Article citation information:

Konieczny, J. Destruction

mechanisms of Cu-ETP copper guides for sectional insulators of railway traction.

Scientific Journal of Silesian University

of Technology. Series Transport. 2021, 113,

101-113. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.113.8.

Jarosław KONIECZNY[1]

DESTRUCTION MECHANISMS OF CU-ETP COPPER GUIDES FOR SECTIONAL INSULATORS

OF RAILWAY TRACTION

Summary. This article

presents the results of a research on the operational damage to sectional

insulator guides made of hard electrolytic copper Cu-ETP (Electrolytic Tough

Pitch Copper). The guides were used on various rail routes, in real conditions,

on which the trains ran at maximum speeds between 40 and 120 km/h for

periods of 6 or 12 months. The microstructure of the surface, the working

layer of the guide, which contacts the graphite plate of the current collector

and the cross-section of the guide in the place where it was damaged was

examined using the Olympus light microscope. The analysis of the chemical

composition in the EDS micro-regions was performed using the Zeiss Supra 53

scanning electron microscope (SEM), while the qualitative X-ray phase analysis

was performed with the use of the Panalytical X'Pert diffractometer. Scratches

and deformations of the surface layer characteristic of the phenomenon of

friction caused by the current collector were observed in the microstructure of

the damaged parts of the guides of section insulators. The effect of a very

intense oxidation process was also observed, as well as the effects of an

electric arc, which according to the author, is the factor that has the most

destructive effect on the condition of the guides.

Keywords: microstructure,

wear mechanisms, electric traction, guide, section insulator

1.

INTRODUCTION

The contact of the current collector –

damages the guide as a result of tribological mechanisms (abrasion, abrasive

wear of the working surface). While the train is moving, a cloud of dust and

fine particles of the rail bed material as well as the transported materials,

for example, coal, sand and other aggregates are stirred up as a result of a

blast of air generated by the fast-moving rolling stock. The excited fine

particles settle on the traction lines or get between the working surfaces of

the current collector and the guide and act as an additional abrasive medium.

Moreover, the difference in the potentials of the two adjacent railway traction

sections causes an electric arc to be generated during the jump of the

pantograph from one guide rail to another [3]. The temperature of an electric

arc in its centre can be as high as 20,000°C [4, 5]. The initiation of an

arc and the generated temperature causes the metal elements close to the arc to

become plasticised or even melted. The guide material is copper Cu-ETP (Table

1), the melting point of which is 1,083°C [6]. The plasticised guide

deforms under the pressure of the pantograph, leading to its further

destruction. In an electric arc, small local discharges are generated,

resulting in small craters burned in the guide.

This publication presents damage to the

guides of section insulators which is the result of their operation in real

conditions.

2. MATERIALS AND METHODS

The chemical composition of Cu-ETP copper, from which the guides of the section insulators subject to the tests were made, is presented in Table 1.

Tab. 1

Approximate chemical

composition of copper Cu-ETP

(based on standards [7, 8])

|

Type of copper |

The maximum concentration of elements, % |

|||||

|

Cu |

Ag |

O |

Bi |

Pb |

Other, in total |

|

|

Cu-ETP |

99.9 |

0.015 |

0.04 |

0.0005 |

0.005 |

0.03 (without Ag, O) |

An X-ray phase analysis was performed using the Panalytical X'Pert diffractometer using filtered radiation from a cobalt anode lamp. The measurement step was 0.05, and the impulse counting time was 10 s.

The samples cut out from the used guides were incorporated in epoxy resin, then sanded with sandpaper of progressively finer grit. The previously prepared specimens were polished with the Al2O3 suspension, which was replaced with a diamond suspension with a grain size of 1 μm. The specimens were then etched in a solution of: 2 g of potassium chromate K2Cr2O7, 100 cm3 of distilled water, 4 cm3 of sodium chloride NaCl solution, 8 cm3 of sulfuric acid H2SO4. The specimens were subjected to multiple alternating polishing and etching to obtain the proper images of the microstructure.

The metallographic specimens were examined using the Olympus light microscope with magnifications of 50, 100, 200, 500, 1000, 2000x.

The Zeiss Supra 25 scanning electron microscope (SEM) was used to perform the microstructure examination employing the EDS method.

3. RESULTS

Given the observations on a macro scale, it was found that the greatest wear, as well as the deformation of the working surface, occurred in the immediate vicinity of the beginning of the arcing horn of the guide (Figure 1).

Given the measurement of the length of the abrasion marks on the guides of the section insulator, it was found that with the increase in vehicle speed (current collector), the length of the marks decreased. For the maximum speed of 40 km/h (the guide used for 12 months), the length of the abrasion mark is 75 mm (P1), for the speed of 120 km/h (the guide used for 12 months), it is 35 mm (P2) and for 120 km/h (the guide used for 6 months), it is only 25 mm (P3) (Figure 2).

![]()

Fig. 1.

Guide of the section insulator at the beginning of the horn extinguishing

an electric arc. a) a new unused element; b) an element operated with a visible

defect

The relation shown in Figure 2 can be explained by the

fact that the sliding speed is an important parameter influencing the process,

which takes place between the copper-graphite elements. As it results from the

research [9], both the friction coefficient and the degree of wear increase at

low speeds. Increasing the sliding speed to moderate speeds reduces the

friction, and consequently, the wear decreases.

The article [10] investigated the mechanisms of

premature tribological wear between the contact strip made of copper and the

copper wire used as a railway line with the use of a graphite layer on the wire.

It was noticed that because of exploitation, wear debris was present between

the mating elements (copper oxides Cu2O and hardened copper).

Additionally, the presence of hard abrasive particles such as SiO2

and Al2O3 was found. These particles, which most likely

got between the mating elements from the outside, intensify the abrasion

process. In all investigated regions without apparent wear, with

moderate wear and severe wear, based on the nature of the cracks of the

surface, it was found that they were caused either by work hardening or thermal

cycle. A material detachment and production

of hard abrasives were also frequently noticed. A material detachment (on a

macro scale) was also found in this article. The presence of a copper oxide

layer, which was formed in the copper wire and acid-resistant steel type 18-8

couple, was also found in the article [11].

Fig. 2. Change in the length of the abrasion marks on

the guide depending on the maximum speed of the locomotive, P1 - 40

km/h, 12 months, P2 - 120 km/h, 12 months, P3 - 120 km/h, 6 months

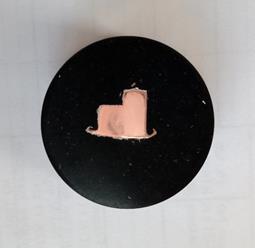

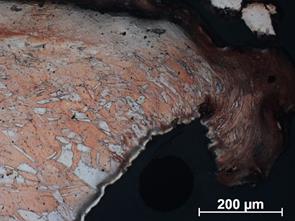

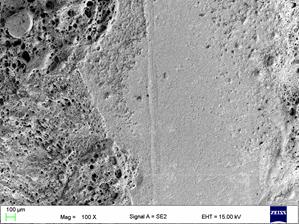

The guide which had been damaged as a result

of operation was cut and a cross-section was mounted in the epoxy resin (Figure

3). Considering the macroscopic observations, it was found that the working

surface of the guide, due to exploitation, was worn and formed in a shape of a

so-called 'cradle' (1). On both sides are visible 'whiskers' (2) – made

by plasticised material of the

guide and then by the pressure of the current collector.

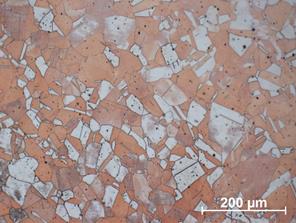

The microstructure in the area of the geometric centre of the

cross-section (3) and the deformed 'whiskers' (2) are shown in Figure 4. Figure

4a shows the microstructure of copper, which is characteristic of a

non-plastically deformed material with a predominant amount of equiaxed grains, with a shape similar to a sphere. Figure 4b shows the

microstructure grains with an elongated shape close to axial, showing the

mechanism and direction of the deformation. The average grain size (diameter)

of the microstructure shown in Figure 4a is 14.9 µm with a standard

deviation of 6.2 µm (41.6% of the average value), whereas, for the microstructure

shown in Figure 4b, it is 7.1 µm with a standard deviation of 4.3

µm (60.5% of the average value). The presented data show that the plastic

deformation in the 'whiskers' (2) resulted in a reduction of the grain size by

over 50%, and the increase in the value of the standard deviation indicates an

increasing difference in grain size.

(3) (2) (2) (1)![]()

![]()

![]()

![]()

Fig.

3. Cross-section of the guide in the area marked in Figure 1B

b) a)

Fig. 4.

Microstructure of the cross-section of the Cu-ETP copper guide; a) central area

of the section;

b) deformed ‘whiskers’

In the next stage of the research, it was verified whether the working surface

of the guide, apart from the deformation of its shape, was not permanently

contaminated, as that could reduce the electrical conductivity in the contact

between the guide and the current collector and also enhance corrosion

processes. Thus, a qualitative X-ray phase analysis was applied.

In the structure of the material of a new guide of the section

insulator made of Cu-ETP copper (Figure 5), only the presence of copper was

confirmed based on the qualitative X-ray phase analysis, which was expected.

However, in the case of a guide that had been used for 12 months on a railway

line, where the trains travelled at the maximum speed of 120 km/h, apart from

copper, the presence of copper oxide Cu2O was found (Figure 6),

which was confirmed by the reflections from the planes (111), (002), (022) and

(113) of this phase. These results prove that during the operation

of the guide, copper oxide was released on its surface. This is because the

flow of electric current produces a thin layer of oxides, which may also play a

positive role as a lubricant on the contact surface [9, 12]. The thin oxide

layer formed on the contact surface excludes direct contact and reduces the

adhesion between the elements. According to some scientists [13, 14], the oxide

layer formed by the electric current on the contact surface of mating elements

plays a major role in reducing the coefficient of friction. However, the

authors [10, 15, 16] suggest that the flowing electric current works as a

lubricant in the pulling process at constant parameters.

Fig. 5. Diffractogram of a new guide

The thickness of

the oxide layer which is released as a result of the flowing electric current

can be determined using the following equation [17]:

![]() (1)

(1)

Rc – contact

resistance,

qc – electrical

resistance of copper,

q0 – electrical

resistance of a thin layer of copper oxide,

X – thickness

of the copper oxide layer,

a – radius of

the circle corresponding to the total contact area.

An unfavourable effect of the current flow through the

railway line during the friction process is the increase in the contact

temperature of the copper-graphite couple.

In the experiment performed by [18], the contact

temperature of the materials increased sharply at the beginning of the

experiment and became stable after about 20 minutes for the current of 0, 10,

20 or 30 A. The stabilisation of the

temperature is slower when the current increases and for 50 A it takes place

only after 50 minutes. The contact temperature of the tribological couple

increased with the increase in the applied electric current. The contact

temperature of the friction couple without the applied electric current was

about 40°C, and for the maximum value of the applied electric current (I =

50A), the temperature was much higher and was about 115-120°C. Similar

results were described in the article [16]. Further, It was found that the

synergistic interaction of Joule's heat, the heat caused by friction and arc

discharge, leads to a rapid increase in the contact temperature [19]. Hence, it

follows that a locomotive, which moves with a heavy freight train, due to the

intense consumption of electricity from the railway line, makes such line most

vulnerable to damage.

Fig.

6. Diffraction pattern of the guide after 12 months of operation on the route

with a maximum train speed of 120 km/h

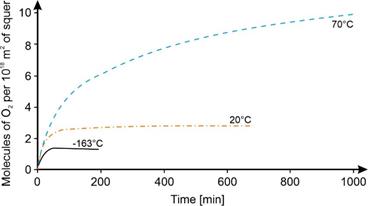

The increase in temperature on the surface adversely

affects the properties of copper. It is conducive to oxidation [6]. Figure 7

shows the dependence of the increase in the volume of copper oxides on its

surface with the time and temperature of exposure. With the increase in

temperature to 70°C, the volume of oxides increases more than four times

compared with the temperature of 20°C after 600 minutes of exposure and five

times after 1000 minutes. Moreover, the composition, size and nature of the

debris consisting of oxides formed on the contact surface affect the friction

between the friction elements, and thus, the nature of the couple's operation

[20].

Oxidation

occurs by diffusion of oxygen ions into the interior of the metal and sometimes

by metal ions, which diffuse out of the rough surfaces. When the oxide layer

reaches a critical thickness, it becomes unstable and disintegrates. Such

exposed unoxidised surface may re-oxidise [21].

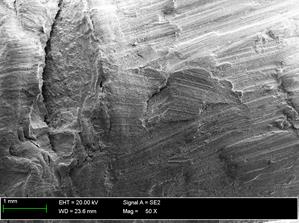

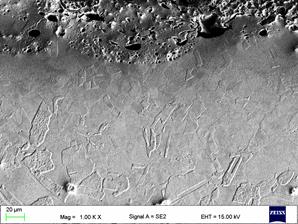

Thereafter, the microstructure of the guide's

working surface was examined using a scanning electron microscope. The

examination revealed abrasion marks visible on the surface caused by sliding

and friction of the current collector on the surface of the guide during

operation. The scratch lines are visible in the photo and run from left to

right (Figure 8) following the working direction of the pantograph. An area of

the base material was also noticed, which was torn off as a result of

exploitation, and then, due to successive slides of the pantograph (current

collector), glued/pressed with the guide base material in the contact place. A

detachment of the base material due to friction was also observed in [10].

The detachment of a part (volume) of the

material may also be caused by the plastification of the material due to a

sudden increase in temperature from an electric arc. Because the pressure force

of the current collector is not big enough to cause the effect shown in Figure

8 without the influence of temperature.

Fig.

7. Effects of temperature on oxidation of copper [6]

Fig.

8. Microstructure of the working surface of P2 sample (120 kph for 12 months)

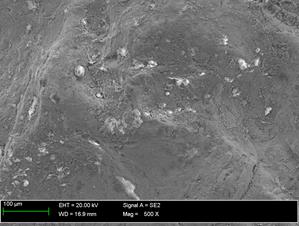

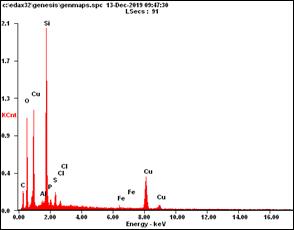

The next step in the analysis of the failure

mechanisms of the section insulator guide was the analysis of intensity as a

function of energy-dispersive X-ray spectroscopy (Figure 9). Burned craters

were noticed in the microstructure of the surface of the guide. The analysis of

the chemical composition in the micro-areas confirmed the presence of carbon,

oxygen, silicon and copper as well as small amounts of iron, sulfur, aluminium,

phosphorus and chlorine (Figure 9c). A large amount of oxygen indicates

the presence of oxides. The reason for such a large increase in oxides is most

likely the phenomenon of an electric arc generated during the jump of the

current collector between the guides of neighbouring sections of the railway

traction. An arc usually occurs as a result of the distinct potential

differences between the neighbouring sections. The temperature in the centre of

an arc may rise to several thousand degrees Celsius [22]. The presence of

oxides on the examined surface is evidenced by numerous bright areas in the

photo (Figure 9a, b) caused by the lack of electrical conductivity of the

electron beam forming the image in the electron microscope. The particle shown

in Figure 9b can also be a grain of sand, which was pulled in the gust of the

moving train, then got between the surfaces of the current collector, softened

by the high temperature of the electric arc of the guide and finally pressed

into the guide. The large increase in temperature also generated local melting

of the basic material and its subsequent rapid cooling caused numerous

stresses, leading to local cracks in the material of the guide (Figure 9b).

burned crater crack b) a)

![]()

![]()

![]()

![]()

c)

Fig. 9.

Microstructure of surface of P2 sample (120 km/h for 12 months) (a, b)

and analysis of the chemical composition of

the marked area (c)

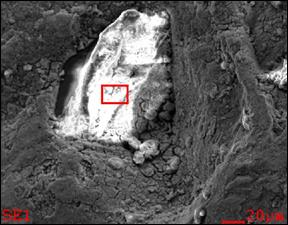

The effect of an

electric arc on the copper guide is shown in Figure 10. In the upper part of the

guide's cross-section (Figure 10a), a melted area of the material is visible,

whereas, below there is a transition zone and then the microstructure of the

Cu-ETP guide. Some grains are visible in the microstructure.

Figure 10b,

which is a top view of the guide's working surface, on the left can be seen a

melted area and on the right side, there is a groove carved by the current

collector. The geometrical features of the groove indicate that it could have

been carved by foreign particles, that is, sand grains that got between the

working surface of the guide and the current collector. The melted layer of the

vitrified material of the guide is interspersed with holes from which gases

escaped during melting. The nature of these damages clearly indicates surface

erosion caused by an electric arc. A negative effect, which an electric arc has

on the elements of the railway traction, is the significant porosity of the

melted metal. The pores can be penetrated by pollutants or water from

precipitation, which may constitute local corrosion centres. Moreover, the

metal melted in such conditions is characterised by unfavourable

mechanical properties and reduced resistance to frictional wear. As earlier

indicated, the oxide layer grows to a critical thickness, and then separates

from the base material, revealing a non-corroded material layer, which may

oxidise again [21].

Depending on the

parameters of the current, an electric arc consists of many separate,

simultaneous discharges. Because the typical spot size is within the sub-micron

range, local melting causes characteristic craters. The arc jumps from one

place to another with a greater likelihood of ignition near the craters of

previous arcs. Eventually, macroscopically visible traces are formed,

consisting of many craters with a micron range [23, 24].

Fig.

10. Microstructure: (a) of the cross-section of the guide,

(b) of the working surface of

the guide

Arc

erosion also depends on the cleanliness of the surface [24]. An electric arc

can move quickly and remove only the surface layer of the material or cause

erosion of the material. Erosion is the result of an arc plasma that consists,

among others, of ions of the material and due to high temperature causes

melting or even evaporation of the surface material [25]. The melted material

can only move a few microns. In this way, craters are formed or the material is

scattered by the pressure of droplets, which form the arc plasma [26].

The ignition

of an electric arc occurs when the actual local electric field strength exceeds

the critical field strength. This value, characteristic for a given place,

depends, among others, on the material of the cathode, the surface geometry in

nano- and microscale, as well as on dielectric layers and solid particles. The

ignition is much easier when dielectric layers and 'contaminants' are present

on the surface so that more spots can ignite and operate in parallel,

electrically competing for available power. In the absence of field enhancing

dielectrics, ignition is less likely, and the power is concentrated in a small

number of fragments [24].

The

article [27] states that the normal load is one of the main controlling factors

for the generation of an electric arc during the friction process of the

copper/graphite coupled with the electric current applied. The strength of an

electric arc is enhanced with the decrease of normal loads and the increase of

electric currents. At lower normal

loads (Fn ≤1.0 N) during tests with applied electric current, the

friction process is unstable, and the friction coefficient fluctuates quite

strongly due to the appearance of an electric arc.

An electric arc burning in the

air is characterised by

high temperature [5, 22], high current density and a small voltage drop along

its length. An electric arc in the air does not limit its length only to the

space between the electrodes, but it elongates under the influence of the force

generated by its own electromagnetic field. One of the effects of an electric

arc is an accompanying pressure shock wave, which rapidly heats the air along

the arc axis. Consequently, a hot stream of gases lifts melted metal particles

from the surface of the conductor [4].

4.

CONCLUSIONS

The guides of section insulators are made of

Cu-ETP copper, and during operation, they wear out because of several

mechanisms. Based on the analysis of the presented research results, it can be

concluded that:

· friction, corrosion (oxidation of copper) and

an electric arc constitute the mechanisms responsible for damage of the guides;

· corrosion depends on the process of

diffusion, which is thermally activated, and its intensity increases with the

increase of energy, the presence of an electric arc will significantly

accelerate it;

· the results of microscopic examinations

clearly show that the dominant wear/destruction mechanism of the guides is an

electric arc, and the damages are its consequences. The increase in temperature

in the centre of an electric arc, which according to the literature data, can

reach even 20,000°C [5, 22], is the factor responsible for the greatest

damage to the guide. Since the action of this factor is very short (a few

hundredths of a second), the damage to the guide may not be visible in a short

time;

· the

increase in temperature at the interface between the guide and the current

collector caused by both friction and Joule heating adversely affect the

properties of the copper. It is conducive to the oxidation phenomenon, and the

composition, size and nature of the oxidation products have an impact on the

friction phenomenon, and thus, on the nature of the mating of the guide-current

collector couple [20];

·

thermal

wear, arc erosion and abrasive wear are the dominant wear mechanisms, which

take place in the process of sliding friction in the flow of electric current

that accompanies the transfer of material [13];

· contamination on the contact surface of the guide with

the current collector and changing the guide geometry may facilitate the

ignition of an electric arc [24].

References

1.

Załącznik

do zarządzenia Nr 14/2010 Zarządu PKP Polskie Linie Kolejowe S.A. z

dnia 10 maja 2010 r. Wytyczne projektowania, budowy i odbioru sieci trakcyjnej

oraz układów zasilania 2×25 kV AC dla linii kolejowych o

prędkości do 350 km/h Iet-6. [In Polish: Annex

to the order No. 14/2010 of the Management Board of PKP Polskie Linie Kolejowe

S.A. of 10 May 2010. Guidelines for the design, construction

and acceptance of the overhead contact line and 2 × 25 kV AC power supply

systems for railway lines with a speed of up to 350 km/h Iet-6]. P. 88. Available

at:

https://www.plk-sa.pl/files/public/user_upload/pdf/Akty_prawne_i_przepisy/Instrukcje/Wydruk/Iet-6.pdf.

2.

BN-769317-109. Sieć

trakcyjna kolejowa. Izolatory

sekcyjne. Warszawa: Centralny Ośrodek Badań i Rozwoju Techniki Kolejnictwa/Instytut

Kolejnictwa. [In Polish: Railway traction

network. Section insulators. Warsaw: Central Research and Development

Center of Railway Technology/Railway Research Institute].

3.

Szeląg

Adam. 2005. “Problemy oddziaływania trakcji elektrycznej na

środowisko”. Technika Transportu Szynowego 11-12: 46-57.

ISSN: 1232-3829. [In Polish: “Problems of the

influence of electric traction on the environment”].

4.

Gierlotka

Stefan. 2008. „Łuk elektryczny i skutki jego działania na

człowieka”. Elektro Info 9: 100-102. ISSN: 1642-8722. [In

Polish: „Electric arc and its effects on humans”].

5.

Kano

Ryota, Nemoto Yusuke, Maeda Yoshifumi, Yamamoto Shinji, Iwao Toru. 2020.

„Arc temperature measurement with microsecond spectroscopic

measurement”. Electrical Engineering in Japan 210: 29-36. ISSN:

0424-7760. DOI: https://doi.org/10.1002/eej.23259.

6.

Chapman

David, Toby Norris. 2014. Copper for Busbars. Copper Development

Association Publication No 22. Available at: https://leonardo-energy.pl/wp-content/uploads/2016/09/EIM6105-Szynoprzewody-wykonane-z-miedzi-poradnik-ang.pdf.

7.

PN-EN

1976:2013-04. Miedź i stopy

miedzi. Wyroby odlewane z miedzi nie przerobione plastycznie. Warszawa: Polski

Komitet Normalizacyjny. [In Polish: PN-EN 1976:2013-04. Copper and copper

alloys. Copper-cast

products not wrought. Warsaw: Polish Committee of

Standardization].

8.

PN-EN 1652:1999. Miedź i stopy

miedzi. Płyty, blachy, taśmy i krążki ogólnego

przeznaczenia.

Warszawa: Polski

Komitet Normalizacyjny. [In Polish: PN-EN

1652:1999. Copper and copper alloys.

General purpose plates, sheets, strips and

pulleys.

Warsaw: Polish Committee of Standardization].

9.

Benfoughal

Abdeldjalil, Ali Bouchoucha, Youcef Mouadji. 2018. “Effect of electrical current on friction and

wear behavior of copper against graphite for low sliding speeds”. UPB

Scientific Bulletin, Series D: Mechanical Engineering 80(3): 117-130.

ISSN: 1454-2358.

10. Azevedo Cesar

R.F., Amilton Sinatora. 2004. “Failure analysis of a railway copper

contact strip”. Engineering Failure Analysis 11: 829-841. ISSN:

1350-6307. DOI: https://doi.org/10.1016/j.engfailanal.2004.03.003.

11. Senouci

A., H. Zaïdi, J. Frêne,

A. Bouchoucha, D. Paulmier. 1999. „Damage of

surfaces in sliding electrical contact copper/steel”. Applied Surface

Science 144-145: 287-291. ISSN: 0169-4332. DOI:

https://doi.org/10.1016/S0169-4332(98)00915-5.

12.

Wang Yian A., Lin Jinxu X., Yan Yu, Qiao Lijie J.

2012. “Effect of

electrical current on tribological behavior of copper-impregnated metallized

carbon against a Cu-Cr-Zr alloy”. Tribology International 50:

26–34. ISSN: 0301-679X. DOI: https://doi.org/10.1016/j.triboint.2011.12.022.

15.

Guangxiong X.FengxueMinghao H.Friction and wear behaviour of stainless steel

rubbing against copper-impregnated metallized carbon”. Tribology

International 42(6): 934-939. ISSN: 0301-679X. DOI: https://doi.org/10.1016/j.triboint.2008.12.011.

16.

Zhao

Han, Barber Gary C., Liu J. 2001. “Friction and wear in high speed sliding with and without

electrical current”. Wear 249(5-6): 409-414. ISSN:

0043-1648. DOI: https://doi.org/10.1016/S0043-1648(01)00545-2.

17.

Holm

Ragnar. 1967. Electric Contacts. Fourth

ed. Berlin: Springer. ISBN: 978-3-540-03875-7.

18.

Ding Tao, Chen Guangxiong, Bu Jun, Zhang Weihua. 2011.

“Effect of temperature and arc discharge on friction and wear behaviours

of carbon strip/copper contact wire in pantograph–catenary

systems”. Wear 271: 1629-1636. ISSN: 0043-1648. DOI: https://doi.org/10.1016/j.wear.2010.12.031.

19.

Filice

Luigino, Fabrizio Micari, Stefania Rizzuti, Domenico Umbrello. 2007. „A

critical analysis of the friction modeling in orthogonal machining”. International

Journal of Machine Tools & Manufacture 47: 709-714. ISSN: 0890-6955.

DOI: https://doi.org/10.1016/j.ijmachtools.2006.05.007.

20.

Bouchoucha Ali, Said Chekroud, Daniel Paulmier. 2004.

“Influence of the electrical sliding speed on friction and wear processes

in an electrical contact copper – stainless steel”. Applied

Surface Science 223: 330-342. ISSN: 0169-4332. DOI: https://doi.org/10.1016/j.apsusc.2003.09.018.

21.

Bouchoucha

A., E.K. Kadiri, F. Robert, H. Zaïdi, D. Paulmier. 1995. „Metals

transfer and oxidation of copper-steel surfaces in electrical sliding contact”.

Surface and Coatings Technology 76-77:

521-527. ISSN: 0257-8972. DOI: https://doi.org/10.1016/0257-8972(95)02603-7.

22.

Szadkowski

Marek. 2016. Zagrożenie

porażeniem łukiem elektrycznym w instalacjach nn I SN. Stowarzyszenie

Elektryków Polskich o. Tarnów [In Polish: Electric arc hazard in LV and MV

installations. Association of Polish Electrical Engineers, Tarnów].

Available at: http://www.sep-tarnow.com.pl/files/Zagrożenie

porażeniem łukiem-elektrycznym w instalacjach-nn-i.pdf.

23.

Jüttner

Burkhard. 2001. „Cathode spots of electric

arcs”. Journal of Physics D: Applied Physics 34: R103. DOI:

https://doi.org/10.1088/0022-3727/34/17/202.

24.

Anders

André. 2005. „The fractal nature of vacuum arc cathode

spots”. IEEE Transactions on Plasma Science 33(5): 1456-1464. ISSN:

0093-3813. DOI: https://doi.org/10.1109/TPS.2005.856488.

25.

Daadler

J.E. 1981. „Cathode spots and vacuum arcs”. Physica

B+C 104(1-2): 91-106. ISSN: 0378-4363. DOI:

https://doi.org/10.1016/0378-4363(81)90040-1.

26.

Rohde

Volker, Martin Balden. 2016. „Arc erosion of full metal plasma facing

components at the inner baffle region of ASDEX Upgrade”. Nuclear

Materials and Energy 9: 36-39. ISSN: 2352-1791. DOI:

https://doi.org/10.1016/j.nme.2016.09.006.

27.

Lin Xiu-Zhou, Min-Hao Zhu, Ji-Liang Mo, Guang-Xiong Chen, Xue-Song

Jin,

Zhong-Rong Zhou. 2011. „Tribological and electric-arc behaviors of

carbon/copper pair during sliding friction process with electric current

applied”. Transactions of

Nonferrous Metals Society of China 21: 292-299. ISSN: 1003-6326. DOI: https://doi.org/10.1016/S1003-6326(11)60712-7.

Received 03.10.2021; accepted in

revised form 20.11.2021

![]()

Scientific Journal of Silesian University of Technology. Series

Transport is licensed under a Creative Commons Attribution 4.0

International License