Article

citation information:

Wieczorek, A.N.

Ensuring

appropriate conditions for lubrication of gear transmissions as a priority

for maintenance services in industrial transport. Scientific Journal of Silesian University of Technology. Series

Transport. 2021, 111, 193-204. ISSN:

0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.111.17.

Andrzej N. WIECZOREK[1]

ENSURING

APPROPRIATE CONDITIONS FOR LUBRICATION OF GEAR TRANSMISSIONS AS A PRIORITY FOR

MAINTENANCE SERVICES IN INDUSTRIAL TRANSPORT

Summary. This paper presents

the problem of the operation of gear

transmissions in the context

of ensuring appropriate lubrication conditions. Damage caused by improper lubrication was discussed. Attention was drawn to the issue of oil contamination. Furthermore, a method for determining the thickness of the oil film of gear wheel teeth was described. There was also performed an analysis of the lubrication conditions of sample gear transmissions

of the load, manufacturing technology and surface roughness.

Keywords: gear, wear, lubrication

1. INTRODUCTION

Root Cause Analysis (RCA) is often

used by industrial plant maintenance services to identify causes of problems or

incidents to eliminate them. Due to the use of the analysis of the causes of

failures/damages, it is possible to effectively counteract their consequences,

thus, significantly affect the economics of the actions taken. This remark

applies in particular to the operation of drive units, the service life of

which is significantly limited by various forms of wear [1]. Excessive wear [2]

of components may, on the one hand, affect the level of safety of the people

operating these machines, and on the other hand, cause additional dynamic

excitations negatively affecting their service life [3-6] or generating vibroacoustic effects

[7-11].

One of the most important components

of the drive units is gear transmission [12, 13]. In the case of these

components, teeth fractures at the base usually occur due to fatigue or surface

chipping. However, if proper lubrication conditions are not ensured, that is,

the layer separating the mating surfaces does not have a sufficient thickness,

the wear of these surfaces may be intensified.

This paper presents a method of

determining the lubrication conditions of teeth in gear transmissions, which

can be used by maintenance services to predict possible damage to gear teeth

caused by improper lubrication conditions, as an element of the RCA analysis

aimed at ensuring proper operating conditions. Knowledge of the parameters characterising the conditions of lubrication of the teeth

allows taking preventive actions, for example, using appropriate lubricants or

reducing the permissible loads.

2. DAMAGE TO TEETH CAUSED BY

INADEQUATE LUBRICATION

In the case of gear transmissions,

the elements particularly vulnerable to damage caused by improper lubrication

[1] are primarily gear teeth. These elements are required to meet demanding

requirements concerning strength and service life. However, they are exposed

to:

- surface seizure (adhesive wear) caused, for example,

by the improper choice of lubricant,

- surface scratches caused by the presence of single

hard grains, for example, sand (Figure 1A),

- local overheating of tooth surfaces due to

insufficient amount of lubricant (Figure 1B),

- abrasive wear caused by improper lubrication conditions

(Figure 1C),

- fatigue chipping of the surface (Figure 1D).

Lubricants, similarly to components

of machines and other equipment, are subject to degradation processes; this

occurs due to the action of high temperatures and oxygen. During the operation

of industrial gear transmissions, the content of solid impurities in oils and

greases usually increases, significantly affecting the intensity of wear of

mating surfaces of teeth and rolling bearings. Figure 2 shows the results of

the analysis of the content of solids and iron as a function of the operating

time for gear transmissions used in armoured face

conveyors and belt conveyors in the mining industry [2]. It can be noticed in

the Figures that the content of solids and iron increases along with the

increase in the operating time and that the differentiation in the content

depends on the type of machine. However, it should be mentioned that the

durability of surfaces of friction pairs depends not only on the conditions of

their operation but also on the correct design and selection of parameters characterising the load, as well as on the material and

lubricating properties.

3. PARAMETERS CHARACTERISING

THE LUBRICATING PROPERTIES OF OILS

The main purpose of lubrication [3]

is to reduce the friction of mating surfaces by creating a layer of lubricant.

It is advisable to form an oil film layer with a thickness that allows

separating the protrusions in the mating surfaces.

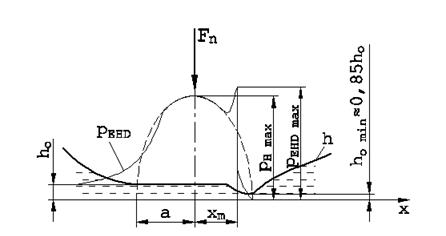

The parameter characterising

the separation layer is the minimum thickness of the lubricant layer (hmin),

which is formed in conditions of the electrohydraulic lubrication (the diagram

showing the elastohydrodynamic contact zone is

presented in Figure 3). The thickness of the oil film depends on some design

and operational factors, as well as on the parameters of the lubricant (this

issue is discussed in detail in [14]). In practice, the method specified in

ISO/TR 15144-1:2014 (E) standard is often used to

calculate the minimum thickness of the lubricant layer hmin in gear teeth [15].

In this standard, calculations of the relative thickness of oil film λ are usually performed only for 5

points of the engagement section (points A, B, C, D and E shown in Figure 4).

However, it is possible to calculate the parameter λ also for other points of the engagement section.

|

|

|

|

A |

B |

|

|

|

|

C |

D |

Fig. 1. Examples of damage to teeth

in industrial gear transmissions: A – surface scratches,

B – signs of overheating, C – abrasive wear, D – pitting

Lubrication conditions depend

primarily on the roughness of the mating surfaces because the thickness of the

oil film may be smaller than the height of the protrusions. In such a

situation, the type of friction will be unfavourable

(mixed or boundary friction). The parameter characterising

the type of friction between the mating surfaces is the relative thickness of

oil film (parameter λ),

determined by the following relationship [16]:

![]() (1)

(1)

where:

Rq1,2 – surface roughness.

|

|

|

A |

|

|

|

B |

Fig. 2. Plots of the content of

impurities (A) and iron (B) in oil as a function of operating time, determined

for gear transmissions of belt conveyors and armoured

scrap conveyors

In the range of values λ=(0–1), there occurs mixed boundary friction (for the parameter Ra, this range will be λ=(0–0.8)). In the range of the relative value of oil film thickness λ=(1–3), the predominant type of friction is mixed friction (for the parameter Ra, this range will be λ=(0.8–2.4), whereas in the range of λ=<3–10> the conditions of EHD lubrication are created (for the parameter Ra, this range will be λ=(2.4–8)). These conditions are characterised by the formation of an oil film layer with a thickness exceeding the height of surfaces irregularities. Above the relative value of the oil film thickness λ>10, there occurs liquid hydrodynamic friction (for the parameter Ra, this range will be λ>8) [16, 17].

Fig. 3. Pressure distribution pEHD and the shape of the lubrication gap h in

the conditions of elastohydrodynamic contact (EHD) between mating surfaces [16]

Fig. 4. Geometry of a gear wheel

with an external involute profile

The thickness of the oil film, and thus, the lubrication conditions of gear transmissions, is affected, inter alia, by the following factors:

- location of the contact point in the engagement

section of the mating teeth,

- variable number of pairs of teeth in meshing,

- nominal and instantaneous loads,

- surface roughness,

- rotational speed of gears,

- oil viscosity

grade.

Figure 5 shows results of calculations (performed according to ISO/TR 15144-1:2014(E)) of the relative thickness of oil film λ as a function of the position of gear wheels of a sample gear transmission in the engagement section (for the needs of the analysis, the parameter λ was determined for 106 points of the engagement section) for a fixed (nominal) load. In the analysis, there were used parameters characterising the teeth of the second stage of the right angle spur planetary gear transmission with the gear ratio i=39. Gear wheels of this gear transmission were made of alloy steels that were subjected to thermal and thermochemical treatment and then ground (accuracy class 6 according to PN-ISO 1328 and roughness Ra=0.8 μm were obtained). In Figure 5, there can be easily noticed, a stepwise change in the thickness of the oil film, associated with the change in the number of pairs of teeth being engaged. The lowest values of the oil film thickness are observed for the inner single-tooth engagement point (point B in Figure 5).

Fig. 5. The plot of the relative

thickness of oil film λ as a

function of the position in the engagement section for the second stage of the

right angle spur planetary gear transmission

Another important factor that affects lubrication conditions is the nominal load of a given stage of the gear transmission. Figure 6 shows plots of the relative thickness of oil film λ as a function of the power of the drive motor of the second stage of the right angle spur planetary gear transmission (calculations considered the value of the torque and the gear ratio for a given stage) for different viscosity grades of the lubricating oil. In this Figure, it is easy to note that satisfactory lubrication conditions can be obtained only in a fairly narrow range of values of the transmitted power and oil viscosity.

During the operation of drives of machines, there are frequent changes in the instantaneous load (sample plot showing the variability of the load of the gear transmission of an armoured face conveyor is presented in Figure 7). The variability of the load causes some fluctuations in the thickness of the oil film, and the value of parameter λ take place during the operation. These changes are relatively large because, as shown in Figure 8, they can lead to variations in the value of the parameter λ up to 0.15.

Typically, problems with lubrication relate to the highest stages of a gear transmission, which have a higher

gear ratio and load torque than the lower stages. Figure

9 shows the results of the calculations of the relative thickness of oil film λ for a 3-stage

spur gear transmission

at point B of the engagement section. This Figure clearly shows that

lubrication conditions deteriorate along with an increase in the gear ratio.

Lubrication

conditions can be improved primarily by reducing the roughness of surfaces of

gear wheel teeth through process changes. This can be seen in Figure 10, which

shows the results of calculations for the relative thickness of oil film λ for the previously analysed second stage of the right angle spur planetary

gear transmission. This Figure shows plots of the relative thickness of oil

film λ depending on the

parameter Ra for various viscosity grades, determined for the second stage of

the right angle planetary gear transmission operating at the assumed drive

motor power of 450 kW.

Fig. 6. Plots of the relative

thickness of oil film λ at point

B of the engagement section as a function of the power of the drive motor and

the viscosity grade (the results obtained for surface roughness Ra = 0.6 μm)

Fig. 7. A sample plot of

the values of the instantaneous load in relation to the nominal load of the

right angle planetary gear transmission of an armoured

face conveyor

Fig. 8. Instantaneous relative

values of the thickness of oil film λ

determined at point B of the engagement section of the right angle planetary

gear transmission

Similarly to Figure 6, the mixed

lubrication conditions shown in Figure 10 are only within a fairly narrow range

of values of the parameter Ra and kinematic viscosity. For a typical roughness

of surfaces of the teeth subjected to profile grinding, the analysed

pair of teeth operate under boundary lubrication conditions.

Fig. 9. Plots of the relative

thickness of oil film λ as a function of the gear ratio, determined for a

3-stage spur gear transmission used in belt conveyors

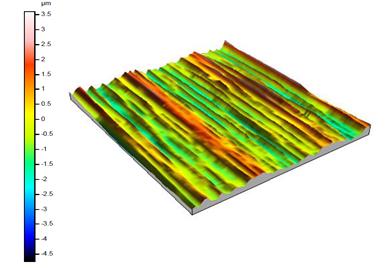

When analysing

lubrication conditions, the direction of measuring the parameter Ra should also be considered. As can be

seen in Figure 11, there is a variation in the roughness depending on whether

the measurement is carried out in the direction of the pitch line or perpendicular

to it (along the tooth profile). In the case of the planetary gear transmission

subject to the analysis, the value of the parameter Ra measured in the

direction of the pitch line was 0.21 μm, while in the direction perpendicular to it

– 0.81 μm.

Figure 12 shows the impact of the direction of measuring the roughness on the

plots of the relative thickness of oil film λ

at point B as a function of the position in the engagement section for the

second stage of the right angle spur planetary gear transmission.

4. CONCLUSION

As a part of this study, there was

presented, a possibility of using a modified calculation method based on the

ISO/TR 15144-1:2014 (E) standard for determining the

lubrication conditions of typical industrial gear transmissions used in drives

of conveyors in industrial transport. The analysis covered primarily the second

spur gear stage of the right angle spur planetary gear transmission with the

gear ratio i=39, as well as a 3-stage spur gear

transmission. The selected method can be used by maintenance services in RCA to

determine the optimal lubrication conditions for given operating conditions of

the gear transmission. The decision regarding the choice of operating

conditions, type of lubricant and requirements concerning the roughness of the

surface of gear wheels should be taken only after the results of these

calculations have been obtained. Such an approach can improve the service life

and the time of failure-free operation of drives of industrial transport

machines.

Fig. 10. Plots of the relative

thickness of oil film λ at point

B of the engagement section as a function of the roughness and the viscosity

grade for a right angle planetary gear transmission (the results obtained for

drive motor power P=450 kW)

Fig. 11. View of the profilogram of the tooth surface subjected to profile

grinding

Fig. 12. Plots of the relative

thickness of oil film λ as a

function of the position in the engagement section for the second stage of the

right angle spur planetary gear transmission, determined for the roughness Ra = 0.21 μm

(direction consistent with the pitch line) and for the roughness Ra = 0.81 μm

(direction perpendicular to the pitch line)

References

1.

Bartz

Wilfried. 1989. Getriebeschmierung.

[In German: Gear lubrication].

Ehningen: Expert Verlag. ISBN: 38-1690-404-1.

2.

Spałek

Jacek. 2003. Problemy inżynierii

smarowania maszyn w górnictwie. [In Polish:

Problems of machinery lubrication engineering in mining].

Gliwice: Publishing house of the Silesian

University of Technology. ISBN: 83-7335-225-2.

3.

Hebda

Michał. 2007. Procesy tarcia,

smarowania i zużywania maszyn. [In Polish: Processes of friction, lubrication and wear of machines]. Warsaw-Radom: PIB. ISBN: 978-83-7204-556-0.

4.

Nadolny

Karol. 1999. Tribologia kół

zębatych: zagadnienia trwałości i niezawodności. [In Polish: Gear tribology: durability and reliability issues]. Poznan-Radom: PIB. ISBN: 83-7204-077-X.

5.

Michalski R., S. Wierzbicki. 2008. „An

analysis of degradation of vehicles in operation”. Eksploatacja i Niezawodnosc

– Maintenance and Reliability 1: 30-32.

6.

Mazurkiewicz D. 2014.

„Computer-aided maintenance and reliability management systems for

conveyor belts”. Eksploatacja i Niezawodnosc – Maintenance

and Reliability 16(3): 377-382.

7.

Madej

Henryk, Piotr Czech, Łukasz Konieczny. 2003. „Wykorzystanie dyskryminant bezwymiarowych w diagnostyce przekładni

zębatych”. Diagnostyka 28:

17-22.

ISSN: 1641-6414.

8.

Medvecka-Benova Silvia, Peter Bigos. 2013. „Analysis of noise reduction of gear transmissions”. In: 13th SGEM GeoConference on Ecology, Economics, Education And Legislation. SGEM2013 Conference Proceedings 1: 57-62. DOI: 10.5593/SGEM2013/BE5.V1/S20.008.

9.

Maláková Silvia,

Michal Puškár,

Peter Frankovský, Samuel Sivák,

Maroš Palko, Miroslav Palko. 2020. „Meshing Stiffness - A Parameter Affecting the Emission of Gearboxes”. Applied Sciences

10(3): 1-12. DOI: 10.3390/app10238678.

10.

Czech Piotr. 2011. „Diagnosing

of disturbances in the ignition

system by vibroacoustic signals

and radial basis function - preliminary research”. Communications

in Computer and Information Science 239: 110-117.

DOI: https://doi.org/10.1007/978-3-642-24660-9_13.

Springer, Berlin, Heidelberg. ISBN: 978-3-642-24659-3. ISSN: 1865-0929. In:

Mikulski Jerzy (eds), Modern transport telematics, 11th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 19-22, 2011.

11.

Czech Piotr. 2013. „Diagnosing

a car engine fuel injectors' damage”. Communications in Computer

and Information Science 395: 243-250. DOI: https://doi.org/10.1007/978-3-642-41647-7_30. Springer, Berlin,

Heidelberg. ISBN: 978-3-642-41646-0; 978-3-642-41647-7. ISSN: 1865-0929. In:

Mikulski Jerzy (eds), Activities of transport telematics, 13th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 23-26, 2013.

12.

Maláková Silvia,

Matej Urbanský, Gabriel Fedorko,

Vieroslav Molnár,

Samuel Sivak. 2021. „Design of Geometrical Parameters and Kinematical Characteristics of a

Non-circular Gear Transmission

for Given Parameters”.

Applied Sciences

11(3): 1-23. DOI: 10.3390/app110311000.

13.

Maláková Silvia,

Peter Frankovský, Daniela Harachová,

Vojtech Neumann. 2019. „Design of constructional optimisation determined for mixed truck gearbox”. AD

ALTA Journal of Interdisciplinary

Research 9: 414-417. ISSN: 1804-7890.

14.

Wiśniewski

Michał. 2000. Elastohydrodynamische Schmierung. Renningen-Malmsheim: Expert Verlag, ISBN: 978-3-8169-1745-8.

15.

ISO/TR 15144-1:2014 (E) Calculation of micropitting load capacity of cylindrical spur and helical gears - Part 1: Introduction and basic principles.

16.

Dowson Duncan, Gordon

Higginson. 1976. Elastohydrodynamic lubrication. Oxford-London:

Pergamon Press. ISBN: 9781483181899

17.

Hamrock Bernard, Duncan Dowson. 1981. Ball Bearing Lubrication. New

York, Chichester, Brisbane, Toronto, Singapore: John Wiley & Sons. ISBN: 9780471035534.

Received 11.03.2021; accepted in revised form 09.05.2021

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License