Article citation information:

Sakno, O.,

Medvediev, I., Kolesnikova, T. Study on the relationship between

vehicle maintenance and fuel consumption. Scientific

Journal of Silesian University of Technology. Series Transport. 2021, 113, 163-172. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.113.13.

Olha

SAKNO[1], Ievgen MEDVEDIEV[2], Tatiana KOLESNIKOVA[3]

STUDY ON THE RELATIONSHIP BETWEEN VEHICLE MAINTENANCE AND FUEL CONSUMPTION

Summary. A

contemporary road vehicle (RV) is a rather complex system, consisting of a

large number of subsystems, assemblies, units, and elements (parts). While

operating, an RV interacts with the environment, and its elements interact with

each other. Consequently, the properties (parameters) of these elements change

in the process - hardness, roughness, size, relative position, gapping, etc.

A partial solution to the presented problems can be the search for a

technique for assessing the RV technical condition by a generalised criterion,

which is quite sensitive to changes in the technical state. One of these

criteria may be fuel consumption in litres per 100 kilometres. This paper

investigates the possibilities of using the fuel consumption indicator as a

criterion for assessing the technical condition of the vehicle and the vehicle

maintenance and repair technologies have been generalised to obtain a given

technical solution. Thus, the possibility of using the fuel consumption

indicator as a criterion for assessing the technical condition of the vehicles

was explored using the Volkswagen Touran 1.9 TDI operating in urban conditions

using a driving cycle. A clear correlation between the fuel consumption and the

service lifetime of the vehicle has been established; therefore, it depends on

the frequency and quality of the maintenance and repair (MR). The vehicle MR

technology has been generalised to obtain a specified technical solution. The

process of creating an RV MR Technology model is implemented based on an

iterative approach (repetition) with the possibility to specify their features.

Keywords: driving

cycle, vehicle maintenance, technical condition,

fuel consumption, technology, iterative approach

1.

INTRODUCTION

While operating, the vehicle interacts with the environment, and its

elements interact with each other. This interaction causes the load of parts,

their mutual displacements, friction, heating, chemical transformations [1].

Resultantly, the properties (parameters) of these elements - hardness,

roughness, size, mutual arrangement, gapping, etc., are changed during the

work.

According to the European DRIVE Project [2], which was carried out

to identify the real operating conditions of vehicles, short trips (urban travel), low warming-up temperatures of the friction

parts, acceleration, and generally, urban traffic conditions have been found to

result in a significant increase in fuel consumption. The obtained data

provided very precise information on the actual use of the vehicle that

provided a broad overview of the normal average European driving [2]. Thus, while idling, especially in urban

areas, the greenhouse gases (CO2, CH4, and N2O)

emissions make ∼37 tonnes of CO2 eq/day [3].

The efficiency, functionality and performance of a vehicle in use should

be investigated with the simplified driving cycle (DC) and the New European

Driving Cycle (NEDC) [4]. When considering, for example, the movement of

a vehicle on two-lane highways, special attention should be paid to speed, both

in terms of safety [5] and the economy of operation of the engine.

A partial solution to the problems presented can be found by finding a method for estimating the technical state of the RV according to a generalised criterion, which is sufficiently sensitive to changes in the technical state. One such criterion could be fuel consumption in litres per 100 kilometres [6]. Different diesel fuel mixtures showed significant differences in combustion efficiency, and hence, in engine performance [7-9].

This research based on the method of comparative analyses of the coolant temperature, gasoline fuel consumption and exhaust emissions including total hydrocarbon (THC), carbon monoxide (CO) and nitrogen oxide (NOX) [10] enabled fuller assessing of the vehicle effective working conditions.

Thus, the feasibility of using the fuel consumption indicator as a criterion for assessing the technical condition of the vehicles is relevant.

Therefore, this article aims to investigate the possibilities of using the fuel consumption indicator as a criterion for assessing the vehicle technical condition and to generalise the vehicle maintenance and repair technology and obtain a given technical solution.

2. ESTABLISHING THE RELATIONSHIP BETWEEN THE VEHICLE TECHNICAL CONDITION AND FUEL CONSUMPTION

Vehicle operation is its intended use. The operating conditions of vehicles are random in nature and have probabilistic characteristics of road conditions, speed of movement, the weight of the transported cargo, mode of movement. Even with the elimination of the action of random factors, the dispersion of the values of the operating time of different cars of the same sample is noticeable.

In the course of the vehicle operation, their components and aggregates are constantly exposed to a wide range of factors that affect their technical condition in different ways.

The factors affecting the change in the technical state can be divided into groups: design and production, which determine the initial quality of the RV, and operational factors, which determine the change in the technical state during operation.

Operating factors depend on road, transport and climatic conditions. They mostly affect the vehicle technical condition. Road conditions are characterised by the type, state and strength of the pavement, the longitudinal profile of the road, the mode of movement, visibility, etc. [11-14]. Climatic conditions in different periods of the year are determined by air temperature and humidity, atmospheric pressure, precipitation, wind strength and direction, snow cover, etc.

Operating conditions significantly influence the operating modes, loads and reliability of the RV, and thus, the maintenance and repair needs, and changing technical specifications. For example, experimental studies were carried out to diagnose the control of wheeled vehicles with different operating times. It was established that when running up to 6000 hours, the diagnostic parameter can be reduced to 15% [15].

The Volkswagen Touran official debut took

place at the motorcycle show in Amsterdam in February 2003. The vehicle

received a modern look, made in the style of the latest VW cars.

The Volkswagen Touran is based on a Golf V

model. The vehicle uses a new rear axle with four suspension wheel levers and

an electromechanical steering wheel booster.

The large protection system includes seat

belts on all 7 seats, ABS, ESP (Electronic Stabilisation Program), BAS (Brake

Assist System), 6 airbags (front and side for the driver, front and rear

passengers). Disc brakes on all wheels (front - with internal ventilation). All

of the above assumes a high level of active safety.

2.1.

Statement of research objectives

The purpose of the experimental study is to establish the relationship between the technical condition and fuel consumption of Volkswagen Touran 1.9 TDI vehicles under certain operating conditions.

To achieve this goal, the following tasks were solved:

1. Define the route parameters of the vehicle.

2. Collect and process statistical data on the dynamics of changes in weather conditions throughout the year.

Experimental data included:

1. Determination of the parameters of the routes of the city of Dnipro using the urban driving cycle.

2. Collecting and processing the

statistical data on the dynamics of changes in atmospheric pressure and ambient

temperature in the city of Dnipro in the period from 1.01.2019 to 31.10.2019.

The objects of experimental research were

Volkswagen Touran 1.9 TDI vehicles (Figure 1), produced in 2003-2012, with a

serial in-line diesel 4-cylinder engine, with a liquid cooling system and

manual transmission 6.

Fig. 1. General view of the Volkswagen Touran 1.9 TDI

2.2.

Research results

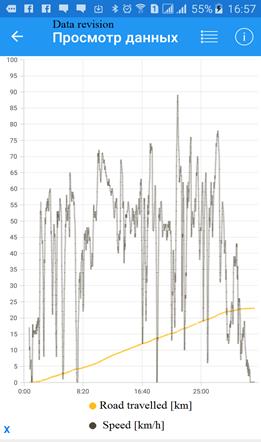

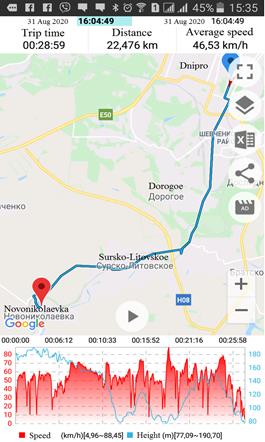

Figures 2 and 3 show the velocity profile,

the track and the topography dynamics during the operation. Vehicle operation

was done in the city.

During the experimental study, the data on the ambient temperature and the value of atmospheric pressure in the city of Dnipro were collected.

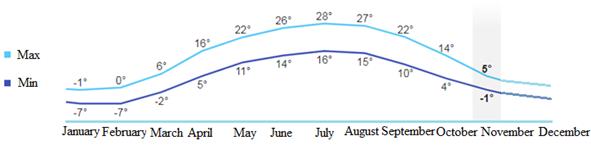

The graph of temperature changes with averaged values for the research period is shown in Figure 4. As observed from the graphs, the ambient temperature changes according to a sinus-like law, and the value of atmospheric pressure has a uniform distribution throughout the year and is at the level of 99.3 kPa.

General temperature range: -1…+28оС.

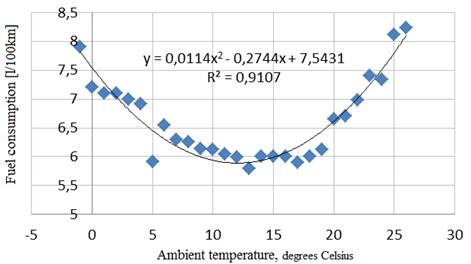

The research results are shown in Figure 5.

Table 1 shows the polynomial dependences of fuel consumption on ambient temperature during operation.

Table 1

Polynomial dependences of fuel consumption on ambient temperature during operation

|

Equation |

Approximation Accuracy |

Qs0 оС |

|

|

Qs(t) = 0,0114·t 2-0,2744·t+7,54 |

0,9107 |

5,34 |

1,41 |

Where:

Qs(t) – fuel consumption depending on the ambient temperature, l/100 km;

t – ambient temperature, degrees Celsius;

Qs0 – fuel consumption in the first month of operation, l/100 km.

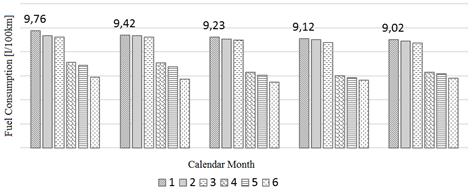

The first stage of the investigation on the

influence of technical conditions on fuel consumption confirmed the general

hypothesis that under the same operating conditions, the new vehicles consume

less fuel than the used vehicles. To do this, we compared the fuel consumption

on the route monthly. The results are shown in Figure 6.

|

Fig. 2. Dependence of the speed of movement and road travelled on the timing |

Fig. 3.

Dynamics of changes in the topography of movement and vehicle speed |

Fig. 4. Graph of changes in the ambient temperature for the research period at Dnipro in 2020 (degrees Celsius)

As seen in Figure 6, there is a clear

dependence of the fuel consumption on the service life of the vehicle, which

means it depends on its frequency and the quality of MR.

Fig. 5. Fuel consumption dependence on ambient temperature

Fig. 6. Fuel consumption (l/100 km) of the vehicles from the research groups for 5 months

3. GENERALISING THE

METHODOLOGIES FOR THE TECHNOLOGY OF THE VEHICLES MAINTENANCE AND REPAIR

Thus, it is possible to generalise the

technology of maintenance and repair and obtain a given technical solution [16-19].

Figure 7 provides a chart for the technology system design, obtaining a given

technical solution. The choice of a given technical solution can be carried out

based on the corresponding system of the hierarchical level of simulation,

which must be worked out based on an iterative sequence. Before starting the

simulation process, it is necessary to set the initial conditions and

restrictions on the performance of works on vehicles maintenance and repair,

determine the modelling principle, consider the features of simulation, that

is, the stage of modelling, the level of complexity, technical progress and the

image of the system. These stages and levels in the systems synthesis process

should be implemented based on an iterative approach. The entire simulation

process should be performed only based on the limiting criterion of reliability

and efficiency of operation during the RV maintenance and repair.

When modelling the RV maintenance and repair

technology, it should be noted that modelling processes can be performed at all

stages of the integrated maintenance and repair technology (Figure 8), namely

1, 2, 3, …, ni. At the same time, the process of creating a

model should be implemented based on an iterative approach (iteratio -

repetition) with the possibility of specifying their features. These features

also need to be clarified at all stages of the simulation (Figure 8b).

![]()

Fig. 7. The

technology system simulation chart of the vehicle maintenance

and repair system and obtaining a given level of technical solution

The iterative direction of the RV MR Technology simulation (Figure 8b) is considered at all levels of complexity. The complexity levels of a system may have the following types: elementary function, level subfunction n-2, level subfunction n-1, high level function n. In this case, the simulation process, as an iterative one, can be carried out with a gradual complication of the function. According to the level of technical condition (reliability level) (Figure 8d), simulating the RV maintenance and repair technologies should also be performed taking into account an iterative approach, which is performed in the following sequence: durability, reliability, maintainability, ..., function with two conditions, function with one condition, function without conditions. By the level of the image (Figure 8e), the simulation process can be carried out at the following levels: graph, chart, structure, model, and list of RV maintenance and repair works, RV design.

|

Steps of simulation |

|

|

а) |

|

|

Stages of simulation |

|

|

b) |

|

|

Level of complexity of the vehicles technical

system |

|

|

c) |

|

|

Vehicle reliability level |

|

|

d) |

|

|

System image level |

|

|

e) |

|

Fig. 8.

Features of the vehicle maintenance technology simulation:

a) by model step; b) by model stage; c) by system complexity level;

d) by technical condition (reliability level); e) by technical system image

level

4. CONCLUSIONS

The possibility of using the fuel consumption indicator as a criterion for assessing the technical condition of vehicles was investigated using the example of the Volkswagen Touran 1.9 TDI during operation (Route Novomykolaivka village – city of Dnipro (Shevchenkovskyy district)). A clear dependence of fuel consumption on the service life of the vehicle was established, which means it depends on its frequency and the quality of maintenance. The technology of maintenance and repair of the vehicles and obtaining a given technical solution was generalised.

The process of creating a model of the RV maintenance and repair technologies is implemented based on an iterative approach (repetition) with the ability to clarify the features of changes in the technical condition, operating conditions, the quality of preventive work, etc.

Acknowledgements

We

wish to express our gratitude to Professor Volodymyr Sakhno (National Transport University, Kyiv,

Ukraine) and the referees for their constructive and valuable

suggestions.

References

1.

Сахно

В.П., Д.О.

Савостін-Косяк.

2017. „Форми

організації

моніторингу

технічного

стану

транспортних

засобів”. Вісник

Національного

транспортного

університету 1(37): 373-380. ISSN: 2308-6645 [In Ukrainian: Sakhno Volodymyr, Danyl

Savostin-Kosiak. 2017. „Ways of vehicle technical condition

monitoring”. Bulletin of the

National Transport University]. Available at: http://nbuv.gov.ua/UJRN/Vntu_2017_1_49.

2.

André M., R. Joumard, n A.J. Hickma, D. Hassel.

1994. “Actual car use and

operating conditions as emission parameters: derived urban driving

cycles”. Science of The Total Environment 146-147(23):

225-233. ISSN: 0048-9697. DOI: https://doi.org/10.1016/0048-9697(94)90241-0.

3.

Sharma

N., P.P. Kumar, R. Dhyani, C. Ravisekhar, K. Ravind. 2019. “Idling fuel

consumption and emissions of air pollutants at selected signalized

intersections in Delhi”. Journal of

Cleaner Production 212: 8-21. ISSN: 0959-6526. DOI: https://doi.org/10.1016/j.jclepro.2018.11.275.

4.

Hereijgers

K., E. Silvas, T. Hofman, M. Steinbuch. 2017. “Effects of using

Synthesized Driving Cycles on Vehicle Fuel Consumption”. IFAC-PapersOnLine 50(1): 7505-7510. ISSN:

2405-8963. DOI: https://doi.org/10.1016/j.ifacol.2017.08.1183.

5.

Ghods

A.H., F. Saccomanno, G. Guido. 2012. “Effect of Car/Truck Differential

Speed Limits on Two-lane Highways Safety Operation Using Microscopic

Simulation”. Procedia - Social and

Behavioral Sciences 53: 833-840. ISSN: 1877-0428. DOI: https://doi.org/10.1016/j.sbspro.2012.09.932.

6.

Кривошапов

C.И. 2015. “Особенности

нормирования

расхода

топлива в

сложных

дорожных

условиях

эксплуатации

машин”. Вісник

НТУ «ХПІ» 10(1119):115-121.

ISSN: 2079-0066. [In

Russian: Krivoshapov S.I.

2015. “Features of rationing of fuel

consumption in difficult road conditions of machine operation”. Bulletin of NTU “KPI”]. Available

at: http://repository.kpi.kharkov.ua/handle/KhPI-Press/15058.

7.

Lopes

M., L. Serrano, I. Ribeiro, P. Cascão, at al. 2014. “Emissions

characterization from EURO 5 diesel/biodiesel passenger car operating under the

new European driving cycle”. Atmospheric

Environment 84: 339-348. ISSN: 1352-2310. DOI: https://doi.org/10.1016/j.atmosenv.2013.11.071.

8.

Degraeuwe

B., M. Weiss. 2017. “Does the New European Driving Cycle (NEDC) really

fail to capture the NOX emissions of diesel cars in Europe?” Environmental Pollution 222: 234-241. ISSN:

0269-7491. DOI: https://doi.org/10.1016/j.envpol.2016.12.050.

9. Mickevicius T., S. Slavinskas, S. Wierzbicki, K. Duda. 2014. „The effect of diesel-biodiesel blends on the performance and exhaust emissions of a direct injection off-road diesel engine”. Transport 29(4): 440-448.

10. Shen K., L. Chang, H. Chen, Z. Zhang,

B. Wang, Y. Wang. 2019. “Experimental study on the effects of exhaust

heat recovery system (EHRS) on vehicle fuel economy and emissions under cold

start new European driving cycle (NEDC)”. Energy Conversion and Management 197. ISSN: 0196-8904. DOI: https://doi.org/10.1016/j.enconman.2019.111893.

11. Beljatynskij Andrey, Olegas Prentkovskis, Julij Krivenko. 2010. “The experimental study of shallow flows of liquid on the airport runways and automobile roads”. Transport 25(4): 394-402.

12. Celko J., M. Kovac, M. Decky. 2011. “Analysis of Selected Pavement Serviceability Parameters”. Communications - Scientific Letters of the University of Zilina 13(3): 56-62.

13. Dell'Acqua, Gianluca, Mario De Luca, Carlo Giacomo Prato, Olegas Prentkovskis, Raimundas Junevicius. 2016. „The impact of vehicle movement on exploitation parameters of roads and runways: a short review of the special issue”. Transport 31(2) Special Issue: 127-132.

14. Staniek M., P. Czech. 2016. “Self-correcting neural network in road pavement diagnostics”. Automation in Construction 96: 75-87. DOI: 10.1016/j.autcon.2018.09.001.

15. Podrigalo M., Y. Dubinin,

A. Molodan, O. Polianskyi, at al. 2020.

“New Methods and Systems for Monitoring the Functional Stability Parameters

of Wheel Machines Power Units”. SAE Technical Paper 2020-01-2014. ISSN: 0148-7191. DOI: https://doi.org/10.4271/2020-01-2014.

16. Михайлов А.Н. 2009. Основы синтеза функционально-ориентированных технологий машиностроения. Донецк: ДонНТУ. ISBN: 966-7907-24-4. [In Russian: Mihaylov A.N. 2009. Basics of the synthesis of function-oriented engineering technologies. Donetsk: DonNTY].

17. Michalski R., S. Wierzbicki. 2008. „An analysis of degradation of vehicles in operation”. Eksploatacja i Niezawodnosc – Maintenance and Reliability 1: 30-32.

18. Kozłowski E., K. Antosz, D. Mazurkiewicz, J. Sęp, T. Żabiński. 2021. „Integrating advanced measurement and signal processing for reliability decision-making”. Eksploatacja i Niezawodnosc – Maintenance and Reliability 23(4): 777-787.

19. Jasiulewicz-Kaczmarek M., K. Antosz, P. Żywica, D. Mazurkiewicz, B. Sun, Y. Ren. 2021. „Framework of machine criticality assessment with criteria interactions”. Eksploatacja i Niezawodnosc – Maintenance and Reliability 23(2): 207-220.

Received 02.10.2021; accepted in

revised form 17.11.2021

![]()

Scientific Journal of Silesian University of Technology. Series

Transport is licensed under a Creative Commons Attribution 4.0

International License