Article

citation information:

Vyshnepolskyi,

Y., Pavlenko, D., Tumarchenko, L. Innovative approach to

ensuring the quality of gas turbine engine parts produced by selective

laser sintering for UAV. Scientific Journal of Silesian University of

Technology. Series Transport. 2024, 124,

243-260. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2024.124.17.

Yevhen VYSHNEPOLSKYI[1],

Dmytro PAVLENKO[2],

Larysa TUMARCHENKO[3]

INNOVATIVE

APPROACH TO ENSURING THE QUALITY OF GAS TURBINE ENGINE PARTS PRODUCED BY

SELECTIVE LASER SINTERING FOR UAV

Summary. The research objects

are gas turbine engines parts, manufactured using an innovative method of

additive manufacturing – selective laser sintering. The main problem solved in

this work is the low quality of the surface layer and the residual porosity of

the parts obtained by this method, which significantly limits their operational

characteristics and durability. As a result of the experimental studies,

rational operating parameters of diamond smoothing were established. This

allowed to significantly improve the surface quality and increase the

operational characteristics of parts made of heat-resistant alloys INCONEL 718

and an intermetallic alloy based on titanium aluminide OX45-3ODS.

The effectiveness of diamond smoothing is explained by local plastic deformation

and compaction of the surface layer of parts under the influence of high

contact pressures and temperatures. This leads to a significant reduction in

surface roughness, an increase in the surface hardness due to strain hardening

and a significant reduction in the size and number of residual pores. A

characteristic feature of the obtained results is the ability to control

the quality parameters of the surface layer by varying the diamond

smoothing operating parameters – smoothing force, feed, radius, and geometry of

the smoother's working part. The established regularities of the smoothing

operating parameters have an impact on the quality characteristics of the

surface. This information can be utilized in the development of highly

efficient technological processes for the production and restoration of gas

turbine engines, critical components of unmanned aerial vehicles, obtained

through selective laser sintering. Implementing the elaborated technological

recommendations will permit broadening the range of goods produced by additive

manufacturing and enhancing their capacity and dependability during operation

under conditions of cyclical loads and extreme temperatures.

Keywords: selective laser sintering, diamond smoothing,

unmanned aerial vehicle, intermetallic alloy, residual porosity, surface

roughness, diamond smoother, smoothing operating parameters, smoothing force,

local plastic deformation, operational characteristics

1. INTRODUCTION

In the modern world, unmanned aerial vehicles

(UAVs) have entered all spheres of human life. Their development causes

constant changes in the requirements for their design and quality parameters.

At the same time, the UAVs industry is still quite young and the data on the

application of certain design solutions is of a non-systematic, fragmented

nature. In many areas of UAVs application their cost, speed of production and

repair in the field conditions come first. Additive manufacturing has become

widespread to solve referred problems, which allows deploying the production

and repair of UAV parts in a small space from almost any material. However, the

features of additive manufacturing and the lack of systematic data limit their

application [1]. Until recently, the application of additive manufacturing was

limited to the production of prototypes and samples for exhibitions

Currently the application percentage of heavy

UAVs for reusable and disposable use is increasing exponentially, in which gas

turbine engines (GTE) have become widespread [2]. This leads to the formation

of new technical requirements that impose on propulsion systems [3]. The

characteristics of reusable gas turbine engines correlate with those of manned

vehicles, so disposable UAVs allow the application of propulsion systems with a

limited-service life, without requiring their repair and high reliability

requirements. This significantly changes the approach to development and allows

the application of new non-traditional approaches, methods, and technologies in

production. A resource of 50 to 250 hours may be sufficient for disposable UAV

propulsion systems. This makes it possible to use new technologies that are not

yet sufficiently developed for traditional aircraft construction but can

significantly reduce installation costs [4]. It is worth mentioning here that

in the case of the traditional approach, modern non-invasive diagnostic

techniques make it possible to significantly reduce the risk of serious and

costly failures [5, 6].

The use of materials with improved physical and

mechanical properties [7], as well as new technologies for processing semifinished products [8] and the surface layer [9, 10] for

the production of GTE propulsion system parts, has made it possible to

significantly improve their characteristics. Among the materials used for the

manufacture of gas turbine engine parts, heat-resistant nickel alloys and

alloys based on titanium aluminides are widely used. Alloys based on titanium

aluminides (TiAl) are of considerable interest in

engineering industries that require low weight and a high strength-to-weight

ratio [11]. However, their use is limited by the high cost and difficulties in

manufacturing parts from these materials.

Additive manufacturing technologies have become

widespread, among which selective laser sintering (SLS) has become widespread

to solve these problems.

The main advantage of using SLS for the

production of UAV propulsion system parts is the implementation of unattainable

or difficult-to-achieve technological production tasks. The modern development

of SLS technology has many advantages compared to traditional technologies for

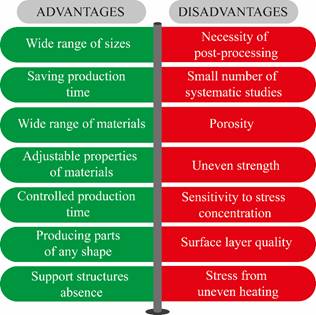

producing parts (Fig. 1).

However, despite all the advantages, there are

numerous disadvantages that hinder their spread, especially their influence

affects the production of GTE critical parts (Fig. 1).

Fig. 1. Advantages and disadvantages of SLS

Many modern studies are devoted to eliminating the factors hindering the development of additive manufacturing technologies. Thus, one of the effective approaches to reducing residual porosity is the use of dispersion strengthening with yttrium oxides [12]. During the synthesis of a part, it is possible to regulate the level of porosity from the core of the sample to its surface by changing the printing modes [13, 14]. However, this leads to an increase in printing time and complicates the process, since it requires studying the influence of selective laser sintering printing parameters on residual porosity. The use of fine-grain powders helps to significantly reduce residual porosity [15]. At the same time, gas atomization is increasingly being used to obtain fine-grain powders. This method makes it possible to obtain a powder with a fraction of 10–80 microns [16, 17], but at the same time significantly increases their cost.

Many studies conducted in different countries are devoted to reducing the cost of titanium alloys powder. One of the approaches is the use of dehydration to obtain non-spherical powders of titanium alloys, which are superior to spherical ones in some parameters [18, 19]. However, this may lead to a decrease in the strength characteristics of the material. For industrial application, it is important to solve the issues of powder distribution in a limited volume and the features of moving non-spherical powder during SLS process.

Hot isostatic pressing is one of the effective methods for reducing residual porosity, but its application is limited by high cost and the possibility of use only for materials with internal pores [20, 21]. For example, its application on INCONEL 718 alloy samples resulted in a significant reduction in the number of internal pores [22]. The study [23] showed that the use of hot isostatic pressing for the TA15 intermetallic alloy led to a decrease in strength characteristics while increasing ductility and toughness.

Unsolved factors limiting the spread of SLS technology in the production of parts is a significant reduction in the characteristics of the surface layer and the negative impact of residual porosity in the presence of structural stress concentrators in the geometry of parts.

A promising solution that will expand the application scope of SLS in the production of gas turbine engine parts is local plastic deformation by diamond smoothing (DS). The peculiarities of the plastic deformation processes occurring in the surface layer during DS make it possible to effectively use it to reduce residual porosity and increase the mechanical characteristics of stress concentration areas in gas turbine engine parts producing by SLS. For example, manufactured by selective laser sintering from an alloy based on titanium aluminide OX45–3ODS and nickel alloy INCONEL 718.

For today, the issue of expanding the application scope of additive manufacturing technologies and improving the surface layer quality of parts made of nickel alloys and alloys based on titanium aluminide, produced by selective laser sintering, is an urgent scientific and applied task.

2. MATERIALS AND METHODS

The following materials were

selected for research: heat-resistant alloy 07Cr12NMBFh,

titanium aluminide-based alloy OX45-3ODS and nickel

alloy INCONEL 718. The characteristics of the materials under study are

shown in Table 1.

Tab.

1

Mechanical characteristics of the researched materials

|

Material |

Density, ρ, g/sm3 |

Young's modulus, Е, GPa |

Yield strength, σ0,2, МPа |

Tensile strength, σВ, МPа |

|

07Cr12NMBFh |

7,77 |

194 |

785 |

930 |

|

INCONEL 718 |

7,94 |

173 |

960 |

1075 |

|

OX45-3ODS |

4,4 |

130 |

795 |

970 |

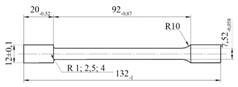

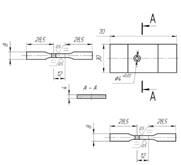

The samples were obtained by

selective laser sintering. In the study of the influence of diamond smoothing operating

parameters on the residual porosity and the surface layer quality used standard

(Fig. 2 a) and specially designed samples (Fig. 2 b, c).

Standard diamond smoothers were used

for hardening, in which the angle of the holder cone was reduced to 75°. To

control quality parameters, the following were used: TAYLOR HOBSON profilometer to measure roughness; Vickers microhardness tester model HVA-1

with an indenter load of 100 g and a load time of 30 s to measure the degree of

strain hardening. The study of porosity parameters was carried out based on the

analysis of metallographic thin sections images using Image Pro Plus software.

|

а |

c |

|

b |

Fig. 2. Geometry of

samples for research

3. RESULT AND DISCUSSION

The research on the

influence of diamond smoothing operating parameters on the surface layer

quality of parts made of 07Cr12NMBFh alloy will make it possible to determine

their rational combination, at which minimum roughness is achieved. This study

will make it possible to establish the nature of the operating parameters’

influence on the hardening of the surface layer, which in turn will

significantly reduce the required number of studies required to study the

effect of diamond smoothing of parts obtained using SLS, since this alloy is

close in characteristics to the studied INCONEL 718.

For this purpose, a

full factorial experiment with a 3k design was carried out at k=3; the planning

matrix and response function values are shown in Table. 2. The following

factors were chosen as varying factors: force, feed and smoothing speed. The

standard deviation of the profile was chosen as the objective function.

Tab.

2

Operating parameters and roughness Ra after diamond smoothing of

samples from alloy 07Cr12NMBFh

|

№ |

F, (H) |

S, (mm/rev) |

v, (m/min) |

Ra, (µm) |

№ |

F, (H) |

S, (mm/rev) |

v, (m/min) |

Ra, (µm) |

|

1 |

200 |

0,03 |

37 |

0,59 |

15 |

300 |

0,05 |

145 |

0,33 |

|

2 |

200 |

0,03 |

92 |

0,50 |

16 |

300 |

0,07 |

37 |

0,36 |

|

3 |

200 |

0,03 |

145 |

0,48 |

17 |

300 |

0,07 |

92 |

0,25 |

|

4 |

200 |

0,05 |

37 |

0,47 |

18 |

300 |

0,07 |

145 |

0,23 |

|

5 |

200 |

0,05 |

92 |

0,38 |

19 |

400 |

0,03 |

37 |

0,86 |

|

6 |

200 |

0,05 |

145 |

0,35 |

20 |

400 |

0,03 |

92 |

0,70 |

|

7 |

200 |

0,07 |

37 |

0,42 |

21 |

400 |

0,03 |

145 |

0,69 |

|

8 |

200 |

0,07 |

92 |

0,38 |

22 |

400 |

0,05 |

37 |

0,65 |

|

9 |

200 |

0,07 |

145 |

0,32 |

23 |

400 |

0,05 |

92 |

0,55 |

|

10 |

300 |

0,03 |

37 |

0,52 |

24 |

400 |

0,05 |

145 |

0,53 |

|

11 |

300 |

0,03 |

92 |

0,41 |

25 |

400 |

0,07 |

37 |

0,42 |

|

12 |

300 |

0,03 |

145 |

0,37 |

26 |

400 |

0,07 |

92 |

0,36 |

|

13 |

300 |

0,05 |

37 |

0,56 |

27 |

400 |

0,07 |

145 |

0,38 |

|

14 |

300 |

0,05 |

92 |

0,35 |

|

|

|

|

|

It was

found that the smoothing speed did not have a statistically significant effect

on the roughness of the surface layer, which confirmed the data obtained by

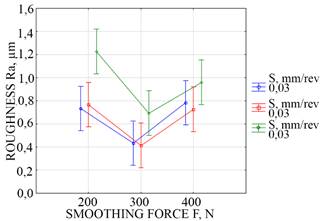

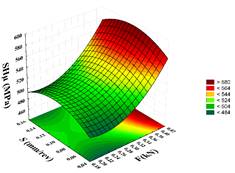

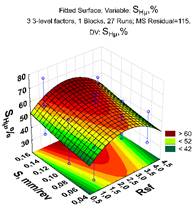

researchers for other materials. Figure 3 shows the influence of diamond

smoothing operating parameters on the surface roughness of the samples.

Fig. 3. Influence of diamond smoothing

operating parameters on

the surface roughness of samples

It was established

that smoothing with forces greater than 300 N was not rational, as the

roughness deteriorated. This can be explained by the exhaustion of plasticity

in the surface layer and the appearance of over-peening.

To

assess the phenomena occurring in the surface layer during diamond smoothing,

studies were carried out on the operating parameters' influence of the

hardening process on the surface layer microstructure of a part made of

07Cr12NMBFh alloy. The microstructure was studied on cross-sections of samples

in the initial state and after diamond smoothing with different combinations of

operating parameters. Etching of the samples was carried out in a reagent of

the following composition: 20 ml HF, 20 ml HNO3, 60 ml H2O. The structure was

sorbitol with precipitation of dispersed carbide particles along the boundaries

of the original martensite needles (Fig. 4). The release of dispersed carbide

particles ensures the stability of defects formed during the martensitic

transformation due to phase peening. In high-chromium steels of this class,

carbides are identified as M23C6 and VC (1).

In the

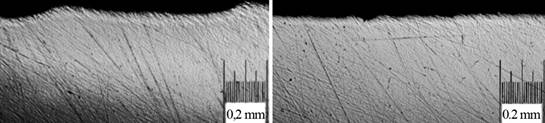

sample after diamond smoothing according to the operating parameters (F=200 N, v=37 m/min, S=0.03 mm/min) in a shallow surface layer up

to 10 µm in-depth, slip lines were revealed in individual grains with a

preferred orientation relative to external acting forces (Fig. 5).

Compared

to the initial state, the roughness decreased significantly. Increasing the

force to 300 - 400 N led to an increase in the depth of the deformed layer to

25 µm and 34 µm, while slip lines were already present in all grains of the

surface layer (Fig. 6 a

and 6 b).

|

|

|

|

Fig. 4. Microstructure of the original sample |

Fig. 5. Microstructure of a sample hardened under operating parameters

(F=200N, v=37 m/min, S=0.03mm/min) |

а b

Fig. 6.

Microstructure of samples hardened under operating parameters:

a - F=300 N, v=145 m/min, S=0.03 mm/min; b - F=300 N, v=115 m/min, S=0.05 mm/min

Analysis

of the microstructure after various diamond smoothing operating parameters

allows to presumably explain the detection of changes in the thin surface layer

as follows. Within the ferrite grain curved lines of a curvilinear type were

observed; they resembled slip lines running in one direction at a certain angle

to the surface of the samples, which was associated with a certain

characteristic vector of acting forces when the movement of a diamond ball with

a diameter of 2.5 mm occurred while the part rotated at a certain speed

Processing

of experimental data made it possible to establish that a rational combination

of operating parameters at which the minimum roughness was achieved: smoothing

force F=300 N; feed S=

0.05 mm/rev; smoothing speed v=115 m/min. The conducted research made it

possible to significantly reduce the number of experiments required to study

the influence of diamond smoothing operating parameters on the characteristics

of the surface and surface layer of parts obtained by SLS from nickel alloys

and alloys based on titanium aluminides.

The

following were selected as varying factors for samples made of the INCONEL 718

nickel alloy: the sphere radius of the diamond smoother Rsf (1.0; 2.5; 4.0 mm);

smoothing force F (0.2; 0.3; 0.4 kN); smoothing feed S (0.05; 0.1; 0.15mm/rev).

A

fractional factorial experiment 32-1 was selected to study the influence of

operating parameters of diamond smoothing on the characteristics of the surface

layer. The standard deviation of the profile Ra, µm and the degree of strain

hardening SHµ, % were chosen as the response functions. The values of the

variable factors and the resulting response functions are shown in Table 3.

The figure

shows an image of a surface layer cross-section of samples hardened by diamond

smoothing with combinations of operating parameters at which the maximum degree

of strain hardening (№ 2 (Fig. 7 a))

and the minimum roughness (№ 7 (Fig. 6 b)) were obtained.

Tab.

3

Values of variable factors and obtained response functions

|

№ |

F (kN) |

S (mm/rev) |

Rsf (mm) |

Ra (µm) |

SHµ (%) |

|

1 |

0,2 |

0,05 |

1 |

1,6 |

37,04 |

|

2 |

0,3 |

0,15 |

1 |

4,92 |

59,33 |

|

3 |

0,4 |

0,10 |

1 |

3,82 |

42,61 |

|

4 |

0,3 |

0,10 |

2,5 |

0,74 |

45,68 |

|

5 |

0,4 |

0,05 |

2,5 |

0,73 |

35,38 |

|

6 |

0,2 |

0,15 |

2,5 |

0,88 |

26,18 |

|

7 |

0,3 |

0,05 |

4 |

0,47 |

3,89 |

|

8 |

0,4 |

0,15 |

4 |

1,22 |

8,07 |

|

9 |

0,2 |

0,10 |

4 |

0,62 |

23,95 |

а b

Fig. 7. Image of the surface layer

cross-section of samples made of nickel alloy

INCONEL 718, hardened by diamond smoothing: a – mode № 2; b – mode №

7 (Table 3)

Compaction

of the surface layer was observed on samples after diamond smoothing. Research

data showed that to obtain minimum roughness, it was necessary to increase the

smoother radius and reduce the feed (mode № 7 (Fig. 7 b)); however, it

contradicted the combination of operating parameters at which the maximum

degree of strain hardening (mode № 2) was obtained (Fig. 7 a). Therefore, for practical application a

compromise is necessary: which is required: low roughness or high degree of

strain hardening. If both parameters are important, then it is necessary to use

a combination of operating parameters at which both response functions will be

rational (mode № 4, Table 3).

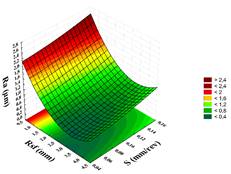

Visualization

of the influence of diamond smoothing operating parameters on the formation of

roughness and the degree of strain hardening is shown in Figure 8.

A

rational degree of strain hardening (Fig. 8 a) was achieved by using a smoother

with a sphere radius of 1 mm and a maximum smoothing force. At the same time,

smoother with a sphere radius of 4 mm and a minimum feed led to achieving

minimum roughness (Fig. 8 b).

Therefore, the radius of the smoother sphere should be 2.5 mm to simultaneously

obtain a rational degree of strain hardening and minimum roughness.

The

regression equations were obtained to predict the magnitude of roughness and

the degree of strain hardening from various combinations of operating

parameters:

![]() (1)

(1)

![]() (2)

(2)

where:

F – smoothing force, kN;

S

– smoothing feed, mm/rev;

Rsf

– radius of diamond smoother, mm;

Rа

– roughness, µm;

SHµ

– degree of strain hardening, %.

а b

Fig. 8. The influence of operating

parameters DS on the degree of strain hardening SHµ

(a) and roughness Ra (b)

In

order to expand the application scope of additive manufacturing technologies,

the study of the influence of diamond smoothing operating parameters on the

quality characteristics of parts manufactured using SLS from alloys based on

titanium aluminide is an urgent task.

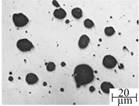

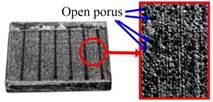

The

alloy has low density, high heat resistance and high mechanical properties. The

residual porosity of the samples produced by SLS obtained from the OX45-3ODS

alloy was at the level of 17-22%. Dead-end pores (Fig. 9) significantly reduced

the quality characteristics of parts made of specified alloys.

Fig. 9. Microstructure and surface

with dead-end pores of the OX45-3ODS alloy sample

A full

factorial analysis was performed using three varied factors (Table 4) in order

to study the effect of diamond smoothing operating parameters on the surface

quality of OX45-3ODS alloy samples.

The

original porosity was chosen as the X4 factor, it had no levels of variation,

since its distribution was random, and it was entered into the planning matrix

as a directly measured value for each sample before diamond smoothing. The

standard deviation of the profile Ra (μm) and the degree of strain

hardening SHµ, %, were chosen as response functions. The number of possible combinations

of factor levels N=27. The planning matrix and the results of the conducted

experiment are shown in Table 5.

Tab.

4

Variations of

factor levels

|

Factor |

Force F, kN |

Feed S, mm/rev |

Radius of diamond

smoother, Rsf, mm |

||||||

|

Х1 |

Х2 |

Х3 |

|||||||

|

Level |

-1 |

0 |

+1 |

-1 |

0 |

+1 |

-1 |

0 |

+1 |

|

Factor value |

0,1 |

0,3 |

0,4 |

0,05 |

0,1 |

0,15 |

1,0 |

2,5 |

4,0 |

Tab.

5

Planning matrix and results of the conducted

experiment

|

№ |

Х1 |

Х2 |

Х3 |

Х4 |

Ra |

SHµ |

№ |

Х1 |

Х2 |

Х3 |

Х4 |

Ra |

SHµ |

|

1 |

-1 |

-1 |

-1 |

0,246 |

1,10 |

45 |

15 |

0 |

0 |

+1 |

0,16 |

0,67 |

47 |

|

2 |

-1 |

-1 |

0 |

0,1233 |

0,85 |

47 |

16 |

0 |

+1 |

-1 |

0,13 |

3,87 |

77 |

|

3 |

-1 |

-1 |

+1 |

0,1866 |

1,15 |

34 |

17 |

0 |

+1 |

0 |

0,11 |

1,0 |

53 |

|

4 |

-1 |

0 |

-1 |

0,13 |

2,04 |

24 |

18 |

0 |

+1 |

+1 |

0,15 |

1,35 |

55 |

|

5 |

-1 |

0 |

0 |

0,1833 |

1,3 |

46 |

19 |

+1 |

-1 |

-1 |

0,1 |

2,99 |

25 |

|

6 |

-1 |

0 |

+1 |

0,1666 |

1,4 |

28 |

20 |

+1 |

-1 |

0 |

0,15 |

1,47 |

53 |

|

7 |

-1 |

+1 |

-1 |

0,1 |

2,6 |

34 |

21 |

+1 |

-1 |

+1 |

0,16 |

0,97 |

58 |

|

8 |

-1 |

+1 |

0 |

0,13 |

1,25 |

42 |

22 |

+1 |

0 |

-1 |

0,11 |

2,97 |

58 |

|

9 |

-1 |

+1 |

+1 |

0,11 |

1,07 |

47 |

23 |

+1 |

0 |

0 |

0,13 |

0,68 |

68 |

|

10 |

0 |

-1 |

-1 |

0,1166 |

4,26 |

50 |

24 |

+1 |

0 |

+1 |

0,1 |

1,0 |

54 |

|

11 |

0 |

-1 |

0 |

0,152 |

1,27 |

64 |

25 |

+1 |

+1 |

-1 |

0,15 |

4,15 |

56 |

|

12 |

0 |

-1 |

+1 |

0,1 |

1,103 |

34 |

26 |

+1 |

+1 |

0 |

0,12 |

0,79 |

53 |

|

13 |

0 |

0 |

-1 |

0,1 |

3,38 |

50 |

27 |

+1 |

+1 |

+1 |

0,18 |

0,704 |

61 |

|

14 |

0 |

0 |

0 |

0,11 |

0,79 |

63 |

|

|

|

|

|

|

|

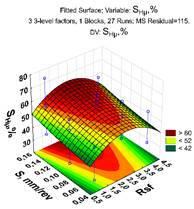

The

regularities of the smoothing operating parameters’ impact on roughness were

subject to the polynomial distribution law. Polynomial surfaces most accurately

approximated the regularities of influence on roughness: the smoothing feed and

the radius of the smoother sphere (Fig. 10). The combination of these factors

had the greatest effect on the roughness of the hardened surface. The

established regularities showed that for smoothing of porous materials it was

necessary to use a diamond smoother with a radius of the diamond sphere

equalled more than 2.5 mm. A smoother with a smaller radius, hitting the

dead-end pores, leading to a deterioration of the surface roughness due to its

cracking.

Due to

the fact that the studied material has high-strength characteristics, its

smoothing with a force of less than 0.3 kN is impractical, since it does not

lead to a sufficient degree of deformation at the point of contact. The

rational value of feed for smoothing the studied alloy was 0.1 mm/rev. A larger

feed led to an insufficient degree of overlap of the grooves after smoothing, a

smaller one, due to the insufficient plasticity of the material, led to the

destruction of the already hardened surface due to the passage of the smoother

over the hardened surface.

Increasing

the wear resistance of the part surface, which is affected by the degree of

strain hardening, is important for improving the quality of parts. According to

the data obtained during the multifactorial experiment (Table 4 and 5), dependencies (Fig. 11) were

constructed, which showed the effect on the degree of strain hardening of

various operating parameters of diamond smoothing: feed, the radius of the

diamond smoother sphere and initial porosity.

а

b

c

Fig. 10. Dependencies of

surface roughness on DS parameters:

а – F=0.1kN; b – F=0.3 kN; c – F=0.4 kN

а

b

c

Fig. 11.

Dependencies of the degree of strain hardening on the operating parameters of

diamond smoothing: а – S=0.05mm/rev; b – S=0.1mm/rev; c – S=0.15mm/rev

Determining

the significance of diamond smoothing operating parameters in the formation of

the degree of strain hardening of alloys based on titanium aluminides OX45-3ODS

was performed by variance analysis (Table 6) based on the conducted full-factor

experiment.

The

variance analysis (Table 6) showed that the smoothing force and its

combination, to a certain extent, with the smoothing feed had the greatest

influence on the degree of strain hardening. A regression analysis (Table 7)

was performed to develop a mathematical model that allowed predicting the

degree of strain hardening from different combinations of operating parameters.

Tab.

6

The variance analysis of the degree of strain

hardening of

the alloy based on titanium aluminides OX45-3ODS after diamond smoothing

|

Factor |

SS |

df |

MS |

F |

P |

|

F(L) |

0,147226 |

1 |

0,147226 |

21,49915 |

0,000159 |

|

(2)s(L) |

0,025689 |

1 |

0,025689 |

3,75129 |

0,067023 |

|

r(Q) |

0,031296 |

1 |

0,031296 |

4,57013 |

0,045066 |

|

1Lby2Q |

0,040899 |

1 |

0,040899 |

5,97245 |

0,023927 |

|

1Qby3L |

0,055225 |

1 |

0,055225 |

8,06438 |

0,010124 |

|

2Lby3Q |

0,037378 |

1 |

0,037378 |

5,45819 |

0,029998 |

|

Error |

0,136960 |

20 |

0,006848 |

|

|

|

Total variance |

0,474674 |

26 |

|

|

|

Tab.

7

Regression analysis of the change in the

degree of strain hardening from different combinations of diamond smoothing

operating parameters

|

Factor |

Regression

coefficients |

Error |

t(14) |

p |

The lower limit

of the confidence interval |

The upper limit

of the confidence interval |

|

Free factor |

0,617 |

0,1986 |

3,10569 |

0,007744 |

0,191 |

1,043 |

|

(1)f(L) |

5,907 |

1,5021 |

3,93250 |

0,001503 |

2,685 |

9,129 |

|

f(Q) |

-17,217 |

3,5587 |

-4,83804 |

0,000263 |

-24,850 |

-9,585 |

|

(2)s(L) |

-26,537 |

5,7237 |

-4,63629 |

0,000385 |

-38,813 |

-14,261 |

|

S(Q) |

154,164 |

32,1935 |

4,78866 |

0,000289 |

85,116 |

223,212 |

|

1Qby2L |

121,953 |

39,7843 |

3,06535 |

0,008390 |

36,624 |

207,281 |

|

1Qby2Q |

-567,653 |

196,8812 |

-2,88323 |

0,012034 |

-989,921 |

-145,385 |

|

1Lby3L |

-1,629 |

0,5195 |

-3,13654 |

0,007284 |

-2,744 |

-0,515 |

|

1Qby3L |

3,636 |

1,0801 |

3,36612 |

0,004614 |

1,319 |

5,952 |

|

2Lby3L |

13,132 |

2,8874 |

4,54818 |

0,000455 |

6,939 |

19,325 |

|

2Lby3Q |

-2,021 |

0,5273 |

-3,83250 |

0,001830 |

-3,152 |

-0,890 |

|

2Qby3L |

-87,932 |

20,8773 |

-4,21182 |

0,000870 |

-132,709 |

-43,154 |

|

2Qby3Q |

14,534 |

3,9864 |

3,64596 |

0,002646 |

5,984 |

23,084 |

Based

on the determined regression coefficients, a regression equation was

established that allowed predicting the degree of strain hardening from

different combinations of diamond smoothing operating parameters:

![]()

(3)

The

adequacy of the obtained regression equation was checked on the basis of the

predicted values to the observed values correspondence graph (Fig. 12).

Fig. 12. Correspondence of predicted values

to observed values

The

predicted values (Fig. 12) did not have a high discrepancy with the values

obtained experimentally, accordingly, the obtained regression equation had

sufficient adequacy and could be used to predict the magnitude of the degree of

strain hardening depending on one or another combination of operating

parameters.

One of the

main disadvantages of powder metallurgy and additive manufacturing is residual

porosity, which contributes to a decrease in strength, plasticity, fracture

toughness, crack resistance, and machinability, and also leads to a decrease in

tribotechnical characteristics. The shape of the pores, characterized by their

perimeter, greatly influences the probability of cracks occurring. The value of

the pore perimeter after diamond smoothing with different combinations of

operating parameters is shown in Table 8.

Tab.

8

Operating parameter modes of diamond

smoothing of OX45-3ODS alloy samples

|

№ |

Р |

№ |

Р |

№ |

Р |

№ |

Р |

№ |

Р |

№ |

Р |

№ |

Р |

|

1 |

1,6722 |

5 |

1,3844 |

9 |

1,4902 |

13 |

0,3852 |

17 |

0,6518 |

21 |

1,5944 |

25 |

2,2129 |

|

2 |

1,1826 |

6 |

1,2334 |

10 |

1,2704 |

14 |

0,4806 |

18 |

0,6824 |

22 |

1,3090 |

26 |

1,8112 |

|

3 |

1,7999 |

7 |

1,3076 |

11 |

2,8276 |

15 |

1,0208 |

19 |

1,1784 |

23 |

1,2643 |

27 |

2,2513 |

|

4 |

0,9925 |

8 |

2,1066 |

12 |

2,1411 |

16 |

0,9533 |

20 |

1,2476 |

24 |

2,0286 |

|

|

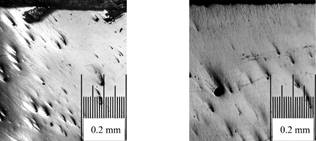

The

influence of diamond smoothing on the pores and their perimeter in the surface

layer of a sample hardened by diamond smoothing with rational operating

parameters is shown in Figure 13.

The analysis of the

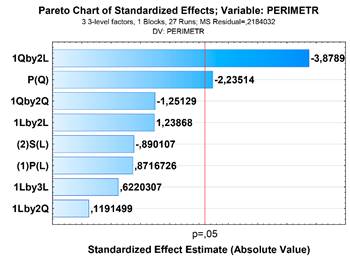

experiment results using Pareto diagrams allowed establishment of the influence

of the smoothing operating parameters and their interactions on the perimeter

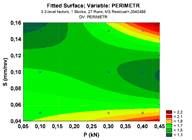

of the pores in the surface layer (Fig. 14).

It was

found that the greatest influence had the combined effect of the feed and the

smoothing force. A regression analysis was carried out (Table 9) in order to

obtain a regression equation that would allow predicting the influence of

diamond smoothing operating parameters on the perimeter of residual pores in

the surface layer.

а b

Fig. 13. The

surface layer of samples from an alloy based on titanium aluminide:

a - initial sample; b - Mode № 14 (Table 5)

Fig. 14. Pareto diagram for the model of the diamond smoothing

operating parameters influence on the perimeter of the pores in the surface

layer

Tab.

9

Regression analysis of the diamond smoothing

operating parameters’ influence on the perimeter of residual pores in the surface layer of titanium

aluminide-based alloy parts

|

Factor |

Regr. Coefficients; Var.:PERIMETER;

R-sqr=,74238; Adj:, 3

3-level factors, 1 Blocks, 27 Runs; MS Residual=,1282098 DV: PERIMETER |

|||||

|

Regressn Coeff. |

Std. Err. |

t(18) |

p |

-95,% Cnf.Limt |

+95,% Cnf.Limt |

|

|

MEAN/Intarc. |

-1,28 |

0,947 |

-1,35615 |

0,191821 |

-3,3 |

0,706 |

|

(1)P(L) |

55,53 |

12,968 |

4,28201 |

0,000449 |

28,3 |

82,771 |

|

P(Q) |

-122,30 |

30,974 |

-3,94846 |

0,000942 |

-187,4 |

-57,225 |

|

(2)S(L) |

35,53 |

8,771 |

4,05044 |

0,000751 |

17,1 |

53,952 |

|

1L by 2L |

-985,88 |

225,444 |

-4,37308 |

0,000367 |

-1459,5 |

-512,245 |

|

1L by 2Q |

2733,26 |

1034,407 |

2,64234 |

0,016555 |

560,0 |

4906,466 |

|

1Q by 2L |

2164,05 |

602,055 |

3,59444 |

0,002073 |

899,2 |

3428,917 |

|

1Q by 2Q |

-6205,10 |

2868,929 |

-2,16286 |

0,044256 |

-12232,5 |

-177,703 |

|

1L by 3L |

0,38 |

0,191 |

2,00200 |

0,060587 |

-0,0 |

0,784 |

A

regression equation was obtained that allowed predicting the perimeter of

residual pores from different combinations of diamond smoothing operating

parameters:

(4)

(4)

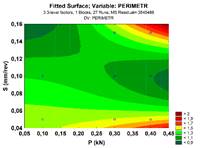

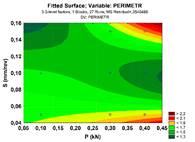

It was

established that the dependencies of the residual pores’ perimeter in the surface

layer on the force and smoothing feed for different radii of the smoother were

of an extreme nature (Fig. 15).

а

b

c

Fig. 15. Effect of force and feed on

porosity during processing with different smoothers:

a – Rsf = 1 mm; b – Rsf =

2.5 mm; c – Rsf = 4 mm

A rational

combination of operating parameters was smoothing with a force of 0.2-0.3 kN, with a feed of 0.12-0.15 mm/rev. The minimum values of the pore perimeter

were obtained when using a smoother with a radius of 1 mm, however, as already

mentioned, its applying led to cracking of the surface (Fig. 15 a). It follows

from the above that the rational radius of the smoother is 2.5 mm (Fig. 15 b).

The use of a smoother with a radius of 4 mm (Fig. 15 c) led to a significant

increase in specific contact pressure, which led to deformation during

processing of a thin-walled part.

The

response surface built on the basis of a nonlinear regression model was

evaluated in order to find the rational smoothing operating parameters,

ensuring the minimum residual porosity. The assessment was performed by the

Box-Wilson steep ascent method (Table 10).

Tab.

10

Rational modes obtained based on the analysis

of the response surface by

the Box-Wilson steep ascent method

|

Factor |

Minimum |

Rational values |

Maximum |

|

Area of residual pores, P, % |

|||

|

F, kN |

0,10 |

0,21 |

0,40 |

|

S, mm/rev |

0,05 |

0,11 |

0,15 |

|

Rsf, mm |

1,00 |

4,60 |

4,00 |

Considering

the possible design limitations of real thin-walled parts, the rational diamond

smoother is 2.5 mm to ensure the best result. The rational smoothing force is

0.22 - 0.3 kN. The rational feed is 0.1 mm/rev, but this parameter may change

depending on the equipment used, in this case it is necessary to take as close

as possible to the established value.

4. CONCLUSION

In order to

expand the application scope of additive manufacturing technologies and improve

the surface layer quality of parts made of nickel alloys and alloys based on

titanium aluminide, produced using selective laser sintering, an innovative

approach to improving their quality was proposed. It is based on the

application of surface layer local deformation treatment of the part's

structural stress concentrators by diamond smoothing. It was established that

the main problems that hindered the spread of additive technologies in

production were porosity, powder cost, uniformity, sensitivity to stress

concentration and surface layer quality. The influence of the diamond smoothing

operating parameters on the formation of surface quality characteristics, the

degree of strain hardening, the distribution of residual stresses and fatigue

resistance during machining parts made of 07Cr12NMBFh alloy were determined. A

rational combination of operating parameters for diamond smoothing of the

mentioned material: smoothing force F=300 N; feed rate S=0.05 mm/rev; smoothing

speed v=115 m/min.

The

main regularities of the quality parameters formation of the treated surface

and surface layer depending on the diamond smoother parameters for parts

obtained by selective laser sintering from an alloy based on titanium

aluminides OX45-3ODS and heat-resistant nickel alloy INCONEL 718 were

determined. The rational diamond smoothing operating parameters of the samples

made of titanium aluminide-based alloy OX45-3ODS were smoothing with a force of

300 N, feed rate of 0.1 mm/rev and a diamond smoother with a radius of 2.5 mm.

The diamond smoothing operating parameters had a different effect on the

roughness and degree of strain hardening of the surface layer of INCONEL 718

alloy samples. The expedient combination of these parameters, in which the

degree of strain hardening and roughness were rational, was machining with a

smoothing force of 250 N, feed rate of 0.1 mm/rev and a diamond smoother sphere radius of 2.5

mm.

The

effect of technological features of processing and operating parameters of

diamond smoothing on the perimeter of residual pores in the surface layer was

determined. The most significant parameter in the study of the effectiveness of

diamond smoothing for hardening materials obtained by selective laser sintering

was the residual porosity. The minimum values of the residual pore perimeters

were achieved by diamond smoothing with the following operating parameters:

force 0.2-0.3 kN, feed rate 0.12-0.15 mm/rev and diamond smoothing sphere

radius 2.5 mm.

References

1.

Goh, G.D., S. Agarwala, G.L. Goh, V.

Dikshit, S.L. Sing, W.Y. Yeong. 2017. „Additive manufacturing in unmanned aerial vehicles

(UAVs): Challenges and potential”. Aerospace Science and Technology 63: 140-151. DOI: https://doi.org/10.1016/j.ast.2016.12.019.

2.

Zhang B., Z. Song, F. Zhao, C. Liu. 2022.

„Overview of propulsion systems for

unmanned aerial vehicles”. Energies 15(2):

455. DOI: https://doi.org/10.3390/en15020455.

3.

Balli O., H. Caliskan. 2021. „On-design

and off-design operation performance assessments of an aero turboprop engine

used on unmanned aerial vehicles (UAVs) in terms of aviation, thermodynamic,

environmental and sustainability perspectives”.

Energy Conversion and Management 243: 114403. DOI: https://doi.org/10.1016/j.enconman.2021.114403.

4.

Clark I. 2005. „Limited

life engines for UAVs”. The Aeronautical Journal 109(1095): 247-254. DOI: https://doi.org/10.1017/S0001924000005224.

5.

Czech Piotr. 2012.

„Identification of Leakages in the Inlet System of an Internal Combustion

Engine with the Use of Wigner-Ville Transform and RBF Neural Networks”.

Communications in Computer and Information Science 329: 175-182. DOI: https://doi.org/10.1007/978-3-642-34050-5_47.

Springer, Berlin, Heidelberg. ISBN: 978-3-642-34049-9; 978-3-642-34050-5. ISSN:

1865-0929. In: Mikulski Jerzy (eds), Telematics in

the transport environment, 12th International Conference on Transport Systems

Telematics, Katowice Ustron, Poland, October 10-13,

2012.

6.

Czech Piotr. 2011.

„Diagnosing of disturbances in the ignition system by vibroacoustic

signals and radial basis function - preliminary research”. Communications in

Computer and Information Science 239: 110-117. DOI:

https://doi.org/10.1007/978-3-642-24660-9_13. Springer, Berlin, Heidelberg.

ISBN: 978-3-642-24659-3. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Modern transport telematics,

11th International Conference on Transport Systems Telematics, Katowice Ustron, Poland, October 19-22, 2011.

7.

Altıparmak S.C., B. Xiao. 2021. „A market assessment of additive

manufacturing potential for the aerospace industry”.

Journal of Manufacturing Processes 68: 728-738. DOI: https://doi.org/10.1016/j.jmapro.2021.05.072.

8.

Karpinos B.S., D.V. Pavlenko, O.Ya. Kachan.

2012. „Deformation of a submicrocrystalline vt1-0

titanium alloy under static loading”. Strength of Materials 44:

100-107. DOI: https://doi.org/10.1007/s11223-012-9354-9.

9.

Vyshnepolskyi Y., D. Pavlenko, D. Tkach. 2020.

„Parts Diamond Burnishing Process Regimes

optimization Made of INCONEL718 Alloy via Selective

Laser Sintering Method”. In: Proceedings

of the 2020 IEEE 10th International Conference on “Nanomaterials: Applications

and Properties”. NAP 2020. DOI: https://doi.org/10.1109/NAP45177.2020.9309661.

10.

Pavlenko D., E. Kondratiuk, Y. Torba, Y.

Vyshnepolskyi, D. Stepanov. 2022. „Improving

the efficiency of finishing-hardening treatment of gas turbine engine blades”. Eastern-European

Journal of Enterprise Technologies. DOI: https://doi.org/10.15587/1729-4061.2022.252292.

11.

Tshephe T.S., S.O. Akinwamide, E. Olevsky,

P.A. Olubambi. 2022. „Additive

manufacturing of titanium-based alloys- A review of methods, properties,

challenges, and prospects”. Heliyon 8(3):

e09041. DOI: https://doi.org/10.1016/j.heliyon.2022.e09041.

12.

Li W.P., H. Wang,

Y.H. Zhou, Y.Y. Zhu,

S.F. Lin, M.

Yan, N.

Wang. 2022. „Yttrium

for the selective laser melting of Ti-45Al-8Nb intermetallic: Powder surface

structure, laser absorptivity, and printability”.

Journal of Alloys and Compounds 892: 161970. DOI: https://doi.org/10.1016/j.jallcom.2021.161970.

13.

Ahmad S., S.

Mujumdar, V. Varghese. 2022. “Role of

porosity in machinability of additively manufactured Ti-6Al-4V”. Precision

Engineering 76: 397-406. DOI: https://doi.org/10.1016/j.precisioneng.2022.04.010.

14.

Kaschel F.R., M. Celikin, D.P. Dowling.

2020. „Effects of laser power on geometry,

microstructure and mechanical properties of printed Ti-6Al-4V parts”. Journal

of Materials Processing Technology 278:

116539. DOI: https://doi.org/10.1016/j.jmatprotec.2019.116539.

15.

Moghimian P., T. Poirié, M.

Habibnejad-Korayem, J.A. Zavala, J. Kroeger, F. Marion, F. Larouche. 2021. „Metal

powders in additive manufacturing: A review on reusability and recyclability of

common titanium, nickel and aluminum alloys”.

Additive Manufacturing 43:

102017. DOI: https://doi.org/10.1016/j.addma.2021.102017.

16.

Cacace S., M.

Boccadoro, Q. Semeraro. 2023. “Investigation

on the effect of the gas-to-metal ratio on powder properties and PBF-LB/M

processability”. Progress

in Additive Manufacturing 9: 889-904. DOI: https://doi.org/10.1007/s40964-023-00490-z.

17.

Soong S.Z., W.L. Lai, A.N. Kay Lup. 2023. „Atomization of metal and alloy powders:

Processes, parameters, and properties”. AIChE Journal 69(11):

e18217. DOI: https://doi.org/10.1002/aic.18217.

18.

Dong S., G. Ma, P.

Lei, T. Cheng, D. Savvakin, O. Ivasishin.

2021. “Comparative study on the densification

process of different titanium powders”. Advanced Powder Technology 32(7): 2300-2310. DOI: https://doi.org/10.1016/j.apt.2021.05.009.

19.

Delpazir M.H., M. Asherloo, S.N.K. Abad,

A. Thompson, V. Guma, S.D. Bagi, A. Mostafaei.

2023. „Microstructure and corrosion behavior of

differently heat-treated Ti-6Al-4V alloy processed by laser powder bed fusion

of hydride-dehydride powder”. Corrosion Science 224:

111495. DOI: https://doi.org/10.1016/j.corsci.2023.111495.

20.

Ng C.H., M.J. Bermingham, M.S. Dargusch. 2023. “Eliminating

porosity defects, promoting equiaxed grains and improving the mechanical

properties of additively manufactured Ti-22V-4Al with super-transus hot

isostatic pressing”. Additive Manufacturing 72: 103630. DOI: https://doi.org/10.1016/j.addma.2023.103630.

21.

Zhang M., C.H. Ng,

A. Dehghan-Manshadi, C.

Hall, M.J. Bermingham, M.S. Dargusch. 2023. “Towards

isotropic behaviour in Ti-6Al-4V fabricated with laser powder bed fusion

and super transus hot isostatic pressing”.

Materials Science and Engineering: A

874: 145094. DOI: https://doi.org/10.1016/j.msea.2023.145094.

22.

Marques A., Â. Cunha,

F. Bartolomeu, F.S. Silva, Ó. Carvalho. 2023. “Inconel

718 produced by hot pressing: optimization of temperature and pressure

conditions”. The

International Journal of Advanced Manufacturing Technology 128(1-2): 891-901. DOI: https://doi.org/10.1007/s00170-023-11950-9.

23.

Zhu L., Y. Pan, Y.

Liu, Z. Sun, X. Wang, H. Nan, X. Lu.

2023. „Effects of microstructure characteristics

on the tensile properties and fracture toughness of TA15 alloy fabricated by

hot isostatic pressing”. International Journal of Minerals,

Metallurgy and Materials 30(4): 697-706. DOI: https://doi.org/10.1007/s12613-021-2371-6.

Received 18.05.2024; accepted in revised

form 30.07.2024

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License