Article citation information:

Dhonde, B.,

Patel, C. Impact of industrial freight flows on the overall

traffic in Surat city, India. Scientific

Journal of Silesian University of Technology. Series Transport. 2021, 113, 45-59. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.113.4.

Bhavesh DHONDE[1],

Chetan PATEL[2]

IMPACT OF INDUSTRIAL FREIGHT FLOWS ON THE OVERALL TRAFFIC IN SURAT CITY,

INDIA

Summary. Surat is one

of the major textile manufacturing hubs in India, having 40% of the synthetic

fabric produced in the country. The textile industry in the city has witnessed

tremendous growth in the last decade, leading to many transportation-related

changes within it. Textile manufacturing has different phases like weaving,

processing, value addition and trading or distribution. These phases are

located as clusters or pockets in different parts of the city. The scattered

nature of the industry generates numerous freight trips. This study focuses on

characterizing and estimating textile freight trips in the city. Establishment

survey data was collected from production units located in various clusters. A

multi-linear regression model for freight trips generated using the quantity of

cloth produced was developed for the estimation of the total textile freight

trips. Thus, this study will help the planner identify the strategic location

of the textile and its allied industries as well as for freight infrastructure

in the city. More so, it would help in understanding the impacts of textile

freight movement on the city’s overall traffic.

Keywords: urban

freight; textile; traffic, industry

1.

INTRODUCTION

Urban freight transportation is entirely

different from passenger transport, and significantly affects the

transportation system and environment [1-3]. The freight movement has gradually

become top on the priority list for all major transport researchers and

stakeholders around the world due to its unpredictable characteristic at the

city level. Although remarkable research studies have been carried out in the

various areas of freight movement like urban, regional and international

freight movement and in technologically advanced nations like the U.S., U.K.,

Germany, Netherlands, Sweden, Japan, etc., it is still at a dormant stage in

most developing economies of the world including India. India is considered one

of the fastest-growing major economies in the world and it is expected to have

at least 10 megacities by 2030. With its high growth in industrialization and

expanding city boundaries, the movement of goods in its cities is becoming

increasingly complex. Cities in India, like most developing nations, have a

highly heterogeneous traffic condition. Lane discipline and traffic sense are

usually in a dismal state in most Indian cities. In such a scenario, the goods

vehicle movement often results in overall speed reduction and acts as a

hindrance to the flow of other private and public vehicles. The current

situation is bound to grow worse with increasing urbanization and cities

getting denser.

Textile manufacturing is the second largest

industry after agriculture, offering large-scale employment to both skilled and

unskilled workforce, with more than 35 million people in the country directly

engaged in it. In India, many cities like Surat, Kanpur, Ahmedabad, Mumbai,

Banaras, Mysore, Kolkata, Coimbatore and Madurai are hubs of textile

manufacturing. The urban freight movement resulting from the textile industry

upsets the city traffic operation and has great impacts on its congestion and

pollution levels. The quantification of this congestion and CO2

emission has prompted the need to control the chaotic movement of goods

traffic. To understand the quantum of trip generation of this industry, this

study was conducted. Multi-linear regression model for trips generated and

quantity of cloth produced due to the weaving unit in the study area was

estimated.

2. STUDY AREA DETAILS

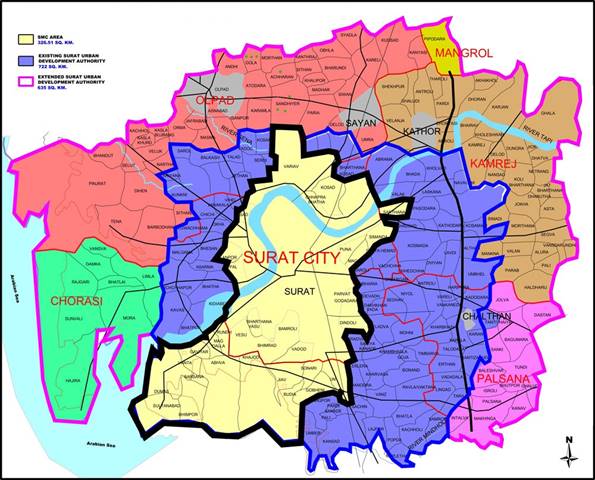

Surat is located in the state of Gujarat in

the western part of India. A detailed map of the Surat metropolitan area

highlighting the area of Surat city is shown in Figure 1. It is one of the

fastest-growing major cities in the country, ranked as the 9th biggest city in

the country from a population and size of the economy point of view. The city

of Surat is popularly known as "The silk city" or "The synthetic

capital of India".As per the census of India in 2011, Surat city has an

area of 326.515 sq. km with a

population of 4,466,826 people [1]. The city has a density of 13,680

persons/sq. km. The decadal population growth of the

city is 55.29% (2001-11). It has seven administrative zones, 29 election wards

and 101 census wards.

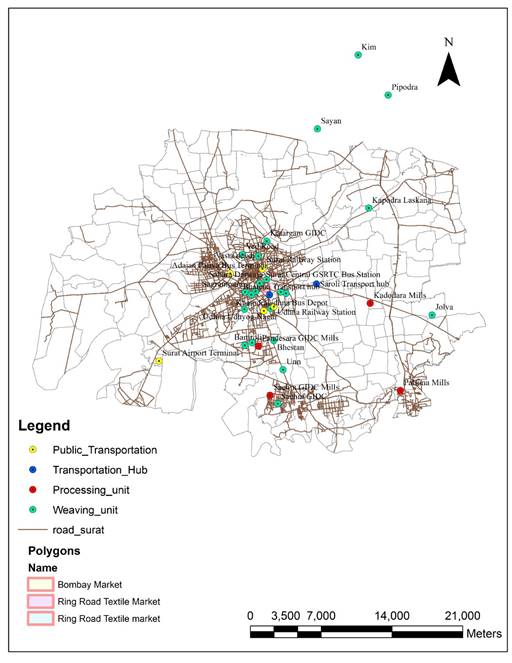

The major industries in Surat are textile, diamond polishing, engineering, chemicals, etc. A report by the Industrial Entrepreneur Memoranda (IEMs) (2006-07) on Surat district showed that textile has the highest employment generation potential. Majority of the population migrating to Surat for employment are involved in the textile industry. Surat accounts for 40% of the nation’s synthetic fabric production and 28% of synthetic fiber production. It similarly accounts for 18% of the total nation's synthetic fiber export. As per the report of Vibrant Gujarat (2017), the textile industry of Surat produces 30 million meters of raw fabric and 25 million meters of processed fabric daily [2]. The textile industry in the city has developed organically with different segments of production units located in different parts of the city. The main segments of the industry, which are the weaving unit, the processing and dyeing unit and value addition, are located in different parts of the city in the form of industrial clusters. A schematic representation of various textile manufacturing segments and various transportation hubs in the city is mapped using the ArcGIS software shown in Figure 2.

Fig. 1. Surat city

and metropolitan area

To understand the scale of operations and have a basic understanding of the textile industry of the city, secondary data regarding the numbers and location of the various units were obtained from the Office of Textile Commissioner, Ministry of Textile, and Regional Office. Various other associations and societies working in collaboration with the textile industry were met to understand and devise an effective and efficient methodology toward obtaining primary data from the various units. These associations included Man-Made Textiles Research Association (MANTRA), Ved Road Art Silk Small Scale Co-operative Federation, Pandesara Weavers Co-operative Society, The Federation of Gujarat Weavers' Association (FOGWA), The Surat Art Silk Cloth Manufacturers Association (SASCMA), Federation of Indian Art Silk Weaving Industry (FIASWI), Southern Gujarat Chamber of Commerce and Industry (SGCCI), District Industries Center (DIC), and the Ministry of Micro, Small and Medium Enterprises.

Fig. 2. Schematic location of

segments of the textile industry in Surat

3. LITERATURE REVIEW

Ideally, like other passenger transport modes, freight transport equally follows the conventional four-step modeling, that is, trip generation, trip distribution, mode choice and route assignment. However, unlike passenger transportation wherein most of the decisions concerning all four stages of the trip are believed to be rationally taken by the passenger himself, the biggest challenge with freight transportation is that each stage involves multiple agents in the decision-making process for the freight or goods transported. This is compounded by the fact that they have their priorities and interests, which are diverging sometimes.

3.1. Commodity flow surveys

The study for achieving harmonious freight flows started in the early '60s in Europe and the U.S. Most researchers used different forecasting tools to project the freight generated using different parameters like establishment size, number of employees, or industry attributes. Several models have been proposed and used for freight generation in different states of the U.S., which are synchronized with their state-level planning policies. Over time, freight studies began to consider regional and interregional commodity flow for understanding freight flow patterns. The major research contributions are; estimation of zonal commodity generation using commodity-type specific growth rates [3], estimation of freight generation at the national level [4], modeling of interregional commodity flows that incorporates regional flow relationships and the corresponding transportation network flows [5]. Giuliano et al. (2010) estimated intra-metropolitan freight flows on a highway network [6], use of input-output (IO) data with employment and population information to estimate commodity production and attraction at zonal level [7]. IO models took commodity flow surveys as their prime database. These models are generally implemented for large-scale systems at the regional, national or international level, as they require a great amount of data on regional economic activity and interregional flows. The basic requirement of these types of models is that they require very rigorous commodity flow data. While the commodity flow survey is fundamentally based on the number of tons produced or attracted by a zone, enabling understanding of the prime economic activity of the study area. The destinations to which these goods are transported give a distribution pattern, which, indirectly, can be used to access the type and volume of vehicles depending on the available modes. This method, however, does not explain the movement of empty trucks or return trips generated after the delivery of goods. In addition, this method assumes that the origin-destination pairs would naturally follow the shortest route, which is not always the case. Besides, the data collection in this method of survey is very expensive and time-consuming, making it less attractive among researchers.

In a country like India, such a system hardly exists, there are interzonal freight flow data available for the rails but no such database for road movement. In this case, it becomes very difficult to prepare commodity flow models in the Indian scenario. However, depending on the type of industry, a strong commodity flow database can be developed by pooling the data of the various commodity produced from the trade association or society, which manages a directory of the list of producers in a particular region. For example, data related to the type and quantity of a particular textile manufactured in a particular industrial clustered can be obtained from the association of processing units or mills.

3.2. Vehicle trips surveys

The time being alternative to these commodity flow models for the Indian scenario is the freight models based on vehicle trips. These models are widely used in countries like the Netherlands, Germany, Italy, the U.K. and the U.S. These models focus on the movement of freight vehicles between their origin and destination points thereby giving an idea of the freight flow across the study area. The data for these models are obtained either from the origin-destination points or from the field data using vehicle volume counts. Over the last two decades, these models have been preferred for surveys at the city or metropolitan region level. Researchers in the west have used different modeling techniques for forecast freight generation (FG), or freight trip generation (FTG). The major contributions include the use of linear regression [8], cross-classification and ordinary least square (OLS) for estimating disaggregated freight trip delivery rates [9], analysis of trip generation characteristics for special land use truck traffic [10]; and consideration of the supply chain decisions made by individual businesses [11]. The basic advantage of a vehicle trip-based survey is that it considers a freight vehicle as a unit, and so a large amount of data can be obtained by various surveys related to the vehicle counts like traffic volume study, screen counts and cordon study. In addition, while considering the vehicle trip survey, considering the empty vehicle trip is not much of a problem as it observes only a trip made by a goods vehicle in either of the direction, which means the return trip with some other goods would be considered as a separate unit in the survey. Thus, data availability is quite easy and at a lower cost using this method

Although the vehicle trip survey method is better compared to commodity flow, it also has some disadvantages. First, it is unable to model any economic value for the study area based on the vehicle trips survey. This is merely the number of trucks moving in the study area, relating it to the amount of various production and consumption pattern is quite difficult. Further, the use of this method becomes even more complicated when more than one mode of transport is likely capable of movement of goods between a pair of locations, which is the usual real-life scenario. Hence, this model alone is also unable to completely model the freight movement. For understanding and modeling the actual freight movement, we need to understand the two dimensions of it, that is, the volume or weight and the vehicle trips, which corresponds to the freight generation and freight trip generation, respectively. Volume or weight of freight generated can be well estimated using the commodity flow method, for forecasting the freight trips generated from the vehicle trip-based models, would give better estimates. Combined studies taking data both from commodity flow and vehicle trips can be modeled to get complete freight flow models, which is probably the way forward.

3.3. End consumer goods movement study

Apart from the trip generation models at the establishment level of various types, another area that is explored in freight studies is the end consumer goods movement. This can be defined as the movement of goods from the retail outlets/points to the point where their end consumption takes place. End consumer goods movement can be a conventional approach wherein the consumer makes the trip for purchasing the goods, or internet or telecommunication-based order is placed for a specific goods/commodity that has been purchased. Estimation of the total number of housing shopping trips by using such variables as household size, number of workers, number of licensed persons, and number of vehicles [12]. Further, a general transportation rates model to find the main factors that affect the total number of shopping trips in North American metropolitan areas, adding to classical models some hypothesized factors, which note the effects of new technologies, such as e-commerce, teleshopping and grocery home delivery services [13]. Similar other studies have been conducted by other researchers in different cities [14-16]. Recently, a study on economic and policy analysis of e-commerce and traffic congestion was reported [17].

3.4. Online shopping and delivery pattern study

In the case of online shopping, the customer goes to a website/mobile application and browses through the goods displayed via text and graphic information. After selecting, the customer pays electronically either using a credit card or some other form of electronic payment or even cash on delivery when the goods are shipped directly to the customer’s home [18]. While substantial literature is available on the impact of online shopping and travel behavior of the customers, there are two schools of thought, first is that the customer would first go to the physical stores to make an actual selection of the goods, and then would browse for online shopping, which would eventually increase the overall vehicle kilometers traveled (VKT) [19]. The second is that online shopping would gradually act as a complete replacement of the old travel patterns and there would be consolidation of the city logistics [20, 21]. On the freight side, among other things, the possibility of cheaper online goods due to economies of scale would increase demand, which, in turn, would increase the number of deliveries made. Additionally, online ordering increases the potential for goods to travel further as they can be ordered from anywhere in the world. The combined outcome of all factors indicates that e-shopping will reduce travel on the net. However, on the contrary, there may be negative impacts due to increased travel, even if those impacts are likely to be localized and/or small in magnitude for the most part [22].

In India, in the recent past, some researchers have worked to model freight transport for urban areas as well as regional levels. Documented findings for the research in these areas include the development of freight trip generation models for Chennai, India, with disaggregated survey data at the establishment level [23]. Development of a static freight distribution model of commodity flows over the city’s transport infrastructure using data collected from a cordon survey of freight vehicles in Ahmedabad [24]. Analysis of the role of Non-Motorized Transport (NMT) in goods movement both in core commercial areas as well as in the old city in Delhi [25]. Inbound and outbound forecasting models for freight generation at Mumbai port [26]. Recently, a study was conducted to access the transferability of freight generation models for seven different cities in the state of Kerala, India [27].

4. DATA COLLECTION

AND ANALYSIS

As per the data registered with the Office of Textile Commissioner for the year 2011-2012, there are about 6.2 lac plain power loom machines, 513 processing units, 140 textile markets and 8 textile parks in Surat. There are more than 60,000 traders associated with the industry here. Recently, value addition units like embroidery and laces have grown and it is estimated that there are more than 1.25 lacs of these machines currently installed in the city. The exact number of the machines or units are not available as the industry is highly segmented and small-scale operation makes it difficult to have exact data. The industry does not have any controlling manufacturing policy; hence, the data obtained are only close estimates from the concerned authorities. It was understood that after every segment of textile, goods travel to ring road trading market area, making additional 4-5 trips of textile goods during the process of manufacturing of finished goods from grey cloth.

From the literature review and meeting with personnel, factors were identified and a questionnaire survey form was made. A survey was conducted by visiting the weaving units located in different parts of the city. Two hundred and fifty weaving units were approached, of which 122 owners agreed to the survey. The questionnaire survey form was divided into sub-sections. The various subsections of the form are- establishment information, owner's information, weaving machine details, building use and area details, cluster details, employee details, work hours details, parking facility, cargo produced/received details, details of the trip starting from the weaving unit, details of the trip ending at the weaving unit and establishment related details.

From the data collected, it was understood that different machines require a different number of employees and area, production varies as per machine type, work time, the method used for manufacturing, even some machines produced finished goods (for example, jacquard machine produced sari). As owners were reluctant to share data; some part of the data was not obtained as required for establishing relationships for a trip generation while some data points were found outlying the other data points. Some data points were not within the 95% confidence interval. As the outcome of the textile industry is dependent on all these factors and deviation in these factors causes deviation in the outcome. Such samples were considered as outliers and a relationship was formed for data obtained for plain power loom machines only, as plain power loom machines account for 96.57% of the total weaving machines in the study area. From the 122 samples, 42 samples were used for the trip generation model. It was observed from the overall information obtained from the survey that the freight trip generation (FTG) and quantity of cloth produced from a unit have a very strong positive correlation. Hence, the quantity of cloth produced is considered as a surrogate measure for estimating FTG from the production units. From the data analysis, it is observed that the quantity of cloth produced and termed as output is largely dependent on three factors of production that are as follows,

· Number of weaving machines installed

· Number of employees at the unit

· The total floor area of the unit.

Linear regression equations were derived for these factors toward understanding the effect of these factors individually on trip generation and quantity of cloth produced by the plain power loom machine. Figures 3 - 5 shows the linear regression results for trips generated and the quantity of cloth produced. Other factors like road width, municipal facilities, and electricity supply have a negligible impact on the production of textiles in the city

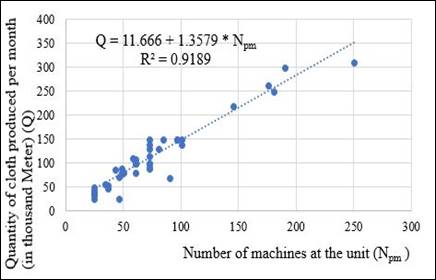

4.1. Relationship between output and number of weaving machines

In linear regression analysis, the quantity of cloth produced is a dependent factor and the number of weaving machines installed at the establishment is an independent factor. Some units have waterjet or rapier type of weaving machine, wherein area requirement is more as compared to the regular power loom machines. As stated by the owners of the weaving unit, the quantity of production varies from unit to unit due to the method of production adopted by the unit. Figure 3 shows the graph for the 42 observations noted at the power loom units. The linear regression equation is given as:

![]() (1)

(1)

where,

Q = Quantity of cloth produced per month in 1000 m,

Npm = Number of power loom machines at the unit (in number).

The linear equation implies that one machine can produce 1.35 thousand meters of cloth per month. From Figure 2, it can be observed that the same number of machines produce different amounts of cloth in some cases. Production is dependent upon the quality of raw material, manufacturing techniques used for production and work hours of the machine. From the graph, it is observed that the same number of machines have a variety of amount of cloth production

Fig. 3. Linear relation graph for production output and number of machines

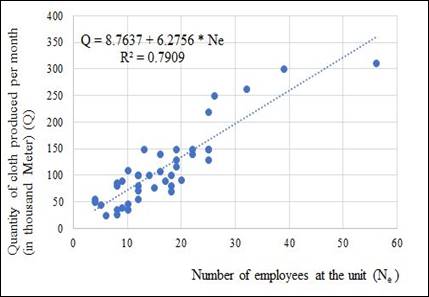

4.2. Relationship between output and

number of employees

For power

loom units, which consist of most

weaving units in the city, the number of employees required for the operation

of the unit is dependent on the type of weaving machines and additional

activities undertaken during and after the fabric production. The survey showed

that there are different categories of workers employed in the weaving unit.

The different workers are the power loom unit workers, TFO workers, winding workers,

etc. It was observed that one worker could handle 12 power loom machines for

one shift. The number of workers depends on the number of machines at the unit

and work hours of the unit, which is the reason for the point lying away from

the trendline as shown in Figure 4. The linear

regression equation is given as:

![]() (2)

(2)

where,

Q = Quantity of cloth produced per month in 1000 m,

Ne = Total Number of employees (in number).

The linear equation

implies that one employee produces 6.27 thousand

meters of cloth per month. As shown in Figure 3, points are away from the

trendline, the reason for this is the work hours of the unit and the type of

fabric variety produced at the unit. The numbers of workers are different for

the same number of machines reason being that the work hours of the unit

varies. Staff scenario is different for different units. In some units, the

owner plays the role of staff, at some places, staff workers work for 2-3 units

at different times of the day, whereas for some units, staff work for a single

unit. The number of staff depends on the need and quantum of working of the

unit. It is observed in certain production units that additional staff is

required for winding, warping and resizing of the fabric, which does not add to

the total production output from the unit.

Fig. 4. Linear relation graph for production output and number of employees

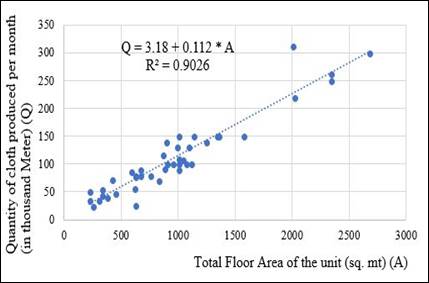

4.3. Relationship between output and

total floor area of the establishment

From

discussion with owners of weaving units, it was understood that power loom

machines are mostly placed on G + 1 floors. In rare cases, they are placed on

the upper floor; on the upper floors other activities of manufacturing (TFO or

warping, etc.),

storage (warehouse), office uses, and use by embroidery units

usually occur. Owners were not able to provide the specific area details (that

is, the area under manufacturing of grey cloth), which is the main reason for

the variation of points from the trend line as shown in Figure 5. The linear regression equation is given as:

![]() (3)

(3)

where,

Q = Quantity of cloth produced per month in 1000 m,

A = Total floor area at the unit (in sq. mt.).

The

linear equation implies that one sq. mt. of the area produces 112 meters of

cloth per month. As explained before, it is difficult to find the exact area

under the machine, which results in variation in the results. At the same time,

for the same area, working hours play an important role in estimating the

quantity of cloth produced. Linear regression derived for the quantity of cloth

produced per month in 1000 m shows results for individual factors as summarized

in Table 1.

To

find the combined effect of these factors on trip generation and quantity

produced, the multi-linear regression should be derived. A multi-linear

regression model was prepared for estimation of the quantity of cloth produced

per month based on independent factors such as the number of power loom

machines, area of the unit and number of employees. This multi-linear

regression model gives a combined result of the independent variable on the

dependent variables.

Fig. 5. Linear relation graph for production output and total floor area

Tab. 1.

Summary of linear

regression for the quantity of

cloth produced per month in 1000 m

|

Linear regression equation

for the quantity of cloth produced per month in 1000 m |

Remark |

|

Q = 3.18 + 0.112 * A |

One sq. mt. of an area can produce 112 m of cloth per month |

|

Q = 11.666 + 1.3579 * Npm |

One machine can produce 1357 m of cloth per month |

|

Q = 8.7637 + 6.2756 * Ne |

One employee can produce 6275 m of cloth per month |

5. RESULTS

Quantity

produced in thousand meters per month is a dependent variable in the multi-linear regression model. The total number

of power loom machines at the unit, total floor area of the unit and the total

number of employees employed at the unit in all shifts are the independent

variables in the model. Multi-linear regression model for quantity produced in thousand meters per month is

given as:

![]()

![]() (4)

(4)

where,

Q = Quantity

of cloth produced in 1000 m per month,

Npm

= Total number of machines at the unit (in number),

Ne

= Total number of employees at the unit (in number),

A = Total

Floor Area of the unit (in sq. mt.).

As

per the data collected, there are 6.2 lac power loom machines, 25,000 weaving

units, and the average area of one unit from the survey is obtained as 970 sq.

mt. The number of employees is considered as per the thumb rule that one worker

can handle 12 machines for one shift of 12 hours. From this data, the magnitude

of trips generated per month due to a weaving unit can be estimated.

Quantity

produced in thousand meters per month = 1751923.269

Quantity

produced in thousand meters per day = 58397.4423

As per the

model, approximately 58.39 million meters of cloth

production per day will be generated due to the power loom unit. From the

interviews with the industry experts, it was derived that light commercial

vehicles having a laden weight capacity ranging between 0.6 to

1.5 tons are commonly used for transportation of

textile goods in the city. In this study, an average loading capacity of 1 ton

per vehicle was considered. Further, from the interviews with the power

loom operators, it was discovered that

the approximate weight of 1000 meters of cloth is around 75 kilograms. Thus,

the total number of trips generated due to textile production in the city can

be estimated from the total production output.

Total freight

trips resulting from textile production in the city =

The total quantity of cloth produced (in 1000

m) ![]() Average laden capacity of LCV

Average laden capacity of LCV

Approximate weight per 1000 m of

cloth

Total trips from textile production are =

4380 LCV trips per day.

Figure 2 shows the location of all the segments of the

textile industry in Surat along with the transit terminals. It can be observed

that most weaving units and transportation hubs are concentrated near the

central part of the city where the ring road market is located. This setup

leads to textile freight movement within the central part of the city. This

textile freight movement creates a hindrance to the normal traffic of the city.

The estimates of the multi-linear regression model for the quantity of cloth

produced shows 58.39 million meters of cloth

production per day and the generation of approximately 4400 LCV freight trips

per day. This huge number of trips creates traffic congestion in the ring

road area. The estimated trips are only the trips for carrying grey cloth from

the weaving unit to the ring road trading area. Further trips are not estimated

in this study. The set-up of different segments of the textile industry in

different parts of the city attracts textile freight movement within the city.

6. CONCLUSIONS

City sprawl plays an important role in the increase and mixed traffic flow conditions of the urban traffic and textile freight movement. Initially, textile segments were located on the outskirts of the city, hence, causing no traffic problems to it. However, gradually, city sprawl took place and segments came near to the city boundary, increasing traffic problems. Presently, due to the further sprawl of the city, most segments of the industry are within the city limits. This results in the ring road textile market area acting as a central trading hub located centrally within the city limits for the industry. Linear regression model for trips generated and quantity of cloth produced showed a linear relationship between dependent and independent variables satisfying the value of R2. A multi-linear regression model for Trips generated and quantity of cloth produced by the plain power loom machine was formed. The estimates of the multi-linear regression model for the quantity of cloth produced showed 58.39 million meters of cloth production per day and generation of approximately 4400 trips per day (approximately 750-800 trips per hour for an average peak of 2.5-3 hours during morning and evening times). Accordingly, these trips included trips from the weaving unit to the ring road market or export (that is, single trip); further trips or the trips attracted for delivery of raw material to the weaving unit are not included. There is a dearth of data in this sector due to its highly decentralized nature, otherwise, there is wide scope for the study of the trips generated and attracted by the setup of the textile industry in the city.

References

1.

Davidich N., A.

Galkin, V. Sabadash, I. Chumachenko, T. Melenchuk, Y. Davidich. 2020.

“Projecting of Urban Transport Infrastructure Considering the Human

Factor”. Communications -

Scientific Letters of the University of Zilina 22(1): 84-94.

2.

Konstantinus A.,

M. Zuidgeest. 2019. “An investigation into the factors influencing

inter-urban freight mode choice decisions in the Southern African Development

Community region”. Journal of

Transport and Supply Chain Management 13: 1-11.

3.

Rossi R., M.

Gastaldi, S. Nocera, R. Danielis (Eds.). 2010. “Freight Transport

Modeling”. European Transport \

Trasporti Europei 46(Special Issue). 13th Euro Working Group on

Transportation Meeting (EWGT2009). September 23-25, 2009 Padua (Italy).

4.

Census of India,

2011. Gujarat Series 25, Part XII-B, District census handbook, Surat.

Directorate of Census Operation, Gujarat, India. Available at: https://censusindia.gov.in/2011census/dchb/2425_PART_B_DCHB_SURAT.pdf.

5.

Vibrant Gujarat

Summit. 2017. Vibrant Gujarat Global Summit Report. Government of

Gujarat. India.

6.

Waliszewski

Janine, Dike Ahanotu, Michael Fischer. 2004. “Comparison of Commodity

Flow Forecasting Techniques in Montana”. Transportation Research

Record – Journal of Transportation Research Board 1870(1): 1-9. DOI:

10.3141/1870-01.

7.

Novak David,

Chirstopher Hodgdon, Feng Guo, Lisa Aultman-Hall. 2011. “Nationwide

Freight Generation Models: A Spatial Regression Approach”. Networks

and Spatial Economics 11(1): 23-41. DOI: 10.1007/s11067-008-9079-2.

8.

Boyce David. 2002.

“Combined Model of Interregional Commodity Flows on a Transportation

Network”. In: Trade, Networks and Hierarchies. Edited by Hewings

Geoffrey, Michael Sonis, David Boyce. P. 29-40.

Springer, Berlin, Heidelberg. ISBN: 978-3-642-07712-8. DOI:

10.1007/978-3-662-04786-6_3.

9.

Giuliano

Genevieve, Peter Gordon, Qisheng Pan, Ji Young Park, Lan

Lan Wang. 2010. “Estimating Freight Flows for Metropolitan Area Highway

Networks Using Secondary Data Sources”. Networks and Spatial Economics

10: 73-91. DOI: 10.1007/s11067-007-9024-9.

10. Al-Battaineh Omar, Islam Kaysi. 2005.

“Commodity-Based Truck Origin-Destination Matrix Estimation Using

Input-Output Data and Genetic Algorithms”. Transportation Research

Record – Journal of Transportation Research Board 1923(1): 37-45.

DOI: 10.1177/0361198105192300105.

11. Iding Mirjam, Wilhelm Meester, Lori Tavasszy. 2002.

“Freight trip generation by firms”. In: 42nd Congress

of the European Regional Science Association: From Industry to Advanced

Services - Perspectives of European Metropolitan Regions. European Regional

Science Association (ERSA). Dortmund, Germany. 27-31 August 2002. Dortmund,

Germany. Available at: http://hdl.handle.net/10419/115840.

12. Bastida Carlos, José Holguín-Veras.

2009. “Freight Generation Models: Comparative Analysis of Regression

Models and Multiple Classification Analysis”. Transportation Research

Record – Journal of Transportation Research Board 2097(1): 51-61.

DOI: 10.3141/2097-07.

13. Middleton Dan, John Jr Mason, Chavala Chira. 1988.

“Trip Generation for Special-Use Truck Traffic”. Transportation

Research Record – Journal of Transportation Research Board 1090: 8-13.

Available at: http://worldcat.org/isbn/0309041104.

14. Kawamura Kazuya, Shin Hyeon-Shic, McNeil Sue. 2005. Business

and Site-Specific Trip Generation Methodology for Truck Trips. Midwest

Regional University Transportation Center, College of Engineering, Department

of Civil and Environmental Engineering, University of Wisconsin, Madison.

15. Badoe Daniel, Gerald Steuart. 1997. “Urban and

travel changes in the Greater Toronto Area and the transferability of

trip-generation models”. Transportation

Planning and Technology 20(4): 267- 290. DOI: 10.1080/03081069708717594.

16. Cubukcu Mert. 2011. “Factors affecting shopping

trip generation rates in metropolitan areas”. Studies in Regional and Urban

Planning 9: 51-67.

17. Ségalou Erwan, Christian Ambrosini, Jean-Louis

Routhier. 2004. “The environmental assessment of urban goods movement”.

In: Logistics systems for sustainable cities. Edited by Taniguchi

Eiichi, Russell Thomson. P. 207-220. Emerald Group Publishing Limited, Bingley.

ISBN: 978-0-08-044260-0. DOI: 10.1108/9780080473222-015.

18. Toilier Florence, Jean-Louis Routhier. 2007.

“FRETURB V3, A Policy oriented software of modelling urban goods

movement”. In: The 11th World Conference on Transport Research

- WCTR'07. 24-28 June 2007. Berkeley, USA. DOI: 10.13140/2.1.4872.4165.

19. Vickerman Roger, Tim Barmby. 1984. “The

Structure of Shopping Travel: Some Developments of the Trip Generation

Model”. Journal of Transport Economics and Policy 18(2): 109-121. Available

at: http://www.jstor.org/stable/20052709.

20. Shao Jing, Hangjun Yang, Xiaoqiang Xing, Liu Yang.

2016. “E-commerce and traffic congestion: An economic and policy

analysis”. Transportation Research Part B: Methodological 83:

91-103. DOI: 10.1016/j.trb.2015.11.003.

21. Anderson W., L. Chatterjee, T. Lakshmanan. 2003.

“E‐commerce, Transportation, and Economic Geography”. Growth

and Change 34(4): 415-432. DOI: 10.1046/j.0017-4815.2003.00228.x.

22. Cairns Sally. 2005. “Delivering supermarket

shopping: more or less shopping?”. Transport Reviews 25(1): 51-84. DOI:

10.1080/0144164042000218391.

23. Visser Johan, Kim Hassall. 2005. “The future of

city logistics: estimating the demand for home delivery in urban areas”.

In: 4th International Conference on City Logistics. P. 147-162. Institute for City

Logistics, Langkawi, Maleisië - Kyoto, Japan. 12-14 July 2005. Langkawi,

Maleisië - Kyoto, Japan. DOI: 10.13140/2.1.1125.2484.

24. Triantafyllou Maria, Tom Cherrett, Michael Browne.

2014. “Urban Freight Consolidation Centers: Case Study in the UK Retail

Sector”. Transportation Research Record – Journal of

Transportation Research Board 2411(1): 34-44. DOI: 10.3141/2411-05.

25. Mokhtarian Patricia. 2004. “A conceptual

analysis of the transportation impacts of B2C e-commerce”. Transportation

31: 257-284. DOI: 10.1023/B:PORT.0000025428.64128.d3.

26. Divya Priya, Gitakrishnan Ramadurai, Gayathri Devi.

2015. “Freight Trip Generation Models for Chennai, India”. In: Transportation

Research Board 94th Annual Meeting.

11-15 Jan 2015. Washington D. C., United States.

27. Swamy Shivanand, Deepak Baindur. 2014. “Managing

urban freight transport in an expanding city - Case study of

Ahmedabad”. Research in Transportation Business & Management

11: 5-14. DOI: 10.1016/j.rtbm.2014.06.010.

28. Gupta Sanjay. 2016. “Role of Non -Motorized

Transport in Distribution of Goods in the Metropolitan City of

Delhi”. Transportation Research Procedia 25: 978-984. DOI: 10.1016/j.trpro.2017.05.472.

29. Patil Gopal, Prasanta Sahu. 2016. “Estimation of

freight demand at Mumbai Port using regression and time series models”. KSCE

Journal of Civil Engineering 20(5): 2022-2032. DOI:

10.1007/s12205-015-0386-0.

30. Pani Agnivesh, Prasanta Sahu, Gopal Patil, Ashoke

Sarkar. 2018. “Modelling urban freight generation: A case study of seven

cities in Kerala, India”. Transport Policy 69: 49-64. DOI:

10.1016/j.tranpol.2018.05.013.

Received 04.10.2021; accepted in

revised form 12.11.2021

![]()

Scientific Journal of Silesian University of Technology. Series

Transport is licensed under a Creative Commons Attribution 4.0

International License