Article

citation information:

Caban, J., Nieoczym, A.,

Matijošius, J., Kilikevičius, A., Drozd, K. Analysis of the construction

of the car trailer frame in terms of changing the assembly technology. Scientific Journal of Silesian University of

Technology. Series Transport. 2024, 124,

47-61. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2024.124.4.

Jacek CABAN[1],

Aleksander NIEOCZYM[2],

Jonas MATIJOŠIUS[3],

Artūras KILIKEVIČIUS[4],

Kazimierz Drozd[5]

ANALYSIS

OF THE CONSTRUCTION OF THE CAR TRAILER FRAME IN TERMS OF CHANGING THE ASSEMBLY

TECHNOLOGY

Summary. Car trailers are quite

a popular means of transport and are offered in many versions, from single axle

light trailers with a maximum permissible weight of 750 kg, through two- or

more-axle specialized trailers. The issues of research car trailers focus on two

directions: testing the driving properties and analysing the strength of the

supporting frame system. Issues related to the construction of light trailers

are often common to trailers used in agriculture or general transport. In this

article, based on a mass-produced car trailer, an analysis was carried out

regarding the choice in the technology of making the supporting structure

consisting of a lower frame and an upper frame. The term upper frame should be

understood as the structure on which the lifted load box rests. The costs of

materials, assembly and technological possibilities of small-scale production

were taken into account. In addition, strength analyses of the numerical models

were carried out for critical areas of the frame during operation. After

considering the unit costs for each of the analysed assembly technologies, it

was shown that riveting would be the cheapest. However, the most suitable

method of assembly is welding, as it allows the use of standard profiles.

Keywords: road vehicles, montage, joining, strength

analysis, production costs

1. INTRODUCTION

Road transport is the most popular type of

transport for moving people and goods. It provides great freedom of movement,

and the multitude of means of wheeled transport makes it quite universal. An

additional advantage is the possibility of connecting the vehicle with a

trailer, which increases the usability in the field of transporting various

goods. Car trailers are quite a popular means of transport and are offered in

many versions, from the simplest single-axle light trailers with a gross

vehicle weight of 750 kg, through two- or more-axle specialized trailers. As

noted by Ladra and Posiadała [13], however, many car trailer solutions are

dedicated to specialized transport, which limits the construction of trailers

to specific types of transport, i.e. very often they are only single-purpose

trailers.

In the publications on car trailers, two topics

dominate: the study of driving properties and the analysis of the strength of

the supporting frame system.

The study of the system: vehicle-trailer in

terms of dynamics is performed due to the requirements related to driving

safety [11, 17, 25, 26]. In the work [28], it was found that axle load transfer

and braking force distribution have a large impact on the dynamic stability of

the combine: a vehicle with a single axle trailer. The stability of the vehicle

and the vehicle with a trailer was also analysed in the following works [2, 12,

22]. The published results are frequently used in general issues of vehicle

motion concerning the behaviour of the vehicle when driving on unevenness and

on a curvilinear track. For example, articles [1, 29] present the results of

dynamic tests of a single-axle trailer when driving through a simulated

obstacle. It was shown that the system did not reach the highest acceleration

values (the most important for safety of the cargo) when the wheel hit the

obstacle, but only when the trailer later bounced off the road. Another aspect

of road safety is the effects of a collision with a vehicle towing a trailer [19]

and the stability of the load carried on the trailer loading platform [5].

Noteworthy are publications [23, 27] where the authors included simulations of

load displacements under the influence of dynamic impact caused by a road

collision.

The second issue is related to the strength

analysis of designed trailers or activities aimed at modifying existing

structures. The published research results are mainly related to the designs of

specialized trailers that are not included in the sales offer [10]. Another

example is the design of a multipurpose light trailer [14], which combines

structural solutions used in trailers for transporting small loads,

motorcycles, quads, or kayaks.

Issues related to the construction of light

trailers are often common to trailers used in agriculture or general transport.

An example is the strength analysis of the frame of a single-axle tractor

trailer [4]. There are maps of stresses and displacements of the frame with the

indication of detailed load cases affecting the strength. The methodology for

optimizing the dimensions of the beams forming the trailer frame is contained

in publication [16]. The authors presented the results of their work based on the

frame of a specialist trailer designed to transport rolls of straw. Aimed at

minimizing the weight of the frame while meeting the strength limitations, it

was carried out in two procedures: changes in the thickness of the profile

walls and the use of steel profiles and a different shape of the cross-section.

Due to the stability of the transported load on the trailer, an important issue

is to determine the centre of gravity [18, 20, 24]. The variables here were:

the type of trailer and the weight and dimensions of the load.

Most of the large trailers and semi-trailers

are made of steel sheets and cold bent metallurgical steel profiles, made in

the technology of welding and riveting. Smaller car trailers are made of

standard steel profiles, and sometimes composite materials are used. The frames

of these trailers are made in the technology of welding, riveting or by means

of threaded connections.

In this article, based on a small-scale

produced car trailer, an analysis was carried out regarding the change in the

technology of making the supporting structure consisting of a lower frame and

an upper frame. The term upper frame should be understood as the structure on

which the lifted load box rests.

2. Methodology

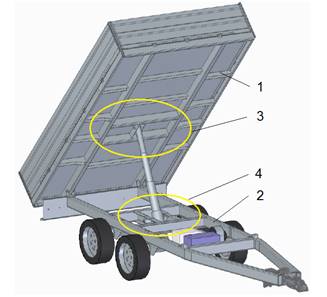

The main purpose of the work was to

indicate whether it is possible to change the production technology of the

load-carrying system of a self-dumping car trailer. For this purpose, solid

models of trailer frames were made in three different technologies: riveting,

bolting and welding, as well as a strength analysis was carried out using the

finite element method (FEM).

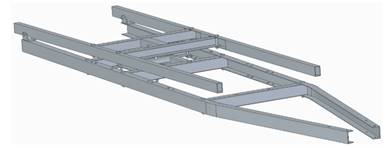

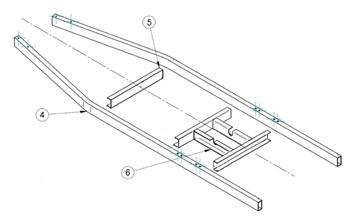

Fig. 1. Axonometric

view of the trailer in the maximum lift position: 1 – upper frame,

2 – lower frame, 3 – actuator mounting node in the upper frame, 4 – actuator

mounting node in the lower frame

The modified trailer is a two-axle

self-dumping trailer equipped with a hydraulic cylinder. The permissible total

weight of the trailer is m = 2000 kg.

The strength analysis using FEM was carried out for the initial moment of the unloading

process, i.e. when the cylinder piston rod advances and the upper frame is

raised. Then, the sup-port points of the load box frame are changed, and the

load is transferred to the nodes (Fig. 1, items 3, 4) in which the cylinder is

mounted. The load on these elements’ changes with the change of the angle of

the upper frame, and the maximum value is recorded for the angle value in the

range of 1.0°-1.5° [4, 15].

In each of the three cases of

design, it was assumed that the frame elements are made of S335JR structural

steel with a yield strength of Re =

355 MPa. During the FEM strength analysis, a 3 mm hex sweep mesh was applied to

all elements. The number of finite elements was equal to 358,557. The load to

which the frame models were subjected reflected the case of a uniformly

distributed load in the volume of the load box. The maximum force in a

hydraulic cylinder resulting from the permissible load weight is equal to F = 17,000 N.

The next step was to prepare

technical documentation containing lists of beams of the upper and lower

frames, indicating whether they are standard profiles or made of sheets of

steel. The last stage of the study was to analyse the costs of making trailer

frames for the three indicated manufacturing technologies.

3. Results

and Discussion

3.1. The construction of frames made

in the technology of twisting

The load bearing structure of the

original trailer frame (Fig. 2) is made in the connection technology with the

use of M8 bolts and nuts. The sleeve with an outer diameter of 14 mm and a wall

thickness of 1.8 mm is used to increase the rigidity of the structure (Fig. 3).

Thanks to the sleeves, the connected channels are not deformed when tightening

the fasteners.

|

|

|

|

(a) |

(b) |

Fig. 2. Trailer frame

assembled using threaded connections: a – general view, b – assembly node using

a screw connection: 1, 2 – connected C-sections, 3 – screw, 4 – nut, 5 – sleeve

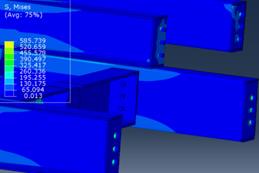

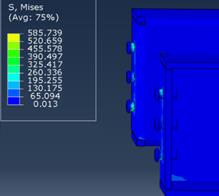

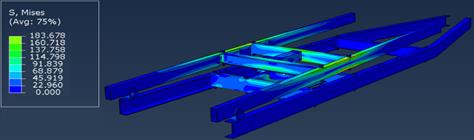

Fig. 3. Stress

distribution in a solid model of frames made by bolted connections

The FEM strength analysis was

carried out at the time of initiation of the load box lifting process. The

stress distributions in the frame assembly are shown in Figure 3 and Figure 4

shows the distribution of stresses in the cylinder mounting actuator node

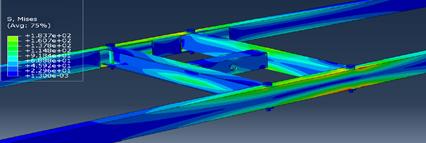

Fig. 4. Stress

distribution in the cylinder mounting nodes: a) in the upper frame,

b) in the lower frame

The maximum stresses are generated

on the upper surfaces of the side members and crossbeams of the upper frame and

reach the value of 183 MPa. This condition is typical for a model of a bending

beam subjected to a continuous load along its entire length. Lifting the load

box causes the actuator to take over the load resulting from the weight of the

load, and the resulting reaction forces concentrate on the sockets that are the

support areas of the lifting unit. High-stress values in these areas also

result from the small contact area – the thickness of the beam walls is 4 mm.

It should be noted that the high values of compressive stresses arising in the

sleeves mounted on the connecting bolts – they reach a value of approx. 120

MPa.

The strength analysis of the

original semi-trailer frame made in the bolted connection technology was aimed

at identifying the places of maximum stress. These places will be treated as a

reference during strength analyses of frames made in different assembly

technologies.

3.2. The construction of frames made

in welding technology

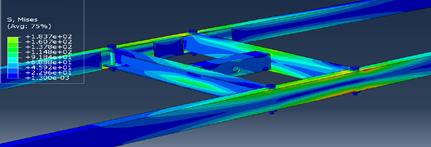

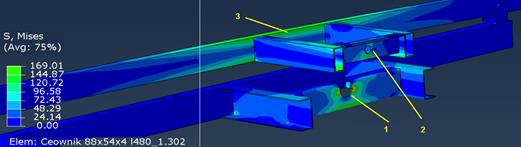

The distribution of stresses in the

frame assembly is shown in Fig. 5. It should be noted that the stress maps are

identical to those in the bolted frames (Fig. 3, 4) despite the use of other

beam profiles (see sections 3.4.1 and 3.4.2), with a decrease in the value of

the maximum stresses (to 169 MPa) reduced by approx. 15 MPa. The most heavily

loaded elements in the upper and lower frames are the hydraulic cylinder

mounting sockets (Fig. 6, items 1, 2) made in channel sections. The next

surfaces where comparable reduced stresses are recorded are the upper and lower

planes of the stringer and crossbeam of the upper frame. Maximum stresses occur

in the middle of its length (Fig. 6, item 3).

Fig. 5. Stress maps on

the assembly of trailer frames made by welding

Fig. 6. The place of

maximum stress in the lower frame – the cylinder socket: 1 – actuator mounting

location in the lower frame, 2 – cylinder mounting hole in the upper frame,

3 – structural element of the upper frame

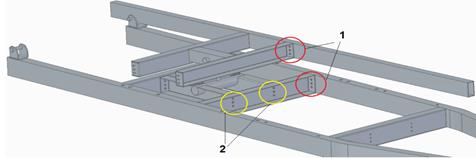

3.3. The Construction of frames made

in riveting technology

Another modification entails

connecting steel profiles with blind rivets. The use of the riveting machine

made it necessary to change the profiles of the crossbeams and longitudinal

beams of the upper and lower frames forming the cylinder mounting nodes (see

section 3.4.3). Rivets with an outer diameter of 6.4 mm made of stainless steel

A2 [3] were used to connect the frame elements. Three rivets were used in each

fastening node (Fig. 7, item 1, 2). They have been arranged so that the

production worker is able to fit a pneumatic riveter with a standard head

diameter.

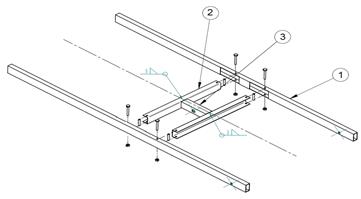

Fig. 7. Trailer frame made with the use of

riveted connections: 1 – connecting the crossbeams to the stringers, 2 –

connecting the longitudinal beams of the cylinder mounting node to the crossbeam

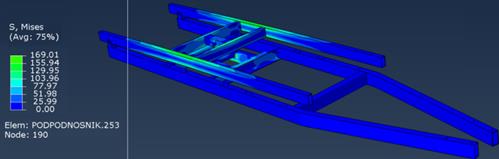

The strength analysis was also

carried out for the situation where the angle between the upper and lower

frames was 1.5°. The distribution of stresses on the stringers and crossbeams

of the upper frame and in the sockets of the cylinders are identical to those

in the bolted and welded frame, but the maximum values of reduced stresses are

not observed here – Fig. 8

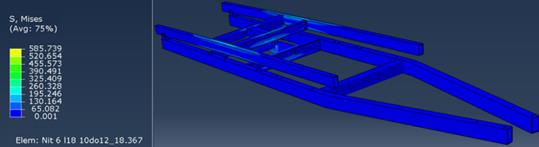

Fig. 8. Stress maps on

the assembly of trailer frames made by riveting

On the cylindrical surfaces of the

rivets, the stresses caused by shear and surface pressures reach the value of σ = 585 MPa (Fig. 8, 9). The rivet material has a yield strength of Re = 450 MPa. Therefore, the possibility

of changing the frame production technology by joining with bolts and nuts for

riveting should be rejected. The rivet is a critical element that determines

the strength of the structure.

|

|

|

|

(a) |

(b) |

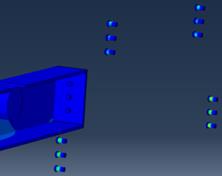

Fig. 9. Distribution of

stresses in rivet nodes: (a) stresses in the rivets fixing the crossbeams

to the longitudinal members of the upper and lower frames (Fig. 7, area 1);

(b) view with hidden longitudinal beams

Below is a list of profiles used to

make the lower and upper frames in three assembly technologies. It was assumed

that the cost of making the loading box, the drawbar, and the cost of

purchasing the complete axle remain unchanged. Dimensions of U-shaped and

rectangular sections, sheets and standard parts, as well as their prices, were

taken from sources [24-27]. The costs of works related to laser cutting,

riveting and welding are approximate costs estimated on the basis of

information contained in [6, 21].

|

|

|

|

(a) |

(b) |

Fig. 10. Distribution

of stresses in rivet nodes: (a) stresses in the rivets connecting the cross-beams

with the lifting elements (Fig. 7, area 2); (b) view with hidden crossbeams

3.4.1. Original frame

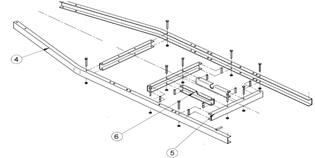

Figure 11 shows the upper and lower

frames made in the technology of screw joints. Table 1 presents a list of

materials needed for the production of car trailer frames made in the

technology of bolting.

|

|

|

|

(a) |

(b) |

Fig. 11. The frame

made in connection technology with the use of bolts and nuts:

(a) upper frame; (b) Lower frame. The beam numbers on the references correspond

to the ordinal numbers in Tab. 1

The elements listed in table 1 marked with the order number 2, 5, 6 will be made of sheet metal. The following sheets can be used for production:

- 3 mm thick

sheet, dimensions 1 x 2 [m] – sheet price: EUR 81.2,

- 4 mm thick

sheet – sheet size 1 x 2 [m] – sheet price: EUR 96.15.

Dimensional analysis indicates that

half a sheet of 3 mm thick and 4 mm thick should be used. So the cost of the

material will be 88.67 EUR.

The cost of laser cutting depends on

the thickness of the sheet:

- 3 mm thick

sheet, dimensions – 2.14 EUR/mr,

- 4 mm thick

sheet dimensions – 3.85 EUR/mr.

Tab.

1

List of materials needed for the

production of frames made in the technology of bolting

|

No. |

Element |

Dimensions [mm] |

Length [mm] |

Quantity |

Unit price [€/mr] |

Value [€] |

|

|

Upper frame |

|||||

|

1 2 3 |

Rectangular section profile |

80x40x3 |

2520 |

2 |

7.70 |

38.80 |

|

C-section profile |

74x50x3 |

711 |

2 |

Made of sheet metal |

||

|

C-profile |

60x40x4 |

260 |

1 |

5.76 |

1.50 |

|

|

Lower frame |

||||||

|

4 |

C-profile |

100x50x4 |

3600 |

2 |

11.75 |

84.60 |

|

5 |

C-section profile |

86x54x4 |

700 |

3 |

Made of sheet metal |

|

|

6 |

C-section profile |

80x54x4 |

480 |

2 |

Made of sheet metal |

|

|

Connecting elements |

||||||

|

7 |

Bolt M8 x100 |

|

|

4 |

0.96 |

3.84 |

|

8 |

Bolt M8 x120 |

|

|

4 |

1.00 |

4.00 |

|

9 |

Bolt M8 x150 |

|

|

6 |

1.35 |

8.10 |

|

10 |

Nut M8 |

|

|

14 |

0.14 |

1.96 |

|

11 |

Pad 8.2 |

|

|

14 |

|

0.21 |

|

12 |

Tube |

ϕ14 |

1024 |

1 |

2.84 |

2.90 |

The total cutting cost will be EUR

21.80.

The cost of bending profiles on a

press brake is calculated on the basis of an employee's hourly rate of EUR

8.55/h, which can be estimated at EUR 4.27.

Table. 2 presents a breakdown of the

labour costs of an employee on the assembly line of car trailers.

Tab.

2

A breakdown of the

labour cost of a worker on an assembly line

|

Number of bolted connections |

Time of completion and assembly of the connection [min] |

Employee rate [€/h] |

Total costs in € |

|

14 |

12 |

6.40 |

1.28 |

To sum up: the total cost of making

the frames using bolting technology is EUR 262.00.

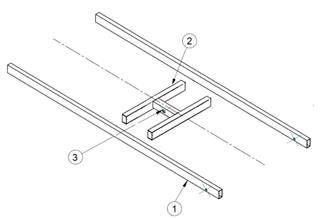

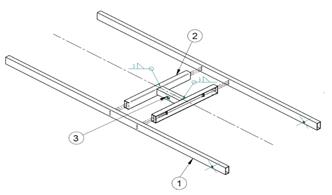

3.4.2. Welding frame

Figure 12 shows the upper and lower

frames made by welding.

|

|

|

|

(a) |

(b) |

Fig. 12. The frame

made in welding technology: (a) upper frame; (b) lower frame. The beam

numbers on the references correspond to the ordinal numbers in Tab. 3

Table 3 presents a list of materials

needed for the production of car trailer frames made in the welding technology.

Table. 4 presents a breakdown of the welder's labour costs on the assembly line

of car trailers.

Tab.

3

List of materials needed for the

production of frames made in the welding technology

|

No. |

Element |

Dimensions [mm] |

Length [mm] |

Quantity |

Unit price [€/mr] |

Value [€] |

|

|

Upper frame |

|||||

|

1 2 3 |

Rectangular section profile |

80x40x3 |

2520 |

2 |

7.70 |

38.90 |

|

Rectangular section profile |

80x40x4 |

711 |

2 |

8.54 |

12.18 |

|

|

C-profile |

60x40x4 |

260 |

1 |

5.77 |

1.50 |

|

|

Lower frame |

||||||

|

4 |

Rectangular section profile |

100x50x4 |

3600 |

2 |

12.80 |

92.20 |

|

5 |

C-profile |

100x50x3 |

700 |

3 |

9.00 |

18.90 |

|

6 |

C-profile |

88x54x4 |

480 |

2 |

9.82 |

9.40 |

Tab.

4

List of the cost of

the welder's work

|

Weld length [mm] |

Welder rate [€/mm] |

Total costs in € |

|

2904 |

0.032 |

93.00 |

To sum up: the total cost of making

the frames in the welding technology is EUR 266.20.

3.4.3. Riveted frame

Figure 13

shows the upper and lower frames made in the riveting technology. Table 5

presents a list of materials needed for the production of car trailer frames

made in riveting technology.

|

|

|

|

(a) |

(b) |

Fig. 13. The frame

made in riveting technology: (a) upper frame; (b) lower frame. The beam numbers

on the references correspond to the ordinal numbers in Tab. 5

Tab.

5

List of materials

needed for the production of frames made in riveting technology

|

No. |

Element |

Dimensions [mm] |

Length [mm] |

Quantity |

Unit price [€/mr] |

Value [€] |

|

|

Upper frame |

|||||

|

1 2 3 |

Rectangular section profile |

80x40x3 |

2520 |

2 |

7.70 |

38.90 |

|

C-section profile |

80x50x3 |

711 |

2 |

Made of sheet metal |

||

|

C-profile |

60x40x4 |

260 |

1 |

5.77 |

1.50 |

|

|

Lower frame |

||||||

|

4 |

Rectangular section profile |

100x50x4 |

3600 |

2 |

12.80 |

9.18 |

|

5 |

C-section profile |

100x50x3 |

700 |

3 |

Made of sheet metal |

|

|

6 |

C-section profile |

100x50x4 |

480 |

2 |

Made of sheet metal |

|

|

7 |

Rivet |

|

|

42 |

0.021 |

0.90 |

The

elements listed in the table marked with the order number 2, 5, 6 will be made

of sheet metal. Dimensions of metal sheets and their prices are given in point

2.1.

Dimensional

analysis shows that half a sheet of each plate can be used to make profiles

intended for the production of one lower and upper frame. So the cost of the

material will be EUR 88.67. The total measurement of the perimeter of

individual profiles cut from 3 and 4 mm thick metal sheets multiplied by the

unit cost of laser cutting allows you to calculate the cost of this

technological operation. Its value is EUR 33.12.

The cost of

bending profiles on the press brake is calculated on the basis of the

employee's hourly rate and is EUR 8.55/h. This cost can be estimated at EUR

4.28.

Table. 6

presents a breakdown of labour costs of a production worker.

Tab. 6

A breakdown of the

labour cost of a production worker

|

Number of riveted connections |

Time of completion and assembly of the connection [min] |

Employee rate [€/h] |

Total costs in € |

|

42 |

10 |

6.40 |

1.10 |

To sum up:

the total cost of riveted frames for one car trailer is EUR 177.80.

Figure 14

shows a chart with a summary of car trailer production costs for individual

assembly technologies.

Fig. 14. Production costs of the trailer in

three production technologies

As can be seen from the summary

presented in Figure 14, the lowest production costs of the car trailer occurs

for the riveting technology. However, in the case of the other two variants,

the costs are at a similar level of about EUR 265.

Finally, it should be added that the

method of protecting the frame against corrosion depends on the assembly

technology. Small elements intended for screwing and riveting can be covered,

for example, with a zinc coating individually, before joining. Each of the

frames, separately upper and lower, should be galvanized in their entirety if

they are welded. This may result in slight variations in electroplating costs,

which are not considered here. In addition, A2 steel rivets should not be used

to connect non-alloy steel components, but if popular blind rivets are used,

their strength is insufficient.

4. CONCLUSIONS

The aim of the research work was to

indicate whether it is possible to change the production technology of the

load-carrying system of a self-dumping car trailer. For this purpose, solid

models of frames made during the process of riveting, bolting, and welding were

made, and a strength analysis was carried out using FEM. The next step was to

prepare technical documentation containing lists of beams of the upper and

lower frames, indicating whether they are standard profiles or made of sheet

metal.

In each of the three versions of the

frames, the highest stress values are generated in the upper frame on the

stringers and in the crossbeams. Another area of maximum stress is the cylinder

pin mounting slots in the upper and lower frames. However, in the case of a

riveted frame, the strength-critical elements are the rivets. The use of

three rivets with a diameter of 6.4 mm in each assembly node causes that the

stresses caused by shear are exceeded in their material. This situation is also

caused by the small wall thickness of the joined profiles, which is 4 mm.

Making the frames in the welding process can be an alternative method of

production in relation to the original frame of the trailer. The implementation

cost is close. It should be noted here that in the case of welded frames, all

beams are made of standard profiles. The need to make beams by laser cutting

from sheet metal and bending on the press brake is eliminated. In the case

of riveted frames, their production cost is the lowest, by about 1/3 compared

to the cost of welded and bolted frames. The cost is low, although it is

necessary to make three beams yourself.

References

1.

Barta D., J. Dižo, M. Blatnický, D. Molnár. “Experimental

research of vibrational properties of a single-axle trailer when crossing an

individual road obstacle”. 2022. Strojnícky

Časopis – Journal of Mechanical Engineering 72(3): 19-26.

2.

De Bernardis M., G. Rini, F. Bottiglione, A.E. Hartavi,

A. Sorniotti. 2023. “On nonlinear model predictive direct yaw moment control

for trailer sway mitigation”. Veh. Syst.

Dyn. 61(2): 445-471. DOI: 10.1080/00423114.2022.2054352.

3.

DIN 7337: 1991. Blind rivets with break

mandrel.

4.

Dižo J., M. Blatnický, R. Melnik, S. Semenov, E.

Mikhailov, J. Kurtulik. 2022. “Static analysis of tipping superstructure of

single-axle tractor trailer”. In: Engineering for rural development, Jelgava,

25.-27.05.2022. DOI: 10.22616/ERDev.2022.21.TF003.

5.

Gnap J., J. Jagelčák, P. Marienka, M. Frančák, M.

Kostrzewski. 2021. “Application of mems sensors for evaluation of the dynamics

for cargo securing on road vehicles”. Sensors

21(8): 2881.

6.

Welding –

definition, types and valuation. Available at:

https://allweld.pl/spawanie-i-spawalnictwo.

7.

Bobrek. Available

at: https://bobrek.pl/.

8.

Manufacturer

of pipes, profiles and steel structures. Available at:

https://www.stalimpex.eu.

9.

Stawex. Available

at: http://www.stawex.com.pl/.

10.

Ibrahim A.M., A.M. Ali, H. Kamel. 2023. ”Design

optimization and production of a small-scale semi-trailer chassis for

testing”. J. Eng. Appl. Sci. 70: 35.

DOI: 10.1186/s44147-023-00201-z.

11.

Jagelčák, J., M. Kiktová, M. Frančák. 2020. ”The

analysis of manoeuvrability of semi-trailer vehicle combination”. Transp. Res. Proc. 44: 176-181.

12.

Kulikowski K., Z. Kamiński. 2019. “Methods for

improving the dynamic properties of the air braking systems of low-speed

agricultural trailers”. Arch. Automot.

Eng. 84(2):

5-22. DOI: 10.14669/AM.VOL84.ART1.

13.

Ladra P., B. Posiadała. 2018. “Strength Analysis of

the Multi-tasking Car Trailer”. In: Rusiński E., D. Pietrusiak (eds).

Proceedings of the 14th International Scientific Conference: Computer Aided

Engineering. CAE 2018. Lecture Notes in

Mechanical Engineering. Springer, Cham. 2019. P. 419-426. DOI: 10.1007/978-3-030-04975-1_49.

14.

Ladra P., B. Posiadała. 2018. “Modeling and strength

analysis of the prototype of the multi-tasking car trailer”. MATEC Web Conf. 157: 01014.

15.

Ladra P., B. Posiadała. 2016. “Modeling and strength

analysis of the specialized car trailer”. In: Proceedings of the 13th International Scientific Conference: 313-321.

16.

Lodwik D., J. Pietrzyk. 2018. “Analysis of the

structure of the frame of a trailer for transport of bales of compressed straw

in the aspect of minimization of materials and energy consumption”. In: 3rd International Conference on Energy and

Environmental Protection, E3S Web

Conf. 46: 00005. DOI: 10.1051/e3sconf/20184600005.

17.

Marienka

P., M. Frančák, J. Jagelčák, F. Synák. 2020. ”Comparison of

braking characteristics of solo vehicle and selected types of vehicle

combinations”. Transp. Res. Proc. 44:

40-46.

18.

Mokričková L., V. Rievaj. 2016. “Position of the

centre of gravity and driveability of the vehicle”. LOGI Sci. J. Transp. Logist. 7: 108-115.

19. Plöchl M.,

P. Lugner. 1999. “ Passenger car and passenger car-trailer – different tasks

for the driver”. JSAE Review 20(4): 543-548. DOI: 10.1016/S0389-4304(99)00036-3.

20.

Sagi R., A. Racotch, D. Wolf. 1973. “Theoretical

considerations in placing the centre of gravity of single-axled trailers”. J. Agric. Eng. Res. 18(2): 159-165.

21.

Schuh G., C. Kelzenberg, J. Wiese. 2019. ”Design

model for the cost calculation of product-service systems in single and small

series production”. Procedia CIRP 84:

296-301. DOI: 10.1016/j.procir.2019.04.216.

22.

Skrúcaný T., J. Vrábel, M. Kendra, P. Kažimír. 2017. ”Impact

of Cargo Distribution on the Vehicle Flatback on Braking Distance in Road

Freight”. In: 18th International

Scietific Conference – LOGI 2017, MATEC

Web Conf. 134: 00054. DOI: 10.1051/matecconf/201713400054.

23. Viano D.C., C.S. Parenteau.

2022. “Significance of tractor-trailer impacts to the rear of light vehicles”.

Traffic Inj. Prev. 23(4):

169-175.

24.

Vrabel J., T. Skrucany, L. Bartuska, J. Koprna. 2019. “Movement

analysis of the semitrailer with the tank-container at hard braking - the

case study”. IOP Conf. Ser. Mater. Sci.

Eng. 710(1): 0120254.

25.

Wang G.L., Y.H. Lu. 2006. “Braking stability analysis

of car-trailer”. Journal of Jiangsu

University 27(2): 130-132.

26.

Figlus Tomasz, Lukasz Kuczyński. 2018. "Selection

of a semi-trailer for the haulage of long oversize loads, taking into account

an analysis of operational damage". In: 11th International Science and Technical Conference Automotive

Safety: 1-5.

27.

Zamecnik J., J. Jagelcak. 2015. “Evaluation of wagon

impact tests by various measuring equipment and influence of impacts on cargo

stability”. Commun. Sci. Lett. Univ.

Zilina 17(4): 21-27. DOI: 10.26552/com.C.2015.4.21-27.

28.

Zhang N.,

J.-H. Wu, T. Li, Z-Q. Zhao, G.-D. Yin. 2021. “Influence of braking

on dynamic stability of car-trailer combinations”. Proceedings of the Institution of Mechanical Engineers, Part D: Journal

of Automobile Engineering 235(2-3): 455-464. DOI: 10.1177/0954407020959895.

29.

Zhang N., G. Yin, T. Mi, X. Li, N. Chen. 2017. ”Analysis

of dynamic stability of car-trailer combinations with nonlinear damper

properties”. Procedia IUTAM 22:

251-258.

Received 29.02.2024; accepted in revised

form 07.04.2024

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License