Article citation information:

Mikhailov,

E., Semenov, S., Shvornikova, H., Dižo,

J., Blatnický, M., Droździel,

P., Kravchenko, K. Possibilities

of improving a rail vehicle running safety with independently rotating wheels. Scientific Journal of Silesian University of

Technology. Series Transport. 2022, 115,

93-106. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2022.115.7.

Evgeny MIKHAILOV[1],

Stanislav SEMENOV[2],

Hanna SHVORNIKOVA[3],

Ján DIŽO[4],

Miroslav BLATNICKÝ[5],

Paweł DROŹDZIEL[6],

Kateryna KRAVCHENKO[7]

POSSIBILITIES OF IMPROVING A RAIL VEHICLE RUNNING SAFETY WITH

INDEPENDENTLY ROTATING WHEELS

Summary. This work is

focused on the possible ways of improving the running safety of a railway

vehicle, which uses IRWs (independently rotating

wheels) in a bogie. It discusses the main positive and negative properties

of an application of IRWs for a railway vehicle while

it is running in a curve. There are evaluated running properties of a railway

vehicle in terms of safety for IRWs and a standard

wheelset (SW). It is assumed that a wheelset design with IRWs

will reduce the risk of derailment of a railway vehicle in a curve with a

smaller radius because it will be reached a more favourable distribution of

decisive forces in the wheel/rail contact. A designed wheelset with IRWs differs from other IRWs

designs; in this case, only a flange can rotate independently from a wheel

treat surface about the axis of rotation. Further, this research presents an

analysis of a friction forces distribution of the friction forces in a contact

of a flange and a rail head and a comparison with an SW. The obtained results

allow concluding that it is advisable to use the wheels with the perspective

wheel design (including independently rotating) to reduce the resistance to

movement and improve the running properties of a railway vehicle for safety.

Keywords: rail

vehicle; running safety; independently rotating wheels; mathematical

calculation

1. INTRODUCTION

Research in

the last decades has focused on the design of railway vehicles and their

running properties to improve dynamical properties for running safety [1, 2].

It mainly relates to increasing the running speed of railway vehicles, reducing

the wear of railway wheelsets and rails and other important facts. However, the

factors described above are not only associated with the high speed but, on the

contrary, with the low speed of a railway vehicle as well. The risk of

derailment of a railway vehicle, a shorter lifetime of its wheels and rails, a

higher level of noise and other negative effects also occur while a railway

vehicle runs at lower speed and mainly in curves with smaller radii. In such

cases, a standard wheelset (SW) of a railway vehicle does not sufficiently meet

the demand of the smallest possible angle of attack (it is given by wheelset

guidance, etc.). Therefore, longitudinal slippage, as well as the running

resistance, arise. The use of IRWs instead of SWs in

a bogie for urban railway vehicles (that is. mainly for trams), is one of the

possible ways of reducing the described negative effects [3-9].

When IRWs are mounted on a railway vehicle bogie, wheels rotate

either as a whole (a flange with a wheel tread surface) or as two parts (a

flange rotates independently from a wheel tread surface) about an axis of

rotation. Such a technical solution helps to eliminate slippage in the

longitudinal direction, which results in reducing running resistance when a

railway vehicle runs in curves. Improvements of running behaviours

of a railway vehicle with IRWs are mainly [3]:

- reduce

wagging at high speeds,

- reduce wear of

contact surfaces of a rail and a wheel with a flange,

- improve railway

vehicles behaviours related with running in curved

sections of a railway track, as it practically eliminates of components the

creep forces in the longitudinal direction.

Hence, two

wheels of one IRW pair rotate at various speeds.

Subsequently, this causes minimal values of creep forces in the longitudinal

direction, ensures the moment for controlling the wheelset motion and centres a wheelset in the longitudinal axis of the railway

track. On the contrary, the angle of attack of the wheelsets is being

increased; therefore, the wear of tread surfaces of the wheels and rails also

increase together with the values of the lateral forces. Higher values of the

lateral forces lead to higher values of the derailment quotient, which means a

higher risk of derailment of a railway vehicle.

2. ANALYSIS OF

RECENT RESEARCH AND PUBLICATIONS

Relatively,

many technical solutions attempt to eliminate the disadvantages of using IRWs in bogies. Some technical solutions include the

application of a joint between a wheel and an axle, which has prescribed

certain elastic characteristics. The simplest solution is the mounting of a

wheel with a flexible element (usually rubber-based elements) to an axle [7].

However, IRWs with rubber elements are not suitable

for railway vehicles, which run at higher speeds.

Other

technical designs are based on more complicated systems that require using

specific components to ensure increasing the torsional flexibility of the axle

of a wheelset. The principle of their functionality is that they allow locking

the wheels on an axle when a railway vehicle runs on a straight track section,

and thus, it behaves as a railway vehicle with SWs. However, when a railway

vehicle with this device enters a curve, the device is activated, and it

unlocks the wheels, so they can rotate independently on an axle [9]. Pioneers

of this approach are believed to be specialists from the MBB

Company (Germany). They have developed large studies based on both theoretical

backgrounds and experiments. As a regulator, they have applied a clutch working

with magnetic powder.

One

of the ways of ensuring the optimal interaction of wheels and rails of rail

vehicles (with IRWs) to minimise lateral forces

together with, is the use of a specialized mechatronic system to monitor the

position of a wheelset in the horizontal plane [11-14]. In rail vehicles bogies

with radial guidance of wheelsets, the angles of attack of the wheelsets

regarding a track when it is running in curves are close to zero. Among the

most known bogies with a system ensuring the additional movement of a wheelset

in a bogie are those with [15, 16]:

- a system for a

self-centring wheelset,

- a system allowing a

semi-forced guidance of a wheelset,

- a system allowing a forced

guidance of a wheelset.

The

results of numerous studies [17-25] have shown an increased propensity of rail

vehicles with IRWs to derailment by climbing of the

wheel flange on a rail head. The absence of longitudinal creep forces when the IRW moves on a rail means that the friction forces in the

wheel/rail contact act entirely in the lateral direction. It results in a risk

when the wheel flange can climb on a rail. This risk increases with the

decreasing distance of a flange lifting [19, 22]. Furthermore, the results of

the research [20] show that the value of the longitudinal forces in the contact

of a wheel and a rail directly increases with the value of the Y/Q

ratio. This ratio is called the derailment quotient. Hence, the Nadal

criterion, which characterizes the conditions where the flange can climb to a

rail head, can be softened and this depends on which values the longitudinal

forces reach in the contact of a wheel and a rail. The creep forces in the

longitudinal direction support the redistribution of the friction forces

components in the contact of a wheel and a rail. This decreases the effective

friction coefficient and increases the Y/Q ratio, which is required for the

derailment of a railway vehicle [23].

Research

in this field has demonstrated more or less satisfying results, hence needs

further investigation.

In

comparison with the IRWs described above, this work

is aimed at research relating to the application of IRWs

with the perspective wheel design (PWD). This

technical design is characterized by a rotating wheel flange relative to the

wheel tread surface, which for this work, are IRWs

with traditional wheel design (TWD).

Generally,

during the moving of a wheel on a rail, contact points of the wheel tread

surface and the flange move in a space and they perform a complex spatial

movement with a cycloidal trajectory [24]. In the case of the SW with a TWD

type, parasitic differential slip arises, as between the geometric

parameters of the rolling surfaces of a railway wheel and the kinematic

parameters of movement is certain dissonance [25-29]. Thus, the wear intensity

of surfaces of a railway wheel and a rail is given by the power of the friction

forces. It is more noticeable in the curved sections of a railway track

[30-33]. One way of decreasing consumed energy together with

wear in curves is to lubricate the contact surfaces. However, this does not

adequately solve the problem.

The

main objective of this contribution is to present the possibilities of

improving a railway vehicle’s running properties for safety, which are

equipped by the IRW of the PWD

type.

3. STATEMENT

OF THE MAIN MATERIAL

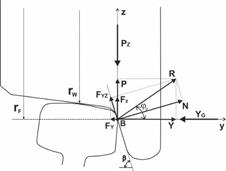

The distribution of forces,

which are important for the evaluation of the risk of derailment of a railway

vehicle, is shown in Figure 1. It captures the situation when it begins to

climb on a rail head. The individual forces are as follows: R is a general reaction, PZ is a magnitude of forces

in a vertical direction, and YG is a magnitude of forces in a horizontal

direction.

The following formulations

describe the common magnitude of reaction forces in the contact of a flange and

a rail head:

![]() (1)

(1)

![]() (2)

(2)

![]() (3)

(3)

Fig.

1. Distribution of forces in the contact of a flange and a rail head at

the moment of climbing: front view (left), side view (right)

The design of a wheelset with the IRWs PWD type allows the flange to rotate relative to the tread

surface of the wheel in the given coordinate system; it increases the number of

degrees of freedom to the solved mechanical system. Equations of equilibrium of

the forces in the z-axis direction and the moments about the B contact point

are as follows (Figure 1, right):

![]() ,

, ![]() (4)

(4)

Where:

![]() - the sum of the

forces, which act on the wheel in the axis OZ direction,

- the sum of the

forces, which act on the wheel in the axis OZ direction,

![]() - the

sum of the moments of the forces

about the B point.

- the

sum of the moments of the forces

about the B point.

Then:

![]() (5)

(5)

Where:

YZ - the component of a

reaction of the guiding force YG in the vertical direction,

FZ - the component of the

friction force in the contact of the flange and the rail head in the vertical

direction,

PZ - the sum of the forces generated by the

wheel gravity and the weight of a railway vehicle corresponding to the wheel.

The process of derailment of

the wheel starts at the moment, when the wheel surface (with the PDW type) begins to leave the rail head surface (point A). At this moment, the centre of

rotation of the wheel moves to point B

(Figure 1). This sliding movement continues up to the rail head in the OZ axis direction. This is

caused by the component of the reaction YZ in the vertical direction, at which, the force

Y is the guiding force. The value of the YZ force component is

given by the formulation:

![]() (6)

(6)

Herein:

![]() (7)

(7)

The values of the forces,

which are used in formulations 6 and 7, that is, force PZ and YG, are given and they can be changed. Further,

the calculation process requires estimating the force FZ. At the earliest,

there have been analysed properties of the movements of the wheels for the TWD

type of wheel and the PWD type of wheel for a

two-point contact [26-30]. The results of analyses of the TWD type of the

railway wheel reveal that the unambiguous determination of the modulus and the

direction of the vector of the friction force depends on the geometric

characteristics for the contact of the wheel and the rail and the wheel angular

speed. However, the railway wheel of PWD type needs

to determine the two parameters mentioned above the additional parameter,

namely the ratio expressing angular velocity of the tread surface of a wheel

and a flange about their mutual axis of rotation. Then, the following

formulations can be considered:

![]() (8)

(8)

![]() (9)

(9)

![]() (10)

(10)

Index “i”, which

appears in equations 8 to 10 means, for which wheel design are these forces

calculated. The PWD type of a wheel is marked by a

“*”.

Formulations for the

determination of the parameters δ

or δ* are as follows:

,

,  (11)

(11)

![]() ,

,  (12)

(12)

where:

![]() ,

,

ψ - is the angle of attack of the considered

wheel,

β - is the angle, which gives the slope of the

flange of a wheel relative to the horizontal plane.

These subsequent

formulations enable the calculation of the component of the friction force for

both TWD and PWD types of wheels in the vertical

direction:

- the

ТWD type of wheel:

![]() (13)

(13)

- the

PWD type of wheel:

![]() (14)

(14)

Next, condition (6) can be

written as:

![]() (15)

(15)

Now, it is possible to

characterize a coefficient of movement stability ![]() of a wheel regarding

derailment:

of a wheel regarding

derailment:

![]() (16)

(16)

where: ![]() .

.

The wheel begins to climb on

the rail head, when the coefficient reaches values lower than 1, that is, ![]() .

.

Figure 2 depicts the

waveform of the calculated values of the ![]() safety coefficient for a TWD

type of wheel and a PWD type of wheel. Curves are

determined for the following parameters: ψ

= 0.015, KW = 1.021 and PZ = 125 kN.

safety coefficient for a TWD

type of wheel and a PWD type of wheel. Curves are

determined for the following parameters: ψ

= 0.015, KW = 1.021 and PZ = 125 kN.

By analysing the graphs shown in Figure 2, we

can observe that the value of the coefficient KS characterizing the margin of stability of the wheels

from derailment, when the flange is climbing at the initial stage of this

process, depending on the guiding force YG magnitude and it is practically the same for

railway wheels of both types. Differences in values of the KS coefficient are determined by the effects of the

considered wheel type on the distribution of individual components of the

friction force. Particularly, the effect of the component of the friction force

in the vertical direction.

Fig.

2. The waveform of the safety coefficient KS

= f(YG): 1

– the TWD of a wheel,

2 – the PWD type of a wheel

In this considered case, the

value of this KS

coefficient gives an idea of whether the flange of a railway wheel can climb to

a rail head.

The criterion of running

safety calculated for the risk of derailment is one of the most important data

for railway vehicle running safety [19, 22, 25]. The

Nadal criterion (usually marked as KN) expresses a standard condition from the

viewpoint of running stability [31]. Based on this criterion, the demand for

running safety given the derailment risk of a railway vehicle must meet the

following condition:

![]() (17)

(17)

where:

KNad - is the normalized Nadal

factor, which reflects the limit of the ratio G/V,

[KN] - is the limit

value for the stability coefficient.

Further:

![]() (18)

(18)

where:

μ - is the friction coefficient of friction

between the flange and the rail head.

G - the horizontal force of pressure of the attacking wheel on

the rail;

β - the angle of inclination of the generatrix of the wheel flange to the horizontal line;

V - the vertical force of pressure of the attacking wheel on the

rail;

The solved task requires

modifying the traditional criterion for the evaluation of railway vehicle

stability.

It is interesting to

determine the friction force magnitude (depicted as FYZ). This force acts

in the plane marked as YOZ. Its value is calculated

following equations 9 and 10 as follows:

(19)

(19)

Thereafter, the value of the

friction coefficient ![]() is determined by the

formulation:

is determined by the

formulation:

![]() (20)

(20)

There are certain

differences in the values of angles marked as δi and χi

for individual variants of the technical solutions of the designed wheels.

Then, the values of the Nadal criterion are calculated as follows:

- for

a wheelset with the ТWD type:

(21)

(21)

- for

a wheelset with the PWD type:

(22)

(22)

In the case of the

requirement to evaluate the derailment criterion depending on the design of a

wheel, the ratio ![]() is quantified. This ratio is

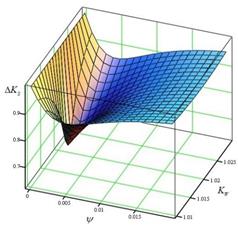

calculated for the same number obtained from the ratio G/V. Figure 3 shows the

dependence of the parameter ΔKN = f(ψ, KW).

is quantified. This ratio is

calculated for the same number obtained from the ratio G/V. Figure 3 shows the

dependence of the parameter ΔKN = f(ψ, KW).

From the graph, it can be seen that there is a

certain range of such operating parameters, for which the

reached Nadal criterion values for the wheel with the PWD

type are lower in comparison with the Nadal criterion values for the wheel with

the ТWD type. This is because the design of the

wheel influences the friction force distribution in contact with the wheel and

the rail.

Fig.

3. Dependence graph ΔKN = f(ψ, KW)

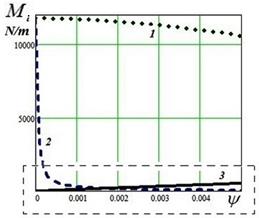

Figures below (Figures 4 and 5) depict the

comparison of the results of the moments calculated for the TWD type as well as

the PWD type of a railway wheel for particular

parameters as follows: YG

= 50 kN, KW

= 1.021, PZ = 125 kN, hF

= 0.01 m, rW

= 0.475 m,

μr

= 0.25.

Fig.

4. Graph depicting the dependency of the values of Mi = f(ψ): 1 - MX1 = f(ψ)

(TWD type of wheel), 2 - MX2 = f(ψ)

(PWD type of wheel), 3 - MZ = f(ψ)

Fig.

5. Detail of the graph depicted in Figure 4

As seen from the graphs

depicted in Figures 4 and 5, the value of the moment MZ is higher than the value of the moment MX for a railway wheel with the PWD

type, although the angle of attack is quite small (that is, for the value of ψ > 0.0017 rad or about

0.1°).

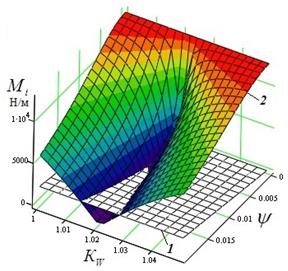

Fig. 6. Dependency

graphs Mi = f(ψ, KW): 1 - MZ = f(ψ, KW), 2 - MZ = f(ψ, KW)

Figure 6 highlights the results of the

calculation of the moment Mi for the given parameters for the PWD type of a railway wheel. It can be recognized that the

described behaviour of the PDW type of a railway

wheel is specific for an obvious range of values KW.

4. CONCLUSION

The research results revealed interesting findings. Practically,

conditions for the beginning of climbing of the wheel flange on a rail head are

the same for IRWs with the TWD type and the IRWs with the PWD type. The Nadal

criterion was used for the calculation of the derailment factor in this work.

This criterion considers the effect of the angle of attack of a wheel as well

as the behaviours of the type of IRW. The reached

results showed that the calculated values of the modified Nadal criterion are a

bit smaller for the PWD type of a wheel in comparison

with the considered criterion for the TWD type of a wheel. This is because the

design of the railway wheel influences the distribution of the friction forces

in contact with the flange and the rail. However, this is not critical for

using the PWD of wheels. Performed analyses have

determined, in this case, that the angle of attack is higher than 1.7∙10-4

rad, the IRW with the PWD

type practically does not roll on a rail. The wheel flange with the PWD type tends to rotate to the opposite side relative to

the direction of the wheel in which it moves. Hence, it seems expedient to

apply railway wheels with the IRW of the PWD type in a bogie of a railway vehicle with IRWs to improve the running properties for safety.

Acknowledgement

This research was supported by the Cultural and

Educational Grant Agency of the Ministry of Education of the Slovak Republic

under project No. KEGA 023ŽU-4/2020: Development of advanced virtual models

for studying and investigating transport means operation characteristics.

References

1.

Zhang Dawei, Peijuan Xu, Daniele Bigoni. 2019.

„Application and comparison of uncertainty quantification methods for

railway vehicle dynamics with random mechanical parameters“. Mechanika 25(6): 455-462. ISSN:

1392-1207

2.

Zhussupov Kenes, Aliya Toktamyssova, Seidulla Abdullayev,

Gabit Bakyt, Manarbek Yessengaliyev. 2018. „Investigation of the stress-strain

state of a wheel flange of the locomotive by the method of finite element

modeling“. Mechanika 24(2):

174-181. ISSN: 1392-1207

3.

Dukkipati Rao V., Swamy S. Narayana, Osman Mohammad O.M.

1992. „Independently rotating wheel systems for railway vehicles - A

state-of-the-art review”. Vehicle

System Dynamics 21(1): 297-330. ISSN: 0042-3114. DOI: https://doi.org/10.1080/00423119208969013.

4.

Liang B., S. Iwnicki. 2007. „An experimental study of

independently rotating wheels for railway vehicles“. In: IEEE International Conference On

Mechatronics And Automation I-V: 2282-2286. August 05-08, Harbin, China.

5.

Zaazaa Khaled E., Brian

Whitten. 2008. „Effect of

independently rotating wheels on the dynamic performance of railroad

vehicles“. In: Рroceedings of

the ASME International Mechanical Engineering Congress and Exposition 2007:

467-477. November 11-15, Seattle, WA, USA.

6.

Nabilah Farhat,

Christopher Ward, Omar Shaebi, David Crosbee, Julian Stow, Ruichen Wang,

Roger Goodall, Martin Whitley. 2020. „Controlling a Rail Vehicle with

Independently-Rotating Wheels“. In: Advances

in Dynamics of Vehicles on Roads and Tracks 1925. Edited by Matthijs Klomp, Fredrik Bruzelius, Jens Nielsen, Angela

Hillemyr. Gothenburg, Sweden: Springer. ISBN: 978-3-030-38077-9. DOI: https://doi.org/10.1007/978-3-030-38077-9.

7.

Bracciali Andrea. 2016. „Railway Wheelsets:

History, Research and Developments“. International

Journal of Railway Technology 5(1): 23-52. ISSN: 2049-5358. DOI: https://doi.org/10.4203/ijrt.5.1.2.

8.

Goodal Roger, Li Hong. 2000. „Solid axle and

independently-rotating railway wheelsets - a control engineering assessment of

stability“. Vehicle System Dynamics

33(1): 57-67. ISSN: 0042-3114. DOI: https://doi.org/10.1076/0042-3114(200001)33:1;1-5;FT057.

9.

Kostrzewski Mariusz, Rafał Melnik. 2017.

„Numerical dynamics study of a rail vehicle with differential

gears“. Procedia Engineering

192: 439-444. ISSN: 1877-7058. DOI: https://doi.org/10.1016/j.proeng.2017.06.076.

10.

Bracciali Andrea, Megna Gianluca. 2016. „Contact

mechanics issues of a vehicle equipped with partially independently rotating

wheelsets“. Wear 366-367:

233-240. ISSN: 0043-1648. DOI: https://doi.org/10.1016/j.wear.2016.03.037.

11.

Perez J., J.M. Busturia, Mei Tan Xue, Vinolas Jordi. 2004. „Combined active steering and traction for mechatronic

bogie vehicles with independently rotating wheels”. In: 2nd IFAC

Conference on Mechatronic Systems: 207-217. IFAC.

December 09-11, Berkeley, CA, USA. ISSN: 1367-5788. DOI:

https://doi.org/10.1016/j.arcontrol.2004.02.004.

12.

Kapitsa Mikhail, Evgeni Mikhailov, Sergii Kliuiev,

Stanislav Semenov, Maksim Kovtanets. 2019. „Study of rail vehicles

movement characteristics improvement in curves using fuzzy logic mechatronic

systems“. MATEC Web of Conferences

294: 03019. ISSN: 2261-236X. DOI: https://doi.org/10.1051/matecconf/201929403019.

13.

Mikhailov Evgeny, Juraj Gerlici, Sergey Kliuiev,

Stanislav Semenov, Tomas Lack, Kateryna Kravchenko. 2019. „Mechatronic system

of control position of wheel pairs by railway vehicles in the rail track“.

AIP Conference Proceedings 2198:

020009. ISSN: 0094-243X. DOI: https://doi.org/10.1063/1.5140870.

14.

Fu Bin, Rocco Libero Giossi, Rickard Persson, Sebastian

Stichel, Stefano Bruni, Roger Goodall. 2020. „Active suspension in

railway vehicles: A literature survey“. Railway Engineering Science 28(1): 3-35. ISSN: 2662-4753. DOI: https://doi.org/10.1007/s40534-020-00207-w.

15.

Dvorak Zdeněk, Bohuš Leitner, Ladislav Novak.

2015. „Software support for railway traffic simulation under restricted

conditions of the rail section“. In: Proceedings

of the 9th International Scientific Conference TRANSBALTICA 2015: 245-255.

Vilnius Gediminas Technical University. May 07-08, Vilnius, Lithuania. ISSN:

1877-7058. DOI: https://doi.org/10.1016/j.proeng.2016.01.066.

16.

Upadhyay R. 2000. „Reduced wear wheels and

railway“. International Railway

Journal 7: 33-34.

17.

Mašek Jaroslav, Martin Kendra, Sanjin

Milinković, Slavko Vesković, Dalibor Barta. 2015. „Proposal and

application of methodology of revitalisation of regional railway track in

Slovakia and Serbia. Part 1: theoretical approach and proposal of methodology

for revitalisation of regional railways“. Transport Problems 10: 85-95. ISSN: 1896-0596. DOI: https://doi.org/10.21307/tp-2015-064.

18.

Leitner Bohuš, Lenka Môcová, Martin

Hromada. 2017. „A new approach to identification of critical elements in

railway infrastructure“. In: Proceedings

of the 10th International Scientific Conference on Transportation Science and

Technology TRANSBALTICA 2017: 143-149. Vilnius Gediminas Technical

University. May 04-05, Vilnius, Lithuania. ISSN: 1877-7058. DOI: https://doi.org/10.1016/j.proeng.2017.04.360.

19.

Wilson Nicholas, Xinggao Shu, Ken Kramp. 2004.

„Effects of independently rolling wheels on flange climb derailment“.

In: ASME 2004 International Mechanical

Engineering Congress and Exposition:

IMECE2004: 21-27. November 13-19, Anahaim, California, USA. ISBN:

0-74918-4712-83. DOI: https://doi.org/10.1115/IMECE2004-60293.

20.

Opala Michał. 2016. „Study of the derailment

safety index Y/Q of the low-floor tram bogies with different types of guidance

of independently rotating wheels“. Archives

of Transport 38(2): 39-47. ISSN: 0866-9546. DOI: https://doi.org/10.5604/08669546.1218792.

21.

Shen G., J. Zhou, L. Ren. 2006. „Enhancing the

resistance to derailment and side-wear for a tramway vehicle with independently

rotating wheels“. Vehicle System Dynamics

44(1): 641-651. ISSN: 0042-3114. DOI: https://doi.org/10.1080/00423110600882738.

22.

Wilson Nicholas, Huimin Wu, Adam Klopp, Alexander Keylin.

2019. „Railway vehicle derailment and prevention“. In: Handbook of Railway Vehicle Dynamics

913. Edited by Simon Iwnicki, Maksym Spiryagin, Colin Cole, Tim McSweeney.

Plce: CRC Press Boca Raton. ISBN: 978-0429-4693-98. DOI: https://doi.org/10.1201/9780429469398.

23.

Xu Jingmang, Jian Wang, Ping Wang, Jiayin Chen, Yuan Gao,

Rong Chen, Kaize Xie. 2020. „Study on the derailment behaviour of a

railway wheelset with solid axles in a railway turnout“, Vehicle System Dynamics, 58(1): 123-143.

ISSN: 0042-3114. DOI: https://doi.org/10.1080/00423114.2019.1566558.

24.

Mikhailov Evgeny, Stanislav Semenov, Svitlana Sapronova,

Viktor Tkachenko. 2020. „On the issue of wheel flange sliding along the

rail“. In: 11th Transbaltica

International Scientific Conference (TRANSBALTICA) - Transportation Science and

Technology: 377-385. Vilnius Gediminas Technical University. May 2-3,

Vilnius, Lithuania. ISBN: 978-3-030-38665-8. DOI: https://doi.org/10.1007/978-3-030-38666-5_40.

25.

Dukkipati Rao V. 2000. Vehicle Dynamics. Narosa Publishing House 591. ISBN: 0-8493-0976-X.

26.

Mikhailov Evgeny, Stanislav Semenov, Viktor Tkachenko,

Svitlana Sapronova. 2018. „Reduction of kinematic resistance to movement

of the railway vehicles“. MATEC Web

of Conferences 235: 00033. ISSN: 2261-236X. DOI: https://doi.org/10.1051/matecconf/201823500033.

27.

Mikhailov Evgeny, Stanislav Semenov, Ján

Dižo, Kateryna Kravchenko. 2019. „Research of possibilities of

reducing the driving resistance of a railway vehicle by means of the wheel

construction improvement“. In: 13th

International Scientific Conference on Sustainable, Modern and Safe Transport

TRANSCOM 2019: 831-838. University of Žilina. May 29-31, Nový

Smokovec, Slovak Republic. ISSN: 2352-1457. DOI: https://doi.org/10.1016/j.trpro.2019.07.117.

28.

Lack Tomáš, Juraj Gerlici. 2017.

„Integration methods for rail vehicle ride dynamics solution

assessment“. In: XXIII Konference s

mezinarodni ucasti: Soucasne problemy v kolejovych vozidlech/ 23rd Conference:

Current Problems in Rail Vehicles 2017: 217-234. Univerzita Pardubice.

September 20-22. Ceska Trebova, Czech Republic. ISBN: 978-80-7560-085-1.

29.

Kurčík Pavol, Juraj Gerlici,

Tomáš Lack, Andrej Suchánek, Jozef Harušinec. 2019.

„Innovative solution for test equipment for the experimental

investigation of friction properties of brake components of brake

systems“. In: 13th International

Scientific Conference on Sustainable, Modern and Safe Transport TRANSCOM 2019:

759-766. University of Žilina. May 29-31, Nový Smokovec, Slovakia. ISSN:

2352-1465. DOI: https://doi.org/10.1016/j.trpro.2019.07.107.

30.

Lack Tomáš, Juraj Gerlici, Pavol

Šťastniak. 2019. „Wheelset/rail geometric characteristics and

contact forces assessment with regard to angle of attack“. MATEC Web of Conferences 254. ISSN:

2261-236X. DOI: https://doi.org/10.1051/matecconf/201925401014.

31.

Nadal Joseph. 1908. Locomotives

a Vapeur, Collection Encyclopedie Scientifique, Biblioteque de Mecanique

Appliquee et Genie. Vol. 186. Paris.

32.

Gerlici Juraj, Rostyslav Domin, Ganna Cherniak, Tomas

Lack. 2017. „Calculated estimation of railway wheels equivalent conicity

influence on critical speed of railway passenger car“. In: XXII Slovak-Polish Scientific Conference on

Machine Modelling and Simlations MMS 2017. University of Zilina, Zilina,

Slovak Republic. 05-08 September 2017, Sklene Teplice, Slovak Republic.

33.

Lack Tomas, Juraj Gerlici. 2017. „The assessment of

the intergration methods for the rail vehicle ride dynamics solution“. In:

XXII Slovak-Polish Scientific Conference

on Machine Modelling and Simlations MMS 2017. University of Zilina, Zilina,

Slovak Republic. 05-08 September 2017, Sklene Teplice, Slovak Republic.

Received 14.01.2022; accepted in

revised form 06.03.2022

![]()

Scientific Journal of Silesian University of Technology. Series

Transport is licensed under a Creative Commons Attribution 4.0

International License