Article

citation information:

Popa, C., Goia, I. The modelling of cargo

transshipment operations using the business process modelling tools. Scientific Journal of Silesian University of

Technology. Series Transport. 2024, 124,

157-169. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2024.124.11.

Catalin POPA[1], Ionela GOIA[2]

THE

MODELLING OF CARGO TRANSSHIPMENT OPERATIONS USING THE

BUSINESS PROCESS MODELLING TOOLS

Summary. This paperwork explores

the transshipment operations at the Port of

Constanta, Romania, focusing on the unloading of big bags from barges.

Utilizing Business Process Management (BPM) software, the study models the transshipment process to identify optimization

opportunities. The investigation reveals challenges such as coordination

complexities and potential cargo damage, alongside the benefits of

cost-efficiency and flexibility offered by transshipment

services. Through literature review and analysis, the study emphasizes the

importance of efficient business processes and the role of BPM software in

enhancing operational efficiency. By employing Aura Portal Modeller for

simulation, the study identifies bottlenecks and proposes optimization

strategies for the transshipment process. The

proposed measures include real-time cargo assessment, inventory tracking

systems, equipment analysis, and storage layout optimization. This research

contributes to the understanding of transshipment

operations and highlights the effectiveness of BPM software in process

visualization and analysis, offering insights for enhancing efficiency and

mitigating delays in supply chain management.

Keywords: business process management, port operations,

process modelling, simulation analysis, cargo handling, inventory management

1. INTRODUCTION – LITERATURE REVIEW

Transshipment

entails the relocation of goods from one transportation mode to another and

serves as a vital element within global supply networks, facilitating the

smooth transportation of goods across extensive distances. While transshipment services offer advantages such as

cost-efficiency, adaptability, and accessibility to inland areas, they also

pose challenges such as the intricate coordination required between diverse

transportation modes, potential setbacks and cargo damage, and the necessity

for proficient inventory handling.

This study aims

to scrutinize the transshipment procedures at the

Port of Constanta, Romania, with a specific emphasis on unloading big bags from

barges. Using Business Process Management (BPM) software, the study seeks to

model the transshipment process and pinpoint

optimization opportunities.

The outcomes of

this investigation will be valuable for researchers and practitioners engaged

in supply chain management, offering insights into the obstacles and prospects

linked with transshipment, while showcasing the

efficacy of BPM software in enhancing transshipment

operations' efficiency.

1.1

Overview

of transshipment services and challenges

Transshipment serves

as a vital link within the intricate network of global supply chains. It

streamlines the movement of goods by enabling them to seamlessly transition

between various transportation methods, ultimately facilitating their delivery

across vast distances. This process typically occurs at designated transshipment hubs equipped to handle large volumes of

cargo. Here, cargo seamlessly transitions from one mode of transport to

another, such as ships to barges, trains to trucks, or vice versa [1]. There

are several types of transshipment, including

sea-to-sea, sea-to-land, and land-to-land transfers. These services offer

numerous benefits, including cost-effectiveness, accessibility to inland

locations, and flexibility in choosing transportation options based on factors

like cost, speed, and capacity.

However, transshipment also

presents challenges, such as the complexity of coordinating transfers between

different modes of transport, which requires meticulous planning and logistics

management [2]. Delays

can occur during the process, affecting delivery schedules, and there's an

increased risk of cargo damage when goods are handled multiple times. Despite

these challenges, transshipment remains an essential

component of modern logistics, enabling the efficient movement of goods

worldwide.

According to industry reports, bulk carriers currently

hold the largest share of the global shipping fleet's carrying capacity. These specialized vessels are designed to

transport large quantities of dry cargo such as iron ore, coal, and grains. As

of 2019, they accounted for an impressive 43% of worldwide capacity [3]. This

dominance appears to be continuing in 2023 [4]. Bulk transshipment terminals are essential components of the

global bulk cargo supply chain, facilitating the smooth transportation of bulk

commodities for subsequent distribution [5].

A significant benefit of utilizing transshipment

services lies in their ability to optimize transportation efficiency and

minimize associated costs. Transshipment hubs achieve

cost reductions through various strategies.

They function by accumulating cargo from diverse origins, enabling them

to capitalize on economies of scale in transportation, storage, and handling

activities. This translates to lower overall costs per unit of cargo moved.

Additionally, these hubs empower businesses with flexibility. They can choose

the most suitable transportation mode for each leg of the journey based on

cost, speed, and reliability. This optimization in route planning enhances the

overall responsiveness and agility of the supply chain [6].

Despite their benefits, transshipment

services also present challenges that need to be addressed to ensure smooth

operations and uninterrupted supply chain flow. These challenges include

coordinating complex multi-modal transportation processes, managing cargo

handling and storage capacity, navigating regulatory requirements, and

mitigating risks such as delays, damages, and security threats [7].

To address these challenges and maximize the benefits of transshipment services, businesses and logistics

stakeholders employ various strategies and technologies. These may include

advanced tracking and monitoring systems, automation and robotics in cargo

handling, predictive analytics for demand forecasting and capacity planning,

and collaboration among supply chain partners to improve coordination and

visibility.

1.2 The basics

of business process management

At the core of every successful organization

lies a well-defined set of interconnected activities known as business

processes. These processes, structured and routinely executed, ensure the

smooth and efficient operation of the entire business. They encompass a wide

range of functions, including supply management, production, distribution,

marketing coordination, and customer service provision. These essential

activities work together seamlessly to maintain the uninterrupted day-to-day

operations of the organization. The core functions of a business can be

understood through its operational processes.

In compliance with Laguna and Marklund’s paper, business processes serve as the

"foundation" for ensuring the efficient functioning of an

organization, profoundly impacting its performance. By effectively managing and

optimizing these processes, organizations can gain significant advantages and

maintain their relevance in an ever-changing and highly competitive business

environment. Thus, ensuring proper adaptation to fluctuating market demands and

supporting sustainable growth in a dynamic and challenging context [8].

According to Rosenberg’s paperwork the

processes are essentially a series of interconnected activities, transforming raw

materials or services into desired outputs.

Their goal is to achieve the organization's specific operational

objectives [9]. Procurement, production, distribution,

marketing, sales, and customer service are all examples of such processes,

though the specific lineup will vary depending on the

nature [10].

Optimizing transshipment

processes requires establishing clear and achievable goals. Kunpeng,

Gharehgozli, & Lee [11] emphasize

the value of employing SMART objectives in this context. By setting Specific,

Measurable, Achievable, Relevant, and Time-Bound goals, organizations can

ensure focused direction for their optimization efforts. This allows for

measurable progress tracking and ultimately increases the likelihood of

achieving desired performance improvements within transshipment

operations.

Measurable objectives are quantifiable,

allowing progress tracking. Achievable objectives are realistic and feasible

within organizational capabilities. Relevant objectives align with overall

organizational strategy and needs. Time-bound objectives have specific

deadlines for completion. Adhering to SMART principles ensures focused

direction, measurable progress, and increased likelihood of achieving desired

outcomes in operational processes [12].

In their exploration of business process

performance evaluation, Nanyam & Neeraj [13] highlight the critical role of defining

clear objectives and expected outcomes. This approach allows organizations to

establish measurable benchmarks for success. By comparing actual results

against these predefined objectives, organizations can conduct unbiased

evaluations of process effectiveness and identify areas for improvement.

Clearly defined objectives are essential for

effective performance evaluation within business processes. These objectives

function as a performance measurement framework, allowing organizations to

assess progress towards achieving desired outcomes. By comparing actual results

against these predefined objectives, organizations can identify areas for

improvement and ensure all stakeholders, including employees, are aligned on the

goals of optimizing process performance [14] [15].

2.

Modeling Transshipment

Operations in Constanta Port using AuraPortal Modeler: Research Hypotheses and Applied Variables in the

Model

2.1

Modelling approach and case study assumptions

This paper aims to analyse the semi direct transshipment operation of a barge carrying 40,000 metric

tons of Clinker Big Bags within a strict 12-day timeframe. Such an endeavour

demands a well-coordinated plan and streamlined processes to ensure both

effectiveness and cost efficiency. To tackle this challenge, a simulation

program has been devised, considering crucial parameters such as the total

cargo volume, the duration of the program, and the estimated cost involved.

With these factors in mind, the simulation aims to optimize the transshipment process, ensuring that all cargo is

efficiently handled within the allocated timeframe.

The process is meticulously broken down into

key stages within the simulation. It begins with the crane lifting a Big Bag

from the ship onto a waiting tractor-trailer, followed by the transportation of

the loaded bag to the designated storage area by the tractor. Subsequently, a

forklift unloads the bag from the trailer and places it in storage. The cycle

is completed with the return of the empty tractor to the crane for the next Big

Bag and the forklift's return to the storage area. Acknowledging real-world

variations, the simulation takes into consideration factors that could impact

the average cycle time, such as equipment efficiency, operational coordination,

and unforeseen events like adverse weather conditions or minor delays. The outcome of the simulation not

only assesses the feasibility of achieving the target goal within the stipulated

timeframe but also serves as a foundation for continuous improvement. Through

regular monitoring and analysis of cycle times during the actual unloading

process, potential bottlenecks can be identified and addressed for future

optimization. Additionally, embracing technological advancements in automation

and equipment efficiency can further enhance the unloading process, ensuring

long-term efficiency and sustainability by remaining adaptable to changing

operational needs.

For process modelling, the authors used Aura

Portal Helium Modeler, a free and dedicated software

tool. Aura Portal is a digital business platform that streamlines process

design and execution without requiring additional programming knowledge. Its

core product, Aura Portal BPM (Business Process Management), is a software

application specifically designed to facilitate the creation and automation of

workflows.

To ensure the model confidentiality, the company

analysed in the case study has been named,

"Danube Investments Ltd.", representing a typical big bag

transshipment service provider in the Port of Constanta. Data on activity

durations and costs have been gathered from ten similar companies to create statistically

relevant averages for variables used in the model (e.g., crane operation time,

personnel costs). A pre-existing transshipment model was selected, and key

processes were identified to map the flow of big bags from retrieval on the

barge to designated storage locations on the land platform. This comprehensive

analysis ensures the model accurately reflects the big bag unloading process at

the Port of Constanta, considering factors like resource allocation and travel

times.

2.2

Process model description. detailed breakdown of the transshipment process activities

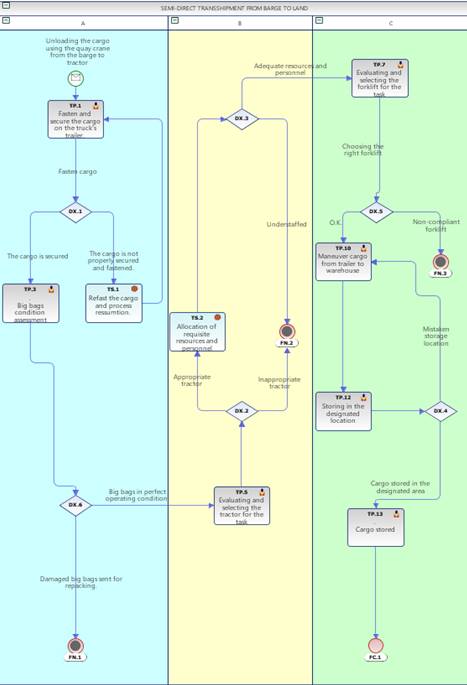

As main activities, the authors begin with

the assumption of completed customs formalities and the ship is docked for

unloading. The process has been divided in three main phases, each with

subsequent tasks for a better understanding of the process.

Phase A reflects the unloading process of the cargo

from the barge using the quay crane and unloading onto the tractor. The initial

task entails the crane's rotation to the required height, directed by the barge

foreman. Upon successful completion, the subsequent activity of moving the

cargo onto the tractor trailer is followed. Herein lies a decision point: if

cargo security is ensured, we advance to the next task; otherwise, the cargo

must be re-secured, and the process will return to task 2 to rectify the issue

before proceeding. If some big-bag is damaged during handling, it is sent for

repackaging.

Following the unfastening the cargo from the

trailer, the process continues with the transportation of the cargo to land

using tractor-trailer units in phase B.

The suitability of the tractor determines the progression, with any unsuitable

choices leading to a temporary halt until a suitable alternative is found.

Therefore, if the tractor is not suitable for the task, the activity will have

a finish point until a suitable tractor is found. The process is followed with

the transporting the cargo to land over 400 meters, leading to positioning the

trailers in the optimal area of action for forklift operations.

The adequacy of personnel and resources

determines progression to phase C,

where the cargo is transferred from tractor to land using a forklift. If the

resources are insufficient, the activity will be suspended. Upon completion of

the positioning task for the forklift on the side of the trailer, guided by the

docker, the process proceeds to lifting the load to

the appropriate height for retrieving the big bag from the trailer. It is then

assessed whether the forklift meets the unloading requirements; if not,

operations are suspended until a suitable replacement arrives. Once a suitable

forklift is available, the process advances to moving the forklift forward to

the pickup position, guided by the docker, followed

by relocating the forklift over 10 m to the designated location for depositing

the big bag. If successful, the process proceeds to placing it at the indicated

location. On-site workers then inspect the task's completion; if the big bag is

misplaced, the process returns to the relocation task to ensure correct

placement. Upon successful completion of the placement task, the process moves

on to raising the hooks vertically, followed by lifting the forks, rotating the

forklift, and moving it without cargo to the pickup point for another big bag,

thus concluding the cycle. Tasks progress sequentially, culminating in the

completion of a cycle with the final task.

In summarizing the process, in figure 1 model

the authors have presented in three distinct phases, each comprising subsequent

tasks for enhanced clarity as depicted below. Phase A encompasses the unloading

of cargo from the barge using the quay crane and its subsequent transfer to the

tractor trailer. Phase B is dedicated to transporting the cargo to land via

tractor-trailer units, with the suitability of the tractor dictating the course

of action. Phase C involves transferring the cargo from the tractor to land

using a forklift, with the sufficiency of personnel and resources guiding the

process forward. Tasks advance sequentially, culminating in the completion of a

cycle with the final task.

Fig. 1. Semi-Direct transshipment

process modeling using Aura Portal

Once the process model has been established,

powerful simulation software comes into play. This software leverages

statistical data to create various scenarios that replicate real-world transshipment operations. The data focuses on activities

deemed critical for successful execution, such as crane operation times or

personnel requirements. By integrating these critical parameters, the

simulation software can anticipate potential results like total unloading time

or resource needs. It can also pinpoint areas within the process that slow down

operations, allowing for targeted optimization efforts. Additionally, the

software analyses how resources like cranes and personnel are currently used

and identifies opportunities for more efficient deployment. Finally, it

evaluates key performance indicators (KPIs) like

total unloading time, cost per ton, and resource utilization to gauge the

effectiveness of the entire process. Through simulation and analysis, the

software empowers authors to identify and address inefficiencies, ultimately

leading to a smoother, faster, and more cost-effective transshipment

process in the Port of Constanta.

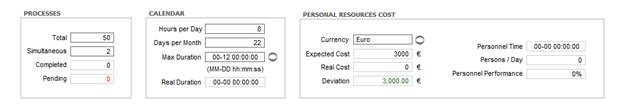

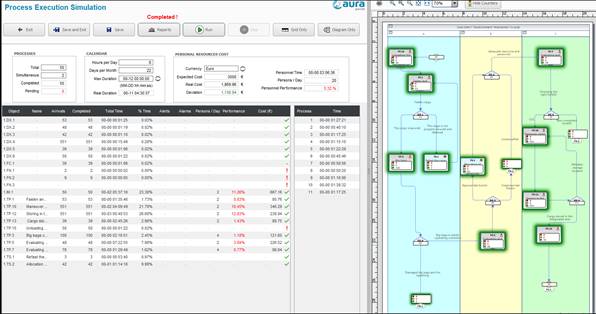

Fig.

2. Configuring parameters for initiating the process simulation

The visual representation depicted in figure

no. 2 illustrates the configured parameters before initiating the simulation.

Within the simulation process, a total of 50 processes have been implemented

per day, enabling the unloading of 800 tons per day. Over the course of 12

days, this setup ensures the complete unloading of the entire quantity.

Additionally, the simulation allows for 2 simultaneous executions, reflecting

industry standards derived from sample companies' analyses. The calendar panel

provides insights into simulation run times, indicating default values for

working hours per day set at 8. This parameter serves as the foundation for

computing simulation outcomes. For instance, if a process requires 24 hours to

complete and the standard workday spans 12 hours, the total execution duration

would equate to 2 working days per month. This default setting assumes 22

working days per month. The simulation is configured to run for a maximum

duration of 12 days, with the actual durations of processes revealed upon

completion. The total cost expenditure of the process amounts to 3,000 Euro for

a twelve-days period, involving twenty individuals per

day in the transshipment operation.

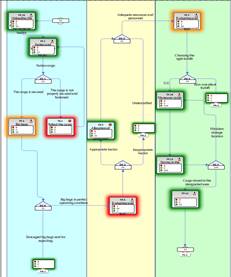

Upon configuring the temporal and financial

parameters, the simulation was brought to a close. Throughout the simulation's

execution, objects within the model illuminate in various hues corresponding to

their temporal status. A green hue signifies that an object has completed its

assigned tasks within the anticipated timeframe and cycle count, while orange

indicates completion within an alert timeframe, and red indicates completion

beyond the projected timeframe.

As shown in

the figure 3, the simulation highlights opportunities to enhance the process.

The current completion time identified in the simulation suggests room for

improvement. To identify these, a deeper analysis of the simulation results is

necessary. Focusing on bottlenecks could involve examining factors such as task

allocation, training needs, or inefficiencies in the process flow itself. By

pinpointing these areas, we can develop targeted solutions, such as refining

process steps or implementing new technologies. These improvements will

ultimately lead to a more streamlined and effective process, resulting in (positive

business outcome, e.g., reduced costs, faster turnaround times, improved

customer satisfaction).

Fig. 3. Process execution simulation diagram

However, despite our best efforts, the initial budget of 3,000 euros was

exceeded by 5,125 Euros due to unforeseen challenges in the procurement of

specialized equipment required for the simulation. Delays in equipment delivery

and unexpected maintenance costs contributed to the budget overrun,

highlighting the importance of comprehensive risk assessment and contingency

planning in future projects. Ultimately, achieving both optimal performance and

cost-effectiveness are crucial for project success.

The simulation within the Aura portal has identified

potential bottlenecks in the unloading process, requiring further analysis and

improvement. These bottlenecks are indicated by the appearance of yellow and

red error messages. Upon initial observation, the software, by iterating the

process through the designed cycle count, identified delays in the transshipment procedure due to task overlap and resource

inadequacies, leading to congestion in the operational queue.

Red Errors: Critical Issues Requiring

Immediate Attention

Ø

TS1 -

Refasten Cargo and Process Resumption (Red Error): This critical error

signifies a severe interruption, likely due to cargo instability or safety

concerns. Immediate action is necessary to refasten the cargo and resume

operations safely and efficiently.

Ø

TP5 -

Evaluating and Selecting Tractor for Task (Red Error): This red error indicates

a significant delay in selecting the appropriate tractor for the job. Potential

causes include equipment unavailability or bottlenecks in the decision-making

process. Optimizing tractor selection procedures can significantly reduce these

delays.

Yellow Errors: Areas for Improvement and

Optimization

Ø

TP7 -

Evaluating and Selecting Forklift (Yellow Error): This yellow error suggests a

moderate delay or inefficiency in selecting the appropriate forklift. Resource

limitations or insufficient planning could be contributing factors.

Streamlining the selection process can minimize these delays.

Ø

TP3 -

Big Bags Condition Assessment (Yellow Error): The presence of this yellow error

highlights the need for a more thorough assessment of the big bags' condition.

Inconsistencies or uncertainties in the current process require investigation

and improvement.

By analysing these red and yellow errors, we

can pinpoint specific areas for improvement within the Aura portal simulation.

By implementing corrective actions and optimizing the identified processes, we

can ensure a smoother and more efficient unloading workflow. The simulation

provides valuable insights into potential problems, allowing us to proactively

address them before they hinder real-world operations.

2.3

Potential bottlenecks revealed in Aura Portal Simulation: software-based

optimization strategies

The Aura portal simulation has uncovered

potential bottlenecks within the unloading process, emphasizing the necessity

for comprehensive analysis and targeted optimization. These bottlenecks are

evident through the appearance of red and yellow error messages, each

indicating areas for improvement.

Red errors, denoting critical issues

requiring immediate attention to prevent disruptions and ensure safety, include

"TS1 - Refasten Cargo and Process

Resumption" and "TP5 - Evaluating and

Selecting Tractor for Task." The former signals a severe interruption,

potentially caused by cargo instability or safety concerns, while the latter

highlights significant delays in selecting the appropriate tractor. To address

these critical issues, optimization measures such as implementing pre-departure

inspections for cargo stability and enhancing communication for tractor

selection can be implemented.

Yellow errors, representing areas for

improvement to enhance efficiency and minimize delays, include "TP7 - Evaluating and Selecting Forklift" and "TP3 - Big Bags Condition Assessment." These errors suggest

moderate delays in selecting the appropriate forklift and emphasize the need

for a more thorough assessment of big bags' condition, respectively.

Optimization measures for yellow errors involve developing centralized resource

management systems, implementing standardized procedures, and using digital

inspection systems to ensure consistent evaluation procedures.

The identified bottlenecks and optimization

measures represent a starting point for continuous improvement. By regularly

monitoring the simulation and analysing performance data, new areas for

improvement can be proactively identified and further optimizations

implemented. This data-driven approach ensures that the unloading process

remains efficient, safe, and adaptable to changing demands. Ultimately, the

Aura portal simulation serves as a valuable tool for identifying and addressing

bottlenecks in the unloading process, leading to a smoother, more efficient,

and safer workflow.

2.4

Optimization actions ensuring budget compliance

Throughout the simulation process outlined in

this study, several optimization actions were meticulously implemented to

ensure that the operations remained within the allocated budget. By

strategically addressing inefficiencies and streamlining workflows, we were able

to achieve the desired outcomes while adhering to financial constraints.

One of the primary optimization measures

undertaken was the refinement of process efficiency. By fine-tuning the

scheduling of tasks and maximizing resource utilization, we significantly

enhanced productivity without compromising on quality or safety standards. This

approach allowed us to capitalize on the available resources more effectively,

ultimately contributing to cost savings.

Additionally, proactive measures were taken

to mitigate potential bottlenecks and disruptions in the workflow. By

identifying and addressing critical issues promptly, we were able to maintain

operational continuity and minimize costly delays. This proactive stance not

only safeguarded the project timeline but also prevented unnecessary

expenditures associated with downtime and rework.

Furthermore, strategic resource allocation

played a pivotal role in budget compliance. By allocating personnel and

equipment judiciously based on task requirements and workload demands, we

optimized resource utilization and minimized unnecessary expenses. This

balanced approach ensured that resources were allocated where they were most

needed, maximizing operational efficiency while staying within budgetary

constraints.

Upon implementing the optimization methods

mentioned earlier, the simulation of the process was successfully conducted

according to the specified parameters. As shown in figure no 4 for the 50

processes with two simultaneous executions, the entire quantity of cargo was

operated within 11-day timeframe. This was accomplished with the involvement of

20 resources in the process, while also adhering to an approximate budget of

2000 euros. This outcome objectively demonstrates the effectiveness of the

optimization methods, enabling the achievement of set objectives within the

defined financial constraints.

In conclusion, the successful completion of

the simulation within the allocated budget underscores the effectiveness of the

optimization actions implemented. By proactively addressing inefficiencies,

mitigating risks, and optimizing resource allocation, we not only achieved the

desired outcomes but also demonstrated our commitment to prudent financial

management. Looking ahead, these optimization strategies will continue to

inform our approach, ensuring that future simulations are conducted efficiently

and cost-effectively.

Fig. 4. Successful implementation of optimization

methods: achieving objectives within budget and time constraints

3.

CONCLUSION

To ensure the robustness and accuracy of the simulation results, data

validation was conducted through a multi-pronged approach. Firstly, data on

activity durations and costs was gathered from ten similar companies operating

at the Port of Constanta. This approach leverages established practices within

the industry and provides statistically relevant averages for variables used in

the model (e.g., crane operation time, personnel costs). Additionally, internal

validation measures were employed to enhance the reliability of the simulation

data. This involved cross-checking activity durations and costs against

historical data maintained by the port authorities and conducting sensitivity

analysis to assess the impact of variations in key input parameters on the simulation

outcomes. By employing these rigorous data validation procedures, we can

confidently assert that the simulation results accurately reflect the

real-world unloading process at the Port of Constanta, providing a solid

foundation for optimization strategies.

This study successfully employed BPM software and simulation techniques

to analyse and optimize the unloading process of big

bags at the Port of Constanta, Romania. The key findings and areas for

improvement are summarized below:

Ø The Aura

Portal simulation revealed critical bottlenecks within the unloading process,

including delays in cargo refastening (TS1), tractor selection (TP5), forklift

selection (TP7), and big bag condition assessment (TP3). These bottlenecks were

highlighted by red and yellow error messages, signifying areas requiring

immediate attention and optimization opportunities, respectively.

Ø Software-Based

Optimization Strategies: To address the identified bottlenecks, the study

proposes a series of software-based optimization strategies. These include

implementing pre-departure cargo stability inspections to minimize refastening

delays (TS1), enhancing communication and streamlining procedures for tractor

selection (TP5), developing centralized resource management systems for efficient

forklift allocation (TP7), using digital inspection systems to ensure

consistent big bag condition assessment (TP3).

Ø The study

emphasizes the importance of budget adherence throughout the optimization

process. Strategies like process efficiency refinement, proactive bottleneck

mitigation, and strategic resource allocation were employed to ensure

cost-effectiveness. Furthermore, the simulation, configured with 50 processes,

2 simultaneous executions, and a budget of approximately €2,000, successfully completed

the unloading of the entire clinker cargo within 11 days using 20 resources.

This demonstrates the effectiveness of the implemented optimization strategies

in achieving project objectives within budgetary constraints.

Ø The study

acknowledges the importance of continuous monitoring and data analysis to

identify further optimization opportunities. By adopting a data-driven

approach, the unloading process can be continuously refined for enhanced

efficiency, safety, and adaptability to evolving demands.

In conclusion, this research demonstrates the value of BPM software and

simulation in optimizing transshipment operations. By identifying and

addressing bottlenecks, and implementing targeted optimization strategies,

significant improvements can be achieved in terms of efficiency, safety, and

cost-effectiveness. By continuously monitoring and analysing

performance data, this approach ensures long-term optimization and adaptability

within the dynamic environment of port operations. In conclusion, this study has

shed light on the intricacies of transshipment operations and demonstrated the

effectiveness of Business Process Management (BPM) software, particularly Aura

Portal Modeller, in visualizing and analysing process flows. By leveraging statistical simulation

functionalities, researchers were able to pinpoint potential bottlenecks within

the process, paving the way for optimization strategies.

The proposed measures for improvement encompass various aspects of the

transshipment process, including real-time assessment of cargo handling needs,

implementation of tracking systems for inventory management, analysis of

equipment capabilities, and optimization of storage layout. By implementing

these solutions, organizations can streamline operations, enhance efficiency,

and mitigate potential delays and errors.

References

1.

Yang D., K. Wang, H. Xu, Z.

Zhang. 2017. ”Path to a multilayered transshipment port

system: How the Yangtze River bulk port system has evolved”. Journal of Transport

Geography 64: 54-64.

2.

Cigolini

R., T. Rossi. 2010. ”Sizing off-shore transshipment systems in dry-bulk transportation”. Journal

of Production Planning and Control 21(5): 508-522.

3.

Kavussanos M., S. Moysiadou. 2021. ”Bulk shipping markets: An overview of market structure

and dynamics”. International Encyclopaedia of Transportation 3:257-279.

4.

UNCTAD.

2023. Review of maritime transport 2023. Technical report.

5.

Cheng L., X. Lin, X. Bai. 2023. “Direct Transshipment

Optimization in Hub Bulk Transshipment Terminal”. SSRN 4679152.

6.

Filina-Dawidowicz L., M. Kostrzewski. 2022. ”The complexity of logistics services at transshipment terminals”. Journal Energies 15(4):

1435.

7.

Archetti C., L. Peirano, M. Speranza, C. Archetti, L. Peirano, M.G. Speranza. 2022. “Optimization in multimodal freight

transportation problems: A Survey”. European Journal of Operational Research

299(1): 1-20.

8.

Laguna

M., J. Marklund. 1998. Business Process Modeling, Simulation and Design. 3rd

edition. New York: CRC Press.

9.

Rosenberg

D. 2006. Business Process Design: The Method. Business Process

Management. Springer.

10.

Lindsay

A., D. Downs, K. Lunn. 2003. “Business processes – attempts to find a

definition”. Information and Software Technology 45(15): 1015-1019.

11.

Kunpeng

L., A. Gharehgozli, J.-Y. Lee. 2023. “Smart

technologies and port operations: Optimal adoption strategy with network

externality consideration”. Computers & Industrial Engineering 184.

12.

Doran G.

1981. “There's a S.M.A.R.T.

way to write management's goals and objectives”. Management Review

70(11): 35-36.

13.

Nanyam

V., K. Neeraj. 2023. “Modeling

challenges affecting the performance of major ports of India”. The Asian

Journal of Shipping and Logistics

39(3): 26-38.

14.

Simons R.

1995. “Control in an age of empowerment”. Harvard Business Review 73(2):

80-88.

15.

Sánchez-González G., F.J. González-Castaño, L.H. Pérez-Bernal.

2019. “Business process management in

warehouses: A systematic literature review”. Journal of Industrial

Engineering and Management 12(4): 756-775.

Received 20.05.2024; accepted in revised

form 29.07.2024

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License