Article

citation information:

Kądziołka, T., Opoka, K. Forecasting the number

of failures of the steering system components with the use of the grey system

theory method. Scientific Journal of

Silesian University of Technology. Series Transport. 2021, 112, 85-97. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.112.7.

Tomasz

KĄDZIOŁKA[1],

Kazimierz OPOKA[2]

FORECASTING

THE NUMBER OF FAILURES OF THE STEERING SYSTEM COMPONENTS WITH THE USE OF THE

GREY SYSTEM THEORY METHOD

Summary. Steering systems are

one of the most important components of a car and have a direct impact on

safety and driving comfort. Therefore, high reliability is required of them.

One of the methods of object reliability estimation may be the grey system

theory. This method can be used not only to calculate the number of failures,

but also to calculate the wear of mating parts, and the vibrations of engines

and rolling elements. This work presents the use of the grey system theory for

the examination of motor vehicle steering system reliability. The forecast

number of failures was calculated for the various components of the steering

system and the grey system accuracy was assessed. This is aimed at finding out

how useful this theory is for forecasting the number of steering system

failures.

Keywords: steering mechanism, steering linkage, servo

system, reliability, grey system theory method

1. INTRODUCTION

The reliability theory in its field comprises the methods of failure

forecasting, detection of the laws affecting defects and the development of

ways of improving the reliability of objects. Forecasting object reliability is

a crucial issue in present times. It enables one to foresee the states of the

object in the future based on information on the states to have occurred

already. Forecasting permits the determination of machine maintenance or

inspection dates to ensure longer machine life and the operators’ or

travellers’ safety when the means of transport are under discussion.

Therefore, forecasting the future values of the symptoms of machinery technical

condition is an issue of importance that has been widely discussed in reference

literature [3, 17-20, 25]. One of the methods of object reliability assessment

is the grey system theory. It was initiated and described by the Chinese

scientist J.L. Deng in 1982 [5]. The theory is not only used in machine

condition forecasting but also in economics [3]. This method can be used to

calculate the number of failures, as well as to calculate the wear of mating

parts, and the vibrations of engines and rolling elements.

This article aims to forecast the number of failures of the selected

elements of the steering system of a selected motor vehicle using the

aforementioned method.

2. THE CHARACTERISTICS

AND OPERATIONAL CONDITIONS OF STEERING SYSTEMS

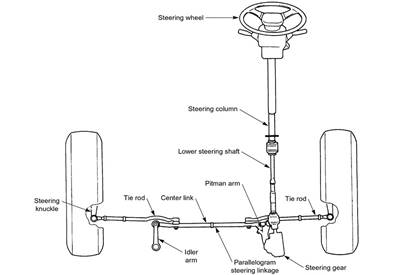

The steering system enables the driver to set, control and maintain the

required direction of the vehicle movement by the appropriate alignment of the

steered wheels. The steering system consists of three basic elements, that is,

the steering mechanism, the steering linkage and the servo system. The steering

mechanism consists of elements such as the steering wheel, steering column (the

housing and articulated steering wheel shaft), steering

gear and Pitman arm.

As mentioned above, the steering mechanism is used by the driver to set

the steered wheels at such an angle that the vehicle moves in the designated

direction. A typical steering system is shown in Figure 1 [7].

The steering wheel is made of a metal rod, polyurethane foam and fabric

or leather. It is important to select the steering wheel diameter properly so

that the force applied by the driver does not have to be too great. Generally,

the steering wheel diameter ranges from 450 [mm] for cars and 550 [mm] for

trucks and buses. Through special catches, fitted by pressing, is the airbag

assembly, placed in a plastic housing which usually functions as a horn

actuator. In cars with automatic transmission, the steering wheel may have

gear selection buttons; owing to them, the driver is not forced to take his or

her hands off the steering wheel, thus, comfort and safety are improved.

The steering column is designed to transmit torque from the steering

wheel to the steering gear. The steering column consists of a jacket attached

to the vehicle body and of a bearing-mounted steering wheel shaft. The shaft

top end is completed with a multi-spline, which is designed for fixing the

steering wheel, as well as with a thread for screwing the central clamp nut on.

The steering wheel shaft can be made as one whole or it can be sectional, that

is, consisting of two or three parts, connected by knuckle joints or

multi-splines.

Fig. 1. The construction of the steering system [23]

The three-part steering wheel shaft consists of the upper and lower

shafts connected with each other by pins, and the intermediate shaft. The lower

intermediate shaft end, seated on a multi-spline, permits a change of its

length, and the two knuckle joints permit the change of the torque transmission

angle. A flexible joint is often placed between the lower end of the steering

wheel shaft or of the intermediate shaft to compensate for small angular

deviations and minimise vibrations transmitted to the steering wheel caused by

driving on rough roads. The steering column is equipped with additional

mechanisms; an energy absorption mechanism, steering wheel lock and adjustment

mechanisms (steering wheel tilt or overhang) [7].

The steering gear is the main steering mechanism unit that acts as a

reducer transmitting the rotary motion from the steering wheel to the steering

linkage. The task of the steering gear is to ensure the appropriate kinematic

and dynamic ratio so that the driver's effort is as low as possible.

Depending on the design details, transmission gears can be divided [7]:

those providing the output rotary motion (worm and nut, globoid as well as ball

and screw gear) and those providing the output translational motion (rack and

pinion gear).

The steering linkage is a set of rods and levers connecting the steered

wheels through the ball joints and Pitman arms. The task of the steering

linkage is to achieve a kinematic connection, causing the vehicle wheels to

move along a curvilinear track without skidding.

There are two types of steering linkage: one for the suspension with a

rigid front axle and one for independent suspension. In the case of a rigid

front axle, the steering linkage has a trapezoidal shape and a simple

structure; however, such linkages are subject to a kinematics error. The

independent suspension steering linkage should ensure the constant steered

wheel toe-in during an independent movement of one of the steered wheels of the

vehicle. The solution to this problem is the use of a central bar connecting

the two side rods: the left and right one. The trapezoidal steering linkage

with the steering gear providing output rotary motion comprises the following

elements: the central rod, side rods (right and left); rod support; Pitman arms

and stub axles (right and left).

In rack and pinion gears, the central rod is a toothed rack. The

triangle-shaped steering linkage with rack and pinion gear comprises: side rods

(right and left), Pitman arms and stab axles (right and left) [7].

The operation conditions to which the steering systems are subjected

cause frequent failures of the components within it. The assessment of the

technical condition of the steering system and the steering linkage pertains to

the steering column and wheel, the steering gear and the condition of the

steering rod ball joints.

The assessment is undertaken by checking the steering wheel lost motion

and clearance in the steering mechanisms. Steering wheel lost motion is the

result of excessive clearance in the steering system. Lost motion is assessed

using the LUZ-1 instrument, permitting the measurement of the “idle”

steering wheel rotation angle, which is the outcome of the total clearance of

the entire system. The permissible value of the angle with the wheels set to

drive straight ahead is 5-7° in cars and 15-29°

in trucks.

The following should be included among the typical kinds of failure of

the steering system:

- steering gear leakage,

- wear and tear of the mating elements of the steering gear,

- clearance in the ball joints of the rods,

- complete destruction of the ball joint (Figure 2),

- development of fatigue wear of cooperating elements.

Fig. 2. An

example of complete destruction of a ball joint

The damage to the elements shown in Figure 2 may be the result of the

development of fretting wear. The condition for the development of this type of

wear is the occurrence of oscillating tangential displacements between

cooperating elements and the action of static forces [10, 13]. Fretting wear

occurs in many fields of technology and science. It is found, among others, in

rail vehicles [11, 12], aircraft components [2], as well as biotechnology [4].

3. RESEARCH METHODOLOGY

Input data needed for the analysis was obtained from a database

concerning the operation of a selected group of vehicles, and such has been

collected over the last ten years by the car repair shop where the vehicles

were serviced. Subject to analysis were the key elements of the steering

system, such as the servo pump, steering gear and steering rod ends. These

elements usually fail due to the condition of the road, and they directly

influence travellers’ safety.

By predicting the failure distribution trend, it is possible to

determine the point at which the failure threshold rises rapidly, and thus,

prevent the destruction of the system. This offers the option of ensuring

system protection and travellers’ safety, saving money.

4. CHARACTERISTICS OF THE GREY SYSTEM THEORY

The grey system theory is a relatively simple method as it does not

require complicated calculations [6, 8, 15, 22, 24].

Generally, the very name “grey system” shows the nature of the

method. It is an object’s operational stage in which an amount of

information (the number of failures) is known, and the other part is unknown.

The purely theoretical “grey system” theory model is

determined by differential equation (1) [1, 11, 24, 26]:

![]() (1)

(1)

The variables such as “a”

and “u” occurring in the

equation are calculated using matrix operators from the following equations

(2):

![]() ;

;

![]() (2)

(2)

Parameters B and Yn may be determined by

solving matrices (3) and (4):

(3)

(3)

![]() (4)

(4)

The matrices come into being from the model input data. The outcome of

those mathematical operations is a two-line matrix a x u, which permits the determination of variables “a” and “u” which have been sought [9, 16].

The forecast values are calculated according to formula (5), which has

come into being by appropriate transformations:

![]() (5)

(5)

The determined parameters “a”

and ”u”

are substituted into the formula in which the initial value X(0) is equal to the first noted value.

The fact that the use of the method is reasonable may be determined by

several formula transformations, and then, the result compared with the values from

Table 1.

At the beginning, the remaining values are calculated based on formula

(6).

![]() (6)

(6)

Thereafter the arithmetic mean of the actual (noted) values is

calculated with the use of formula (7).

![]() (7)

(7)

The average of the remaining data q(k) is determined

based on formula (8).

![]() (8)

(8)

Parameters S1 and S2, that is, the variances of

the actual and remaining data are, in turn, determined based on formulae (9)

and (10).

![]() (9)

(9)

![]() (10)

(10)

The quotient of the values obtained based on the formula above is equal

to C:

![]() (11)

(11)

Now the method accuracy is checked by comparing the result with the

values in Table 1.

Tab. 1

The table permitting method accuracy

determination

|

Forecast accuracy |

P |

|

|

Good |

>0.95 |

<0.35 |

|

Satisfactory |

0.8-0.9 |

0.35-0.5 |

|

Unsatisfactory |

0.7-0.8 |

0.5-0.65 |

|

Poor |

<0.7 |

>0.65 |

5. FORECAST OF THE NUMBER OF FAILURES OF THE SELECTED STEERING SYSTEM

COMPONENTS

5.1. Steering gear

Input data in the form of the number of the noted steering gear failures

for specific mileage are collated in Table 2. Fifteen time intervals within

15,000-225,000 km have been indicated, in which the input data is noted in the

form of the number of recorded failures of the ten vehicles under observation.

The number of failures within the other five time intervals, that is, from

240,000 km to 310,000 km, are estimated based on the analysis.

Tab. 2

Schedule

of input data

|

Measurement |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

Mileage [km] |

15000 |

30000 |

45000 |

60000 |

75000 |

90000 |

105000 |

120000 |

135000 |

150000 |

|

A |

35 |

37 |

41 |

49 |

56 |

69 |

77 |

85 |

93 |

101 |

|

Measurement |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

|

Mileage [km] |

165000 |

180000 |

195000 |

210000 |

225000 |

240000 |

265000 |

280000 |

295000 |

310000 |

|

A |

113 |

129 |

134 |

141 |

160 |

- |

- |

- |

- |

- |

A – number of failures noted X0(i)

With the use of formulae (1)-(4), parameters B and Yn were

first determined, then parameters a and u needed for

the estimation of the number of failures were calculated.

![]()

![]()

The values of parameters a and u,

respectively, are as follows:

a = -0,101378

When all the unknown quantities are already known, the forecast number

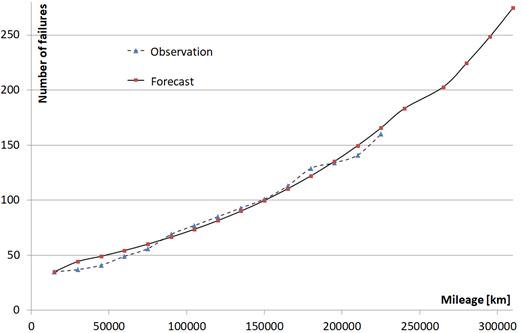

of steering gear failures may be determined based on formula (5). The results

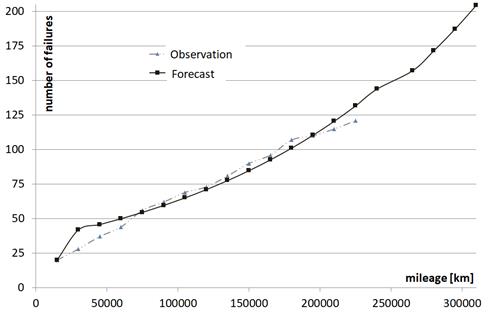

of those calculations are compiled in Table 3. The comparison of the number of

failures noted with the forecast number is shown in Figure 3.

The next stage of the calculations is the

determination of method accuracy. Formulas (6)-(11) will be used for this purpose. Parameter C has been determined, which will be

compared with Table 1. The obtained result is C=0.121725, which confirms that method accuracy is at a good level.

Tab. 3

Forecast number of steering gear failures

|

X'0(1) |

X'0(2) |

X'0(3) |

X'0(4) |

X'0(5) |

X'0(6) |

X'0(7) |

X'0(8) |

X'0(9) |

X'0(10) |

|

35 |

44.33 |

49.06 |

54.30 |

60.09 |

66.51 |

73.60 |

81.46 |

90.15 |

99.77 |

|

X'0(11) |

X'0(12) |

X'0(13) |

X'0(14) |

X'0(15) |

X'0(16) |

X'0(17) |

X'0(18) |

X'0(19) |

X'0(20) |

|

110.41 |

122.19 |

135.23 |

149.66 |

165.63 |

183.30 |

202.85 |

224.50 |

248.45 |

274.96 |

Fig. 3. The distribution of the noted and estimated number

of steering gear failures

5.2. Steering rod ends

Input data in the form of the number of the noted steering gear failures

for specific mileage are collated in Table 4. As in the previous case, fifteen

time intervals within 15,000-225,000 km were indicated, in which the input data

is noted in the form of the number of recorded failures of the ten vehicles

under observation. The number of failures within the other five time intervals,

that is, from 240,000 km to 310,000 km, are estimated based on the analysis.

Tab.

4

Schedule of initial values and mileage

|

Measurement |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

Mileage [km] |

15000 |

30000 |

45000 |

60000 |

75000 |

90000 |

105000 |

120000 |

135000 |

150000 |

|

A |

45 |

48 |

50 |

61 |

73 |

86 |

94 |

101 |

115 |

124 |

|

Measurement |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

|

Mileage [km] |

165000 |

180000 |

195000 |

210000 |

225000 |

240000 |

265000 |

280000 |

295000 |

310000 |

|

A |

136 |

148 |

159 |

166 |

172 |

- |

- |

- |

- |

- |

A – the

number of noted failures X0(i)

With the use of formulas (1)-(4), parameters B and Yn were

first determined, then parameters a and u needed for

the estimation of the number of failures were calculated.

![]()

![]()

The values of parameters a and u,

respectively, are as follows:

a = -0.0907

u = 50.96

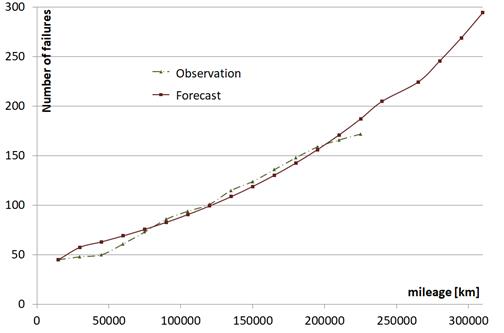

When all the unknown quantities are already known, the forecast number

of failures of steering rod ends may be determined based on formula (5). The

results of the calculations are compiled in Table 5. The comparison of the

number of failures noted with the forecast number is shown in Figure 4.

Tab.

5

Forecast numbers of steering rod end failures

|

X'0(1) |

X'0(2) |

X'0(3) |

X'0(4) |

X'0(5) |

X'0(6) |

X'0(7) |

X'0(8) |

X'0(9) |

X'0(10) |

|

45 |

57.61 |

63.08 |

69.07 |

75.62 |

82.80 |

90.67 |

99.27 |

108.70 |

119.02 |

|

X'0(11) |

X'0(12) |

X'0(13) |

X'0(14) |

X'0(15) |

X'0(16) |

X'0(17) |

X'0(18) |

X'0(19) |

X'0(20) |

|

130.32 |

142.69 |

156.24 |

171.07 |

187.31 |

205.10 |

224.57 |

245.89 |

269.23 |

294.79 |

The next stage of the calculations is the determination of method

accuracy. Formulas (6)-(11) will be used for this purpose. Parameter C has been determined, which will be

compared with Table 1. The obtained result is C=0.161643, which confirms that method accuracy is at a good level.

5.2. Servo pump

Input data in the form of the number of the noted servo pump failures

for specific mileage are collated in Table 6. In this case, fifteen time

intervals within 15,000-225,000 km have been indicated as well, in which the

input data is noted in the form of the number of recorded failures of the ten

vehicles under observation. The number of failures within the other five time

intervals, that is, from 240,000 km to 310,000 km, are estimated based on the

analysis.

Fig. 4. The distribution of the noted and

estimated number of steering rod end failures

Tab. 6

Schedule of initial values and

mileage

|

Measurement |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

Mileage [km] |

15000 |

30000 |

45000 |

60000 |

75000 |

90000 |

105000 |

120000 |

135000 |

150000 |

|

A |

20 |

28 |

37 |

44 |

56 |

62 |

69 |

73 |

81 |

90 |

|

Measurement |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

|

Mileage [km] |

165000 |

180000 |

195000 |

210000 |

225000 |

240000 |

265000 |

280000 |

295000 |

310000 |

|

A |

96 |

107 |

110 |

115 |

121 |

- |

- |

- |

- |

- |

A – the number of noted failures X0(i)

With the use of formulae (1)-(4), parameters B and Yn were

first determined, then parameters a and u needed for

the estimation of the number of failures were calculated.

![]()

![]()

In this case, the values of parameters a and u, respectively, are as follows:

a= -0.08816

u= 38.27891

When all the unknown quantities are already known, the forecast number

of servo pump failures may be determined based on formula (5). The results of

the calculations are compiled in Table 7. The comparison of the number of

failures noted with the forecast number is shown in Figure 5.

Tab.

7

Schedule of initial values and

mileage

|

X'0(1) |

X'0(2) |

X'0(3) |

X'0(4) |

X'0(5) |

X'0(6) |

X'0(7) |

X'0(8) |

X'0(9) |

X'0(10) |

|

20 |

41.86 |

45.71 |

49.93 |

54.53 |

59.56 |

65.05 |

71.04 |

77.59 |

84.74 |

|

X'0(11) |

X'0(12) |

X'0(13) |

X'0(14) |

X'0(15) |

X'0(16) |

X'0(17) |

X'0(18) |

X'0(19) |

X'0(20) |

|

92.55 |

101.08 |

110.40 |

120.57 |

131.69 |

143.82 |

157.08 |

171.56 |

187.37 |

204.64 |

Fig. 5. The distribution of the noted and estimated number of servo pump

failures

The next stage of the calculations is the determination of method

accuracy. Formulas (6)-(11) are used for this purpose. Parameter C has been determined, which will be

compared with Table 1. The obtained result is C=0.191000, which confirms that method accuracy is at a good level.

6. CONCLUSION

The analysis aimed to assess the possible number of selected steering

system component failures that may occur as mileage increases.

Based on the method accuracy determination results, it may be believed

that the grey system analysis proposed in this article is suitable for

forecasting the number of steering system failures.

Moreover, system efficiency decreases with the distance covered by

vehicles. The question is about the number of the recorded failures, which

permits the relevant inspection cycles for the vehicles under analysis to be

designed. Based on the forecast, the number of possible system failures

increases proportionally. After covering 300,000 km, 275 various steering

gear failures, 295 steering rod failures and 205 servo pump failures should be

expected.

The considerations contained in the paper allows, among other things, to

increase road safety by forecasting possible damage to the steering systems and

repairing them in advance, before their complete destruction (Figure 2). By

analogous considerations, it is possible to predict damage to other mechanisms

or systems used not only in motor vehicles (braking system, drive system,

power-running system, drive unit) but also in working

machines as they can be used to predict their failure-free time operation and

precisely define the intervals between maintenance and repair.

References

1.

Bezuglov Anton,

Gurcan Comert. 2016. „Short-term freeway traffic parameter prediction: Application of grey system

theory models”. Expert Systems With Applications 62:

284-292.

2.

Bok-WonLee, Jungjun Suh, Hongchu Lee, Tae-gu Kim. 2011. „Investigations on fretting fatigue in

aircraft engine compressor blade”. Engineering Failure Analysis 18 (7):

1900-1908.

3.

Cempel

Czesław, Maciej Tabaszewski. 2007. „Application of grey system theory to modeling and

forecasting in machine condition monitoring”. Diagnostyka 2(42): 11-18.

4.

Chen-EnTsa, Jiames Hung, Youxin Hu, Da-Yung Wang, Robert M.Pilliar, Rizhi Wang. 2021. „Improving fretting corrosion resistance

of CoCrMo alloy with TiSiN and ZrN coatings for orthopedic applications”.

Journal of the Mechanical Behavior of

Biomedical Materials 114: 104233.

5.

Deng J-L. 1982. „Control Problems of Grey Systems”. Systems and Control Letters 1(5):

288-294.

6.

Deng Julong. 1989.

„Introduction to Grey System Theory”. The Journal of Grey System 1: 1-24.

7.

Gabryelewicz M.

2011. Podwozia i nadwozia pojazdów

samochodowych. [In Polish: Chassis

and bodies of motor vehicles]. Part

2. Warsaw: WKiŁ. ISBN: 9788320618266.

8.

Jui-Chen Huang. 2011.

„Application of grey system theory in telecare”. Computers in Biology and Medicine 41(5): 302-306.

9.

Kayacan Erdal, Ulutas Baris, Kaynak Okyay. 2010. „Grey system theory-based models in time series

prediction”. Expert Systems with Applications 37 (2):

1784-1789.

10.

Kowalski

Sławomir. 2018. „Analysis of

the possibilities of using CrN+a-C:H:W coatings to

mitigate fretting wear in push fit joints operating in rotational bending

conditions”. Tribologia 1:

45-55.

11.

Kowalski

Sławomir. 2016. „Application of dimensional analysis in the fretting wear studies”. Journal of the Balkan Tribological

Association 22(4-I):

3823-3835.

12.

Kowalski

Sławomir. 2020. „Failure analysis of the elements of a

forced-in joint operating in rotational bending conditions”. Engineering Failure Analysis 118: 104864.

13.

Kowalski

Sławomir. 2017. „Selected problems in the exploitation of wheel sets

in rail vehicles”. Journal of

Machine Construction and Maintenance 2: 109-116.

14.

Kowalski

Sławomir, Mariusz Cygnar. 2019.

„The application of TiSiN/TiAlN

coatings in the mitigation of fretting wear in push fit joints”. Wear 426: 725-734.

15.

Li-Qiang Hu,

Chao-Feng He, Zhao-Quan Cai, Long Wen, Teng Ren. 2018. „Track circuit fault prediction method

based on grey theory and expert system”. J. Vis.

Commun. Image R. 58: 37-45.

16.

Liu Sifeng. 2007.

„The Current Developing Status on Grey System Theory” The Journal of Grey System 2: 111-123.

17.

Maláková Silvia, Peter Frankovský, Daniela

Harachová, Vojtech Neumann. 2019. „Design of constructional

optimisation determined for mixed truck gearbox”. AD ALTA Journal of Interdisciplinary Research 9: 414-417. ISSN:

1804-7890.

18.

Maláková Silvia, Michal Puškár, Peter

Frankovský, Samuel Sivák, Maroš Palko, Miroslav Palko. 2020.

„Meshing Stiffness - A Parameter Affecting the Emission of

Gearboxes”. Applied Sciences

10(3): 1-12. DOI: 10.3390/app10238678.

19. Mazurkiewicz D. 2014. „Computer-aided

maintenance and reliability management systems for conveyor belts”. Eksploatacja i

Niezawodnosc – Maintenance and Reliability 16(3): 377-382.

20. Michalski R., S. Wierzbicki. 2008. „An

analysis of degradation of vehicles in operation”. Eksploatacja i

Niezawodnosc – Maintenance and Reliability 1: 30-32.

21.

Mu-Shang Yin.

2013. „Fifteen years of grey system theory

research: A historical review and bibliometric analysis”. Expert Systems with Applications 40:

2767-2775.

22.

Shuwei Wanga, Peng

Wanga, Yifei Zhang. 2020. „A

prediction method for urban heat supply based on grey system theory”. Sustainable Cities and Society 52: 101819.

23.

Steering and

suspancion components. Available at: https://en.tw-central.com.

24. Tabaszewski Maciej. 2014. “Prediction of

diagnostic symptom values using a set of models GM(1,1)

and a moving window method”. Diagnostyka

15(3): 65-68.

25.

Vaičekauskis

M., R. Gaidys, V. Ostaševičius. 2013. „Influence of boundary

conditions on the vibration modes of the smart turning tool”. Mechanika 3: 296-300.

26.

Xingqi Wang, Lei

Qi, Chan Chen, Jingfan Tang, Ming Jiang. 2014. „Grey System Theory based

prediction for topic trend on Internet”. Engineering Applications of Artificial Intelligence 29:

191-200.

Received 07.04.2021; accepted in revised form 23.06.2021

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License