Article citation information:

Stanik,

Z., Kubik, A., Hadryś,

D., Csiszár, C. Methods for

assessing the technical condition of bearing hubs in means of transport. Scientific Journal of Silesian University of

Technology. Series Transport. 2021, 113,

191-204. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.113.15.

Zbigniew

STANIK[1], Andrzej KUBIK[2], Damian HADRYŚ[3], Csaba

CSISZÁR[4]

METHODS FOR ASSESSING THE TECHNICAL CONDITION OF BEARING HUBS IN MEANS

OF TRANSPORT

Summary. This article

presents two methods of testing bearing hubs, which may supplement the existing

subjective and unreliable methods of diagnostics of rolling bearings used in

wheel bearing hubs of motor vehicles and other means of road transport. One of

the most important elements responsible for the safety of a vehicle is the

bearing hub. Regular monitoring of the technical condition of bearings should

become an obligation at vehicle inspection stations when carrying out a

technical inspection of a vehicle, authorising it to travel on public roads.

This article presents the results of vehicle tests with signs of damage to

rolling bearings, using two test stands: one on which the dynamic balancer

acted as a device for accelerating the wheel, and the other, which was designed

as a test dedicated to automotive rolling bearings, where a dynamic weighbridge

was used as the wheel drive, made it impossible to test the wheel at lower

rotational speeds. The newly designed and manufactured bearing testing device

eliminates the disadvantages of the previous stand, and additionally, enables

the measurement of a fully loaded bearing hub, which enables the simulation of

real operating conditions on the bearing hub.

Keywords: vibration

diagnostics, bearing, wear, means of transport

1. INTRODUCTION

Increasing technological progress,

growing expectations of users and standards related to environmental protection

are one of the reasons for the growing use of rolling bearings in means of

transport. However, the degree of complexity of the construction of means of

transport is increasing, which in turn causes the extension of repair and

maintenance procedures, making access to bearing hubs more difficult compared

to the previous structures [1-3]. Often, rolling bearings, for example, in

automotive vehicles, despite a relatively low price, can cause damage to other

components and entire components due to failure, generating significant repair

costs. The significant function of transport means, including motor vehicles,

should also be considered in the entire logistics process aimed at moving

people and goods among other things. Thus, the reliability of the means of

transport has a great influence on the proper functioning of the transport.

Subsequently, breakdowns of motor vehicles caused by damage to rolling bearings

are often surprising, unexpected, disrupting the transport cycle. Therefore, it

is necessary to use reliable methods for assessing the technical condition of

rolling bearings used in road transport [4, 5].

The widespread use of rolling

bearings in the construction of machines and means of transport has many

advantages. The main advantages of rolling bearings are:

● low

movement resistance, which is especially important during start-up,

● standardising

the basic dimensions of the bearings, which facilitates their practical

application,

● compactness

of bearing hubs structure,

● motion

stability at low speeds,

● giving off a small

amount of heat,

● structural

materials of the shaft do not have a significant impact on the durability of

bearings and their functioning,

● the

amount of lubricant required is small, which usually makes bearing

maintenance-free.

Rolling bearings also have

disadvantages, including:

● the

need for high-quality steel susceptible to cracking and chipping,

● using specialised procedures related to bearing assembly,

● the

need to use specialised devices to prevent dirt,

● sensitivity

to lubricant contaminants, which results in repeated shortening of durability

[4-7].

One of the drawbacks that deserves

special attention is the generation of mechanical vibrations through bearing

hubs equipped with rolling bearings. This phenomenon is closely related to the

bearing geometry and the structural materials from which they are made.

However, the parameters of generated vibrations, after registration and

appropriate analysis, may become the basis for diagnosing the technical

condition of rolling bearings [8-12]. This method is used to diagnose other

elements in machines, including cars [13-18].

Automotive manufacturers do not

specify procedures or time periods for reviewing or replacing most rolling

bearings, including bearings fitted in car wheel bearing hubs. Vehicle control

stations and car services do not have a highly specialised

diagnostic procedure for diagnosing automotive rolling bearings. They refer

only to unreliable organoleptic methods consisting of auscultation of the

diagnosed placenta with or without a stethoscope. It is worth mentioning that

periodic rolling bearing diagnostics is regularly used in the industry,

especially concerning stationary rotor machines. However, it cannot be used

directly in motor vehicles, due to their completely different nature of

functioning associated with mobility, which often forces operation in transient

states.

This article presents original

methods for assessing the technical condition of rolling bearings using two

test stands.

2. DIAGNOSTICS OF ROLLING BEARINGS

The basic symptom related to the

functioning of rolling bearings is:

● generating noise

(both in the acoustic band and outside it),

● generating vibrations

in a wide frequency band,

● generating heat

● generating

electromagnetic field interference,

● the

appearance of wear products (for example, in a lubricant),

● degradation

of the internal structure of the material in the form of, for example,

corrosion, microcracks,

● the

state of cooperating surfaces of elements of tribological

pairs [19-21].

Rolling bearing diagnostics can be

carried out based on their observation and analysis. Considering the symptoms

described, they determine the diagnostic methods for disassembly and without

disassembly.

Treating the rolling bearing as a

mechanical vibration generator, the most common diagnostic method is vibration

diagnostics, based on the recording of time courses of parameters describing

the generated vibration. Obtained and properly processed time courses are used

to build measures of the technical condition of rolling bearings. The advantage

of this method is its assembly-free nature and a large amount of information in

a relatively short unit of time.

The course of rolling bearing damage

over time can be divided into three stages [21, 22]:

● noise

stage - the broadband nature of the acceleration of vibrations associated with

the normal operation of the bearing is narrowed to frequencies associated with

the operation of individual bearing components. However, the maximum

acceleration of housing vibrations takes on large values, which indicates the

need to replace the bearing with new ones.

● vibration

stage - the progressive degradation of the surface layer of rolling elements

results in a significant increase in the actual values of housing vibration

acceleration.

● thermal stage - there

is avalanche wear of the surface of the elements, which results in their

deformation and increasing friction is generated, causing a very high

temperature of the bearing hub, followed by failures.

Vibration diagnostics of rolling

bearings makes it possible to determine the suitability of a rolling bearing

for further operation at the noise stage.

This method clearly surpasses the

subjective and unreliable organoleptic methods currently used in the field of

vehicle service, which consists of detecting possible play or auscultation of

the bearing hub.

However, using this method entails

the need to consider many individual design features, including not only the

hub itself but also the entire vehicle, with particular emphasis on the

propulsion and running gear [23, 24]. Specialised

equipment is also required, for example, a device for accelerating non-driven

road wheels and an apparatus that records the signal from vibration

acceleration sensors.

The use of vibroacoustic methods allows for objective results, and the effectiveness of this

method depends on the correct selection of measuring points and ensuring the

right measurement conditions. The design of rolling bearings causes the

detection of damage to individual components of the bearings to cause another

disturbance in the vibroacoustic signal. In the frequency spectrum,

the local damage to each component corresponds to a different component, so

that spectral analysis can answer not only whether damage has occurred but also

which bearing element has been damaged [5, 21].

From an operational point of view,

however, it is more important to detect damage in the early stages of its

development or excessive wear than determining which bearing component has been

damaged. Observing the frequency spectrum for changes in the frequency

amplitudes of the characteristic bearings may enable this task. The repeat

frequencies of the damage-induced impressions are determined by formula 1 to 3

[5, 21].

Failure of the current element

causes a pattern to occur in the frequency component spectrum [5, 21]:

![]() (1)

(1)

where: D – bearing split diameter, d –

rolling element diameter, fr –

relative frequency of rotation between inner and outer raceways, β –

bearing operating angle.

The frequency caused by damage to

the inner raceway can be recorded with the formula [5, 21]:

![]() (2)

(2)

where: e – number of elements.

The frequency caused by damage to the outer raceway can be determined by the formula [5, 21]:

![]() (3)

(3)

Determining the amplitudes of characteristic frequencies and comparing them with the symptom database or with the results of measurements previously performed on the test subject allows one to determine whether there have been adverse changes in the technical condition.

3. METHODS OF DIAGNOSTIC OF ROLLING

The results of the conducted tests

indicate that it is possible to diagnose rolling bearings used in various means

of transport. The methods for

diagnosing rolling bearings using two test stands are presented in this

section. The tests were carried out on an Opel car model Corsa

D, in which various symptoms indicating damage to the wheel hub bearing could

be observed while driving. The research used vibroacoustic

measurements, which were then subjected to appropriate transformations and

analysis. For signal recording, a manual LMS SCADAS XS data acquisition module

was used. This enables the recording of 6 channels with a sampling frequency of

51.2 kHz and 3 vibration acceleration sensors. Signal transformations and

analysis were performed using the Matlab 2019b computing environment using the Signal Processing

Toolbox. For measuring the rotational speed of the wheel, a SELS

PCID-8ZP induction sensor with an operating range of

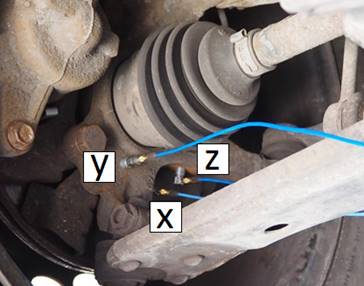

8 mm was used. Figure 1 shows the view of the mounted vibration acceleration

sensors in the test vehicle, together with the marking of the axis measurement

directions by the vibration acceleration sensors. Regardless of the test method

used, the vibration acceleration sensors remained mounted in the same places.

Fig. 1. View of placing vibration

acceleration sensors on the wheel hub of the tested vehicle

The methods for diagnosing rolling

bearings using two test stands are presented thus; The

first test post was the position described in Section 3.1. – dynamic balancer of the vehicle wheel. While the second test

bench was the position described in Section 3.2. – prototype

stand – stand designed for testing vehicle wheel bearing hubs.

3.1. Diagnostics of rolling bearings implemented with the use of the vehicle

wheel dynamic balancer

During the bench tests, the car was

raised on a two-column lift. A dynamic balancer was used to accelerate the

wheel, which enables acceleration of one wheel for two different values of

wheel speed. Figure 2 shows the performance of tests while accelerating the

wheel with a dynamic wheel balancer.

Fig. 2. Measurement stand during tests

During the tests, vibration

accelerations in three directions around the bearing hub were recorded. The

vibration signals and the rotational speed signal were recorded with a sampling

frequency of 51.2 kHz and stored in a digital form on the memory card of the

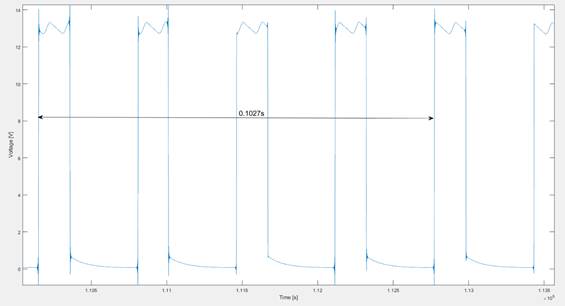

data acquisition device. Based on the mileage of the wheel speed signal, the

actual wheel speed was calculated. The wheel speed time course is shown in Figure

3. The time of execution of 4 full turns of the wheel was = 0.1027 s.

Fig. 3. Time course of the wheel speed signal - dynamic

balancer

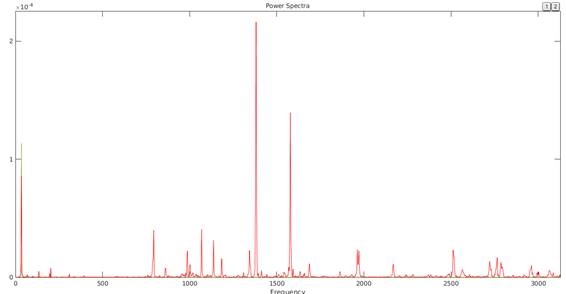

A dynamic balancer accelerated the

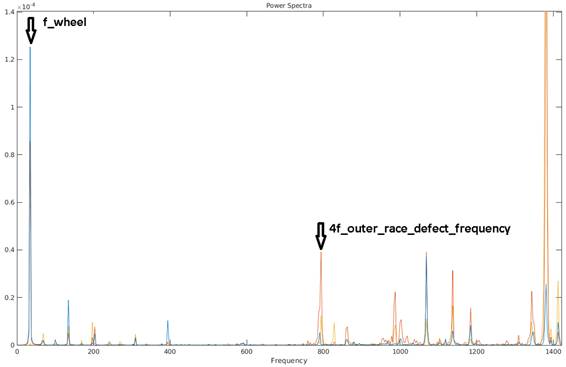

wheel of the vehicle to a constant speed of 129.6 km/h, which corresponds to f_wheel = 37.5 Hz. Then, a spectral analysis of the

recorded signals was performed to search for frequencies characteristic of

damage to the individual elements of the bearing hub. Figure 4 presents an

analysis of the time-frequency waveforms of recorded signals.

Fig. 4. Analysis of vibration signal waveforms of a

wheel with a damaged rolling bearing - dynamic balancer – where: blue

line - X-axis, red line - Y-axis, yellow - Z-axis

Based on the geometrical parameters of the bearing, the bearing failure frequency was determined for a bearing failure frequency of f_wheel = 37.5 Hz. Based on formulas 1 to 3, the following frequencies were calculated:

●

wheel speed frequency 37,50 Hz,

●

inner race defect frequency 307,54 Hz,

●

outer race defect frequency 217,46 Hz,

●

cage defect frequency 21,97 Hz.

As seen, the 4th harmonic of the

outer track damage frequency changes depending on the measurement axis. The

highest amplitude values are assumed for the Y-axis, which corresponds to the

vertical displacement of the bearing hub. Then the same measuring procedure was

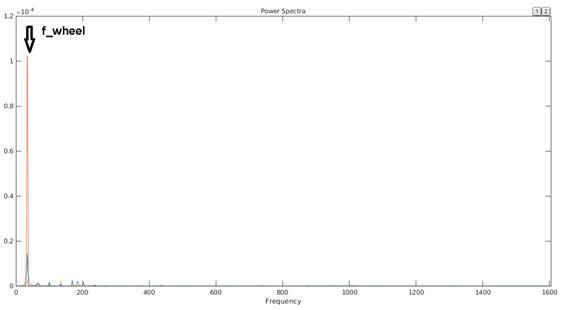

used for the bearing hub with the new bearing. The same analysis of the

recorded vibration signal was also made. The

obtained results are a reference for earlier measurements and analysis of

vibration signals of a bearing hub equipped with a worn bearing. Comparison of

the obtained results enables the construction of measures of the technical

condition of the tested bearing hub. Figure 5 shows the time-frequency course

of vibration accelerations for a new bearing.

Fig. 5. Analysis of time-frequency waveforms of

vibration signals of a wheel with a new rolling bearing – where: blue

line - X-axis, red line - Y-axis, yellow - Z-axis

Figure 6 shows a comparison of

time-frequency courses of damaged vibration accelerations and a new rolling

bearing, whose measurements were made for the Y-axis. As seen in Figure 6, the

analysis of the time-frequency waveform of vibration signals shows the

differences between a signal with a damaged bearing (red line) and a signal

recorded with a new bearing (green). For a bearing junction with a new rolling

bearing, the time-frequency spectrum has no higher component frequencies, and

none of the frequencies characteristic of damage to individual bearing

components occurs.

Fig. 6. Analysis of the time-frequency waveforms of the

road wheel - comparison of

a new and a damaged bearing - where green line indicates a new bearing,

red line indicates a damaged bearing

3.2.

Bearing diagnostics using a prototype stand dedicated to testing bearing hubs

Bench tests of the technical

condition of rolling bearings were carried out with the use of a typical

device, which is a dynamic wheel balancer. The dynamic wheel balancer has its

advantages, for example, ease of access and quick measurement. Due to the

limitations of the method presented in Section 3.1., a station for testing

rolling bearings of road wheels was designed and manufactured, which enables,

among others:

●

acceleration

and maintenance of constant speed of the road wheel in a wide range of

rotational speed,

●

measurement

of slip occurring between the wheel and the ground,

●

constant measurement of wheel pressure on the road.

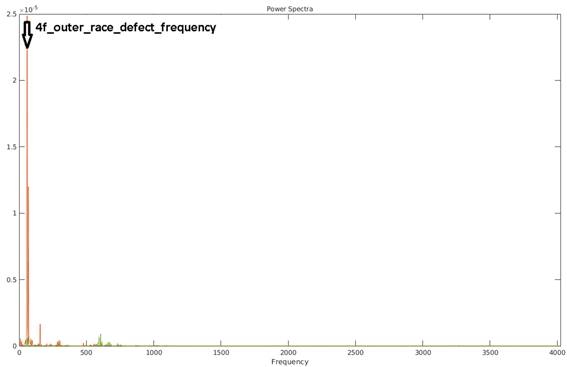

During the tests, acceleration of

vibrations in the three axis directions and rotational speeds of the road wheel

and the drum driving the wheel near the bearing hub were recorded. The wheel

pressure on the device was mapped according to real conditions. The road wheel

was accelerated to a frequency of 5 Hz, which corresponds to a speed of 17.28

km/h. Reducing the wheel speed results in the

elimination of higher frequency components and simultaneously reduces the

signal amplitude. Figure 7 shows a partial view of the station and the tested

vehicle.

Fig. 7. Prototype stand during tests of the technical

condition of

the road wheel bearing hub

Based on the pulse time

course determining the speed of the driven road wheel, the vehicle speed is

determined. The results of

the analysis in the form of time

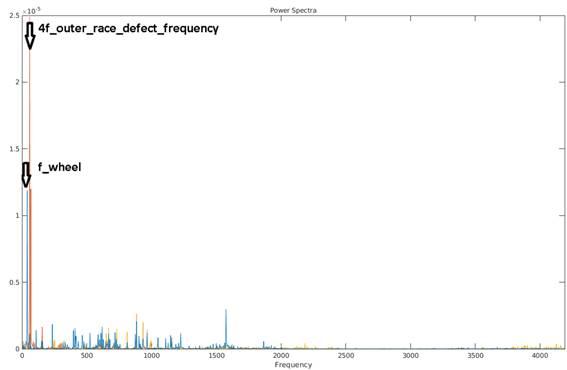

frequencies of wheel vibration signals with a damaged rolling bearing are shown in Figure

8.

Fig. 8. Analysis of time-frequency waveforms of

vibration signals of a wheel with

a damaged rolling bearing - prototype stand – where: blue line - X-axis,

red line - Y-axis, yellow - Z-axis

A peak can be observed at a

frequency of 29 Hz. For the tested bearing hub, based on formulas 1 to 3, the

frequency of damage to individual rolling bearing components is:

●

shaft speed frequency 5,00 Hz,

●

inner race defect frequency 41,01 Hz,

●

outer race defect frequency 29,00 Hz,

●

cage defect frequency 2,93 Hz.

This frequency corresponds to the

frequency of damage to the outer race of the road wheel bearing.

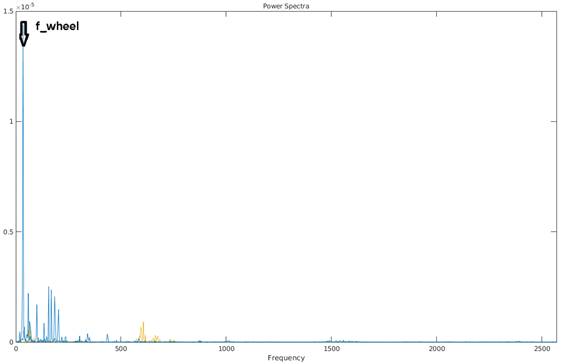

Thereafter, the damaged bearing hub

was replaced with a new one. The whole wheel bearing was tested again. The

result of the time-frequency analysis of the new bearing hub is shown in Figure

9.

Then, the results of the

time-frequency analysis of damaged and new bearings were compared, and the results are shown

in Figure 10.

As observed, the value for a damaged

bearing frequency = 29 Hz is 2.7x10^-5 m/s2

and is almost three times higher than for a new bearing. In

addition, there are higher frequency components for the damaged bearing that

are not present for the new bearing.

Fig. 9. Analysis of time-frequency waveforms of

vibration signals of a wheel with

a new rolling bearing-where: blue line - X-axis, red line - Y-axis, yellow -

Z-axis

Fig. 10. Analysis of the vibration time-frequency

waveforms - comparison of signals with new and damaged bearing - where green

line indicates a new bearing, red line indicates

a damaged bearing

4. SUMMARY

The testing methods of bearing hubs

presented in this paper may complement existing, subjective and unreliable

methods of rolling bearing diagnostics used in the bearing hubs of road wheels

of motor vehicles and other means of road transport. Bearing hubs are one of

the most important elements responsible for the safety of a motor vehicle.

Regular monitoring of the technical condition of bearings should become an

obligation at vehicle inspection stations when performing the technical

inspection of a vehicle entitling the vehicle to drive on public roads.

The methods for diagnosing rolling

bearings were presented using two test stands. The first test post was the

position described in Section 3.1. – dynamic

balancer of the vehicle wheel. The second test bench was the position described

in Section 3.2. – prototype stand – stand

designed for testing vehicle wheel bearing hubs.

The vehicle with symptoms of rolling

bearing damage was tested using two test stands. One, in which a dynamic

balancer was used as a wheel acceleration device, and the other, which was

designed as a dedicated test for automotive rolling bearings. The previous

stand, where a dynamic weighbridge was used as the wheel drive, made it

impossible to test the wheel at lower rotational speeds. It was impossible to

map real conditions, for example, those prevailing in urban conditions. In

addition, an error resulting from the acceleration of the road wheel itself was

introduced, because the accelerated wheel was a side part of the tyre. This type of acceleration introduces an additional

normal force in the direction of the rolling bearing. Thus, this type of error

may cause the generation of additional vibrations or damping of damage, which

will be the subject of further research.

The designed and constructed device

for testing bearings eliminates the previous disadvantages of the previous

stand. In addition, it enables measurement of a fully loaded bearing hub. This

allows simulation of the real conditions operating on the bearing hub.

Test results presented in this

paper, regardless of the method used, showed that the outer race of the rolling

bearing was damaged. Picture 11 shows the damage to the outer race of the

rolling bearing, which was detected with the help of the aforementioned testing

devices.

Fig. 11. View of

damage to the outer race of the rolling bearing of the tested vehicle

Comparing the results of both

methods, it can be concluded that the time-frequency waveforms of vibration

signals differ from the method used. Using the balancing method, additional

components are generated in the higher frequency range. These vibration signals

are levelled during tests in which a stand dedicated to tests of rolling

bearings of road wheels of means of transport was used.

References

1.

Randall Robert.

2011. Vibration-based Condition Monitoring: Industrial, Aerospace and

Automotive Applications. Chichester: Wiley. ISBN:

978-0-470-74785-8.

2.

Chiliński Bartosz. 2014. “The proposal of the bearing

arrangement to work in a swinging motion”. Mechanical Overview 1

(14): 15-18. ISSN 2354-0192.

3.

Figlus Tomasz. 2019. “A Method

for Diagnosing Gearboxes of Means of Transport Using Multi-Stage Filtering and

Entropy”. Entropy 21(5): 1-13. ISSN 1099-4300.

4.

Batko Wojciech,

Mikulaski Andrzej. 2002. „The use of wavelet

methods in the vibroacoustic monitoring systems of

the hoisting device bearing”. Diagnostyka 26: 7-12. ISSN

2449-5220.

5.

Cioch

Witold, Oskar Knapik, Jacek Leśkow. 2013. “Finding a frequency signature for a cyclostationary signal with applications to wheel bearing

diagnostics”. Mechanical Systems and Signal Processing 38(1):

55–64. ISSN 0888- 3270.

6.

Dąbrowski Zbigniew, Jacek Dziurdź.

2007. “New concept of using coherence function in digital signal

analysis”. Machine Dynamics Problems 31(3): 25-31. ISSN 0239-7730.

7.

Deuszkiewicz Piotr, Stanislaw Radkowski. 2003. “On-line condition monitoring of

a power transmission unit of a rail vehicle”. Mechanical System

and Signal Processing 17(6): 1321-1334. ISSN 0888- 3270.

8.

Engel Zbigniew. 1981. Vibrations in technology. Wrocław: The Ossoliński

National Institute. ISBN

83-04-00646-4.

9.

Junsheng Cheng, Yu Dejie, Yang Yu. 2007. “Application of an impulse

response wavelet to fault diagnosis of rolling bearings”. Mechanical

Systems and Signal Processing 27(2): 920-929. ISSN 0239-7730.

10. Zhou

Tong, Yuan Li, Yijia Jing , Yifei Tong. 2021. “Bearing Fault Identification Based on Deep Convolution

Residual Network”. Mechanika 27(3): 229-236. ISSN: 1392-1207.

11. Wang Jingyue, Haotian Wang, Lixin Guo,

Diange Yang. 2018. “Rolling bearing

fault detection using autocorrelation based morpho-logical filtering and empirical mode decomposition”. Mechanika 24(6): 817-823. ISSN:

1392-1207.

12. Bensana

T., S. Mekhilef. 2016. “Numerical

and experimental analysis

of vibratory signals for

rolling bearing fault diagnosis”. Mechanika

22(3): 217-224. ISSN: 1392-1207.

13. Czech Piotr. 2011. „Diagnosing

of disturbances in the ignition

system by vibroacoustic signals

and radial basis function - preliminary research”. Communications

in Computer and Information Science 239: 110-117.

DOI: https://doi.org/10.1007/978-3-642-24660-9_13.

Springer, Berlin, Heidelberg. ISBN: 978-3-642-24659-3. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Modern transport telematics,

11th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 19-22, 2011.

14. Czech Piotr. 2013. „Intelligent

Approach to Valve Clearance Diagnostic in Cars”. Communications

in Computer and Information Science 395: 384-391.

DOI: https://doi.org/10.1007/978-3-642-41647-7_47.

Springer, Berlin, Heidelberg. ISBN: 978-3-642-41646-0; 978-3-642-41647-7. ISSN:

1865-0929. In: Mikulski Jerzy (eds), Activities of transport telematics,

13th International Conference on Transport Systems Telematics, Katowice Ustron, Poland,

October 23-26, 2013.

15. Czech Piotr. 2013. „Diagnosing

a car engine fuel injectors' damage”. Communications in Computer

and Information Science 395: 243-250. DOI: https://doi.org/10.1007/978-3-642-41647-7_30. Springer, Berlin,

Heidelberg. ISBN: 978-3-642-41646-0; 978-3-642-41647-7. ISSN: 1865-0929. In:

Mikulski Jerzy (eds), Activities of transport telematics, 13th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 23-26, 2013.

16. Graževičiūtė J., I. Skiedraitė, V. Jūrėnas,

A. Bubulis, V. Ostaševičius.

2008. „Applications of high frequency vibrations for surface milling”. Mechanika

1: 46-49.

17. Ubartas M., V. Ostaševičius, S. Samper,

V. Jūrėnas, R. Daukševičius.

2011. „Experimental investigation

of vibrational drilling”.

Mechanika 4: 368-373.

18. Ostaševičius V., V. Jurėnas, M. Žukauskas.

2014. „Investigation of energy

harvesting from high frequency

cutting tool vibrations”. Mechanika

5: 500-505.

19. Raymond A. Guyer. 1996. Rolling

Bearings Handbook and Troubleshooting Guide, Ohio: Taylor & Francis.

ISBN 97-80-801988-714.

20. Radkowski Stanislaw. 2008. “Vibro-acoustic

diagnostics of low-energy stage of failures evolution”, Proceedings of

the Institution of Mechanical Engineers Part G Journal of Aerospace Engineering

223: 589-597. ISSN 0954-4100.

21. Stanik Zbigniew. 2013. Diagnosing rolling bearings of motor

vehicles with vibroacoustic methods. Radom:

Scientific Publisher of the Institute of Sustainable Technologies - National

Research Institute. ISBN 978-83-7789-204-6.

22. Cempel Czesław. 1978. Applied vibroacoustics.

Warszawa: PWN. ISBN 83-01-09034-0.

23. Maláková Silvia, Matej Urbanský,

Gabriel Fedorko, Vieroslav Molnár, Samuel Sivak.

2021. „Design of geometrical parameters and kinematical characteristics of a non-circular

gear transmission for given parameters”. Applied Sciences

11(3): 1-23. ISSN: 2076-3417.

24. Maláková Silvia, Michal Puškár, Peter Frankovský, Samuel Sivák,

Maroš Palko, Miroslav Palko. 2020. „Meshing Stiffness - A Parameter Affecting the Emission of Gearboxes”. Applied Sciences

10(3): 1-12. ISSN:

2076-3417.

Received 08.09.2021; accepted in

revised form 13.11.2021

![]()

Scientific Journal of Silesian University of Technology. Series

Transport is licensed under a Creative Commons Attribution 4.0

International License