist transport, and costs are so high

that using own means of transport is cost-effective.

Fig. 5. Extended shopping model

Fig. 6. Commodity brokering model

3. AN ANALYSIS OF EXECUTION OF THE PROCESSES OF

DISTRIBUTION AND SUPPLY ILLUSTRATED WITH AN

EXAMPLE OF THE ANALYZED

E-COMMERCE ENTERPRISE

Analyzed trade and service

enterprise is functioning in the Sub-Carpathian region. Its assortment includes

metal articles and materials for steel processing. The offer also includes

acid-resistant fittings and stainless-steel elements used in yachting. The

company also provides services within the scope of production of steel

structures designed for storage and production halls. The area that this

enterprise is focused on is the domestic market. Analyzed enterprise does not

run stationary sale, and offers its assortment via websites, the one with a

general offer of all metal elements and the other oriented towards an offer of

stainless-steel products. External e-commerce platforms are also used for

selling, which helps to reach a broader group of customers. Due to the

specificity of offered goods, the target group that company’s offer is destined

for are both individual customers and service enterprises. The enterprise

offers their customers the possibility of issuing a certificate of conformity

of offered products with requirements and certificates containing information

about species of material, melt number and chemical composition of offered

goods. The logistical model that the enterprise is based on its own warehouse

model (Fig. 7.). The company has its own warehouse, in which goods are

collected, properly labelled, distributed in a way allowing their efficient

completion. In the warehouse, the process of completion and preparation of

ordered goods for shipment is also conducted. The last of the warehouse’s tasks

is to give a proper parcel to a previously hired courier. The company also has

an office responsible for marketing actions, that is, preparation and

improvement of trade offers and contact with customers and, if necessary,

after-sales service.

Fig. 7. Diagram of the flow of goods

in the analyzed e-commerce company

In the event of the analyzed

enterprise, the logistical model that this company is based on has many

advantages, but unfortunately also disadvantages. Own warehouse model enables

an

e-commerce enterprise to immediately execute

the orders while maintaining also supervision of the whole process and

high quality of an offered service. Having its own warehouse also allows

reducing the susceptibility to fluctuations of prices of goods on the markets.

Whereas, disadvantages include the necessity of having warehouse space, as well

as costs of maintenance of property, employment of people who will work in such

warehouse and supervise the process of goods acceptance and deal with proper

storage. Having its own warehouse is also connected with the difficulty of

having broad assortment because the broader offer, the more goods the

enterprise must purchase, which requires appropriate financial resources and

appropriate warehouse space for purchased goods.

The supply chain of the analyzed

enterprise consists of producers manufacturing goods that the company trades

in, as well as suppliers that the company purchases assortment from, trade

enterprise and end customers who purchase these goods. Goods in this chain are

given to the customers through the producer of goods and the suppliers and

shops. Remaining information about the needs of the customers (types of goods,

amount, etc.) and financial resources cover opposite distance (Fig. 8.). Goods are exchanged between suppliers, e-commerce

enterprise and customers through external transport companies. It is

similar with information and finances, external operators providing such

services are responsible for their flow. Reverse flow directions occur in the

event of returns and complaint – a customer sends to an enterprise previously

ordered product that turned out to be defective, or did not meet expectations,

then the enterprise investigates a complaint, or returns and provides

information concerning further actions and

if necessary, gives financial resources back. The form of functioning of an

enterprise is not limited only to local customers, but also allows

reaching the customers throughout the country at the right time.

Fig. 8. Diagram of the supply chain

in the analyzed company

In the analyzed enterprise, adopted

strategy and model of conducting activity assumes the sale of assortment stored

only in its own warehouse. An enterprise acting on such basis is responsible

for the majority of logistical tasks connected with running a company in the

e-commerce industry, and only transport is outsourced. It requires storing the

whole assortment in its own warehouse, which is connected with the need of

market analysis and selection of stock levels to the demand of the customers

for specific products. In an enterprise acting on such basis, supply logistics

is important, that is, connection between production and distribution of goods.

Supply logistics includes all decisions and actions connected with delivery of

goods, and it is also responsible for the flow of financial resources and

information connected with it.

The process of supplying the

warehouse of the analyzed enterprise with assortment starts from an analysis of

current stock levels. This action allows familiarizing with current state and

allows depicting sale in a specific period of time. Due to the specificity and

broad assortment, forecasting demand based on sale is important because using

only its own warehouse, an enterprise may not have considerable reserves of

every type of assortment. Another step in the process allowing correct

execution is to determine what assortment and in what amount are required, due

to the fact that supply has its limits and, it is important to avoid the

situation of excess of specific goods, as well as shortages of other goods.

Another phase of supply is to find an appropriate supplier. This problem occurs

regardless of adopted strategy because either enterprise executes itself the

distribution of goods, or commissions it to an external company, it must have

suppliers of goods. Current contractors are usually employed in this process,

although to be a competitive, an enterprise must constantly analyze the market

situation and use the best offers. If

demand and supplier are already determined, the next stage is the determination

of financial conditions, dates and forms of deliveries, as well as the

determination of conditions of returns and complaints. An important aspect is

delivery date because long waiting time may cause goods shortages, which will

have negative impact on customer service. The final stage of supply process is acceptance of goods in the

warehouse and proper distribution. In the event of the analyzed

enterprise, specificity of offered assortment requires careful labelling and

distribution because goods are often small in size and in large amounts, which

causes that only multipacks are labelled. Therefore, appropriate arrangement

and labelling of goods using adopted norms in a company enables unproblematic

execution of the orders of customers (Fig. 9.).

Distribution of goods is the final

stage of the logistical supply chain. Its task is to make available by the

sellers goods that meet expectations of the purchasers. The components of

distribution include a form of sale and delivery service. Logistics

distribution plays a very important role because delivery of goods in time to

an appropriate place and customer largely affects the quality of customer

service and reduction of duration of movement of goods, as well as reduction of

costs. Logistics distribution combines all physical tasks connected with goods

service and marketing to meet the requirements of customer service and

reduction of costs connected with sale. Logistics distribution is connected

with making many strategic and organizational and operational decisions,

allowing to achieve the main goals of the enterprise [5].

In the event of the analyzed

enterprise, the process of distribution starts from placing an order by the

customer in an online shop on the company’s website or external e-commerce

platform. After placing an order, depending on the selected payment option, we

wait for information from an external payment system, or execution of an order

in the event of cash on delivery. In the event of no payment, an order after a

lapse of specific time is annulled. The next stage is completion of goods,

which were ordered. In the event of the analyzed enterprise, the process of

completion is very important because due to specificity of goods and wide

assortment, it must be conducted correctly. If given good in an appropriate

amount was taken from the warehouse, goods are packed. While all actions are

taken (completion, packing), the customer is informed about progress in

execution of his/her order. If goods are completed and packed, the courier

company chosen by the customer is informed that there is a parcel to collect.

Another stage is a proper sending of a parcel using data provided by the

customer. These actions are taken using a form made available by an external

company, allowing better controlling of the flow of parcels and tracking by the

customer where ordered goods are at a specific moment. If all actions connected

with preparation of a parcel were taken, it is given to a hired courier. The

analyzed enterprise in order to deliver ordered goods to the customers, uses

courier parcels and offers an option of personal collection of ordered goods

from the company’s warehouse. Along with sending a parcel, a sale document is

also issued, depending on the customer, it is a VAT invoice or receipt. That is

how the execution of an order ends, all tasks that the e-commerce enterprise

was responsible for were done. A courier company is responsible for finishing

an order and delivery of a parcel to the final customer. Upon collection of a

parcel by the customer, the order is found executed (Fig. 10.).

In the event that a customer is not

satisfied with delivered goods, or these goods are defective, or not the ones

that were ordered, a return or complaint process is initiated (Fig. 11.).

If goods are defective, or there is an error in completion, the customer may

make a complaint through sending a form and sending ordered goods back to the

seller. In the response to a reported complaint, the seller must investigate it

within a specific period of time and take appropriate steps depending on a

specific decision. If delivered good is correctly completed, the customer has

the right to return purchased goods within 14 days. In such a case, the

customer must fill in a return form and send ordered goods back to the

company’s address, where the completeness of goods is checked and if everything

is OK, the customer is given financial resources back.

4. THE IMPROVEMENT OF THE PROCESSES OF DISTRIBUTION

ILLUSTRATED WITH AN EXAMPLE OF AN E-COMMERCE ENTERPRISE

One of the most

problematic and time-consuming stages in the warehouse processes in the

analyzed enterprise is the moment of accepting goods from suppliers and

entering the warehouse system. This stage requires considerable time and

transfer to an employee, as each delivered load requires manual entry into the

warehouse system. It is a time-consuming process and there is a high risk

of human error. This process is automated by RFID (Radio Frequency

Identification), that is, automatically identifying system with the use of

radio waves. This system, apart from automatic identification, allows also to

collect data, which allows managing warehouse reserves more efficiently. A

significant advantage of RFID in the warehouse is also an option of accurate

checking of the location of selected goods. To implement RFID in the warehouse

of the analyzed e-commerce enterprise, it is necessary to assemble antennas

that would cover the whole warehouse and collect data about goods within its

range. Another required element of the system is a post, responsible for

placing codes on the goods and programming of transponders, so data contained

in it would correspond to the actual state of goods that they are fastened to.

An important element that such post must be equipped with is also a reader,

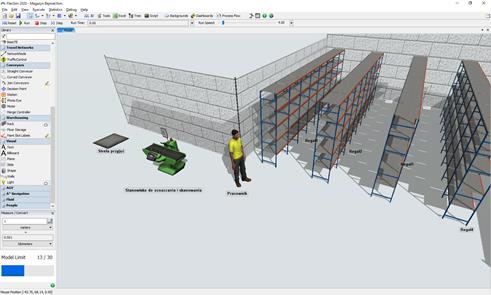

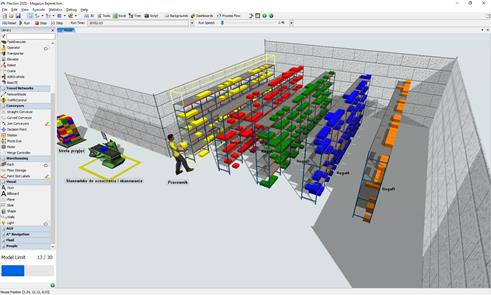

allowing that data from a transponder to be saved in the system (Fig. 12.). To

increase automation, the manual reader can be replaced with an RFID gate, which

allows that every good transferred by it will end up in the system.

Fig. 9. Algorithm of the supply

process in the enterprise

Fig. 10. Algorithm of

the goods distribution process in the enterprise

Fig. 11. Algorithm for the return/

complaint process of goods in the enterprise

Fig. 12. Design of the receiving

area of the warehouse of the analyzed company using the Flexsim

environment [23]

Apart from

technical aspects of implementation of RFID, IT system must also be implemented

in an enterprise with initial data such as the base of suppliers, goods,

employees and appropriate authorizations allowing the employees to use the

system. Remaining data is entered into the system in an automatic way. Thanks

to RFID, the process of entering goods into the warehouse system does not require

every good to be individually entered into the company's system every time, and

partial automation can make it faster. Upon implementation of RFID in the

enterprise, only labelling of goods using appropriate labels and scanning it

will have to be done. After performance of such an operation, no other actions

will be required, goods will be automatically entered into the warehouse's

system and put on the racks in the warehouse. The process of arranging goods in

the case of the analyzed company, owing to the limited space and high level of

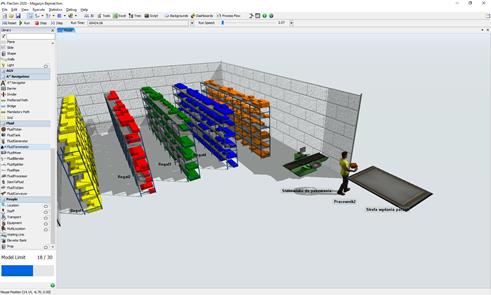

filling, is not automated and is executed by the warehouse employee (Fig. 13.)

[23]. In contrast with manual entering of every good individually, RFID

technology allows accelerating this process by scanning many codes at the same

time. Apart from speeding up this process, this technology allows reducing the

risk of mistake connected with wrongly identified goods, or wrongly entered. In

the event of the analyzed enterprise, minimizing the risk of an error is

particularly important because despite small warehouse storage space, a very

broad assortment is kept there, which hinders the warehouse processes. Another

advantage of this system is an option of tracking current stock level, which

makes management of reserves and keeping smaller stock levels easier, and also

minimizing the risk of a mistake and occurrence of goods shortages.

In the event of an e-commerce

industry, a very significant factor shaping the high quality of customer

service is time. The speed of execution of an order is very significant because

it has a real impact on satisfaction of the customers and increases the

probability that customer will choose a specific company next time. Apart from

duration of executed order, certainty, and reliability are also key factors,

which in the event of an e-commerce industry can be achieved through

eliminating the errors during completion of an order. The abovementioned

factors are impacted by RFID, as current access to information for an employee

dealing with completion allows for executing this process in a quicker manner.

As well as avoiding any errors connected with taking incomplete packaging,

which is crucial for enterprises dealing with retail trade.

Fig. 13. Warehouse design of the

examined company

Fig. 14. Warehouse design – packing

and picking zone

5. AN ANALYSIS AND SELECTION OF OPTIMAL COMPLETION

ROUTE FOR THE WAREHOUSE OF THE ANALYZED ENTERPRISE

The duration for execution of a

given order largely depends on how a specific warehouse is run. Proper planning

of works allows doing warehouse tasks more efficiently, for example, completion

of goods and delivery to the customer. While optimizing the warehouse tasks, we

must also remember about correctness of completion, so goods delivered to the

customer are those ordered by him/her. The combination of fast and careful

completion assures proper planning of completion route, that is, the distance

covered by a warehouseman to collect the goods located in a storage zone that

he/she needs for execution of the orders.

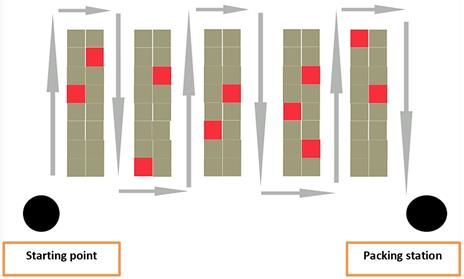

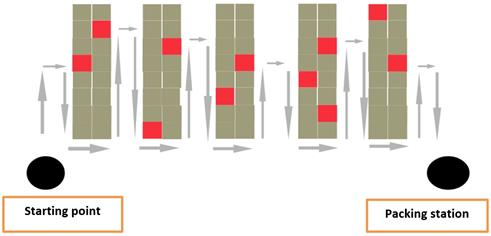

One of the most popular methods is

the S-Shape. According to this method, a warehouseman during completion moves

around the route shaped like letter S (Fig. 15.). The completion starts from

taking an assortment container, then the employee enters the alley where he/she

can find required good. If he/she takes all goods from a given alley, then goes

to the end of racks and turns to the nearest point that he/she was not in and

where goods from a completion list can be found. RFID can be used to find goods

in alleys and avoid entering the alleys only to look for goods.

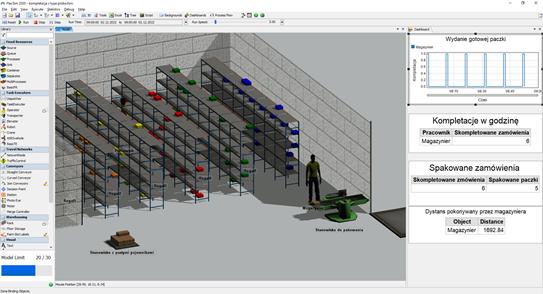

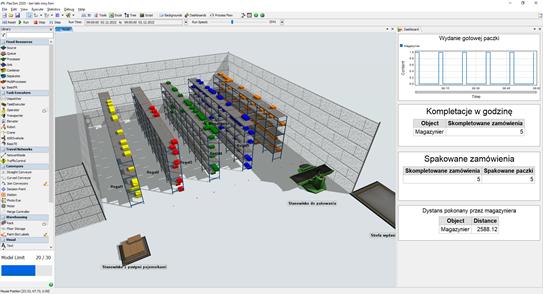

In the event of application of the

S-Shape completion route in the simulation of the warehouse of the analyzed

enterprise, an employee can finish within an hour on average 6 completion

cycles starting from taking empty packaging,

covering full route using S-Shape guidelines and delivery of goods to

the packing station. In the event of the analyzed enterprise, full cycle also

includes packing of completed goods by an employee and in such a case, an

employee can finish within one hour 5 full

cycles (completion, packing). The average duration of a full cycle, assuming

also return to an initial place, is 10 minutes and 51 seconds (Fig.

16.).

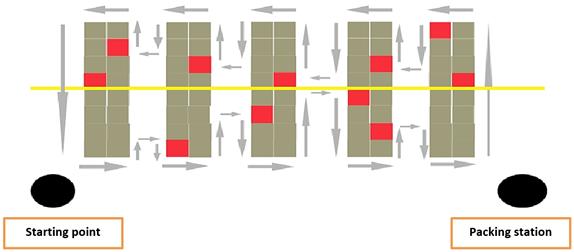

Another method

that can be applied in completion of goods is the Return method. The route in

this method is the

following: warehouseman goes through each of the alleys, in which goods

necessary for execution of an order can be found. An employee completing goods

enters selected alleys with necessary goods as far as necessary goods will be

taken, and then returns to the main corridor that he/she goes to the next alley

where necessary goods can be found (Fig. 17.).

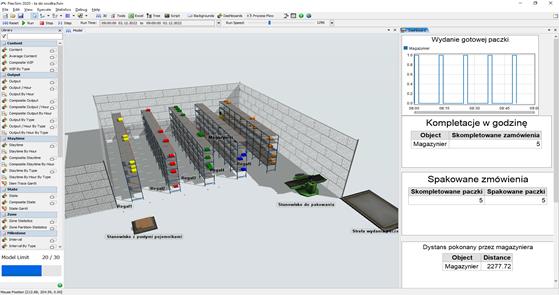

Using the Return method in the event

of the warehouse of the analyzed company, warehouseman is able on average to

finish 5 cycles that include completion and packing and return to the initial

point. Full cycle and return to the start in this case lasts 12 minutes and

14 seconds (Fig. 18.).

Another method of determining

completion routes is the Midpoint method. This method assumes the division of

the warehouse into two equal halves. A warehouseman, while completing an order,

enters the first alley, in which he/she can

find the good that he/she needs, then collects all goods from the list, but assuming that he/she cannot exceed

the agreed half of the warehouse. When the warehouseman reaches the half

or collects the good earlier, he/she moves back to the main alley and repeats

the process entering other alleys. When he/she reaches the last alley, he/she

must cover it fully to analogically conduct this process from the other side of

the racks. When the whole process is finished, he/she goes through the whole

alley again to return to the initial point (Fig. 19.).

Fig. 15. Diagram of the S-Shape

completion route

Fig. 16. Simulation of the picking

route using the S-Shape method on the example of the warehouse of the

examined company [23]

Using the

Midpoint method in the designed warehouse of the analyzed enterprise, an

employee responsible

for completion will be able to finish on average 5 cycles consisting of completion

and packing. Duration of full cycle along

with return to an initial place is 11 minutes and 43 seconds (Fig. 20.).

In the warehouse of the analyzed

enterprise, the best method of determining a completion route, considering the

results of simulation, is the S-Shape method. The results are not considerably

different in comparison with other methods because using each of them,

warehouseman was able to finish 5 full cycles (completion and packing), but

unlike others, in S-Shape method within one hour, he/she has enough amount

of time to finish completion of the next, 6th order. Another factor showing

that the S-Shape solution is the best method, is the distance that

the employee must cover while completing goods and returning to an initial

place, which in the event of this method was the shortest.

Fig. 17. The Return method picking

route diagram

Fig. 18. Simulation of the picking

route using the Return method

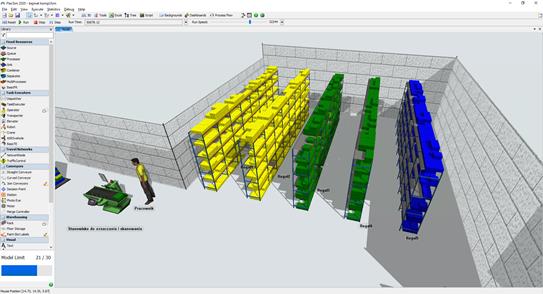

Moreover, taking into account

volume, arrangement of racks and the best completion route in the warehouse of

the analyzed enterprise, an optimal solution may be application of the XYZ

method. X goods were marked yellow, Y goods were marked green, whereas, Z goods

were marked blue in the simulation (Fig. 21.).

Locating the goods that there is a

regular demand for, and they have a considerable share of the total number of

sold goods in an enterprise on the first racks, may result in acceleration of

completion route. It results from the fact that goods that are most often sold

can be found in the most of executed orders; therefore, they are most often

taken from the warehouse. When an employee goes through the

completion route, he/she starts it from the rack number 1, and then moves to

the others. Shortening the time of execution of this process results from the

possibility of visiting lower number of racks because if an order includes only

goods that are frequently sold or even seasonal, then warehouseman will not

have to move next to a rack containing goods that are rarely sold, which will

result in shortening the route and shortening the time necessary to do it. This

solution allows managing the reserves more efficiently, and also largely

facilitates and shortens the process of finding goods by a warehouseman, which

really affects shortening the time of parcel preparation while maintaining a

high quality of completion. Whereas, such actions result in increased

satisfaction of the customers, which influences the development of an

enterprise.

Fig. 19. The Midpoint method picking

route diagram

Fig. 20. Simulation of a picking

route using the Midpoint method

Fig. 21. Simulation of the method of

arranging goods in the warehouse of the examined enterprise using Flexsim

environment

6. CONCLUSIONS

An analysis of logistics

distribution of the selected enterprise shows that for the purposes of

efficient functioning of a company in an e-commerce industry, it is important

to adopt a proper strategy and constantly improve the execution of the

processes in an enterprise. In the event of action strategy in the analyzed

enterprise, the warehouse was the key place that we could seek improvements in.

In the article, we improved the execution of warehouse processes through

adopting an appropriate strategy of distribution of goods in the warehouse and

selecting an optimal completion route.

As a result of conducted research on

completion routes in the warehouse of the analyzed enterprise, it was found that selecting an appropriate diagram of the

S-shape completion route allows speeding up completion to 10 minutes and

51 seconds, allowing in comparison with remaining methods such as the Return

method to save 1 minute and 23 seconds and 52 seconds in comparison with the

Midpoint method, which enables to increase the number of completions within a

specific time. As a result of conducted modelling and simulations, a of

distribution of goods in the warehouse space to improve the processes in the

analyzed enterprise has been proposed.

References

1.

Chodak G. 2014. Wybrane

zagadnienia logistyki w sklepach internetowych – modele, badania rynku. [In Polish: Chodak G. 2014. Selected logistics issues in online stores – models, market research].

Wrocław: Publishing house of the Wrocław University of

Science and Technology. ISBN: 978-83-7493-828-0.

2.

Dyczkowska J. 2012. „Logistyka zaopatrzenia i produkcji –

wpływ na logistykę dystrybucji”. [In Polish:

Dyczkowska J. 2012. „Supply and production logistics – impact on distribution

logistics”]. Prace naukowe Politechniki Warszawskiej. Transport 84.

3.

Niedźwiedzińska H. 2018. „Rozwiązania logistyczne w

handlu elektronicznym”. [In Polish:

Niedźwiedzińska H. 2018. „Logistic solutions in e-commerce]. Autobusy – Technika Eksploatacja Systemy Transportowe 12: 931-935. DOI:

10.24136/atest.2018.526.

4.

Ragin-Skorecka K., S. Frankiewicz. 2019. „Analiza

wybranego modelu logistycznego sklepu internetowego”. [In Polish:

Ragin-Skorecka K., S. Frankiewicz. 2019. „Analysis of a selected logistic model

online store”]. Informatyka Ekonomiczna

3(53): 74-85. DOI: 10.15611/ie.2019.3.06.

5.

Smużniak M. 2016. „Charakterystyka strategii

logistycznych w e-handlu zastosowanych przez sklepy internetowe z sektora

małych i średnich przedsiębiorstw”. [In Polish: Smużniak M. 2016.

„Characteristics of logistics strategies in e-commerce used by online stores

from the small and medium sized enterprise sector”]. Available at: https://www.ptzp.org.pl/files/konferencje/kzz/artyk_pdf_2016/T1/t1_1022.pdf.

6.

Karaenko P., M.

Bichler, S. Minner. 2019. „Coordination is hard: electronic auction

mechanism for increased efficiency in transportation Logistics”. Management Science 65(1). DOI: 10.1287/mnsc.2018.3208.

7.

Liu W., J. Zhang, S.

Wei, D. Wang. 2021. „Factors influencing organisational efficiency in a

smart-logistics ecological chain under e-commerceplatform leadership”. International Journal ofLogistics Research

and Applications 24(4). DOI: 10.1080/13675567.2020.1758643.

8.

Gupta A., R. Singh, P.K. Suri. 2018.

„Sustainable service quality management by logistics serviceproviders: an

Indian perspective”. Global Business

Review 19(3): S130-S150. DOI: 10.1177/0972150918758098.

9.

Premkumar P., S. Gopinath, A. Mateen.

2020. „Trends in third party logistics –

the past, thepresent & the future”. International

Journal of Logistics Research and Applications. 24(2). DOI:

10.1080/13675567.2020.1782863.

10. Briel F.

2018. „The future of omnichannel retail:a four stage Delphi study”. Technological Forecasting and Social Change

132(3). DOI: 10.1016/j.techfore.2018.02.004.

11. Rai H.B., S. Verlinde, C. Macharis. 2018. „How are logistics service

providers adapting to omnichannel retail?”. IFAC-PapersOnLine

51(11): 588-593. DOI: https://doi.org/10.1016/j.ifacol.2018.08.382.

12. Wang Y.,

S. Peng, Ch. Xu, K. Assogba, H. Wang, M. Xu, Y. Wang. 2018. „Two-echelon

logistics delivery and pickup network optimization based on integrated

cooperation and transportation fleet sharing”. Expert systems with applications 113: 44-65. DOI: https://doi.org/10.1016/j.eswa.2018.06.037.

13. Chunli Li.

2023. „Research on Crowdsourcing Distribution Model of Community E-commerce

Logistics Development”. Academic Journal

of Management and Social Sciences 2(3). DOI: 10.54097/ajmss.v2i3.8753.

14. Qianyu

Lin. 2022. „Research on Cross-Border E-Commerce Logistics in Shandong Province”. Emergence

and Transfer of Wealth 12(3). DOI: 10.12677/ETW.2022.123003.

15. Ailawadi

K.L., P.W. Farris. 2017. „Managing Multi- and Omni-Channel Distribution:

Metrics and Research Directions”. Journal

of Retailing 93(1): 120-135. DOI: https://doi.org/10.1016/j.jretai.2016.12.003.

16. Ocicka,

B., M. Raźniewska. 2016. „In Search of Excellencein E-Customer Logistics

Service”. International Journalof

Management and Economics 49(1). DOI: 10.1515/ijme-2016-0007.

17. Tauseef Aized, Srai Jagjit Singh. 2014. „Hierarchical modelling of

Last Mile logistic distribution system”.

The International Journal of

Advanced Manufacturing Technology 70: 1053-1061.

DOI: 10.1007/s00170-013-5349-3.

18. Rodrigues

V.S., I. Harris, R. Mason. 2015. „Horizontal logistics collaboration for

enhanced supply chain performance: An international retail perspective”. Supply Chain Management 20(6): 631-647.

DOI: 10.1108/SCM-06-2015-0218.

19. Zhang X.,

G. Zhou, J. Cao, A. Wu. 2020. „Evolving strategies of e-commerce and express

delivery enterprises with public supervision”. Research in Transportation Economics 80:

100810. DOI: 10.1016/j.retrec.2019.100810.

20. Demo Gisela, Patricia Guarnieri, Beatriz

Alvarenga. 2018. „Analysis of the relation of logistics service

level and the shopping experience in brazilian e-commerce: a rating scale”. Revista Gestão Industrial 13(4).

DOI: 10.3895/gi.v13n4.7455.

21. Gutierrez

A., L. Dieulle,

N. Labadie, N.

Velasco. 2018. „A multi-population algorithm to

solve the VRP with stochastic service and travel times”. Computers & Industrial Engineering 125: 144-156. DOI:

10.1016/j.cie.2018.07.042.

22. Zhang

Y.L., Z.J.M. Shen, S.J. Song. 2017. „Lagrangian relaxation for the reliable

shortest path problem with correlated link travel times”. Transportation Research Part B Methodological 104: 501-521. DOI:

10.1016/j.trb.2017.04.006.

23. Distribution logistics strategy on the

example of an enterprise providing services in the area e-commerce. Study of

the Chair. 2023. Rzeszów: University of Information Technology and Management

in Rzeszow.

24. Wanling

Li, Gao Gengjun. 2023. „Research on Multi-product Order Splitting and

Distribution Route Optimization of

"Multi-warehouse in One Place"”.

Frontiers in Business, Economics

and Management 8(3). DOI: 10.54097/fbem.v8i3.7449.

25. Catalán A,

M. Fisher. 2013. „Assortment allocation to distribution centers to minimize

split customer orders”. SSRN Electronic

Journal. DOI: 10.2139/ssrn.2166687.

26. Živičnjak Margareta, Kristijan Rogić, Ivona Bajor 2022. „Case-study

analysis of warehouse process optimization”. Transportation Research Procedia 64: 215-223.

DOI: 10.1016/j.trpro.2022.09.026.

27. Fu Z., J. Yue, Y. Yan. 2024. „Optimized design of multi-level

low-carbon logistics distribution scheme based on two stages”. Archives of Transport 69(1): 145-165.

Received 31.05.2024; accepted in revised form 18.08.2024

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License