Article

citation information:

Naumov, V., Taran, I., Zhanbirov, Z., Mussabayev, B., Konakbai, Z. Assessing

the synergetic effect of selecting the optimal structure of a logistics chain. Scientific Journal of Silesian University of

Technology. Series Transport. 2024, 124,

109-126. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2024.124.8.

Vitalii NAUMOV[1], Ihor TARAN[2], Zhumazhan ZHANBIROV[3], Batyrbek MUSSABAYEV[4], Zarina KONAKBAI[5]

ASSESSING

THE SYNERGETIC EFFECT OF SELECTING THE OPTIMAL STRUCTURE OF A LOGISTICS

CHAIN

Summary. This study tackles a

critical challenge in logistics optimization: assessing the economic efficiency

not only of individual entities within a logistics chain, but also the

synergistic benefits that arise from their collaboration. We achieve this by

proposing a methodology that evaluates the economic efficiency of interactions

between participants in a logistics chain. This methodology goes beyond

individual efficiency and delves into how the overall economic benefit is

distributed among key stakeholders. These stakeholders include freight owners,

who initiate the delivery process, forwarders who manage and optimize

deliveries, carriers who physically transport goods, and freight terminals that

facilitate cargo handling and storage. To ensure the methodology’s relevance to

contemporary practices, we begin with a comprehensive review of recent

advancements in delivery chain optimization research. We propose to measure the

synergetic effect by considering delivery demand parameters, such as the weight

of the consignment and the distance it needs to travel. To validate our

methodology and gain practical insights, we conducted a series of experimental

studies specifically tailored to the Kazakhstani transportation market. By

analysing the share of the synergistic effect under varying delivery demand

parameters, we were able to identify trends and patterns.

Keywords: freight transportation, synergetic effect,

requests flow, logistics chain

1. INTRODUCTION

An efficient transportation system serves as

the lifeblood of any modern economy. It facilitates the seamless movement of

goods and people, fulfilling the critical needs of both consumers and

businesses. This paper delves into the intricate world of logistics, exploring

the fundamental role of the transportation industry and the challenges inherent

in designing and optimizing delivery systems.

Transportation bridges the gap between

production and consumption. By efficiently delivering goods, businesses can

reach wider markets, fostering economic growth. Reliable and cost-effective

transport empowers businesses to access raw materials, distribute finished

products, and connect with a wider network of employees and clients.

Furthermore, robust transportation systems underpin international trade,

enabling the smooth flow of goods across borders and fostering global economic

cooperation.

Within the transportation sector, road

transport plays a central, yet often underappreciated, role. It serves as the

foundation, handling the crucial “first mile” and “last mile” deliveries in

most journeys. This ensures seamless movement of goods throughout the entire

supply chain, even when other modes of transport, such as airplanes or ships,

are involved.

Behind the scenes, logistics companies act as

the masterminds, meticulously coordinating the intricate web of activities that

form the supply chain. Forwarding companies play a vital role in managing this

complex network. The effectiveness of their services directly impacts the

efficiency of the entire system. Their primary task is to meticulously plan and

organize the transportation process, ensuring goods arrive at their destination

on time, within budget, and in good condition. These efforts may be summarized

by selecting the proper structure of the logistics chain that ensures the minimum

total expenses for all entities participating in the delivery process.

This study aims to develop a

methodology for evaluating the economic efficiency of delivery processes within

a logistics chain. Furthermore, the methodology will assess how the resulting

synergetic effect is distributed among the different entities involved in the

delivery process.

The paper is structured as follows. Section 2

provides a concise review of recent research directions in delivery chain

optimization. Section 3 details the methodology employed to estimate the

synergistic effect for various delivery process participants: freight owners,

forwarders, carriers, and freight terminals. Section 4 presents the results of

experimental studies conducted to calculate the share of the synergistic effect

under varying delivery demand parameters (consignment weight and delivery

distance). Finally, Section 5 offers concise conclusions and outlines potential

avenues for future research.

2. LITERATURE REVIEW

The field of transportation process

optimization is rich with diverse challenges. Researchers grapple with issues

like managing fleets, controlling costs, and developing optimal strategies for

both customer service and vehicle routing [1-4]. Ensuring quality control

throughout the transportation process, understanding market behaviour

to predict demand [5-7], and allocating resources efficiently are all crucial

aspects [5, 8]. Additionally, mitigating risks associated with transportation

decisions and maximizing supply chain reliability are key areas of research [9,

10]. This complex field draws on a multitude of academic disciplines.

Operations research, economics, and engineering all contribute valuable

approaches to finding optimal solutions, as evidenced by the variety of models

and algorithms developed. Notably, a recent area of focus involves optimizing

supply chains while considering factors like risk, uncertainty, and

sustainability [11].

The ever-changing technological

landscape constantly presents new research opportunities. Studies like [12]

highlight how the evolving business environment challenges the effectiveness of

current optimization methods. This research also identifies key trends and

knowledge gaps relevant to both practitioners and academics, exploring future directions

for optimization research in emerging markets and evolving freight transport

organizations [12]. Similarly, Köhler and Brauer delve into the transformation of freight transport,

outlining new analytical needs and potential modelling approaches for the

future [13].

The transportation and logistics

industry is undergoing a digital revolution fuelled

by the Internet of Things and Big Data. The COVID-19

pandemic and the shift to remote work further accelerated this trend, pushing

major players like Maersk, MSC, and Hapag-Lloyd to

embrace online platforms. This digital shift has a ripple effect, forcing even

smaller transport companies to adapt. Research by [14] explores the impact of

online freight platforms (OFPs) on traditional

logistics service providers (TLSPs). The authors

found that OFPs don’t necessarily threaten TLSPs, but rather offer manufacturers new options for

outsourcing deliveries. Similarly, authors of [15] examine the interaction

between information systems and the performance of international freight

forwarders. Looking ahead, digitalization and automation are expected to

continue shaping the industry with advancements in artificial intelligence and blockchain technology, as evidenced by works like [16] and

[17]. These developments hold promise for real-time shipment tracking and

increased supply chain transparency.

Sustainability is emerging as a

second major trend within the transportation and logistics industry. Sustainable practices act as a crucial bridge

between modernization and responsible industry functioning. Research by [18]

exemplifies this by developing a model that integrates resilience and agility

into designing sustainable agri-food supply chains.

This model considers uncertainties in the environment. The ultimate goal of sustainability

efforts in freight transport is to minimize overall costs while reducing

negative environmental and social impacts. To achieve this, research by Pamucar et al. [19] recommends maximizing the potential of

alternative transportation modes, like rail, to lessen the negative

consequences of road freight transport such as emissions, noise, and

congestion. The authors propose a transportation planning strategy for freight

companies based on fuzzy sets to rank these alternative modes effectively. Similar

studies in [20] further explore ways to encourage a shift towards rail and

other alternatives to road transport. Focusing on eco-friendly solutions, [21]

proposes an effective algorithm for routing vehicles specifically within the

context of sustainable transport. This algorithm, based on restrictive

inheritance, helps determine environmentally friendly routes. By implementing

such solutions, the transportation industry can contribute to sustainable

development by minimizing the environmental and social impact of transport.

Another key direction for the

transportation and logistics industry involves integrating passenger and

freight movement within cities, often referred to as “urban co-modality”.

Research by Ma et al. [22] explores the potential benefits of such integration

by modelling a public transport system that accommodates both passengers and

goods. Their study examines how this co-modality can impact existing

forwarding, trucking, and passenger services across the urban transport system.

Notably, the authors identify scenarios where co-modality can improve profits

for forwarders, carriers, and transit operators, while also increasing consumer

surplus for both freight customers and passengers compared to traditional

separated systems. Beyond modelling, the paper [23] presents a practical

framework for developing and evaluating an innovative service called Integrated

Demand-Responsive Transport (I-DRT). This service combines passenger and

freight transportation with a demand-responsive approach, meaning it adapts to

real-time needs. The study utilizes Osterwalder’s

business model canvas to outline the infrastructure, vehicles, personnel,

costs, revenue streams, and partnerships required for I-DRT implementation. A

pilot project in Misano Adriatico,

Italy, demonstrated the service’s potential. The results suggest that

addressing challenges related to legislation, policy, and stakeholder

participation is crucial for achieving more robust and sustainable long-term

outcomes. Further supporting this trend, a comprehensive review by [24]

explores existing practices and approaches used to integrate passenger and

freight transport in urban areas. This review highlights the numerous positive

impacts of integration, including reduced traffic congestion, improved resource

utilization, and increased overall sustainability within cities.

The transportation and logistics

industries are navigating a turbulent economic landscape shaped by geopolitical

tensions and global downturns. These disruptions necessitate that transport

companies re-evaluate their operational practices. To thrive in this

environment, effectively combining traditional approaches with modern modelling

and analysis techniques is crucial. This allows for the development of

efficient strategies for managing and optimizing transportation processes. The

paper [25] exemplifies this by exploring the synergy between business analytics

and modelling in freight transport. The study establishes updated criteria for

evaluating business intelligence in this context and applies the IF-AHP method to assess the implementation of data analytics

and modelling in logistics. Additionally, the research [26] provides an

empirical analysis of factors contributing to volatility in the freight

transportation market. Technological advancements also play a key role. For

instance, the study [27] proposes an architecture for telematics tools along

with a methodology that merges delivery planning with transportation demand

modelling. This allows for calculating performance indicators used in the

preliminary assessment of delivery scenarios. Understanding shipper

decision-making is another crucial aspect. The research [28] utilizes latent

class modelling to analyse the heterogeneity of

freight shippers’ preferences when choosing transportation modes. This research

sheds light on the thought processes behind shipper and agent choices.

Optimization remains a critical focus. The paper [29] proposes a mathematical

algorithm for route construction, leveraging real-world data and demonstrating

its effectiveness in solving large-scale instances. Similarly, the authors of

the study [30] aim to create a tool that generates cargo loading plans and

route sequences for efficient pallet distribution, tackling a combined vehicle

routing, and loading problem. Furthermore, the paper [31] proposes a two-stage

model to optimize procurement of road-rail transshipment and truck routing,

fostering synergies between these transportation modes. By embracing these

advancements and fostering a data-driven approach, the transportation and

logistics industries can navigate economic challenges and develop more

efficient and resilient operations.

The research presented utilizes a

diverse range of methodologies to tackle various challenges in transportation

and logistics. Optimization problems are frequently addressed through mixed

integer linear programming [2, 4] and hybrid approaches combining goal

programming with genetic algorithms [4]. Additionally, game theory proves

valuable in analysing strategic interactions between

different players within the transportation ecosystem [3, 14, 31, 32]. For modelling and analysis, researchers leverage techniques

like discrete event modelling [5] to simulate real-world scenarios and

functional analysis [6] to understand complex relationships. Cluster modelling

[6, 28] helps identify groups with similar characteristics, while fuzzy logic

approaches and fuzzy stochastic programming [8, 18] allow for incorporating

uncertainty into decision-making. Statistical methods, including structural

equation modelling [10, 15] and regression analysis [15], are employed to

identify relationships between variables. Furthermore, cluster, variance, and a

posteriori analyses [15] provide deeper insights into data. Decision-making

support tools are explored as well, with research by Pamucar

et al. [19] utilizing an order priority approach based on fuzzy sets of images.

Qualitative methods also play a role. Studies based on in-depth interviews [20]

offer valuable insights from industry professionals, while SWOT

analysis [21] provides a framework for strategic planning. Looking towards the

future, research by [25] highlights the potential of the intuitionistic fuzzy

analytical hierarchy process for decision-making. Additionally, empirical

analysis and panel regressions used in [26, 33] offer valuable insights into

market trends. Finally, research by [29, 30] demonstrates the effectiveness of

operational research techniques for solving complex optimization problems

related to vehicle routing and cargo loading. This rich tapestry of

methodologies ensures a comprehensive understanding of the transportation and

logistics landscape, allowing researchers to develop effective solutions for

the challenges faced by the industry.

The presented literature review

emphasizes that efficient transportation systems require strong interaction

between all participants in the transport market. This collaboration allows for

considering the inherent randomness of demand and technological processes.

Additionally, it helps eliminate roadblocks caused by poorly defined goals at

the tactical planning stage.

3. THE PROPOSED APPROACH TO ESTIMATE THE

SYNERGETIC EFFECT

Our proposed

methodology builds upon the research presented in [34] on optimal delivery

chain structure selection. While we demonstrate the approach for calculating

the synergistic effect for each participant type within the context of four

basic logistics chain structures, the methodology itself is inherently

scalable. The framework can be readily extended to accommodate a wider range of

alternative structures or additional delivery process participant types without

requiring any fundamental modifications.

3.1. Alternative structures of a logistic chain

Within a logistics system,

individual supply chains involve a set of potential structures for delivering

goods. These structures can be analysed by

considering the key players involved in the flow of materials. The starting

point of any supply chain, acting as the source of the material flow, is the

freight owner, also known as the consignor. The destination point is another

cargo owner, the consignee. Therefore, both the beginning and end points of the

delivery chain involve freight owners. Physically, the movement of materials

(the material flow processing) is handled by a carrier company. The

organization and planning of this flow are often managed by a freight

forwarder, who may utilize resources such as freight terminals when necessary.

Within the logistics chain, freight

forwarders act as organizers of technological processes. They play a crucial

role by concentrating information flows and ensuring smooth communication

between all parties involved in moving goods. When a cargo owner needs to

deliver goods, it typically contacts a freight forwarder who then coordinates

the entire delivery process. This is known as the 1F-structure

[34], where one forwarder and one carrier are involved. Notably, cargo

terminals are not utilized in this specific scenario. The process starts with

the shipper informing the freight forwarder about the need for delivery. The

forwarder then identifies a suitable carrier capable of transporting the

shipment to the consignee (receiver). Bilateral agreements are then

established: one between the forwarder and the shipper, and another between the

forwarder and the carrier. The shipper pays the forwarder for their services,

and the forwarder uses these funds to pay the carrier. Depending on the

specific arrangement, the carrier might be responsible for delivering the

shipment from the shipper to the border, and then from customs to the

destination. This type of logistics chain is commonly used for road

transportation when the shipment weight matches the capacity of a single

vehicle.

The 2F-structure

represents a more complex variant within the logistics chain where two freight

forwarders are involved [34]. Upon receiving a shipment request from a shipper,

the initial freight forwarder locates a carrier to deliver the goods to the

border. They then send the request to a partner forwarder, who arranges onward

delivery to the consignee using a regional carrier in their area. This

structure necessitates four bilateral agreements: shipper and initial freight

forwarder, initial freight forwarder and carrier delivering to the border, the

two freight forwarding companies, partner forwarder, and regional carrier

completing the final leg of the delivery. The financial flow involves the

shipper paying the initial forwarder. From this payment, the initial forwarder

then compensates both the regional carrier and the partner forwarder for their

respective services. The partner forwarder, in turn, uses their received

payment to cover the costs of the regional carrier they utilize.

The cargo terminal plays a central

role in the logistics chain with the 1T-structure

[34]. Upon receiving a request from a shipper, the freight forwarder assesses

the economic feasibility of using the cargo terminal. If this option proves

cost-effective, the forwarder then identifies carriers for two legs of the

journey: one to deliver the cargo to the terminal and another for international

export to the destination. This process involves establishing four bilateral

agreements: between the forwarder and the shipper, between the forwarder and

the regional carrier delivering to the terminal, between the forwarder and the

cargo terminal, and between the forwarder and the international carrier for

export. The freight forwarder utilizes funds received from the shipper to pay

for the services of both carriers and the cargo terminal itself. The 1T-structure is particularly suited for situations where

initial cargo deliveries occur by road, followed by consolidation based on the

destination at the terminal, and finally, onward shipment using a main

transport mode like rail. In some cases, the cargo terminal may even handle the

export of the consolidated shipment, offering comprehensive logistics services.

The 2T-structure

is a common option for deliveries involving long distances and the use of a

main transport mode [34]. In this scenario, the freight owner initiates the

process by contacting a freight forwarder. The freight forwarder, after evaluating

various logistics chain options, selects the 2T

structure as the most efficient solution. The forwarder then takes charge of

coordinating the entire process. They first arrange for a regional carrier to

transport the goods from the shipper’s location to a nearby cargo terminal.

Agreements are then established with the terminal, the main carrier (e.g.,

shipping line or railway company), and a partner forwarder in the recipient’s

region. The partner forwarder mirrors these actions in their region, arranging

for a regional carrier to deliver the goods from the receiving terminal to the

destination. Contracts are also established with the terminal and the regional

carrier. Additionally, a separate agreement exists between the two forwarders.

Financially, the freight forwarder in the sender’s region uses the payment

received from the freight owner to cover the costs of all involved parties:

regional and international carriers, the local terminal, and the partner

forwarder’s services. The recipient region’s forwarder, in turn, uses the funds

received from the first forwarder to pay for the local terminal and carrier

services. There can be variations in this payment structure. Sometimes, the

sender’s terminal might directly pay the regional carrier there, while the

recipient’s terminal handles the final delivery costs.

3.2. The method to calculate the synergistic

effect

The use of the most effective

structures of cargo delivery chains is possible through the interaction of

transport market entities within a single system. Therefore, the effect of

choosing the optimal supply chain options is a synergistic effect.

The effect of a management decision

on choosing a delivery chain structure is assessed relative to other

alternative options. For a given request for transport services, the effect ![]() relative

to the

relative

to the ![]() -th option is

determined as follows:

-th option is

determined as follows:

![]() , (1)

, (1)

where ![]() is total

costs of delivery process participants for

is total

costs of delivery process participants for ![]() -th structure, [EUR/request];

-th structure, [EUR/request]; ![]() is total

costs of delivery process participants for the optimal structure,

[EUR/request].

is total

costs of delivery process participants for the optimal structure,

[EUR/request].

For a set of alternative structures,

the effect of choosing the optimal option can be assessed as an arithmetic

mean, but it is more correct to estimate the average considering the weight of

each of the alternative options, assessed by the corresponding value of the

total costs:

![]() , (2)

, (2)

where ![]() is the

effect of choosing the optimal structure for a given request for transport

services, [EUR/request];

is the

effect of choosing the optimal structure for a given request for transport

services, [EUR/request]; ![]() is the

set of alternative structures,

is the

set of alternative structures, ![]() .

.

Using the models developed in [34]

to calculate the costs of the subjects of the delivery process, the total costs

of servicing one request for the ![]() -th type of a

logistics chain can be estimated based on the average number of requests

received over a given period:

-th type of a

logistics chain can be estimated based on the average number of requests

received over a given period:

![]() , (3)

, (3)

where ![]() is the

total costs of delivery process subjects for the

is the

total costs of delivery process subjects for the ![]() -th structure of a logistics chain, [EUR];

-th structure of a logistics chain, [EUR]; ![]() is the

expected value of the time interval between requests in a flow [hours/request];

is the

expected value of the time interval between requests in a flow [hours/request];

![]() is the

duration of the period during which the process of receiving requests for

transport services is considered, [hours].

is the

duration of the period during which the process of receiving requests for

transport services is considered, [hours].

Then formula (2) can be written as:

![]() , (4)

, (4)

where ![]() is the

total costs of subjects of the delivery process

during the simulated period for the optimal structure of a delivery chain,

[EUR].

is the

total costs of subjects of the delivery process

during the simulated period for the optimal structure of a delivery chain,

[EUR].

Let us consider expression (4) for

the case when the 1F structure is the optimal one for

a given request:

![]() , (5)

, (5)

![]() , (6)

, (6)

Finally, from (6) we obtain:

![]() . (7)

. (7)

Generalizing (7) for the case where

the ![]() -th logistics chain

structure is optimal (

-th logistics chain

structure is optimal (![]() ), we obtain the following relationship for

determining the synergistic effect per request:

), we obtain the following relationship for

determining the synergistic effect per request:

![]() . (8)

. (8)

The synergistic effect for the

entire logistics system servicing a flow of requests for deliveries, that

arises due to the justification by a freight forwarder of the most effective

logistic chain structures, can be determined as the sum of effects obtained for

the requests in the flow.

3.3. Estimating a part of the synergetic effect

for the participants

The share of the synergistic effect

attributable to a specific participant in the delivery process is assessed

based on the effect per request using the following formula:

![]() , (9)

, (9)

where ![]() is the

share of the synergistic effect attributable to the

is the

share of the synergistic effect attributable to the ![]() -th entity of the delivery chain;

-th entity of the delivery chain; ![]() is the

synergistic effect from servicing a request

attributable to the

is the

synergistic effect from servicing a request

attributable to the ![]() -th participant, [EUR/request];

-th participant, [EUR/request]; ![]() is the

set of the delivery process participants,

is the

set of the delivery process participants, ![]() :

: ![]() –

freight owner,

–

freight owner, ![]() –

freight forwarder,

–

freight forwarder, ![]() –

carrier,

–

carrier, ![]() –

freight terminal.

–

freight terminal.

The synergistic effect of the ![]() -th participant is

estimated as the weighted average value of the difference in expenses according

to the total expenses of all entities that participate in the delivery process

similarly to (4):

-th participant is

estimated as the weighted average value of the difference in expenses according

to the total expenses of all entities that participate in the delivery process

similarly to (4):

![]() , (10)

, (10)

where ![]() is the

expenses of the

is the

expenses of the ![]() -th participant in the delivery process during

the simulated period when the

-th participant in the delivery process during

the simulated period when the ![]() -th structure of the logistics chain is used,

[EUR/request];

-th structure of the logistics chain is used,

[EUR/request]; ![]() is the

expenses of the

is the

expenses of the ![]() -th participant for

the optimal structure of the delivery chain, [EUR/request].

-th participant for

the optimal structure of the delivery chain, [EUR/request].

Let us consider expression (10) for

freight owner for the case when the 1F-structure is

optimal for the given demand parameters:

![]() , (11)

, (11)

where ![]() is the

synergistic effect obtained by cargo owners, [EUR/request];

is the

synergistic effect obtained by cargo owners, [EUR/request]; ![]() ,

, ![]() ,

, ![]() , and

, and ![]() are

expenses of freight owners during the simulated period when 1F-, 2F-, 1T- and

2T-structures of delivery chain used, [EUR/request].

are

expenses of freight owners during the simulated period when 1F-, 2F-, 1T- and

2T-structures of delivery chain used, [EUR/request].

Summing up the synergistic effect of

all participants in the delivery process, we obtain the following expression:

![]()

![]()

![]() (12)

(12)

![]()

![]() ,

,

![]()

![]()

![]() (13)

(13)

![]() .

.

The following equalities are true by

definition:

![]() . (14)

. (14)

Substituting (14) into (13), we

obtain the following:

![]() (15)

(15)

![]() .

.

Or, similar to the transformations

in (5), equality (15) can be shown in the following form:

![]() (16)

(16)

Since the expression on the right

side of equation (16) in accordance with (8) is the synergistic effect in the

logistics chain from using the 1F-structure as the

optimal one, it can be argued that the sum of the synergistic effects of the

delivery chain entities when choosing the optimal 1F-structure

is equal to the synergistic effect for the entire chain.

It is easy to verify that equality

(16) is satisfied for cases when the 2F-, 1T-, and 2T-structures of the

delivery chain are optimal.

Thus, the sum of the effects of the

delivery process participants is equal to the synergistic effect of choosing

the optimal delivery option for the logistics chain as a whole:

![]() . (17)

. (17)

The described approach allows us to

calculate the share of synergetic effect for each type of the delivery

participants, such that the sum of shares equal to 1.

4. RESULTS OF EXPERIMENTAL STUDIES AND

DISCUSSION

To evaluate the synergistic effect

for each participant within a given logistics chain structure, a simulation

model was developed based on the proposed methodology for calculating this

effect. This model determines the corresponding share of the synergistic effect

for each participant. Implemented in the C# programming language, the

simulation model leverages a library available from a publicly accessible

repository [35].

The simulation experiment

incorporated numerical parameters reflecting the Kazakhstani cargo

transportation market. These parameters included fuel costs, operator wages,

tariffs for storage and transportation services, etc. The results of this

experiment, investigating the impact of request flow parameters on the

distribution of the synergistic effect among delivery process participants, are

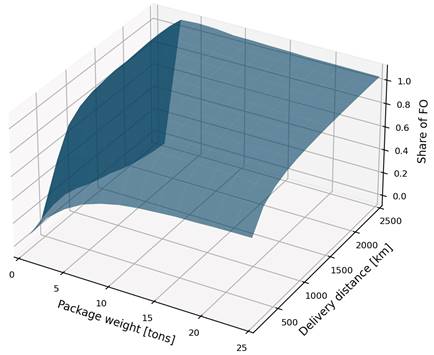

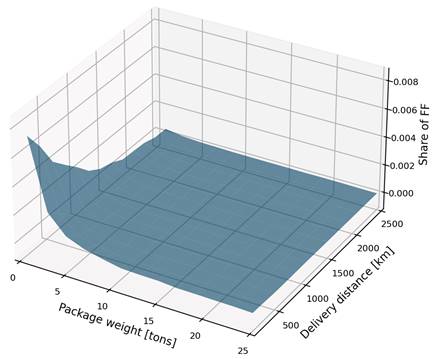

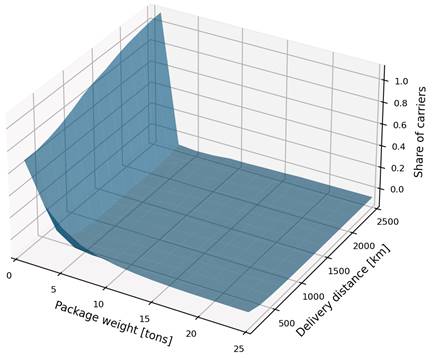

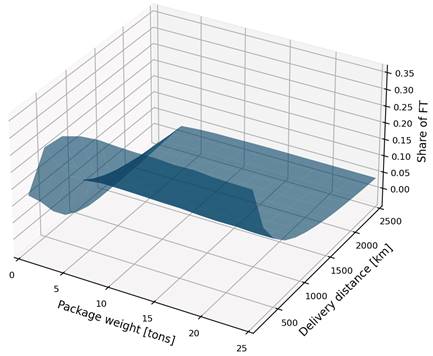

presented in Fig. 1-4.

Fig. 1. Dependence of freight

owners’ share in the synergistic effect on demand parameters

Fig. 2. Dependence of a freight

forwarder’s share in the synergetic effect

from demand parameters

Fig. 3. Dependence of a carrier’s

share in the synergetic effect from demand parameters

Fig. 4. Dependence of a freight

terminal’s share in the synergistic effect

from demand parameters

Analysis of the results of a

simulation experiment conducted for the expected values of the consignment

weight in the range from 1 ton to 25 tons, as well as the values of

the average delivery distance in the range from 100 km to 2500 km,

allows us to draw the following conclusions:

-

across a considered range of request flow

parameters, freight owners generally experience the largest share of the

synergistic effect (Fig. 1);

-

forwarders see the smallest share of the

synergetic effect; within the considered parameters’ range, their maximum share

remains low at around 0.7% (Fig. 2);

-

the distribution of the synergistic effect

is not linear; it exhibits a non-linear relationship with the parameters

characterizing the request flow for forwarding services;

-

for specific combinations of request flow

parameters, some participants, including freight owners, might even experience

a negative share of the synergistic effect; this can be attributed to negative

individual effects for a specific participant when servicing a request within

the overall optimal chain structure for the entire delivery system;

-

the share of the synergistic effect

captured by freight owners is minimized when request flow parameters approach

the lower limit of the considered range; conversely, as average delivery

distance and average consignment weight increase, the freight owners’ share

also increases;

-

for forwarders, the share of the

synergistic effect is maximum when servicing requests that are characterized by

the delivery of small weights over short distances; with the increase in

expected values of the consignment weight and the delivery distance, the share

of the synergistic effect of forwarders decreases;

-

the share of the synergistic effect

attributable to freight terminals is maximum when servicing the flow of

requests, which is characterized by delivery distances close to the lower limit

of the considered range;

-

for carriers, the share of the synergistic

effect from the interaction of the delivery process entities is maximum if the

flow of requests with small expected values of the consignment weight is

serviced.

Fig. 5-7 present diagrams

illustrating the distribution of the synergistic effect across participants in

the delivery process. These diagrams are generated for various combinations of

the expected values of delivery distance and average consignment weight.

Examining Fig. 5, we observe the

distribution of the synergistic effect for a consignment weight of 1 ton.

Carriers capture the greatest share of this effect, with this share reaching a

maximum at the highest considered average delivery distances. In contrast,

freight owners experience a peak share for delivery distances around 600-700

km. Interestingly, freight terminals achieve their

maximum portion of the synergistic effect at the expected value of a delivery

distance of 100 km.

Fig. 5. Distribution of the

synergistic effect between entities of the delivery process

for an average parcel weight of 1 ton

The diagram in Fig. 6 shows an

average cargo volume of 7 tons. In this case, the carrier’s contribution to the

overall synergistic effect is reduced compared to the scenario shown in

Fig. 5. With an average of 7 tons, the carrier only benefits when the

average delivery distance is 100 km or more. In this scenario, most of the

synergistic effect goes to cargo owners. This synergistic effect for freight

owners increases as the average delivery distance gets longer. Conversely,

cargo terminals see a decrease in their share of the synergistic effect as the

average delivery distance rises.

Fig. 6. Distribution of the

synergistic effect between entities of the delivery process

for an average parcel weight of 7 tons

Fig. 7. Distribution of the synergistic

effect between entities of the delivery process

for an average parcel weight of 25 tons

Analysis of Fig. 7 reveals that

increasing the expected value of the consignment weight does not alter the

observed distribution of the synergistic effect among delivery participants.

Cargo owners continue to capture the largest share, while freight terminals

receive a negligible contribution. Notably, the share for carriers remains

negative. Furthermore, the trend of increasing cargo owners’ share and decreasing

freight terminal share persists with rising average delivery distance.

5. CONCLUSIONS

Recent

research has focused on optimizing supply chains while considering risk,

uncertainty, and sustainability. As technology evolves and the industry

changes, scholars continue to develop innovative solutions for a more efficient

and sustainable transportation system. The proposed methodology enables

researchers to evaluate the effect of selecting the proper structure of a

delivery chain for all participants of the delivery process.

The

results of the conducted experimental studies allowed us to state that the

combined effects experienced by individual participants in the delivery process

are equivalent to the synergistic effect achieved by selecting the optimal logistics

chain structure for the entire system. Analysis of the simulation experiment

reveals that cargo owners exhibit limited values for their share of the

synergistic effect, while forwarders capture the smallest portion.

Interestingly, certain request flow parameter combinations can lead to negative

shares of the synergistic effect for one or more participants. This phenomenon

can be attributed to situations where a specific participant experiences

negative effects when servicing a request that is deemed optimal for the entire

delivery chain.

The

findings of our research offer valuable guidance for optimizing logistics

chains within the Kazakhstani market, and potentially other markets with

similar characteristics. Ultimately, the results of this study go beyond the

Kazakhstani context. They offer a broader contribution by demonstrating how to

maximize economic efficiency within logistics chains through a focus on

collaboration and the equitable distribution of synergistic benefits. This

knowledge can empower stakeholders across the logistics industry to make

informed decisions when configuring their supply chains.

Future

research efforts can be directed towards a more comprehensive understanding of

the factors influencing the distribution of the synergistic effect. This could

involve investigating the impact of additional demand parameters beyond those

explored in this study. For instance, factors such as order frequency, delivery

time windows, and shipment urgency could be examined to determine their influence

on the share of the synergistic effect for each participant type. Additionally,

expanding the scope of the analysis to encompass a broader range of alternative

logistics chain structures would be valuable. This could be achieved by

incorporating a more detailed consideration of the technological processes

performed by various entities within the chain. By analysing how these

processes interact and contribute to the overall efficiency, researchers could

gain deeper insights into how different chain structures influence the

generation and distribution of the synergistic effect.

References

1.

Pani A., S. Mishra, P. Sahu. 2022. “Developing multi-vehicle freight trip

generation models quantifying the relationship between logistics outsourcing

and insourcing decisions”. Transportation Research Part E: Logistics and

Transportation Review 159: 102632. DOI: https://doi.org/10.1016/j.tre.2022.102632.

2.

Li J., Y. Zheng, B. Dai, J. Yu. 2020.

“Implications of matching and pricing strategies for multiple-delivery-points

service in a freight O2O platform”. Transportation Research Part E:

Logistics and Transportation Review 136: 101871. DOI:

https://doi.org/10.1016/j.tre.2020.101871.

3.

Nugymanova G., M. Nurgaliyeva, Zh. Zhanbirov,

V. Naumov, I. Taran. 2021. “Choosing a servicing company’s strategy while

interacting with freight owners at the road transport market”. Naukovyi Visnyk

Natsionalnoho Hirnychoho Universytetu 1: 204-210. DOI:

https://doi.org/10.33271/nvngu/2021-1/204.

4.

Taheri F., A. Taft.

2024. “Reliable scheduling and routing in robust multiple cross-docking

networks design”. Engineering Applications of Artificial Intelligence

128: 107466. DOI: https://doi.org/10.1016/j.engappai.2023.107466.

5.

Kogler C., P. Rauch. 2023. “Lead time and

quality driven transport strategies for the wood supply chain”. Research in

Transportation Business & Management 47: 100946. DOI: https://doi.org/10.1016/j.rtbm.2023.100946.

6.

Ramazan B., R. Mussaliyeva, Z. Bitileuova,

V. Naumov, I. Taran. 2021. “Choosing the logistics chain structure for

deliveries of bulk loads: case study of the Republic Kazakhstan”. Naukovyi

Visnyk Natsionalnoho Hirnychoho Universytetu 3: 142-147. DOI:

https://doi.org/10.33271/nvngu/2021-3/142.

7.

Tjandra S., S. Kraus, S. Ishmam, T. Grube, J. Linßen, J.

May, D. Stolten. 2024. “Model-based

analysis of future global transport demand”. Transportation Research

Interdisciplinary Perspectives 23: 101016. DOI:

https://doi.org/10.1016/j.trip.2024.101016.

8.

Taran I., A. Karsybayeva, V. Naumov, K. Murzabekova,

M. Chazhabayeva. 2023. “Fuzzy-logic approach to estimating the fleet efficiency

of a road transport company: A case study

of agricultural products deliveries in Kazakhstan”. Sustainability

15(5): 4179. DOI: https://doi.org/10.3390/su15054179.

9.

Barmuta K., N.

Rusakova, A. Malkhasyan. 2022. “Improving

the method of analyzing risks of the company’s logistics processes”. Transportation

Research Procedia 63: 737-745. DOI:

https://doi.org/10.1016/j.trpro.2022.06.069.

10.

Geyi D.G., Y. Yusuf, M.S. Menhat, T. Abubakar,

N.J. Ogbuke. 2020. “Agile capabilities as necessary conditions for maximising

sustainable supply chain performance: An empirical investigation”. International

Journal of Production Economics 222: 107501. DOI:

https://doi.org/10.1016/j.ijpe.2019.09.022.

11.

Suryawanshi P., P. Dutta. 2022.

“Optimization models for supply chains under risk, uncertainty, and resilience:

A state-of-the-art review and future research directions”. Transportation

Research Part E: Logistics and Transportation Review 157: 102553. DOI:

https://doi.org/10.1016/j.tre.2021.102553.

12.

Chen G., W. Cheung,

S.-C. Chu, L. Xu. 2017. “Transshipment hub

selection from a shipper’s and freight forwarder’s perspective”. Expert

Systems with Applications 83: 396-404. DOI:

https://doi.org/10.1016/j.eswa.2017.04.044.

13.

Köhler J., C. Brauer. 2023.

“Transformation in freight transport: New analysis requirements and potential

modelling approaches”. Transportation Research Procedia 72: 4420-4427.

DOI: https://doi.org/10.1016/j.trpro.2023.11.303.

14.

Yang C., J. Bian, X. Guo, W. Jiang. 2024.

“Logistics outsourcing strategy with online freight platforms”. Omega

125: 103042. DOI: https://doi.org/10.1016/j.omega.2024.103042.

15.

Bae H.-S. 2019. “The interaction effect of

strategic information systems on performance of international freight

forwarders: An analysis of gaps in performance”. The Asian Journal of Shipping

and Logistics 35(2): 108-117. DOI:

https://doi.org/10.1016/j.ajsl.2019.06.003.

16.

Wang Y., J. Sarkis. 2021. “Emerging

digitalisation technologies in freight transport and logistics: Current trends

and future directions”. Transportation Research Part E: Logistics and

Transportation Review 148: 102291. DOI:

https://doi.org/10.1016/j.tre.2021.102291.

17.

Kmiecik M. 2023. “ChatGPT in third-party

logistics – The game-changer or a step into the unknown?” Journal of Open

Innovation: Technology, Market, and Complexity 9(4): 100174. DOI:

https://doi.org/10.1016/j.joitmc.2023.100174.

18.

Sharifi E., S.H. Amin, L. Fang. 2024.

“Designing a sustainable, resilient, and responsive wheat supply chain under

mixed uncertainty: A multi-objective approach”. Journal of Cleaner

Production 434: 140076. DOI: https://doi.org/10.1016/j.jclepro.2023.140076.

19.

Pamucar D., M.

Deveci, I. Gokasar, L. Martínez, M. Köppen. 2022. “Prioritizing

transport planning strategies for freight companies towards zero carbon

emission using ordinal priority approach”. Computers & Industrial

Engineering 169: 108259. DOI: https://doi.org/10.1016/j.cie.2022.108259.

20.

Holguín-Veras J., L.

Kalahasthi, S. Campbell, C.A. González-Calderón, X. Wang. 2021. “Freight

mode choice: Results from a nationwide qualitative and quantitative research

effort”. Transportation Research Part A: Policy and Practice 143:

78-120. DOI: https://doi.org/10.1016/j.tra.2020.11.016.

21.

You G. 2022. “Sustainable vehicle routing

problem on real-time roads: the restrictive inheritance-based heuristic

algorithm”. Sustainable Cities and Society 79: 103682. DOI:

https://doi.org/10.1016/j.scs.2022.103682.

22.

Ma M., F. Zhang, W.

Liu, V. Dixit. 2023. “On urban

co-modality: Non-cooperative and cooperative games among freight forwarder,

carrier and transit operator”. Transportation Research Part C: Emerging

Technologies 153: 104234. DOI: https://doi.org/10.1016/j.trc.2023.104234.

23.

Cavallaro F., S. Nocera. 2023.

“Flexible-route integrated passenger–freight transport in rural areas”. Transportation

Research Part A: Policy and Practice 169: 103604. DOI:

https://doi.org/10.1016/j.tra.2023.103604.

24.

Rześny-Cieplińska J. 2023. “Overview of

the practices in the integration of passenger mobility and freight deliveries

in urban areas”. Case Studies on Transport Policy 14: 101106. DOI:

https://doi.org/10.1016/j.cstp.2023.101106.

25.

Ben Rabia M., A. Bellabdaoui.

2023. “Collaborative intuitionistic fuzzy-AHP to

evaluate simulation-based analytics for freight transport”. Expert Systems

with Applications 225: 120116. DOI:

https://doi.org/10.1016/j.eswa.2023.120116.

26.

Lim K.G., N. Nomikos, N. Yap. 2019.

“Understanding the fundamentals of freight markets volatility”. Transportation

Research Part E: Logistics and Transportation Review 130: 1-15. DOI:

https://doi.org/10.1016/j.tre.2019.08.003.

27.

Comi A., M.M. Schiraldi, B. Buttarazzi. 2018.

“Smart urban freight transport: tools for planning and optimising delivery

operations”. Simulation Modelling Practice and Theory 88: 48-61. DOI:

https://doi.org/10.1016/j.simpat.2018.08.006.

28.

Kim H.-C., A. Nicholson, D. Kusumastuti. 2017.

“Analysing freight shippers’ mode choice preference heterogeneity using latent

class modelling”. Transportation Research Procedia 25: 1109-1125. DOI:

https://doi.org/10.1016/j.trpro.2017.05.123.

29.

Angelelli E., C. Archetti,

L. Peirano. 2020. “A

matheuristic for the air transportation freight forwarder service problem”. Computers’

Operations Research 123: 105002. DOI:

https://doi.org/10.1016/j.cor.2020.105002.

30.

Silva E., A.G. Ramos,

A. Moura. 2024. “Pallets delivery: Two matheuristics for

combined loading and routing”. Expert Systems with Applications 243:

122893. DOI: https://doi.org/10.1016/j.eswa.2023.122893.

31.

Yuan Y., J. Zhou, H. Li, X. Li. 2023. “A

two-stage optimization model for road-rail transshipment procurement and

truckload synergetic routing”. Advanced Engineering Informatics 56:

101956. DOI: https://doi.org/10.1016/j.aei.2023.101956.

32.

Adler N., A. Brudner, S. Proost. 2021. “A

review of transport market modeling using game-theoretic principles”. European

Journal of Operational Research 291(3): 808-829.

DOI: https://doi.org/10.1016/j.ejor.2020.11.020.

33.

Feo M., R. Espino, L.

García. 2011. “A stated preference analysis of Spanish

freight forwarders modal choice on the south-west Europe Motorway of the Sea”. Transport

Policy 18(1): 60-67. DOI: https://doi.org/10.1016/j.tranpol.2010.05.009.

34.

Naumov V. 2020. “Substantiating the

logistics chain structure while servicing the flow of requests for road

transport deliveries”. Sustainability 12(4): 1635. DOI:

https://doi.org/10.3390/su12041635.

35.

GitHub. „Library

for simulations of delivery processes”.

Available at:

https://github.com/naumovvs/delivery-chain-simulation.

Received 05.05.2024; accepted in revised

form 16.07.2024

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License