Article citation information:

Manafov,

E., Isgandarov, I., Huseynov,

F. Investigating the protection

system of electric motors based on its main working parameters. Scientific Journal of Silesian University of

Technology. Series Transport. 2022, 115,

63-74. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2022.115.5.

Elshan

MANAFOV[1],

Islam ISGANDAROV[2],

Farid HUSEYNOV[3]

INVESTIGATING THE PROTECTION SYSTEM OF ELECTRIC MOTORS BASED ON ITS MAIN

WORKING PARAMETERS

Summary. This research

was devoted to the creation of a protection system for electric motors used in

industry and transport, based on modern and traditional sensors. In the course

of operation, the malfunctions of electric motors have been investigated and it

was found that the accident modes occur mainly due to exceeding the permissible

values of the current, voltage and temperature parameters. Modern sensors of

current, voltage, and temperature have been compared and the most effective

ones were selected for use in electric motors. Based on reasoning from these

sensors, a protection system for a low-power electric motor has been developed

in the laboratory. In addition, in the Multisim application software package, a

simulation of the operation of the protection system at different voltage and

current values was performed, and a circuit of the sensor control unit and the

power source for powering the protection system was constructed. It has been

proposed to apply such a multi-parametric complex protection system for

electric motors, especially in transport.

Keywords: electric

motor, short circuit, overload, current sensors, voltage sensors,

temperature sensors, relay control, protection system

1. INTRODUCTION

In industry,

transport and various fields of technique, AC (asynchronous, synchronous) and

DC current machines are used. Currently, it is used more than asynchronous

machines that function in motor mode.

Regarding

the development of static converters, the capabilities of induction motors have

significantly increased. Thus, the possibilities of using these motors in

electric transport are considered more effective. In modern electric vehicles,

the short-circuit rotor asynchronous motor is mainly used as an electric motor.

As in all

electrical machines, there is always a high probability of occurrence of

abnormal and failure regimes and damages caused to induction motors. Therefore,

the working process and operating parameters of induction motors, especially in

railway transport, operating in difficult working conditions should be

constantly monitored.

One of the

most important issues in increasing the efficiency and durability of the power

supply system of vehicles is to provide reliable and accurate control of its

electrical parameters and optimal protection against voltage, current and other

parameters in case of accident operation.

From this

research, it has been identified that the application of modern electronic

sensors to control the technical condition of electric motors can provide a

more reliable mode of operation.

It is known

that the increase in load for one reason or the other during the use of

electrical equipment results in the failure of the device, and at best, damage

to the elements of the electrical circuit of the device. Faults of electrical

origin occur as a result of the effects of short-circuit currents, electric

arcs and sparks, reduced insulation resistance as well as other causes. This

shortcoming requires more cost and workers. In recent years, significant

research has been conducted to develop new methods required to monitor the

technical condition of electric motors, overcoming the shortcomings of

traditional methods. The incidence of motor failures or abnormal modes

increases with the complexity of its operating mode; therefore, it is essential

to develop more sensitive and modern protection systems based on the results of

additional failures and the results obtained.

Furthermore,

only the temperature parameter is used to conduct diagnostic monitoring of

traction electric motors - produced by some leading companies in the world -

operating in railway transport. The results of this research show that the

temperature parameter alone does not provide complete and perfect information covering

the technical condition of the motors and several parameters are required to be

added to these parameters in a row to obtain more accurate results. Hence,

complex diagnostic monitoring of electric motor and the creation of

multi-parameter protection systems based on it is actual [1-5].

2. STATEMENT OF THE PROBLEM AND SELECTION OF

SENSORS FOR A MULTI-PARAMETER PROTECTION SYSTEM

The

technical condition of electrical equipment is carried out primarily by

checking the level of reliability and parameters. It is possible to create more

reliable and sensitive protection systems from the information obtained from

the diagnostic monitoring of the technical condition.

To

ensure more stable working conditions, the reserve and reliability indicators

in the motors need to be considered. Suppose

two identical motors are used as a backup in a system. If one of them fails,

the other motor will run at full system load.

Suppose

two identical motors are used as a backup in a system. If one of them fails,

the other motor will run at full system load. The breakdown intensities of the

motors are the same and constant, l= l1 =l2 = 0,0005 1/s. In this

case, it is demanded to identify the exponential law of the probability of

proper operation of the motor at t = 400 hours.

Since the

motors are of the same type, the probability of a malfunction is as follows:

![]() (1)

(1)

According

to the data, the average operating time of the system is calculated as follows:

![]() (2)

(2)

To

increase the probability of proper operation of the electric motor, it is

necessary to ensure its protection against jumps and possible accidents during

the transition process.

Acute

voltage fluctuations, current overloads, short circuits, temperature changes,

etc. in such cases, the establishment and application of a multi-parameter

protection system to prevent equipment, source and load failures are of

particular importance.

During

the operation of electric motors, non-standard and possible accident cases can

be divided into the groups stated below:

• Abnormal

and accident modes occurring in the network (voltage above or below the nominal

value, frequency change, etc.)

• Non-standard currents and accidents

(inter-phase short-circuits in three-phase motors, breakage in stator or rotor

windings, leakage of insulation due to temperature rise caused by overload or

short-circuit currents, etc.)

Special protection devices are developed and applied to protect motors

from damage in unacceptable and accident modes. As it is known, a short-term decrease in voltage leads to a

decrease in the torque of electric motors used in transport. After the voltage

is restored, the motor restores its torque and returns to the nominal operating

mode. In this case, the value of the current required by the motor increases

sharply, which, in turn, can lead to the activation of the protection. The

setting parameters of the protection installed in the electric motor should be

selected so that the protection does not start and turn on the motor circuit

when the short-term voltage drops. For this, special attention should be given

to the selectivity of the security system.

In addition to the current and voltage parameters, one of the other main

parameters subject to protection is the operating temperature of the windings.

It is unacceptable to increase the temperature in the windings. If the

operating temperature of the motor windings exceeds the +10oC heat limit for any period of time, the

insulation of the stator and rotor windings is reduced by half the service

life.

It

is known that there are plenty of sensors based on various physical effects

that control the values of current and voltage: resistive, inductive and

capacitive sensors based on Ohm's law; transformer sensors based on Faraday's

electromagnetic induction law; voltage and current sensors based on the

Holl’s effect, and traditional voltage and current sensors based on other

effects [1, 6, 7].

At

the same time, there are modern sensors based on the application of Rogovsky

winding, electro-optical and magnetic-optical effects intended for non-contact

measurement of high voltages and currents.

Resistors,

transformers and Holl-effect sensors are mainly used to measure the electrical

parameters of modern locomotives used in railway transport.

Resistive

sensors are simple and economical, the principle of operation is based on the

direct proportion of the voltage across the reference resistor connected in

series with the load in the current circuit (Ohm's law), which can be used to

measure direct and alternating currents.

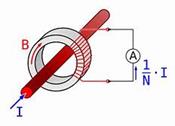

The

external appearance and connection diagram of different types of widely used

current sensors are shown in Figure 1, and the constructive and principle

diagram of the voltage sensors are shown in Figure 2.

a)

b)

b)

Fig. 1. Constructive and principle scheme

of current sensors:

a) Current transformer; b) Rogowski winding

In

the laboratory, a current transformer was used to control the current value in

the protection system designed for a low-power asynchronous motor. In

high-power motors, the introduction of the Ragowsky windings is considered to

be more promising than the current sensors [8].

Voltage

sensors based

on electrical, electromagnetic, electromechanical, electro-thermal,

electro-optical and other similar physical effects are widely used in

theoretical and practical research.

The

measurement procedure, which is the selection of the appropriate type of sensors,

is determined by the

type and level of voltage. It is important to amplify the signals to record low

voltages in the measurement circuit and reduce the received signals to an

acceptable level at high voltages [9-11].

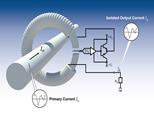

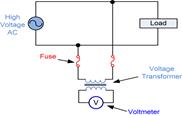

Voltage

dividers (resistive, capacitive and inductive), voltage transformers,

electronic voltage sensors, etc. are generally used as voltage sensors (Figure 2).

The

use of voltage transformers for measuring high voltages is considered more

expedient.

A resistive divider was used to control the

voltage value in the protection system designed for the low-power electric

motor. The resistive divider is considered simpler and technically more

economical.

Voltage

transformers are often used as voltage sensors in high-power motors. Due to the

large dimensions of voltage transformers, it is more expedient to use a

resistive shunt and a resistive divider as voltage sensors, where possible [12,

13].

a)

b)

b)

Fig. 2. Constructive and principle scheme of

voltage sensors:

a) resistive shunt; b) voltage transformer

Several

methods are used to measure temperature. These include fiber-optic temperature

sensors, electrical resistance thermometers, thermographic methods,

thermocouple-based temperature sensors, etc. (Figure 3).

As

a contact temperature sensor for determining the temperature value in

high-powered motors, the thermocouple is considered the most suitable.

The

main advantage of a thermocouple-based module sensor is the transmission of a

signal with a direct relay output. Based on the signal received from the

sensor, it is possible to both protect the motor and perform diagnostic

analysis of the recorded data, as well as set up special alarm systems by displaying

the data on special displays. Thanks to this, it is possible to ensure a more

reliable and stable operation of the motor.

Fig. 3. Constructive and principle scheme

of temperature sensor

Experiments were carried out on the electric motor

according to the three important parameters mentioned above, and a protection

system based on automatic control with relay output was installed. The

operation of the relay is determined by the electrical signal received from the

sensors. Based on the

electrical signals, in any abnormal and accident situation, the relay motor controlled by the protection system is

disconnected from the mains. MLE00137 of type relay was used to protect the

motor (Figure 4).

Fig. 4. MLE00137 type protection relay

This

type of relay is distinguished by its compactness, large process switching

capabilities, start-up speed, etc. This relay is able to provide normal

operation when the supply voltage of the working winding is in the range of

6-15 V.

3. MAGNETIC FIELD MEASUREMENT AND OUTPUT SIGNAL ANALYSIS

In

laboratory conditions, an experimental stand built upon a low powerful motor

was developed to simulate malfunctions that may occur in motors and control the

changes occurring in electrical parameters.

One of the most modern

and promising methods intended for diagnosing motor malfunctions and building a

protection-warning system based on this is the measurement and spectral

analysis of the magnetic field.

The results of the analysis show that the defects

and malfunctions in the electric motor have a significant effect on the

spectrum of the electromagnetic field generated outside it. By continuously

monitoring the magnetic aura of the motor in working conditions, it is possible

to determine the change of some parameters and create special protection and

warning systems based on the results obtained. For example, overload, increase

and decrease of voltage, change of current frequency, etc.

In

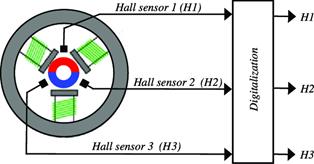

research, the use of a Hall sensor as a sensor to allow non-contact diagnostics

without interfering with motor design is preferred. Thus, this sensor can be

considered one of the most informative sensors allowing accessing the condition

of the motor by monitoring the electromagnetic spectrum.

In experimental research, the use of the KY-024 Hall sensor, which is less sensitive to external influences, was

preferred. The connection scheme and design structure of these types of sensor

is given in Figure 5.

The recorded oscillograms of the magnetic field

change in different modes of the electric motor studied using the KY-024 sensor

are given in Figure 6.

As seen

from the analysis of the oscillograms, in normal, failures or defects, overload

and other conditions, the magnetic field around the electric motor changes with

a big difference. Thus, based on the recorded data, it is possible to create a

modern protection-warning system by diagnosing the motor while at the same time

analyzing the signals at the output of the sensor.

4. MODELING OF THE MULTI-PARAMETER PROTECTION SYSTEM

In

reality, the development and implementation of a working version of the system

that can perform the above functions is accompanied by many technical problems.

Therefore, since modern applications are more accessible for individual and

complex simulation of functions, it is more advantageous to develop an

imitation model of the system through these programs. This, in turn, allows the

creation of a working model based on an imitation model of the system in

research and production facilities, which allows one to design a real prototype

of the system. In our research, based on the Multisim program, an imitation

model of the device was developed, protecting against short circuits, overloads,

as well as drops in voltage and overvoltage in the phase of the motor powered

by an electric power source.

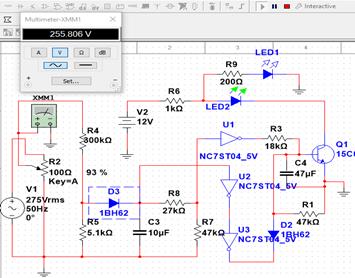

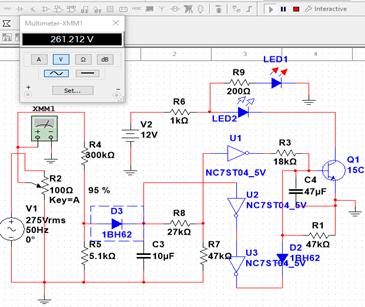

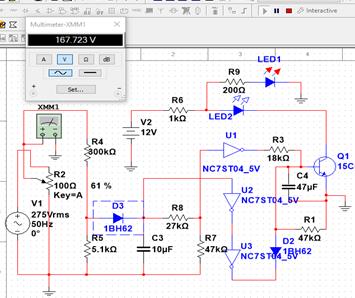

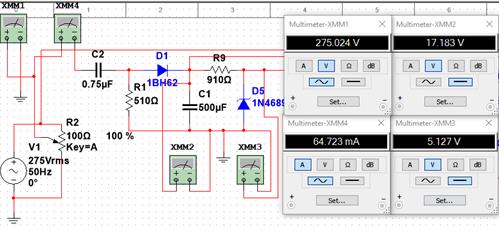

Relay

control is applied at both high and low voltage limits at specified values. In

the Multisim program, the protection circuits are built and modeled according

to the voltage limit. Schematics of protection activation at normal, high and

low voltage values are shown in Figures 7, 8 and 9. The green LED turning on

indicates that the voltage is within the normal range. While, in abnormal

modes, the red LED turning on indicates that the mains voltage has exceeded the

allowable limit.

Fig. 5. Traditional connection scheme and constructive descriptions

of the Hall sensor

a)  b)

b)

Fig. 6. Oscillograms of the motor

magnetic field: a) in normal operation; b) in overload

Fig. 7. Electrical circuit of the protection device

at the range of

normal operating voltages (168-260 V)

Fig. 8. Electrical circuit of

the protection device at the value of

the voltage above the nominal (Uin > 260 V)

Fig. 9. Electrical circuit of the protection device at a voltage

below the nominal value (Uin <168 V)

The current protection ensures the opening of the

motor from the food source by activating the relay at the limits of the current

above the specified values. A resistive shunt-based protection circuit was used

to simulate current protection in Multisim, and the current variation in the

intended range was simulated by applying an adjustable voltage to the input of

the circuit. The simulation results for the current performed in Multisim are

given in Figures 10 and 11.

Fig. 10. Electrical circuit of the protection device at the nominal

value of current

The

rated motor current is 0,55 A at 220 V. In our case, the critical value of

overloading, that is, the minimum value of the current required for the

protection of operation, is 0,9 A.

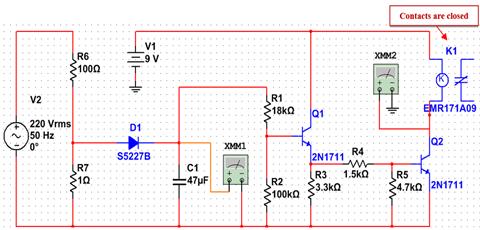

Built on the logic elements of the protection

system, a second transformless unit was developed to provide the nominal 5 and

9 V supply voltages required to power the electronic control unit for voltage

limits, transistor control unit for current limits, temperature protection unit

and output relay unit. An autotransformer was used to obtain a controlled

voltage value in laboratory conditions.

Fig. 11. Electrical circuit of the protection

device during accident operation

(short circuit or allowable value overload)

As mentioned, the second power supply of the unit

is for the power supply of sensors of the voltage, current and temperature also

of the control and protection system. Based on the transformerless power supply

circuit for the power supply of the protection system, the input voltage is 170

– 275 V, the output voltage is 5,1 V, the relay circuit is 7,5 – 12

V, and the total current required by the parametric stabilized power supply is

40-65 mA. Since there is no autotransformer in the Multisim software base, the regulated voltage is supplied to the

circuit via a potentiometer.

For sufficient load capacity of the power supply,

it is possible to use a transistor in the output circuit of the stabilizer as

an amplifier. Since the

base-emitter junction of the transistor has a voltage drop of 0,7 – 0,8

V, a stabilitron with a stabilization voltage of 5,6 – 5,7 V should be

selected to provide 5 V at the output. For the selected stabilitron to operate

in stabilization mode, its current in the range Ist = 3 – 50

mA, as well as the current of the base circuit and stabilitron together can be

selected 10 - 15 mA, given that the rated voltage of the transistor is higher

than 50 and the current at the output of the transistor is less than 100

– 200 mA.

The type of relay designed to replace the power

chains of the selected relays and powerful analog motors can normally operate

at wide voltages (in this case, 7 – 15 V), thus, stabilization is not

required for the relay power circuit. If necessary, the same stabilization

scheme can be applied.

A protection

system based on the relay control was installed and experiments were performed

on the motor to control the temperature parameter. The normal temperature of

the motor windings is identified using the insulation class. Traction electric

motors operated in most modern locomotives used in railway transport are

equipped with C-class insulation (200![]() C and above).

C and above).

(3)

(3)

·

![]() –

operating temperature of the protection system;

–

operating temperature of the protection system;

·

![]() –

normal motor operating temperature;

–

normal motor operating temperature;

·

![]() –

reconnection temperature;

–

reconnection temperature;

Fig. 12. Electrical circuit of the second power supply of the

protection device

To connect the

protection system (opening the motor) in the motor, which is the object of

study, the temperature of the windings should reach ![]() . These temperature values were conditionally taken

for the experiments. To restore the operation mode of the motor started through

protection, the temperature of the windings must be conditionally lowered to

the reconnection temperature value

. These temperature values were conditionally taken

for the experiments. To restore the operation mode of the motor started through

protection, the temperature of the windings must be conditionally lowered to

the reconnection temperature value ![]() . When the winding temperature cools down to normal

operating temperature (that is, reconnection temperature), the relay restarts

the motor.

. When the winding temperature cools down to normal

operating temperature (that is, reconnection temperature), the relay restarts

the motor.

A

modular thermocouple was used to determine the temperature of the motor

windings. The input of the module is supplied with a constant supply voltage of

9V. The output terminals are similarly connected to the motor and relay. The

thermocouple transmits the signal to the module, where it compares the opening

temperature with the normal temperature and sends a pulse to the relay. The

relay turns on the motor following the received impulse or restarts the motor

with protection.

5. CONCLUSION

Thus, in this research, the faults of the electric motor were

investigated and it was determined that the accident modes occur mainly due to exceeding the permissible values of current,

voltage and temperature parameters. Further, modern current, voltage, and

temperature sensors were

compared and those with the best performance for use in electric motors were

selected. According to the mentioned main parameters, the main control and

power supply blocks of the protection system were analyzed in the Multisim

application program and a model of the system providing complex protection

in the laboratory was practically established.

Based on theoretical and practical research, it can be assumed that it

is possible to show the warning signals on the appropriate display by

protecting the temperature, voltage and current of electric motors used in

transportation and industry and transmitting also the results sent to the relay

control circuit and the central control station.

Having applied the modern sensors we offer, it is possible to ensure a

stable operating mode of electric motors assisted by a complete multi-parameter

protection system.

References

1.

Ferreira Fernando

J.T.E., André M. Silva, Aníbal T. de Almeida. 2018.

“Single-Phasing Protection of Line-Operated Motors of Different

Efficiency Classes”. IEEE

Transactions on Industry 54(3).

2.

Karpavičius

Paulius, Vytautas Ostaševičius, Vytautas Jūrėnas, Jolantas

Baskutienė. 2017. „Self-powered wireless sensor system application

for cutting process control”. Mechanika

23(3): 456-461.

3.

Kozłowski E., K. Antosz, D.

Mazurkiewicz, J. Sęp, T. Żabiński. 2021. „Integrating advanced measurement and signal processing for

reliability decision-making”. Eksploatacja

i Niezawodnosc – Maintenance and Reliability 23(4): 777-787.

4.

Mazurkiewicz D.

2014. „Computer-aided maintenance and reliability management systems for

conveyor belts”. Eksploatacja i Niezawodnosc – Maintenance and

Reliability 16(3): 377-382.

5.

Vaičekauskis M.,

R. Gaidys, V. Ostaševičius. 2013. „Influence of boundary

conditions on the vibration modes of the smart turning tool”. Mechanika 3: 296-300.

6.

Dickinson R., S.

Milano. 2002. “Izolated Open Loop Current Sensing Using Hall Effect

Techn”. In: Optimized Magnetic Circuit. Allegro

MicroSystems, Inc.C.NH, USA. P. 1-12.

7.

Jianghua Feng,

Junfeng Xu, Wu Liao, Yong Liu. 2017. “Review on the Traction System

Sensor Technology of a Rail Transit Train”. Sensors 17(6): 13-26.

8.

Данилов А.Б. 2004.

“Современные

промышленные

датчики

тока”. Современная

электроника

10: 26-28. [In Russian: Danilov A.B.

“Modern industrial current sensors”. Modern electronics].

9.

Bayrak M. 2002.

“A New Digital Relay for Generator Protection Against Asymmetrical

Faults”. IEEE Trans. On Power

Delivery 17(1): 54-59.

10. Jose E.D., T.B. Roy, C. Chai, L. Yu. 1995.

“Stall Protection of Large Induction Motors”. IEEE Transactions on Industry Applications 31(5): 1159-1166.

11. Novak T., A.L. Morley, C.T. Frederick. 1988.

“Sensitive Ground-Fault Relaying”. IEEE Transactions on Industry Applications 24(5): 853-861.

12. Paoletti G.J., A. Rose. 1989. “Improving

Existing Motor Protection for Medium Voltage Motors”. IEEE Transactions on Industry Applications

25(3): 456-464.

13. Zocholl S.E. 1989. “Integrated and Protective

Relay Systems”. IEEE Transactions

on Industry Applications 25(5): 889-893.

Received 07.01.2022; accepted in

revised form 03.03.2022

![]()

Scientific Journal of Silesian University of Technology. Series

Transport is licensed under a Creative Commons Attribution 4.0

International License