Article citation information:

Shpachuk, V.,

Chuprynin, A., Suprun, T., Kovalenko, A. Mechanical

interaction of the rail transport car and joint irregularity. Scientific Journal of Silesian University of

Technology. Series Transport. 2021, 113,

173-189. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.113.14.

Vladimir SHPACHUK[1], Aleksandr CHUPRYNIN[2], Tatiana

SUPRUN[3], Andriy KOVALENKO[4]

MECHANICAL INTERACTION OF THE RAIL TRANSPORT CAR AND JOINT IRREGULARITY

Summary. Mechanical

models of a transport system “carriage - track” while crossing a

joint irregularity are proposed. An investigation was conducted on the

peculiarities of static, shock and dynamic interaction between the four-axle

car and the track, considering tram wheelsets motion features over joint

irregularity. A method to solve the equations of a mathematical model of

static, shock and dynamic interaction is developed. Numerical analysis is used

to determine deflections of the facing rail under the first sleeper for each

phase of motion depending on motion phases, and car load and speed.

Keywords: railway

rolling stock, four-axle car, track, ballast, joint irregularity, trailing

rail, facing rail

1. INTRODUCTION

In the current state

of rail transport operating conditions, one should pay special attention to

improving its design, as well as improving the reliability and operational

properties of rolling stock. This is why in electric transport,

scientific and technical works and research related to solving problems,

devoted to the problem of ensuring the reliability of the tramcar-rail

complex are particularly important at the present stage of development. Thus,

scientific and technical papers and investigations that provide task solutions

devoted to the problem of ensuring the reliability of the tramcar-track

complex are particularly important in the electric transport area at the

current stage of development.

When a tramcar moves,

its components and assemblies are affected by the interaction forces that arise

between the cars and the trolleys, the trolleys wheel pairs and the upper

structure of the track. They change both in time and in direction. Problem

solutions related to the investigation of the practical application of the

mechanical interaction science of rolling stock and rail tracks significantly

affects the development of electric transport and the safety of railcars, as

well as on the capacity of stations, on the economy of maintenance of rolling

stock and rail tracks, conditions of overall cross-country ability of rolling

stock, etc. At the same time, the deformation characteristics of the ballast

layer under the rail supports (parameters of elastic and residual sediment)

ultimately regulate the technical resource and duration of its operation.

Practice shows that the greatest sediment of the ballast layer occurs in places

of butt irregularities under the first sleepers of the facing rail. This is

because these places of the rails are usually subjected to the greatest dynamic

load of the impact type.

Subsequently, investigations of the mechanical interaction processes in

the system «tramcar - track»

are becoming important, as well as establishing new regularities based on the

analysis results, noting the peculiarities of their static, impact and dynamic

interaction while considering the operating, design and mechanical parameters

of the tramcar and upper truck structure and motion phase of the tramcar

through joint irregularity.

2. LITERATURE

REVIEW AND RESEARCH OBJECTIVE

Currently, significant attention is given

to the development of the transport structure in many countries of the world.

In addition, funds are been invested into the track and railway rolling stock.

The world`s experience indicates mechanical complex`s «tramcar -

track» reliability and durability indicators to depend on

the characteristics of the joint operation of rolling stock and track, the type

of rolling stock, the type of rails and sleepers, and the operating conditions

of the mechanical system. It also depends on the ability to resist the

destructive effects of the resulting shock and vibration loads.

Furthermore,

it is known that the highest level of deposition of the ballast layer occurs

under the first sleeper of the facing rail. This is because the first sleeper

under the facing rail in these places usually experiences the greatest force

interaction between the tramcar and the upper structure of the track due to

their impact. Thus, the deflection of the facing rail under the first sleeper

is a significant indicator that corresponds to the features of mechanical

interaction of the receiving rail of the track when investigating static,

impact and dynamic interaction with the upper structure of the track in places

with isolated butt joints of the track.

Investigation analysis dedicated to the

mechanical interaction of a four-axle car and a rail track shows [1] that the

weakest link in the system is the isolated zones of the track joints. Further,

it is similarly known that the highest level of deposition of the ballast layer

occurs under the first sleeper of the receiving rail. This is because in these

places the first sleeper under the receiving rail usually experiences the

greatest force interaction between the tramcar and the upper structure of the

track due to their impact. Thus, the deflection of the receiving rail under the

first sleeper is a significant indicator that corresponds to the features of

the mechanical interaction of the receiving rail of the track in the investigation, static, impact and dynamic interaction

with the upper structure of the track in places with isolated butt joints of the

track.

In addition, the expediency of

considering the phases of movement through joint irregularity [2], as well as the stiffness characteristics

of the ballast layer of the track is emphasised. The issues of joint operation

of rolling stock and rail track are also analysed, determining the features of

their static [1, 3] and dynamic interaction [4] during the passage of joints by

the car.

Various factors that change

during the operation of the rail track make it necessary to apply an integral

model that considers various impact factors.

Thus, this research, devoted to the improvement of existing models of

interaction between the car and the upper structure of the track, is modern and

relevant.

The load of rolling stock

elements and the upper structure of the track determining the parameters of

durability in operation [5], the strength and rigidity of the track [6], are

conducted in the field. This together, affects the technical resource and

service life. Operational experience of rail transport shows that the

"car-track" indicators of reliability and durability in the

mechanical complex significantly depend on the features of the interaction

processes between the track and rolling stock and the operating conditions of

the system under consideration. In addition, this interaction affects the

ability of the system to withstand the destructive effects of the resulting

shock and vibration loads [7], which are cyclically repeated.

To analyse the mechanical

interaction of rolling stock and the upper structure of the track, it is

necessary to solve several related problems. Much attention is focused on these

issues and a sufficient amount of new research is emerging in this area.

2.1. Analysis of recent studies

Most scientific works are currently limited to the

consideration of individual parameters of the electric transport operation. To

ensure a reliable modelling, it is necessary to use the most generalised

approach from possible ones, which considers the totality and mutual influence

of various factors [8].

Improving the quality

and capacity of existing services and developing new infrastructure are essential

to meet the growing demand for high quality and reliable logistics of goods and

people. The efficiency and reliability of the path design are crucial for a

successful operation. Many modern rail track investigations focus on specific

aspects of design and operation, such as fatigue [7], ballast destruction [6],

ride comfort [1], noise or vibration [2].

Thus, some works [5], present the processes of mechanical

interaction in the "car-track" system, where they are considered only

taking into account the movement of the vehicle on non-jointed sections of the

track. Other works [7] do not observe the boundary conditions for the facing

rail. In practice, this does not correspond to the conditions of real

mechanical loading of a tramcar, sections of the trailing and facing rails.

Therefore, the values of the structural speed of rolling stock determined in

the studies are not sufficiently complete and needs to be improved.

Thus, there is a need to develop a sufficient and

easy-to-use model of the mechanical interaction of rolling stock and track.

Additionally, an analysis technique considers a rail car as a multidimensional

discrete one, and the upper structure of the track as a continuous system. In this

formulation, the characteristics of mechanical interaction in the

"car-track" system in the joint area will correspond to the actual

loading conditions.

2.2. Purpose and research objective

This

study investigates the mechanical interaction of the car and the upper

structure of the track for the improvement of the parameters of a

discrete-continuous system by rationally selecting and optimising the

parameters of its components. This will provide an additional impact on the

reliability and durability of the system through components that depend on the

parameters of dynamic interaction in the transport mechanical complex

"car-rail track on a section with isolated joint

irregularity".

Hereby, one can formulate

the following research task:

·

to create a method of sequential static-impact-dynamic calculation

of deflections of the facing rail under the first sleeper in the growth phase,

considering the phases of movement of the tramcar relative to the butt joint;

·

to study the influence of the phases of movement of the tramcar on

the height of the joint when varying the operational, structural and mechanical

parameters of the tramcar and the upper structure of the track;

·

to improve the dynamic model of deflections of the receiving rail

under the first sleeper in the growth phase, noting the characteristics of the

elastic suspension of the tramcar, the ballast layer, as well as the

quantitative parameters of the reduced masses of the wheels corresponding to

the phase of movement of the tramcar;

·

analyse the features of the influence of operational, structural

and mechanical parameters of the tramcar and the upper structure of the track

on the deflections of the receiving rail under the first sleeper in the growth

phase.

3. RESEARCH MODEL AND METHOD

A mechanical discrete-continuous model of a four-axle car

is considered. This can be a tramcar, a passenger or a freight car of a

railway transport. This takes into account the multi-factor influence of

structural, operational and mechanical parameters of the "car-rail track

on a section with isolated butt joint" system. These are car speed,

its loading, the conditions for connecting the facing and trailing rails to

each other through the butt rail cover, the rigidity of the ballast layer, and

others.

The phases of the car movement during static interaction

are determined as follows: in the first phase, all wheelsets are located on the

trailing rail, in the second phase – three remain on it, in the third

– two and in the fourth only one. At the same time, accordingly, the

number of wheels on the facing and trailing rails affect their static

deflections, that is, the height of the joint

irregularity that is created.

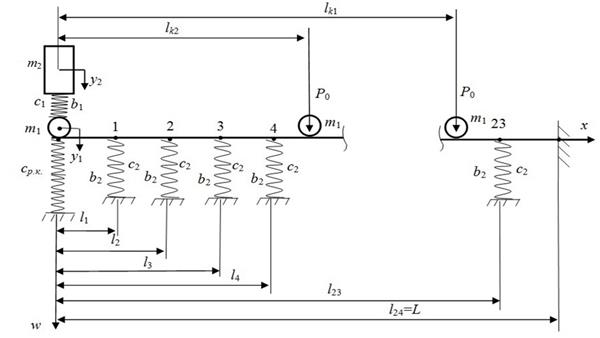

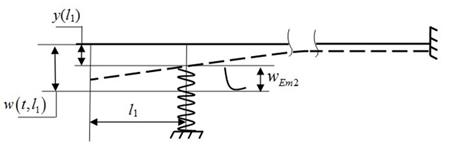

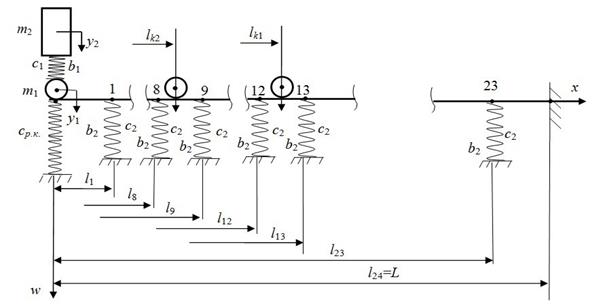

The calculated mechanical scheme

of the dynamic interaction processes of the facing rail with the vehicle in the

joint area on the example of the third phase of the car's movement is shown in

Figure 1. This scheme differs from the processes of static interaction, as well

as other phases of movement of the facing rail in conditions of dynamic interaction.

Currently, there is only one wheel on the trailing rail, and all three on the

facing rail.

Here c1,

b1 – suspension

stiffness and damping coefficient; c2, b2 – ballast stiffness and damping

coefficient; ![]() – stiffness

of the rail at its end; m1, m1

– reduced masses of the wheel and the car, considering the load; y1, y1 – displacement

of reduced mass of the wheel and the car;

– stiffness

of the rail at its end; m1, m1

– reduced masses of the wheel and the car, considering the load; y1, y1 – displacement

of reduced mass of the wheel and the car; ![]() ,

, ![]() – geometrical

coordinates of the elastic supports, as well as the

wheels of the first and second axles of the car.

– geometrical

coordinates of the elastic supports, as well as the

wheels of the first and second axles of the car.

Accordingly, the number of wheels on the facing rail

significantly changes its mechanical load relative to the oscillatory motion,

both relative to the car and the ballast layer.

When calculating deflections of a discrete-continuous

system, mechanical, geometric characteristics, static deflections, and

post-impact velocity are set for the receiving rail. Deflections of the system

are considered as a superposition of the first five eigenvalues of vibrations

of the receiving rail as a discrete-continuous mechanical system.

Fig. 1. Calculated mechanical scheme of dynamic interaction for

the facing rail during the first phase of the car motion

3.1. Static interaction

The essence of the static interaction of the car and the

rail track assumes the height determining of the joint irregularity by the

initial parameters method based on elastic lines of the facing and trailing

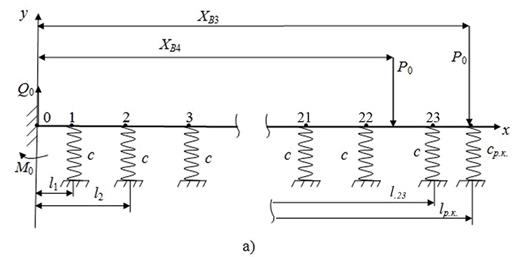

rails, which loading corresponds to all four phases of the car's movement.

In the static calculation of rail deflections, a model of a multi-span

beam is used on 24 elastic supports (23 sleepers and a support that simulates

the connection to an adjacent rail through a working pad) and is shown in the

third phase of the car's movement in Figure 2. The force factors here that

ultimately determine the static deflection of the facing and trailing rails, as

well as the height of the joint corresponding to the third phase of movement of

the tramcar, are constant forces Р0. They

correspond to the current number of wheel pairs on the rails and have

coordinates: for the facing rail (Figure 2a)

ХВj, where ![]() – tramcar wheelset number; for the facing rail (Figure 2b) ХПj

(j=1, 2).

– tramcar wheelset number; for the facing rail (Figure 2b) ХПj

(j=1, 2).

In Figure 2: ![]() ,

, ![]() – geometric coordinates

of elastic supports;

– geometric coordinates

of elastic supports; ![]() – load

on the side of a tramcar per wheel; Р0 – weight of a tramcar, including

its load;

– load

on the side of a tramcar per wheel; Р0 – weight of a tramcar, including

its load; ![]() –

elastic force applied in the third phase of movement of the tramcar to the end

of the facing rail from the side of the trailing rail when

–

elastic force applied in the third phase of movement of the tramcar to the end

of the facing rail from the side of the trailing rail when ![]() m;

m; ![]() –

deflection of the facing rail at the end in the third phase of the tramcar

movement; Q0, M0

– cross force and bending moment at the origin of the coordinates;

c – stiffness of the ballast

layer under the sleeper of the upper track structure;

–

deflection of the facing rail at the end in the third phase of the tramcar

movement; Q0, M0

– cross force and bending moment at the origin of the coordinates;

c – stiffness of the ballast

layer under the sleeper of the upper track structure; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m;

m; ![]() m.

m.

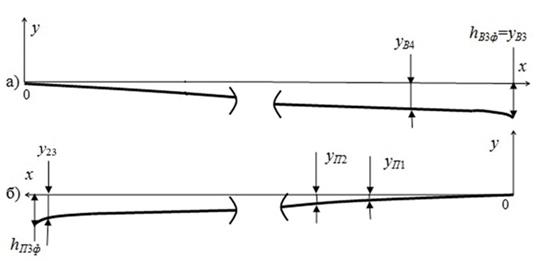

Fig. 2. Calculated mechanical schematic

of static interaction

during the third phase of the car motion:

a) trailing and b) facing rails

The equation of the curved axis of the rails in the first phase of

movement is written using the method of initial parameters, noting the

conditions of their fixation ![]() :

:

trailing rail:

,

(1)

,

(1)

facing rail:

. (2)

. (2)

The

elastic lines of the facing and trailing rails

in the third phase of movement are shown in Figure 3,

where уВ3, уВ4, уП1, уП2, у23 – deflections of the rails,

respectively, under the wheels of the car and the first sleeper of the

receiving rail.

The current height of the joint irregularity in the third phase of the

tramcar movement is calculated by the expression:

![]() ,

(3)

,

(3)

Where:

![]() –

deflections of the facing and trailing rails

at the ends, respectively, when

–

deflections of the facing and trailing rails

at the ends, respectively, when ![]() m, that is

m, that is ![]() ,

, ![]() .

.

Fig. 3. Elastic lines of the trailing a)

and facing b) rails in the third phase of

the tramcar movement

Considering the fact that expressions (1) and (2) contain summands on

the right side, which in turn depends on deflections, the solution of these

equations is performed numerically according to the work algorithm. The

calculations were performed following the mechanical scheme of the tramcar and

the rail track, as shown in Figure 1, as well as geometric and

mechanical characteristics of the Р-65 rail and T-3 tram [9]: elastic modulus of the rail material – ![]() N/m2; moment of inertia of the rail section

relative to the neutral axis –

N/m2; moment of inertia of the rail section

relative to the neutral axis – ![]() cm4; path ballast layer stiffness –

cm4; path ballast layer stiffness – ![]() N/m. Mass of a tramcar reduced to one wheel (empty)

N/m. Mass of a tramcar reduced to one wheel (empty) ![]() kg, when maximum (with 193 passengers) uploaded –

kg, when maximum (with 193 passengers) uploaded –

![]() kg.

kg.

The

established values of the joint stage value in the third phase of the tramcar

movement (![]() mm) makes it possible (using mass, load and reduced wheel

mass) to determine the value after the impact speed of the facing rail at the

end at the stage of impact interaction.

mm) makes it possible (using mass, load and reduced wheel

mass) to determine the value after the impact speed of the facing rail at the

end at the stage of impact interaction.

3.2. Impact in reaction

This work mainly discusses the peculiarities, assumptions, and expressions for

determining the post-impact vertical velocity of the end face of the facing

rail. The results obtained are used further at the stage of dynamic interaction

in the form of initial data when calculating deflections of the facing track

rail under the first sleeper during its growth phase. It is established that in

the third phase of movement of the tramcar, the post-impact speed changes in

the range of ![]() m/s. The results obtained are used as

initial data when calculating the deflections of the facing track rail under

the first sleeper during its growth phase.

m/s. The results obtained are used as

initial data when calculating the deflections of the facing track rail under

the first sleeper during its growth phase.

3.3. Dynamic interaction

The solution of the formulated problem is carried out by the method of sequential static-impact-dynamic calculation. It is based on the principle of superposition of the action of forces with respect to elastic linear systems that deform [10].

Structurally, the method consists of the following three steps.

Stage 1. Here we consider the problem of free vibrations of the mechanical system “tramcar- rail track”, which is reduced to a superposition of eigenforms. This does not consider the components associated with the phenomena of dissipation, as well as the impact of static load from the tramcar on the facing rail. In a generalised form for all phases of movement of the tramcar, the deflections of the receiving rail considering the geometric coordinates and sprung mass of the tramcar are determined by the expressions:

![]() ,

,

![]() (4)

(4)

![]() ,

,

where Ds, Ms – constant integrations, coefficients found from the conditions of orthogonality of oscillation forms, considering the pre-impact speed of the wheel of the third wheelset (defined in Section 3.2 of this paper) and the post-impact speed of the rail compatible with the wheel; ![]() ,

, ![]() – eigenvalues

and eigen frequencies of

vibrations of the facing rail as a system with distributed parameters; l*

– linear mass

coordinate m1.

– eigenvalues

and eigen frequencies of

vibrations of the facing rail as a system with distributed parameters; l*

– linear mass

coordinate m1.

Stage 2. Here, an exponential component is

superimposed on the solution of expression (4):

![]() ,

(5)

,

(5)

where hs – damping coefficient of the corresponding waveform.

In

addition, the dissipation factor is determined by the expression ![]() , where bs – coefficient of resistance

relative to the corresponding waveform;

, where bs – coefficient of resistance

relative to the corresponding waveform; ![]() – reduced

weight of the rail. In calculations, it is

– reduced

weight of the rail. In calculations, it is ![]() kg,

kg, ![]() N·s/m

(independent from s [10]).

N·s/m

(independent from s [10]).

Step

3. On the elastic line ![]() of the facing rail, defined for

the third phase of movement in Section 3.1, according to the superposition

principle, the deflection of the facing rail is superimposed by the addition method, which is

calculated in step 2 by formula (5), also see the diagram in Figure 4, where:

of the facing rail, defined for

the third phase of movement in Section 3.1, according to the superposition

principle, the deflection of the facing rail is superimposed by the addition method, which is

calculated in step 2 by formula (5), also see the diagram in Figure 4, where:

![]()

Fig. 4. Deflection diagram of the facing rail under the first sleeper

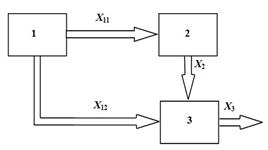

This method provides determination

of the deflection under the first sleeper of the facing rail in dynamics,

depending on the phase of movement of the tramcar due to joint irregularity,

structural and mechanical characteristics of the tramcar and the rail track. A flowchart of the method for determining the parameters of the mechanical

interaction of the tramcar and the rail track in the area of the track

junction, providing determination of deflections of the facing rail track under

its first sleeper in the growth phase from the loading parameters and speed of

the tramcar is shown in Figure 5,

where 1, 2, and 3 are blocks for calculating static, impact, and dynamic

parameters of the mechanical interaction of the tramcar with the rail track,

respectively; ![]() – vector of joint height parameters

corresponding to the car's movement phases (section 3.1);

– vector of joint height parameters

corresponding to the car's movement phases (section 3.1); ![]() – vector of

rail stiffness at the end and static deflections of the facing rail under the

first sleeper (Section 3.1);

– vector of

rail stiffness at the end and static deflections of the facing rail under the

first sleeper (Section 3.1); ![]() –

post-impact velocity vector of the facing rail (Section 3.2);

–

post-impact velocity vector of the facing rail (Section 3.2); ![]() – vector of parameters of

maximum deflections of the facing rail under the first sleeper (Section 3.3).

– vector of parameters of

maximum deflections of the facing rail under the first sleeper (Section 3.3).

Fig. 5. Flowchart of the method

To calculate the deflections of the facing rail under the first sleeper in the zone of butt unevenness, the dynamic interaction of the tramcar with the rail track in the joint irregularity is considered with the following factors. The height of the joint irregularity corresponds to [3] the parameters of static interaction of the car, its loading, structural and operational factors of the mechanical system "tramcar – rail track". Dynamic characteristics after impact interaction at the growth phase of deflections of the facing rail under the first support are determined noting the parameters of a real object in the form of a tramcar and a rail track in a zone of isolated joint irregularity of the "gap – step up" type.

To achieve the goal, the following tasks were solved:

·

using

modelling methods, the mechanical system was represented in the form of a

multi-span beam on elastic supports;

·

the

butt plate is an equivalent elastic element at the end of the facing and trailing rails of the joint with a

stiffness coefficient that is determined considering its flat stress state.

With

the impact interaction of the wheel with the end face of the facing rail, a

tramcar interacting with the facing rail is considered as a sprung reduced

mass. In addition, the current step height is determined taking into account

the static interaction of the tram with the rail track, which corresponds to

the phase of movement of the tramcar due to the joint irregularity.

When analyzing the processes of dynamic interaction in the

system «two-dimensional discrete elastic – dissipative system –

continuous system in the form of an indistinguishable multi-span beam on 24

elastic supports», the following assumptions were made. When the wheel hits

the end face of the facing rail, it does not break off, as well as its sliding

relative to the rail; vibrations of the wheelset and the rail head occur in

continuous mode (since m2>>m1, the assumption is acceptable); deflections of the rail

are realised without violating the integrity of the ballast layer (since the deformation

characteristics of the ballast layer under the first sleeper are considered

during the growth phase of deflections of the receiving rail only downwards,

the assumption is also acceptable).

According

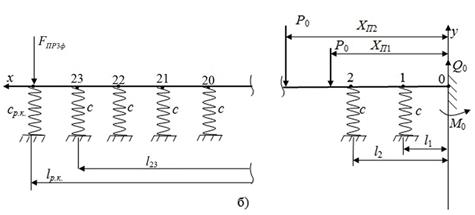

to the design mechanical scheme of the facing rail in the third phase of the

tramcar movement in Figure 6, differential equations of oscillations at

![]() are as follows:

are as follows:

(6)

(6)

where ![]()

The solution of the equations system (6) is constructed based on the proposed three-stage method.

Then, in step 1, the motion differential equations of a mechanical system will have the form:

(7)

(7)

Equations (7) for eigenforms will be reduced to the form:

(8)

(8)

where

![]() ;

; ![]() ;

; ![]() ;

; ![]() – eigen shape for the coordinate

– eigen shape for the coordinate ![]() in Figure 6.

in Figure 6.

The solution of the system`s first equation is performed using the Laplace-Carson transformation:

(9)

(9)

Let us further move in (9) to the original using Krylov functions [10]:

(10)

(10)

The diagram of sections following the structure of the facing rail is shown in Figure 6.

Fig. 6. Diagram of rail sections in the third phase of movement

Considering equations (8) and (10), as well as the diagram in Figure 6, we obtain:

at a section ![]() :

:

at a section ![]()

![]() і

і ![]()

at a section ![]()

![]() і

і ![]()

(11)

(11)

at a section ![]() і

і ![]()

![]()

(12)

(12)

In this case, we will have 31 variables: ![]() ,

, ![]() ,

, ![]() ,

, ![]() ,

, ![]()

![]() ,

, ![]() ,

, ![]() ,

, ![]() ,

, ![]() .

.

Next,

we determine the eigenfrequencies ωs

with respect to solutions (6) and the initial conditions of the mechanical

system in Figure 6, which we will additionally include equalities in:

![]() ;

;

![]() ;

;

![]() ;

;

![]() .

.

The orthogonality conditions of the system in the third phase of motion then takes the following form:

(13)

(13)

Consequently, we obtain the following expressions for

determining the constants Ms,

Ds of motion equations (when ![]() and

and ![]() ):

):

;

(14)

;

(14)

where ![]() and

and ![]() , when

, when ![]() ,

, ![]() ,

,

(15)

(15)

Finally, the deflection of the facing rail in the third phase of the tramcar’s movement will be determined by the expression:

![]() .

(16)

.

(16)

At stage 2 of the method, the actions of static Р0 and inertial m1 loads with coordinates lk1, lk2 are additionally considered.

At stage 3 of the method, the deflection of the receiving rail under the first sleeper in the third phase of the tramcar movement will be determined by the formula:

![]() .

(17)

.

(17)

Here ![]() , it is determined by the data of Section 3.1 of this

article.

, it is determined by the data of Section 3.1 of this

article.

Analysis of these calculations shows that:

1) change in the tramcar load

when ![]() kg with motion speed

kg with motion speed ![]() m/s leads to a change in the dynamic deflection of the

facing rail under the first sleeper in the range

m/s leads to a change in the dynamic deflection of the

facing rail under the first sleeper in the range ![]() mm, that is, to its growth of 1.9 times;

mm, that is, to its growth of 1.9 times;

2) it is determined that the

increase in the speed of a tramcar in the range of ![]() m/s when loading a tramcar

m/s when loading a tramcar ![]() kg leads to the amount change in the deflection in the

range

kg leads to the amount change in the deflection in the

range ![]() mm, that is, to its growth of 1.89 times.

mm, that is, to its growth of 1.89 times.

The results obtained are used when solving the issue of improving the upper structure of the rail track, as well as in determining the safe operating modes of tramcars.

4. RESEARCH RESULTS

In this paper, based on the improved

dynamic model that describes the deflections of the facing rail, considering

the characteristics of rigidity and damping of the suspension of the tramcar

and the ballast layer, the speed, loading and phase of movement of the tramcar

through the current number of reduced masses of wheels on the rail, it was

possible to calculate the parameters of post-impact interaction in the

mechanical system "tramcar-rail track" at the phase of growth of

deflections under the first sleeper.

A method of sequential static-impact-dynamic calculation of

deflections of the facing rail under the first sleeper in the growth phase was

developed. This made it possible to note the phases of movement of the tramcar

relative to the joint irregularity,

its loading and speed, as well as the boundary conditions for fixing the facing

and trailing rails, geometric and mechanical characteristics of rails and butt

linings, sleepers and ballast layer. The method provides opportunities for

studying the processes of mechanical interaction of a tramcar and a rail track

aimed at improving the operating modes of the vehicle, as well as the upper

structure of the track.

The dependences of static, impact and generalised components of the height of joint irregularity at the growth stage on the phases of movement of the tramcar are obtained. This was done taking into account the orthogonality of the vibrations forms of the facing rail, the operational, structural and mechanical characteristics of the tramcar and the upper structure of the track. Thus, allowing determining whether the maximum deflections of the receiving rail under the first sleeper belong to the range of acceptable values of elastic deformations, which are set by the regulatory document. This paper suggests using the mechanical interaction of a tramcar with a rail track in the joint zone as a normative factor – the deflection of the receiving rail under the first sleeper. Loads on the ballast layer of the upper track structure are caused by deflections of the track rails. They are affected by the operational, mechanical and geometric parameters of the vehicle, rails, butt linings, sleepers and ballast layer. Following the standards of operation of electric transport, the pressure transmitted from the sleeper to the ballast layer should not exceed the maximum permissible value, which, for example, in summer is equal to [σ] = 19.62 N/cm2. In real operating conditions, an informative parameter that will characterise the mechanical interaction of the car with the rail track in the joint area, which is derived from the pressure factor on the ballast layer and can be measured by external controls, is the deflection of the sleeper. The generalised deflection of the rail, which corresponds to the standard maximum permissible pressure, depends on the specific area and weight of the sleeper, the specific weight of the rail and the stiffness of the ballast layer. It is known that the most important generalised deflection occurs under the first sleeper of the receiving rail. In general, the value of the specified deflection must satisfy irregularities that do not contradict the standard condition for not exceeding the maximum permissible pressure.

5. CONCLUSIONS

The numerical calculation results for the parameters of

the mechanical railway

rolling stock – track interaction in the area of joints are given.

The analysis is based on the integral model, which considers operational,

mechanical, and geometric factors. This approach allows establishing new

patterns of interaction between the four-axle car and the track while passing

over joint irregularity, as well as to improve the operational parameters, car

characteristics and the upper structure of the track by rational selection and

optimisation.

The model proposed can be used

in the development of design solutions for improving the rail track joint,

determining the operating modes of tramcars depending on the type of rail

track, creating an experimental and theoretical complex for studying, calculating

and improving the parameters of rail transport knots. All of this makes it possible to take a significant step

in the development of electric transport towards a more environmentally

friendly, safe, convenient and economical way to transport passengers and

cargo.

References

1.

Вериго М.Ф., А.Я. Коган. 1986. Взаимодействие

пути и

подвижного

состава.

Москва:

Транспорт. 559 с. [In Russian: Verigo M.F., A.Ya. Kogan. 1986. Interaction of track and rolling stock.

Moscow: Transport. 559 p.].

2.

Auersch L., S. Said. 2021. „Dynamic

track-soil interaction-calculations and measurements of slab and ballast

tracks”. Journal of

Zhejiang University - Science A: Applied Physics & Engineering 22(1): 21-36. DOI: https://doi.org/10.1631/jzus.A1900651.

3.

Даренський

О.М.,

А.В. Клименко. 2013. „Моделирование взаимодействия пути и подвижного состава при дискретном подрельсовом основании в зоне рельсовых стыков”. Інформаційно-керуючі

системи на

залізничному

транспорті 4: 15-22. [In Ukrainian: Darensky O.M., A.V. Klimenko. 2013. „Simulation

of the interaction of the track and rolling stock at a discrete sub-rail base

in the area of rail joints”. Information

and control systems in railway transport 4: 15-22].

4.

Манашкин

Л.Я., С.В. Мямлин,

В.И. Приходько. 2008. „Оценка

силы

ударного взаимодействия

колеса и

рельса на

стыке двух

рельсов”. Вісник

Дніпропетровського

національного

університету

залізничного

транспорту імені

академіка В.

Лазаряна 22: 36-39. [In Ukrainian: Manashkin

L.A., S.V. Myamlin, V.I. Prihodko

. 2008. “Otsenka silyi udarnogo vzaimodeystviya kolesa i relsa na styike

dvuh relsov”. Visnik

Dnipropetrovskogo natsionalnogo universitetu zaliznichnogo transportu Imeni

akademika V. Lazaryana 22: 36-39]. Available at: http://nbuv.gov.ua/UJRN/vdnuzt_2008_22_10.

5.

Sun

Y., C. Cole, M. Spiryagin. 2013. “Study on track dynamic forces

due to rail short-wavelength dip defects using rail vehicle-track dynamics

simulations”. Journal of Mechanical Science and

Technology 27(3): 629-640. DOI: https://doi.org/10.1007/s12206-013-0117-8.

6.

Auersch L. 2021. „Train-induced ground vibration due to the irregularities of

the soil”. Soil Dynamics and

Earthquake Engineering 140. DOI: https://doi.org/10.1016/j.soildyn.2020.106438.

7.

Кузьмицкий

Я.О., Д.В.

Шевченко, А.К. Беляев.

2015. ”Конечно-элементное

моделирование

процесса

перекатывания

колеса через

стык”. Научно-технические

ведомости

СПбГПУ 4(23): 170-178. [In Russian: Kuzmickij Ja. O., D.V. Shevchenko, A.K.

Beljaev. 2015. “Finite element modeling of the wheel rolling process through

the joint”. Nauchno-tehnicheskie

vedomosti SPbGPU 4(23): 170-178]. DOI: https://doi.org/10.5862/JEST.231.18.

8.

Jasiulewicz-Kaczmarek

M., K. Antosz, P. Żywica, D. Mazurkiewicz, B. Sun, Y. Ren. 2021. „Framework

of machine criticality assessment with criteria interactions”. Eksploatacja i Niezawodnosc –

Maintenance and Reliability 23(2): 207-220.

9.

Иванов

М.Д., А.А. Пономарев, Б.К. Иеропольский.

1977. Трамвайные вагоны Т-3. Москва: Транспорт. 240 с. [In Russian: Ivanov

M.D., A.A. Ponomarev, B.K. Ieropolsky. 1977. Tram cars T-3. Moscow: Transport. 240 p.].

10. Бабаков И.М. 1968.

Теория колебаний. Москва:

Наука. 691 с. [In Russian:

Babakov I.M. 1968. Theory of

oscillations.

Moscow: Science. 691 p.].

Received 18.09.2021; accepted in

revised form 04.11.2021

![]()

Scientific Journal of Silesian University of Technology. Series

Transport is licensed under a Creative Commons Attribution 4.0

International License