Article

citation information:

Chernets, M., Wrona, R., Chernets,

Y. Analytical study of durability and contact characteristics of metal-polymer

composite sliding bearings for means of transport. Scientific

Journal of Silesian University of Technology. Series Transport. 2024, 123, 5-21.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2024.123.1.

Myron

CHERNETS[1], Rafał WRONA[2], Yuriy CHERNETS[3]

ANALYTICAL

STUDY OF DURABILITY AND CONTACT CHARACTERISTICS OF METAL-POLYMER COMPOSITE

SLIDING BEARINGS FOR MEANS OF TRANSPORT

Summary. The field of

application of metal-polymer bearings is vast: transport of various types,

processing industry equipment, medical equipment, various types of maintenance

equipment, etc. With the use of the developed generalized author's analytical

method of metal-polymer plain bearings on the basis of which it is laid the

author's research methodology of materials wear kinetics at sliding friction

(dry, lubricated), calculation of their durability is carried out. Contact

parameters are also determined. Metal-polymer bearings with a bushing made of

PA6, PA66 polyamide and PA6 based composites filled with glass (PA6 + 30GF) and

carbon (PA6 + 30CF) dispersed fibres, molybdenum disulphide (PA6 + MoS2)

and oil filled cast polyamide (PA6 + oil) are considered. These polyamides

(unfilled and filled), as self-lubricating materials, are widely used in this

type of dry friction sliding bearings. The predictive estimation of durability

of investigated bearings depending on loading, polymer materials Young's

modulus, their wear resistance and sliding friction coefficient is executed.

Regularities of change from the specified factors of bearing's durability and

the maximum contact pressures are established. Experimental indicators,

diagrams, and wear resistance characteristics of the specified polymeric

materials are presented. The results of researches of sliding friction

coefficient and modulus of elasticity for carbon steel (0.45%C) – polyamides

tribocouples are presented.

Keywords: metal-polymer sliding bearings, analytical

method, polyamides, PA6, PA66, composites PA6 + 30GF, PA6 + 30CF, PA6 + MoS2,

PA6 + oil, Young's modulus, wear resistance, coefficient of friction,

durability, contact parameter

1. INTRODUCTION

Metal-polymer plain

bearings (MP) are used in a variety of machines, equipments, and devices in

automotive, mechanical engineering, instrumentation, aerospace, rocket and

space technologies, etc.; in all types of processing industry – food, textile,

pharmaceuticals, chemical, etc. They are commonly found in household

appliances, computer, office, medical, measuring equipment, and other related fields.

They operate in water, gas, liquid, boundary and dry friction. The

self-lubricating MP bearings offer numerous advantages in comparison to rolling

bearings, including simplicity or lack of maintenance, high manufacturability,

a wide range of shaft diameters (ranging from micro to large), small

cross-sectional dimensions, significant shaft speed, ability to operate under

dynamic and shock loads, high damping capacity, low noise generation, and the

ability to operate in polluted technological environments or water, at elevated

and lowered temperatures, in vacuum, and other characteristics.

The reliability of

MP bearings is particularly important because many technical devices are forced

to operate without the use of lubricants due to various reasons and production

conditions. In fact, such conditions may be provided for in the operation

of different types of vehicles or may arise under different circumstances.

Given that dry friction

causes significantly more intense wear compared to the boundary friction, for

MP bearings it is very relevant and necessary to calculate their durability and

load carrying capacity in the design. However, the corresponding effective

methods of calculation of MP bearings in the literature are virtually absent.

Developed calculation [1-8] or numerical methods [9-11] of the study of metal

plain bearings have not found practical application for calculating the

durability and load carrying capacity of MP bearings. In the existing studies

of MP sliding bearings [12-14], the authors use the well-known linear Archard`s

law of abrasion / adhesive wear. However, even in MP dry friction bearings, not

to mention metal bearings, where dry friction is almost non-existent, the

mechanism of abrasive wear is unlikely. Regarding the presence of a dominant

mechanism of adhesive wear in metal-polymer couples, [15] states that the wear

of polymers at sliding friction is a combination of three mechanisms (fatigue,

adhesive, and sometimes abrasive). Which of them will be the main and which are

concomitant depends on the polymer properties, the friction conditions and the

course of wear. Under certain conditions, the polymeric material is transferred

to the metal counterpart, forming a thin adhesive film, which is a sign of

adhesive wear as the main process [16-18]. However, in [16] it is noted that at

friction coefficients greater than 0.3, characteristic of MP dry friction

pairs, surface fracture (wear) of polymers occurs by the mechanism of surface

fatigue under the influence of shear stresses (specific friction forces).

Adhesion wear can also partially occur as a minor concomitant process.

Considering this, the author's methodology for studying the materials wear

kinetics during sliding friction [19-22] and, accordingly, the calculation

method for studying the wear of metal [21-25] and MP bearings [26, 27] assumes

a fatigue mechanism, and takes into account changes in conditions of contact

interaction due to wear.

MP bearing bushings are made of various

polymers (polyamides – PA, polyacetal – POM, polytetrafluoroethylene – PTFE,

polyester ketones – PEEK, ultra-high molecular weight polyethylene – UHMWPE,

etc.) and filled composites based on them [11]. Materials (glass and carbon

fibres, molybdenum disulphide, graphite, bronze powder, polytetrafluoroethylene,

etc.) with different volumetric contents are used as fillers in the polymer

matrix, the function of which is increasing the wear resistance and durability

of bearings. In particular, a widely used polymer for MP bearings is polyamide

PA66 and partially PA6. Polyamide based composite materials are much more

widely used, in particular PA6 filled with fibreglass (PA6 + 30GF), carbon

fibre (PA6 + 30CF), molybdenum disulphide (PA6 + MoS2), oil filled

cast polyamide (PA6 + oil).

The literature presents

a number of results of tribological experimental studies of different polymeric

materials used in MP plain bearings [28-36]. In particular, in [28] the wear

and friction coefficient of PA6 based polyamide composites coupled with AISI 02

steel (0.90% C, 1.6% Mn) were studied according to the pin-on-disk scheme

during dry friction. In [29], the tribological behaviour of various bearings

with polymer bushings coupled with steel shaft during dry friction was studied:

polyacetal (POM-Delrin), cast polyamide PA6, and others. The work [30] is

devoted to the study and evaluation of wear resistance of bearings based on PE

(polyethylene), PA, POM, PTFE and Bakelite. Study [31] establishes the effect

of sliding speeds on friction and wear in bearings made of composites PA66,

PA66 + 18PTFE and PA66 + 20GF + 25PTFE at room temperature. Tribological

analysis of the dry friction behaviour of cast nylon (PA6) for the connecting

rod plain bearing was performed in [32]. G. Kalácska presents in [33] the

results of pin-on-disk wear testing of twenty-one engineering polymers, both

basic and composites. In [34], the patterns of friction and wear of PA6 and ABS

(acrylonitrile butadiene styrene) sliding on metal under dry friction

conditions were studied on a pin-on-disc tribometer. [35] is devoted to the

study of the tribological properties of PA6 polyamide in dry friction at

different speeds and loads. In [36], the coefficient of friction, friction

force and temperature of six polymer composites were investigated according to

the ball-on-disk scheme under dry friction: cast polyamide PA6G + oil, PA6G +

MoS2, polyacetal POM + Al, polyterephthalate ethylene PET + PTFE,

PTFE + Bronze, PTFE + Graphite. Although the results of these studies are quite

extensive, it is not possible to establish the wear resistance characteristics

of polymers in order to calculate the durability of plain bearings.

The presented article is

the result of the investigation conducted by the author's calculation method

for metal-polymeric plain bearings.

- durability of the MP

bearing at allowable wear of the polymeric bushing;

- initial maximum

contact pressures;

- initial contact angle;

- wear resistance of

basic polyamides PA6, PA66;

- wear resistance of

filled composites РА6 + 30GF, РА6 + 30CF, РА6 + MoS2, РА6 + oil;

- influence of fillers

on the wear resistance of the studied polymeric materials;

- effect of contact

pressure on the coefficient of sliding friction.

2. METHODS OF

CALCULATION OF METAL-POLYMER BEARINGS

The plane contact problem of the linear

theory of elasticity is studied. In the plain bearing (Fig. 1) the shaft 2,

which is under the action of the reduced force ![]() rotates

at angular velocity

rotates

at angular velocity![]() =

const. Under the influence of full external static load

=

const. Under the influence of full external static load ![]() , the shaft journal 1 and the bushing 2

located in the housing 3 are contacted in the area

, the shaft journal 1 and the bushing 2

located in the housing 3 are contacted in the area ![]() on which act unknown in magnitude contact

pressures

on which act unknown in magnitude contact

pressures![]() . A radial clearance

. A radial clearance ![]() will be guaranteed between the outer radius of

the steel shaft

will be guaranteed between the outer radius of

the steel shaft ![]() and

the inner radius of the polymer bushing

and

the inner radius of the polymer bushing![]() . The elements materials of MP bearing

have significantly different strength, elastic characteristics, wear resistance

(strength characteristics of 8… 10 times, Young's modulus of 50… 200 times,

wear resistance by 2… 3 orders of magnitude). This fundamentally affects their

contact strength, bearing capacity, contact parameters and, of course,

recourse. When rotating, the shaft 2 wears along the contour

. The elements materials of MP bearing

have significantly different strength, elastic characteristics, wear resistance

(strength characteristics of 8… 10 times, Young's modulus of 50… 200 times,

wear resistance by 2… 3 orders of magnitude). This fundamentally affects their

contact strength, bearing capacity, contact parameters and, of course,

recourse. When rotating, the shaft 2 wears along the contour ![]() and the bushing 1 - in the area

and the bushing 1 - in the area ![]()

Fig. 1. Metal-polymer plain

bearing: general view and scheme

According to the

tribokinetic mathematical model of wear at sliding friction [20, 21] and the

method of calculation of plain bearings [22-25] for the forecast estimation of

durability at the given bushing wear![]() the following expression is used

[20, 21]:

the following expression is used

[20, 21]:

![]() (1)

(1)

where![]() - wear resistance characteristics

of tribocouple materials, which are established by the results of model

triboexperimental studies [20, 21]; k

is shaft or bushing index (Fig. 1);

- wear resistance characteristics

of tribocouple materials, which are established by the results of model

triboexperimental studies [20, 21]; k

is shaft or bushing index (Fig. 1); ![]() - sliding speed; ch is the wear rate

coefficient;

- sliding speed; ch is the wear rate

coefficient; ![]()

![]() - respectively, the coefficients of mutual overlap of the bushing and

the shaft;

- respectively, the coefficients of mutual overlap of the bushing and

the shaft; ![]() ,

, ![]() - relative wear in the

tribosystem.

- relative wear in the

tribosystem.

(2)

(2)

The specific force of

friction is determined by the Amontons-Coulomb law.

![]() (3)

(3)

where ![]() is the coefficient

of sliding friction.

is the coefficient

of sliding friction.

The initial maximum contact pressure ![]() will occur along

the line of force

will occur along

the line of force ![]() and is determined

by the formula [20, 21]:

and is determined

by the formula [20, 21]:

![]() (4)

(4)

where![]()

![]()

![]()

![]()

![]() – Young's moduli

and Poisson's ratios of the materials of the shaft 1 and bushing 2.

– Young's moduli

and Poisson's ratios of the materials of the shaft 1 and bushing 2.

As a result of wear of the composite bushing,

the initial maximum contact pressures ![]() will decrease, i.e. in the tribocontact there

will be wear contact pressures

will decrease, i.e. in the tribocontact there

will be wear contact pressures![]() , which are

determined as follows:

, which are

determined as follows:

![]() (5)

(5)

where ![]() – change in initial pressures due to wear.

– change in initial pressures due to wear.

To find them, we used the dependence given in

[20, 21]:

![]() (6)

(6)

where ![]() ;

; ![]() >0 – wear rate indicator;

>0 – wear rate indicator; ![]()

The initial specific friction force ![]() during the polymer

bushing wear will decrease.

during the polymer

bushing wear will decrease.

![]() (7)

(7)

where ![]() is the unknown contact semiangle occurring due

to bushing wear.

is the unknown contact semiangle occurring due

to bushing wear.

In the studied type of contact problem, the

initial contact angle ![]() is also unknown.

Determination of the initial contact semiangle

is also unknown.

Determination of the initial contact semiangle ![]() is carried out

under the equilibrium condition of forces acting on the shaft 2.

is carried out

under the equilibrium condition of forces acting on the shaft 2.

(8)

(8)

Taking into account the

expression for the coefficient![]() , it is expressed as:

, it is expressed as:

![]() (9)

(9)

To determine the

tribocontact semiangle ![]() , which outlines the contact area during wear, the following condition

is used:

, which outlines the contact area during wear, the following condition

is used:

![]()

![]() (10)

(10)

3. MATERIALS, TRIBOEXPERIMENT

To calculate the MP bearing durability according

to (1) should be determined the wear resistance characteristics ![]() of materials in

tribocouple steel-polymer. The author's method of model research of materials

wear [20, 21] involves several levels of contact pressure in the tribosystem

and provides determination at the same time both wear (mass or linear) of

samples, and specific force of friction

of materials in

tribocouple steel-polymer. The author's method of model research of materials

wear [20, 21] involves several levels of contact pressure in the tribosystem

and provides determination at the same time both wear (mass or linear) of

samples, and specific force of friction![]() Model triboexperiments are performed according

to the pin-on-disk friction scheme, which ensures the constancy of the initial

external conditions during the study, namely the contact pressures and sliding

speed, the contact temperature of the experimental tribocouple. This approach

to triboexperimental research significantly expands the information on the wear

resistance of materials in a certain range of contact pressures, in contrast to

the standards ISO 7148-2 and ASTM G99, which provides to conduct experimental

studies at one value of contact pressure. In the author's methodology of

studying the material’s wear kinetics, it is accepted that the level of

Model triboexperiments are performed according

to the pin-on-disk friction scheme, which ensures the constancy of the initial

external conditions during the study, namely the contact pressures and sliding

speed, the contact temperature of the experimental tribocouple. This approach

to triboexperimental research significantly expands the information on the wear

resistance of materials in a certain range of contact pressures, in contrast to

the standards ISO 7148-2 and ASTM G99, which provides to conduct experimental

studies at one value of contact pressure. In the author's methodology of

studying the material’s wear kinetics, it is accepted that the level of ![]() unambiguously

determines their wear rate. It should be noted that it is the coefficient of

sliding friction f determines the

level of t in the tribocontact. That is, at the same level of contact pressure

unambiguously

determines their wear rate. It should be noted that it is the coefficient of

sliding friction f determines the

level of t in the tribocontact. That is, at the same level of contact pressure![]() , its value can

vary several times depending on the type of friction (dry, semi-dry friction,

boundary).

, its value can

vary several times depending on the type of friction (dry, semi-dry friction,

boundary).

The material’s wear resistance characteristics ![]() in the tribocouple

are determined by the results of model triboexperimental studies as invariant

wear resistance parameters in the selected range

in the tribocouple

are determined by the results of model triboexperimental studies as invariant

wear resistance parameters in the selected range ![]() . In the

following, they are necessary to calculate the durability or wear of plain

bearings by the above method.

. In the

following, they are necessary to calculate the durability or wear of plain

bearings by the above method.

According to the method of model

triboexperiments, the calculation of experimental indicators of wear resistance

(wear resistance functions) Фі of polymeric materials for each level of

contact pressure pі and correspondingly specific friction force![]() was carried out by using the formula:

was carried out by using the formula:

Фі=Lі/hі (11)

where L is the path of friction, hi is the linear wear of samples at

the i- th level of pressures pі.

Research program: sliding speed v = 0.4 m/s; contact pressure ![]() = 2, 4, 6, 8 MPa;

friction path L = 5000… 10000 m;

sample diameter d = 3 mm. Forced

cooling of the friction unit was carried out to ensure the temperature of the

end surface of the polymer sample T =

23 ± 1°C at a relative humidity of 50 ± 5% (standard ISO 7148-2).

= 2, 4, 6, 8 MPa;

friction path L = 5000… 10000 m;

sample diameter d = 3 mm. Forced

cooling of the friction unit was carried out to ensure the temperature of the

end surface of the polymer sample T =

23 ± 1°C at a relative humidity of 50 ± 5% (standard ISO 7148-2).

For approximation of the wear resistance

experimental indicators Фі the next type of ratio was used [20, 21]:

(12)

(12)

The wear resistance characteristics of

tribocouple materials are determined by using the method of the least squares,

where ![]() is the limiting value of the specific friction

force at which wear at the macro level will be virtually absent.

is the limiting value of the specific friction

force at which wear at the macro level will be virtually absent.

According to the wear resistance characteristics

determined in this way, graphical indicators (diagrams) of wear resistance are

plotted for each polymer (Fig. 2).

4. RESULTS, DISCUSSION

The source data for calculation of durability

and parameters of contact at dry friction: ![]() = 5000, 3000 N; D2 = 50 mm;

= 5000, 3000 N; D2 = 50 mm; ![]() ;

; ![]() 0.2 mm;

0.2 mm; ![]() = 6.28 rad / sek; h1* = 0.5 mm.

= 6.28 rad / sek; h1* = 0.5 mm.

Metal-polymer bearings from the following

materials of the elements are investigated:

Shaft 2 – carbon

steel 0.45%C, normalized, roughness ![]() = 0.8-1 μm; Е2 = 210 GPa,

ν2 = 0.3;

= 0.8-1 μm; Е2 = 210 GPa,

ν2 = 0.3; ![]() = 1013,

= 1013,

![]() = 2,

= 2, ![]() = 0.1 MPa;

= 0.1 MPa;

polymeric bushing 1 (Table 1).

Tab. 1

Parameters

of bushing materials

|

Wear resistance characteristics |

Thermoplastic polymeric materials |

|||||

|

РА6 |

РА66 |

РА6+ 30GF |

PA6+ МоS2 |

PA6+ 30CF |

PA6+oil |

|

|

В1 ∙1010 |

2.26 |

3.37 |

4.12 |

5.58 |

6.53 |

7.03 |

|

m1 |

1.09 |

1.09 |

1.09 |

1.1 |

1.1 |

1.1 |

|

τ10,

MPa |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

|

Young's module E1, GPa |

2.0 |

2.3 |

2.7 |

1.66 |

3.3 |

1.96 |

|

Poisson's

ratio ν1 |

0.4 |

0.4 |

0.41 |

0.4 |

0.41 |

0.4 |

Note: for PA6 + 30GF the volume content of filler

(fibreglass) is 30%.

The results of triboexperimental studies and numerical solution are

presented in Fig. 2-9. Fig. 2 presents diagrams of wear resistance of the above

polymeric materials, and Fig. 3 presents their relative wear resistance.

The figure shows the determined experimental

functions of the wear resistance of polyamides Фi with different markers at four values of the

specific force of friction ![]() in the

tribocontact. Their location along the

in the

tribocontact. Their location along the ![]() axis at the same contact pressures depends on

the coefficient of friction in the studied tribocouple. However, the

qualitative patterns of changes in wear resistance in the form of wear

resistance diagrams are practically the same for these polymer materials. These

graphic indicators of wear resistance - wear resistance diagrams of polyamides

are obtained by approximation of Фі according to (12). They make it possible to

conduct a visual comparative assessment of the wear resistance of these

polyamides at a specific value of

axis at the same contact pressures depends on

the coefficient of friction in the studied tribocouple. However, the

qualitative patterns of changes in wear resistance in the form of wear

resistance diagrams are practically the same for these polymer materials. These

graphic indicators of wear resistance - wear resistance diagrams of polyamides

are obtained by approximation of Фі according to (12). They make it possible to

conduct a visual comparative assessment of the wear resistance of these

polyamides at a specific value of ![]() . From the

analysis of Fig. 2 it is noticeable which of the polyamides has low wear

resistance (PA6), and which has the highest wear resistance (PA6 + oil). It

should be noted that the wear resistance of polyamides depends non-linearly on

the effective specific force of friction.

. From the

analysis of Fig. 2 it is noticeable which of the polyamides has low wear

resistance (PA6), and which has the highest wear resistance (PA6 + oil). It

should be noted that the wear resistance of polyamides depends non-linearly on

the effective specific force of friction.

Fig. 2. Diagrams of polyamides wear

resistance

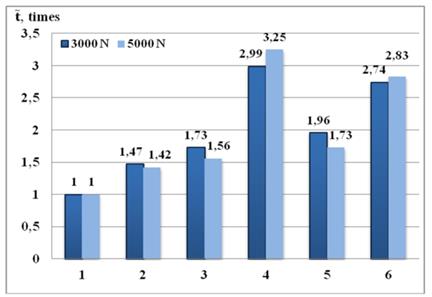

For example, the ranking according to the

criterion of wear resistance of the studied polyamides at 2 MPa relative to the

least resistant polyamide PA6 at ![]() 2 MPa is shown in

Fig. 3.

2 MPa is shown in

Fig. 3.

Fig. 3. Relative wear

resistance of polyamides

1 - РА6, 2 - РА66, 3 - РА6 + 30GF, 4 - РА6 + МоS2, 5 - РА6 + 30СF, 6 - РА6 + oil

Since the wear resistance index m (Table 1) of all studied polyamides is

almost the same, in the whole range of changes in ![]() their relative wear resistance

their relative wear resistance ![]() will be almost the same as shown in Fig. 3.

Increasing the durability of polyamides is close to linear.

will be almost the same as shown in Fig. 3.

Increasing the durability of polyamides is close to linear.

According to the given data, the calculation of durability of MP bearings

with various materials of bushings (Fig. 4) is carried out.

Fig. 4. Durability of MP bearings

There is no increase in the durability in the

order of increasing their wear resistance (Fig. 2) from polymer 1 to polymer 6,

although the wear resistance characteristic B

is increasing (Table 1). This type of sequence does not exist either in

the coefficients of sliding friction (Fig. 5 and 6) or in the value of the

Young's moduli (Table 1, Fig. 9). As a result, the MP bearing with a polymer

sleeve made of a more durable material (PA6 + oil) will not have the highest

durability. The highest durability has a composite PA6 + MoS2. It

depends on the complex influence of these three characteristics. This, in fact,

applies to composites PA6 + 30CF and PA6 + oil.

Fig. 5 shows the relative durability (ranking by durability) of MP bearings

relative to polyamide PA6.

If the durability (Fig. 4) at higher loads is

lower for all materials, then in the case of relative durability (Fig. 5) there

is no such pattern for two polyamide composites - PA6 + MoS2, PA6 +

oil.

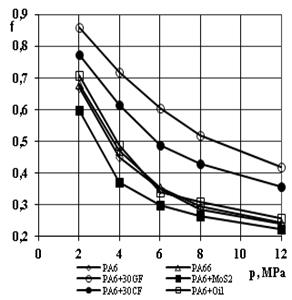

As a result of triboexperimental studies, the non-linear nature of the

decrease in the friction coefficient with increasing contact pressure was

established (Fig. 6).

The highest is the coefficient of friction in

the pair РА6 + 30GF - steel, slightly lower - in the pair РА6 + 30СF - steel, and the lowest - in the pair РА6 + МоS2 - steel.

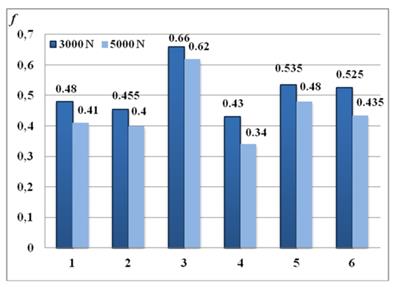

Accordingly, at contact pressures caused by loads ![]() = 3000, 5000 N, their values are shown in Fig. 7.

= 3000, 5000 N, their values are shown in Fig. 7.

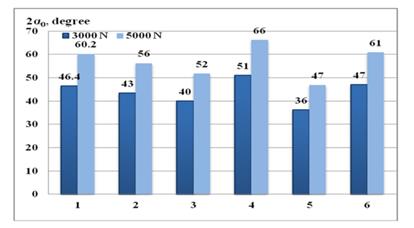

By using the presented method, the maximum

contact pressures р0

(Fig. 8) and contact angles ![]() (Fig. 9) were estimated.

(Fig. 9) were estimated.

The value of the maximum contact pressure р0 under

the same conditions depends only on the value of the modulus of elasticity E of polymeric materials.

As the Young's modulus increases, the rigidity

of the polymer material increases, because of which the contact angle ![]() decreases and the

maximum contact pressure р0 increases.

decreases and the

maximum contact pressure р0 increases.

Fig. 5. Relative durability of MP

bearings

It is known that in the design calculation of

metal plain bearings in engineering practice, the conventional method based on

the average pressure p as a criterion for their bearing capacity,

calculated according to a simplified method, is used. It is assumed that ![]() when the contact angle

when the contact angle ![]() 114.6º =

const, i.e.

114.6º =

const, i.e.

![]() (13)

(13)

where [p] is

the allowable contact pressure for less durable material.

Fig. 6. Experimental

dependence of the average coefficient of sliding friction on the pressure in

polyamide-steel tribocouples

Fig. 7. The effect of load and type

of polyamide on the coefficient of sliding friction

A modified formula for maximum contact pressure рmax is given in

[37], where the cosine law of its distribution by contact area at angle ![]() = 180º is

laid down.

= 180º is

laid down.

![]() (14)

(14)

Fig. 8. Maximum contact pressures

in the MP bearing with

various types of polyamide bushings

Fig. 9. Contact angles

These formulas do not take into account both the

radial clearance ![]() and the elastic

characteristics

and the elastic

characteristics![]() of the materials of bearing elements.

of the materials of bearing elements.

As was shown above, the characteristics of the

bearing and materials have a decisive influence on the contact parameters - р0, ![]() . The specified

contact conditions of the bearing elements in these methods are inappropriate.

There is always a certain radial clearance here, which ensures reliable

operation of the bearing. It should also be noted that the contact angle

. The specified

contact conditions of the bearing elements in these methods are inappropriate.

There is always a certain radial clearance here, which ensures reliable

operation of the bearing. It should also be noted that the contact angle ![]() 114.6º can be

achieved only with a significant load on the bearing and small radial

clearances, as is known from the literature and from the works of the author

[20, 21, 23]. The contact angle

114.6º can be

achieved only with a significant load on the bearing and small radial

clearances, as is known from the literature and from the works of the author

[20, 21, 23]. The contact angle ![]() = 180º is not

achieved even at zero clearance. In contrast, in MP plain bearings, the use of

these techniques is unreasonable given the significant difference between the

Young's modulus of the steel shaft and the composite bushing, as mentioned

above.

= 180º is not

achieved even at zero clearance. In contrast, in MP plain bearings, the use of

these techniques is unreasonable given the significant difference between the

Young's modulus of the steel shaft and the composite bushing, as mentioned

above.

The contact pressures p and рmax in the considered MP bearings are estimated: ![]() = 5000 N: р0 = 4.94 – 6.34 (by Eq. (4)), р = 2.0 MPa

(by Eq. (13)), рmax = 2.55 MPa (by Eq. (14));

= 5000 N: р0 = 4.94 – 6.34 (by Eq. (4)), р = 2.0 MPa

(by Eq. (13)), рmax = 2.55 MPa (by Eq. (14)); ![]() = 3000 N:

р0 = 3.5

– 4.89 (by Eq. (4)), р = 1.2 MPa

(by Eq. (13)), рmax = 1.53 MPa (by Eq. (14)). That is, according to

the conditional method of calculation of bearing capacity without taking into

account the type of polymeric material in the bearing, there will be much lower

contact pressures than determined by the above author's method of calculation.

= 3000 N:

р0 = 3.5

– 4.89 (by Eq. (4)), р = 1.2 MPa

(by Eq. (13)), рmax = 1.53 MPa (by Eq. (14)). That is, according to

the conditional method of calculation of bearing capacity without taking into

account the type of polymeric material in the bearing, there will be much lower

contact pressures than determined by the above author's method of calculation.

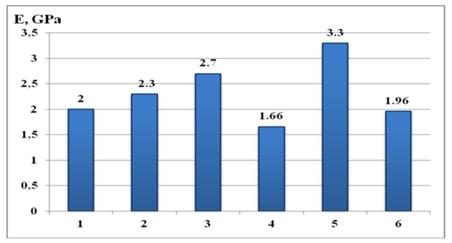

Fig. 10 shows the Young's modulus of unfilled (base) polyamides and

polyamide-based composites established by the Oliver - Farr method.

Fig. 10. Modulus of elasticity of

polyamides and polyamide composites

Different polyamide fillers PA6 have different

effects on the Young's modulus of composites. Fibreglass and carbon fibre

increase it, molybdenum disulfide reduces it, and oil has almost no effect on

it.

The methods of calculation of durability and

bearing capacity of MP bearings presented together with a technique of model

triboexperimental research of materials at sliding friction provide an

opportunity of their effective research at designing.

Program for calculations was developed in

PYTHON.

5.

CONCLUSIONS

The main research results are:

1.

For

polyamides widely used in MP bearings (PA6, PA66, PA6 + 30GF, PA6 + 30CF, PA6 +

MoS2, PA6 + oil) the wear resistance was experimentally investigated

according to the pin-on-disk friction scheme (ISO 7148-2) and wear resistance

indicators were determined. Wear resistance diagrams were plotted using them.

The wear resistance characteristics of polymeric materials as basic parameters

of their wear kinetics at dry sliding friction were determined. Due to the

modification of polyamide PA6 with different fillers, its wear resistance

increased almost threefold (oil filled cast polyamide PA6 + oil).

2.

The influence

of load, wear resistance and friction coefficient, Young's modulus on the

durability of the bearing and its contact parameters was investigated. It was

established that the durability of the MP bearing depends on the complex effect

of these three characteristics, and not only on the wear resistance of the

bushing polymeric material. It was found that the durability of the

bearing with a bushing made of filled composites increases and was three times

greater than for the composite PA6 + MoS2 than PA6.

3.

It was

established that at the same loads on the bearing, the contact parameters

differed markedly depending on the type of polyamide. This was due to their

different elastic properties (rigidity), which are characterized by the Young's

modulus.

4. Quantitative and qualitative regularities of the

influence of contact pressure on the coefficient of sliding friction in the

investigated metal – polymer tribocouples were established. The confirmation of

the general regularity of its significant decrease upon an increase in contact

pressure in an experimental tribocouple was obtained.

5. A typical method of calculating contact

pressures gives a significant understatement for MP bearings (in 2.5… 4.1

times) depending on the load.

6. One important property of the developed methods

for calculating the durability and bearing capacity of MP bearings was that the

solution to the problem is presented in a closed form, which allows its

practical implementation to be carried out using simple software tools,

starting from Microsoft Excel. Based on these methods, it was also possible to

carry out, when designing bearings, an optimization according to the criteria

of durability, contact strength, wear, as well as the optimal choice of

materials.

7.

The results of the research

can be used in practice to optimize the choice of polyamides in moving sliding

friction assemblies of vehicles in terms of load-bearing capacity, wear

resistance, and durability.

8.

In particular, polyamides of

the studied type were used in the engine connecting rod bearing [32], clutch

discs [38], shaft-bushing bearing of an automotive turbocharger wastegate

system [39], for the bearing of an automatic car belt tensioner [40].

References

1.

Chernets M.

2000. Contact-friction strength and

durability of tribotechnical sliding systems. Lublin University of

Technology, Lublin.

2.

Goryacheva

I.G. 2001. Mechanics of frictional

interaction. Nauka, Moscow.

3.

Kuzmenko

A.G. 2002. Methods for the Numerical

Analysis of Wear and Reliability. Podillya Technological University, Khmelnytsky.

4.

Kuzmenko

A.G. 2010. Development of methods of

contact tribomechanics. KhNU, Khmelnytsky.

5.

Dykha O., O. Babak, M. Dykha. 2017. The

wear models of cylindrical sliding tribosystems. Actual problems of modern

science. Bydgoszcz, Poland.

6.

Dykha A.,

D. Marchenko. 2018. Prediction the wear of sliding bearings. International Journal of Engineering &

Technology 7(2): 4-8. DOI: http://dx.doi.org/10.14419/ijet.v7i2.23.11872.

7.

Sorokatyi

R., M. Chernets, A. Dykha, O. Mikosyanchyk. 2019. Phenomenological model of

accumulation of fatigue tribological damage in the surface layer of materials. Mechanisms and Machine Science 73:

3761-3769. DOI: https://doi.org/10.1007/978-3-030-20131-9_371.

8.

Zwieżycki W. 1999. Prognozowanie niezawodności zużywających się elementów maszyn. [In Polish: Forecasting the reliability of wearing machine elements]. ITE,

Radom.

9.

Sorokatyi

R.V. 2002. Modelling the behaviour of tribosystems using the method of

triboelements. Journal of Friction and

Wear 23(1): 16-22.

10.

Sorokatyi

R.V. 2003. Solution of the problem of wear of a fine elastic layer with a rigid

bearing mounted on a rigid shaft using the method of triboelements. Journal of Friction and Wear 24(1):

35-41.

11.

Wielieba W. 2013. Bezobsługowe łożyska ślizgowe z polimerów termoplastycznych. [In Polish: Maintenance-free plain bearings made of thermoplastic polymers].

Politechnika Wrocławska, Wrocław.

12.

Rezaei A., W.

Ost, W.V. Paepegem, P. De Baets, J. Degrieck. 2011. Experimental study and numerical simulation of

the large-scale testing of polymeric composite journal bearings:

Three-dimensional and dynamic modelling. Wear

270: 431-438. DOI: https://doi.org/10.1007/s11249-009-9518-3.

13.

Rezaei A., W.

Ost, W. Van Paepegem, P. De Baets, J. Degrieck. 2012. A study on the effect of the clearance on the

contact stresses and kinematics of polymeric composite journal bearings under

reciprocating sliding conditions. Tribology

International 48: 8-14. DOI: https://doi.org/10.1016/j.triboint.2011.06.031.

14.

Rezaei A., W.

Ost, W. Van Paepegem, P. De Baets, J. Degrieck. 2012. Adaptive finite element simulation of wear

evolution in radial sliding bearing. Wear

296(1-2): 660-671. DOI: https://doi.org/10.1016/j.wear.2012.08.013.

15.

Bely V.A., A.I. Sviridenok, M.I.

Petrokovets, V.G. Savkin. 1982. Friction and wear in polymer – based

materials. Pergamon Press, Oxford.

16.

Myshkin

N.K., M.I. Petrokovets, A.V. Kovalev. 2005. Tribology of polymers: Adhesion,

friction, wear, and mass-transfer. Tribology

International 38: 910-921. DOI: https://doi.org/10.1016/j.triboint.2005.07.016.

17.

Myshkin N.,

A. Kovalev, D. Spaltman. 2014. Contact mechanics and tribology of polymer

composites. J Appl Polym Sci 131:

39870. DOI: https://doi.org/10.1002/app.39870.

18.

Myshkin N.,

A. Kovalev. 2018. Adhesion and surface forces in polymer tribology –

A review. Friction 6: 143-155.

DOI: https://doi.org/10.1007/s40544-018-0203-0.

Chernets M.V., I.N. Gonchakivskii, Yu. Skvarok. 1987. Solution of a Contact Problem for Cylindrical Bodies with Faceted Configuration and with Internal Contact. 19(6):-https://doi.org/10.1007/BF01522847.

20.

Chernets M.,

M. Pashechko, A. Nevchas. 2001. Methods of forecasting and increasing the wear

resistance of tribotechnical sliding systems. In 3 volumes. Vol. 1. Research and calculation of sliding

tribosystems, methods to increase durability and wear resistance. KOLO,

Drogobich.

21.

Chernets

M.V. 2013. Tribocontact problems for

cylindrical joints with technological roundness. Lublin University of

Technology, Lublin.

22. Chernets M.V., O.E. Andreikiv, N.M. Liebiedieva,

V.B. Zhydyk. 2009. A model for evaluation of wear and durability of plain

bearing with small out-of-roundness. Materials

Science 3: 279-290. DOI: https://doi.org/10.1007/s11003-009-9176-5.

23.

Chernets

M.V. 2009. Сontact

problem for a cylindrical joint with technological faceting of the contours of

its parts. Materials Science 6:

859-868. DOI: https://doi.org/10.1007/s11003-010-9252-x.

24.

Chernets

M., Ju. Chernets. 2015. Generalized method for calculating the durability of

sliding bearings with technological out-of-roundness of details. Proc. IMechE. Part J: Journal of Engineering

Tribology 229(2): 216-226. DOI: https://doi.org/10.1177/1350650114554242.

25.

Chernets

M.V. 2015. Prediction of the life of a sliding bearing based on a cumulative

wear model taking into account the lobing of shaft contour. Journal of Friction and Wear 36(2):

163-169. DOI: https://doi.org/10.3103/S1068366615020038.

26.

Chernets

M.V., S.V. Shil’ko, M.I. Pashechko, M. Barshch. 2018. Wear resistance of glass-

and carbon-filled polyamide composites for metal-polymer gears. Journal of Friction and Wear 39(5):

361-364. DOI: https://doi.org/10.3103/S1068366618050069.

27. Chernets M., J. Chernets, M. Kindrachuk, A.

Kornienko. 2020. Methodology

of calculation of metal-polymer sliding bearings for contact strength,

durability and wear. Tribology in

Industry 42(4): 572-584. DOI: https://doi.org/10.24874/ti.900.06.20.10.

28.

Palabiyik

M., S. Bahadur. 2002. Tribological studies of polyamide 6 and high-density рolyethylene blends filled with PTFE and copper

oxide and reinforced with short glass fibers. Wear 253: 369-376. DOI: https://doi.org/10.1016/S0043-1648(02)00144-8.

29.

Feyzullahoglu

E., Z. Saffak. 2008. The tribological behaviour of different engineering

plastics under dry friction conditions. Materials

and Design 29: 205-211. DOI: http://dx.doi.org/10.1016/j.matdes.2006.11.012.

30.

Ünlü B.S., E.

Atik, S. Köksal. 2009. Tribological

properties of polymer-based journal bearings. Mater. Design. 30(7): 2618-2622. DOI: https://doi.org/10.1016/j.matdes.2008.11.018.

31.

Turan

Demirci M., H. Düzcükoğlu. Wear behaviours of PTFE reinforced PA 66. Journal bearings. International scientific

conference. 19-20 November, 2010. Gabrovo, Bulgaria. P. 249-253.

32.

Mastan V., V.

Raja Kiran Kumar, Ch. Kiran Kumar. 2012. Study

of Friction and Wear on Journal Bearings. International

Refereed Journal of Engineering and Science 1(4): 63-70.

33. Kalácska G. 2013. An engineering approach to dry

friction behaviour of numerous engineering plastics with respect to the

mechanical properties. Express Polymer

Letters 7(2): 199-210. DOI: http://dx.doi.org/10.3144/expresspolymlett.2013.18.

34.

Mithun Kulkarni V., K. Elangovan, K.

Hemachandra Reddy, S.J. Basappa. 2016.

Tribological behaviours of ABS and PA6 polymer metal sliding combinations under

dry friction, water absorbed and electroplated conditions. Journal of Engineering Science and Technology 11(1): 068-084.

35.

Pogaˇcnik A., A. Kupec, M. Kalin. 2017. Tribological properties of polyamide (PA6)

in self-mated contacts and against steel as a stationary and moving body. Wear 378-379: 17-26. DOI: https://doi.org/10.1016/j.wear.2017.01.118.

36. Jozwik

J., K. Dziedzic, M. Barszcz, M. Pashechko. 2020. Analysis and Comparative Assessment of Basic

Tribological Properties of Selected Polymer Composites. Materials 13(1): 75. DOI: https://doi.org/10.3390/ma13010075.

37.

Budynas R.G., Nisbett J.K. 2019. Shigley’s

Mechanical Engineering Design.

McGraw-Hill, New York.

38.

De Almeida Rosa A.G., J.A.

Moreto, M.D. Manfrinato, L.S. Rossino. 2014. Study

on friction and wear behaviour of SAE 1045 steel, reinforced nylon 6.6 and NBR

rubber used in clutch disks. Mat. Res. 17(6): 1397-1403. DOI: https://doi.org/ 10.1590/1516-1439.282714.

39. Schmidt A.A., T. Schmidt, O. Grabherr, D. Bartel. 2018. Transient wear simulation based on three-dimensional finite element analysis for a dry running tilted shaft-bushing bearing. Wear 408-409: 171-179. DOI: https://doi.org/10.1016/j.wear.2018.05.008.

40. Fortes R.R., J.R. de Camargo, G.E.O.

Giacaglia, W. de Queiróz Lamas. 2021. Tribological study of a polymer bushing wear

with a steel axle for an automatic car tensioner. Proc. IMechE. Part J: Journal

of Engineering Tribology 236. DOI: https://doi.org/10.1177/13506501211053514.

Received 20.02.2024; accepted in revised

form 10.05.2024

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License