Article

citation information:

Vakulenko, I.A., Plitchenko, S.,

Kurt, B., Proydak, S., Askerov, H. Transformation of structure during friction stir

welding. Scientific Journal of Silesian

University of Technology. Series Transport. 2021, 111, 181-191. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.111.16.

Igor Alex VAKULENKO[1], Sergey

PLITCHENKO[2], Bulent

KURT[3], Svetlana PROYDAK[4],

Hangardas ASKEROV[5]

TRANSFORMATION

OF STRUCTURE DURING FRICTION

STIR WELDING

Summary. In comparison with low carbon steels, there is increased

interest in the use of aluminium-based alloys as materials for the manufacture

of welded structures rolling stock of railway transport. During friction stir

welding aluminium-based alloy, against the background of the analysis

structural transformations, issues of development hardening processes are

considered. Under conditions of existence, a temperature gradient at zone of

weld formation, shown degree approximation alloy to the conditions of

superplastic flow and influence from presence particles of the second phase on

grain size of matrix is estimated. Evaluation of the separate influence grain

size of matrix and state of solid solution at total hardness of the weld showed

dependence of their contributions on temperature of hot plastic deformation. As

the temperature of plastic deformation of alloy at area of the weld

increases, contribution to the total hardness from grain size increase and on

state of the solid solution decreases.

Keywords: chemical compound, grain size, hardness, recrystallisation, temperature

1. INTRODUCTION

The high activity of aluminium-based

alloys to oxygen atoms significantly limits their use for the manufacture of

structures using the electric arc welding technology. In the last few decades,

for the manufacture of welded structures from aluminium alloys in aviation [1],

automobile [2] mechanical engineering and railway transport [3], friction stir

welding (FSW) [4-7] has become widespread. A distinctive feature of this

technology is the absence of change at state aggregation of the metallic

material. The technology of FSW is based on the achievement of the area of the connect edges

high degree mixing of the metal material from the simultaneous action of hot

plastic deformation and rate of diffusion [8-10]. Indeed, if degree at mixing

of the metal and density of the weld is determined by the plastic properties,

the characteristics of strength and crack resistance would depend on the

development of structural transformation after finish active phase connected of

edges. For most aluminium alloys with a multiphase structure, the volume fraction,

dispersion and morphology of the phase components influence the development of

recrystallisation processes and the final grain size of the matrix. On the

other hand, most chemical compounds of aluminium alloys are partially

interacting with matrix [11-13], which involves their dissolution with

increasing heating temperature of the alloy. Consequently, with increasing

heating temperature and duration work tool, the greatest possible degree

plasticisation of the alloy for the implementation of FSW technology [14-16],

dissolution of the chemical compound should increase mobility boundaries of the

matrix grains with large angles of disorientation and increase size of grain [12,

14]. The above provisions are confirmed by the high sensitivity of stir friction

welding to the temperature and speed of hot plastic deformation [18]. Moreover,

small deviations from their optimal ratio significantly complicate the process

of forming a quality welded joint [9, 14, 19].

2. STATE OF PROBLEM

The special shape of the working tool ensures

transition of the metal along the entire thickness of the connecting edges in

such a plastic state, which should be sufficient for its quality mixing during

weld formation. With increasing temperature, decrease resistance to the propagation

of plastic deformation is not always accompanied by an increase at plasticity

of the metal material. This position is due to the implementation of a certain

ratio between the development of the hardening and softening processes during

hot deformation. To achieve high ductility, in addition to proposals to

maintain a uniform distribution of deformation [18, 19], it would, analysing

the mechanism of structural changes, achieve and maintain stable conditions for

the propagation of super plastic deformation at alloy. Further, in addition to

increasing the plastic properties by tens to hundreds times [19], there is a

decrease at deformation stress to abnormally low levels. In general, the

conditions for achieving a superplastic state correspond to the relationship:

![]() ,

(1)

,

(1)

where

s - deforming stress, m - a coefficient sensitivity to rate of

deformation, s1 - characteristic, which by absolute value and physical meaning

corresponds to stress of non-inverse motion of dislocations [20]. On the other

hand, the value s

has a certain dependence on the degree of plastic deformation (e):

![]() , (2)

, (2)

where:

K - coefficient of

proportionality, n - the exponent (coefficient of strain hardening [21]).

After

substitution (2) in (1), by the ratio:

![]() (3)

(3)

it

is possible to determine the contribution of strain hardening on deviation from

the achievement conditions of the superplastic state in metallic material.

Thus, when approaching the superplastic flow, the structural transformations

during hot deformation should compensate for the negative contribution of

deformation hardening. As you approach the specified state of the metal

material s

will be decrease, the corresponding decrease will be for s1 and n. Thus, when s1®0 and n@0, K will be equal to the operating stress. By the

relation (3) maximum value of m cannot exceed 0.5. In fact, given the high

sensitivity to small deviations from the optimal ratio parameters of hot

deformation (temperature, strain rate, grain size, invariance, etc.), this

characteristic will be at range 0<m<0,5. In addition to the temperature and deformation

conditions of the superplastic flow, the issues of achieving optimal structural

state metallic material and maintaining it constant during deformation period

are of great importance. At process of hot plastic deformation, effective

stress depends on the grain size (d) according to the ratio:

![]() ,

(4)

,

(4)

where:

a is an exponent (for most

metallic materials, it is approximately equal to 1 [22]), A is constant [23]. By (4) the decrease in s will be approach to superplastic state will be provided by a decrease

d. Then, it is quite reasonable to obtain a stable structure during hot

deformation, with the small grain of polyhedral shape [18, 21], in sizes to

several microns. The need to maintain a constant grain structure is due to a

change in the nature of the deformation distribution from grain size during the

superplastic flow. The smallest grains are predominantly deformed along near

boundaries with large angles of disorientation, at low level s. In large grains, the deformation is distributed throughout the

volume, which requires a continuous increase applied stress [20]. Such

different conditions can only be met by maintaining a certain ratio between the

hardening and the softening processes during hot plastic deformation. Indeed,

at temperatures below optimum value, when the plastic properties of the metal

become insufficient to achieve desired level of mixing, traces of the working

tool become coarser, with obvious signs of exfoliation dispersed fragments [15,

17]. Under conditions when the metal is overheated to

temperatures higher than optimal value, as shown in [14, 16], the zone

influence of thermal and region of the weld have strength properties of a

much lower level compared to the initial state. Then, preservation of the

partial influence from development of deformation hardening processes during

the propagation of plastic flow can be a factor of increasing strength of metal

in the weld to level by initial state [10, 14]. The question of mechanism

propagation of plastic deformation under conditions superplastic state remains

open. According to [9, 19], it is believed that over plastic flow should be

accompanied by rotation of randomly oriented grains relative direction of the

applied stress or alternation of slippage in volumes near the grain boundaries,

with subsequent migration of boundaries.

3. MATERIAL AND RESEARCH METHODS

As a material for

research, used alloy based on aluminium with a content of Mg 6.5%, Mn 0.85%, Fe

0.13%, a rest of Al. Plates 2.5 mm thick was butt welded by FSW technology, on

a specially designed research stand, using a working tool of known size and shape

of the shoulder and pin [8, 14, 19]. Investigations of the welding process were

carried out at different ratios of rotational speed working tool (![]() ) and force of its pressing to the connecting

edges (P). The speed of movement

working tool along connecting edges was constant and was 40 mm/min, the change

interval

) and force of its pressing to the connecting

edges (P). The speed of movement

working tool along connecting edges was constant and was 40 mm/min, the change

interval ![]() was

800-1600 min-1, and P was

100 - 1420 N. The temperature distribution (T)

by heating edges of the metal was measured using thermocouples such as chromel

- alumel, with location at different distances from the connecting edges. The

structure of the alloy was examined using a light microscope

"Epiquant". Size of grain alloy was determined by the use of methods

quantitative metallographic. Measurements of microhardness (Hm) were performed on a device

type PMT-3, under load on the indenter 0.05N. Measurement data Hm was used as a characteristic

of strength properties for micro volumes of the alloy.

was

800-1600 min-1, and P was

100 - 1420 N. The temperature distribution (T)

by heating edges of the metal was measured using thermocouples such as chromel

- alumel, with location at different distances from the connecting edges. The

structure of the alloy was examined using a light microscope

"Epiquant". Size of grain alloy was determined by the use of methods

quantitative metallographic. Measurements of microhardness (Hm) were performed on a device

type PMT-3, under load on the indenter 0.05N. Measurement data Hm was used as a characteristic

of strength properties for micro volumes of the alloy.

4. RESULTS AND DISCUSSION

In general, the process of FSW can

be divided into two successive stages. From the beginning, a pin and shoulder

are immersed at alloy under load, without moving the tool along the edges.

According to the scheme (Figure 1a), the action of pressing force for a certain

duration leads to a corresponding increase at heating temperature of the edges

on the opposite side from the surface shoulder of the instrument (Figure 1b). The first stage ends with

heating the edges to a temperature that provides the required level of plastic

properties for high-quality mixing of the metal. The second stage starts from

the moment the tool is moved along the connecting edges. In proportion to the

speed of the weld formation, the energy consumption for continuous heating of

cold volumes of metal first with the shoulder, and then with the tool pin leads

to the emergence gradient of temperature and decrease of average temperature on

the thickness of the edges. This is confirmed by the decrease in temperature

from extremes in Figure 1b. To analyse the combined effect of the main

technological parameters (P and ![]() ) on

heating temperature metal of the connecting edges, dependences P ~ f (T) were constructed using

experimental data

) on

heating temperature metal of the connecting edges, dependences P ~ f (T) were constructed using

experimental data ![]() (Figure 1a, b). According to the curves

(Figure 1c), it is determined that regardless of the value

(Figure 1a, b). According to the curves

(Figure 1c), it is determined that regardless of the value ![]() ,

moment of violation directly proportional relation P ~ f (T) corresponds to approximately the equal temperature of

90-95°C. Generally, it should be assumed

that at this temperature, the process of softening begins to compensate for a

significant part resistance of the edges to immersion of the tool

(strengthening alloy from hot plastic deformation). Indeed, with the increase

of hot deformation temperature, processes moving of dislocations on different

crystallographic sliding systems are significantly accelerated, which promotes

their annihilation and redistribution at alloy matrix [20]. As a result,

dislocation subgrains of polygonal shape are formed, separated by subboundaries

of different types, with different angles of disorientation [19, 22]. It is

experimentally determined that the sharp decrease at deforming force (Figure

1b), especially at elevated

,

moment of violation directly proportional relation P ~ f (T) corresponds to approximately the equal temperature of

90-95°C. Generally, it should be assumed

that at this temperature, the process of softening begins to compensate for a

significant part resistance of the edges to immersion of the tool

(strengthening alloy from hot plastic deformation). Indeed, with the increase

of hot deformation temperature, processes moving of dislocations on different

crystallographic sliding systems are significantly accelerated, which promotes

their annihilation and redistribution at alloy matrix [20]. As a result,

dislocation subgrains of polygonal shape are formed, separated by subboundaries

of different types, with different angles of disorientation [19, 22]. It is

experimentally determined that the sharp decrease at deforming force (Figure

1b), especially at elevated ![]() , is

actually due to the rapid heating of the thin layer of metal under by shoulder,

with simultaneous occurrence of a high temperature gradient by thickness of

connecting edges. To determine factors of influence that lead to a violation of

proportional nature at curves P ~ f (T)

(Figure 1c), the possibility of recrystallisation at alloy was

evaluated. For this purpose, the known relation

, is

actually due to the rapid heating of the thin layer of metal under by shoulder,

with simultaneous occurrence of a high temperature gradient by thickness of

connecting edges. To determine factors of influence that lead to a violation of

proportional nature at curves P ~ f (T)

(Figure 1c), the possibility of recrystallisation at alloy was

evaluated. For this purpose, the known relation ![]() was used, where TR and TS

- is the temperature of development static recrystallisation

and melting of metallic material, respectively. After substitution TS investigated alloy, the calculated value of TR was 100°C. Thus, under certain assumptions,

the moment of deviation from proportional of curves P ~ f (T) equal 90-95°C should

correspond to the conditions at the beginning of the development of the recrystallisation processes. In comparison with

single-phase alloys, the presence of structure particles at the second phase

can significantly change the influence of hot plastic deformation on the

development processes of primary and secondary recrystallisation.

On the other hand, the effectiveness of this effect on the grain size of the

matrix can be limited stability of existing particles second phase at hot

deformation temperatures (0.75-0.85 at FSW [8-10]. Given the presence of alloying chemical elements at alloy, the

option of forming only binary chemical compounds was considered to simplify

evaluation. According to the state diagrams of Al-Mg [11], Al-Fe [12]

and Al-Mn [13] possibility of dissolving

particles of the second phase at FSW

temperatures was analysed. Thus, by the Al-Mg

diagram (Figure 2a), a chemical compound Al2Mg (β-phase) must be

interacting with the matrix. For a Mg concentration

of 6.5%, the volume fraction of β-phase, considering the solution of 2.95%

of Mg atoms in a-solid solution, should be

approximately 9-9.2%. In the process of isothermal exposure, at temperatures of

approximately 375-380°C, one should expect beginning

solution Al2Mg particles

(Figure 2a). However, the small degree of overheating from the phase

equilibrium temperature indicates the need for a long enough exposure to

complete dissolution.

was used, where TR and TS

- is the temperature of development static recrystallisation

and melting of metallic material, respectively. After substitution TS investigated alloy, the calculated value of TR was 100°C. Thus, under certain assumptions,

the moment of deviation from proportional of curves P ~ f (T) equal 90-95°C should

correspond to the conditions at the beginning of the development of the recrystallisation processes. In comparison with

single-phase alloys, the presence of structure particles at the second phase

can significantly change the influence of hot plastic deformation on the

development processes of primary and secondary recrystallisation.

On the other hand, the effectiveness of this effect on the grain size of the

matrix can be limited stability of existing particles second phase at hot

deformation temperatures (0.75-0.85 at FSW [8-10]. Given the presence of alloying chemical elements at alloy, the

option of forming only binary chemical compounds was considered to simplify

evaluation. According to the state diagrams of Al-Mg [11], Al-Fe [12]

and Al-Mn [13] possibility of dissolving

particles of the second phase at FSW

temperatures was analysed. Thus, by the Al-Mg

diagram (Figure 2a), a chemical compound Al2Mg (β-phase) must be

interacting with the matrix. For a Mg concentration

of 6.5%, the volume fraction of β-phase, considering the solution of 2.95%

of Mg atoms in a-solid solution, should be

approximately 9-9.2%. In the process of isothermal exposure, at temperatures of

approximately 375-380°C, one should expect beginning

solution Al2Mg particles

(Figure 2a). However, the small degree of overheating from the phase

equilibrium temperature indicates the need for a long enough exposure to

complete dissolution.

Analysis of the state diagrams of Al-Mn [10] and Al-Fe [12] (Figure 2b) showed the presence volume fraction of

particles of Al6Mn - 3.7%, with a solution above 500°C

[13] and Al3Fe -

up to 0.6% the stably existing up to melting points of the alloy [12] (Figure

2b). At a speed of movement working tool along connecting edges of 40 mm/min,

overcoming distance of 12 mm (diameter of a shoulder) occurs in 17 s. Thus, the

total duration alloy will be under influence at weld temperatures should be

divided into effects action from the shoulder and the rod. At the beginning,

heating from a shouldered with a high temperature gradient, only one surface

each of the edges with a width of 6 mm for 8-9 s to a temperature of about 440°C.

The temperature opposite surface of the edges is lower by about 25%. Action of

the pin will be lead to additional heating (especially root of the seam) and

rapid mixing alloy on the thickness connecting edges to equalise temperature to

an average value of 380-375°C at a distance 3-4 mm from the pin.

Analysis of the state diagrams of Al-Mn

[10] and Al-Fe [12] (Figure 2b)

showed the presence volume fraction of particles of Al6Mn -

3.7%, with a solution above 500°C [13] and Al3Fe - up to 0.6% the stably existing up to melting points of the alloy [12]

(Figure 2b). At a speed of movement working tool along connecting edges of 40

mm/min, overcoming distance of 12 mm (diameter of a shoulder) occurs in 17 s.

Thus, the total duration alloy will be under influence at weld temperatures

should be divided into effects action from the shoulder and the rod. At the beginning,

heating from a shouldered with a high temperature gradient, only one surface

each of the edges with a width of 6 mm for 8-9 s to a temperature of about 440°C.

The temperature opposite surface of the edges is lower by about 25%. Action of

the pin will be lead to additional heating (especially root of the seam) and

rapid mixing alloy on the thickness connecting edges to equalise temperature to

an average value of 380-375°C at a distance 3-4 mm from the pin.

а

b

c

Fig. 1. Influence ![]() (♦ -800, ■ -1240, ▲

-1600 min

(♦ -800, ■ -1240, ▲

-1600 min![]() ) on

the change at resistance edges to immersion of the tool (a), the heating

temperature edges on the opposite side of the shoulder (b) depending duration

of the tool action and the ratio P ~ f (

T) for different

) on

the change at resistance edges to immersion of the tool (a), the heating

temperature edges on the opposite side of the shoulder (b) depending duration

of the tool action and the ratio P ~ f (

T) for different ![]()

(1-800, 2-1240, 3-1600 min![]() ) (c)

) (c)

а

b

Fig. 2. Parts of state diagrams

binary alloys Al-Mg - (a) and Al-Fe - (b)

Then for the same 8-9 s, there is a further decrease at the temperature

gradient along the cross-section of the seam due to the distribution of metal

from the shoulder. It follows from the above analysis that during the period of

tool operation time, there is not enough heat for a complete dissolution of the

particles of the chemical compounds. The presence of the second phase at

structure should be considered as a factor that will help maintain a constant

grain size of the alloy matrix during FSW. Stability

of the structure during the development of secondary recrystallisation is determined by the conditions of compensation driving force of grain

boundary movement by effect of inhibition on their motion by particles of the

second phase. By these conditions, grain size (d) of alloy matrix on particle diameter second phase (D) and volume fraction (f) will be determined by the dependence

[24]:

![]() ,

(5)

,

(5)

where A is a coefficient.

For

alloys, when f > 8-10% A = 2/3 [24]. Using relation (5), it is

possible to determine the factors influencing d under the conditions of FSW development. The stability of the structure as the

alloy approaches the superplastic state

will be determined by the coalescence of the particles of the second phase,

their volume fraction and the possible solution in the matrix. In its original

state, the grain size of alloy matrix was equal to 15-17 μm. Areas with

different degrees mixing of metal edges were selected for the analysis of

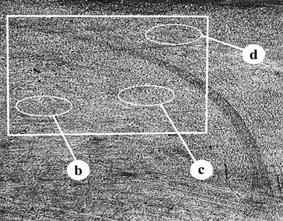

structural transformations of FSW. Figure 3

shows the structures of alloy volumes in which temperature, microhardness and

grain size were measured. When forming a weld, the occurrence of a significant

difference in temperature and degree of plastic deformation near the tool rod,

lead to the formation of very complex gradient structures. In this case, there

is a significant change not only at average grain size, but also its shape.

When approaching surface near tool rod, the temperature 360°C and the

degree of plastic deformation is sufficient for formation in alloy grains of

relatively small size, with a shape close to a polygon (Figure 3d). On the

other hand, a slight increase in distance leads to the expected decrease in

temperature, for example, to 345°C (Figure 3c), and accordingly, degree of hot

plastic deformation. A characteristic feature of this area is the increased

structural heterogeneity of the formed grains. One of the reasons for the

existence of such a structure to be considered incomplete is the completion of

the recrystallisation processes [20]. For volumes of alloy

with lower temperature (Figure 3b), a structure with an even larger interval of

grain size change is observed. The location studied micro-volume relative to

the curved portion of weld (Figure 3a) indicates a more significant influence

on structure transformations from tool pin to shoulder. For average values of d (10-16 μm) and temperature range

330-360°C at f ![]() 13%, the conditional diameter particles of the second

phase was estimated by relation (5). The calculated D values were in the range of 2-3 μm, which coincides with

known data [20, 22]. Given the possible solution in particles of chemical

compounds at studied temperature range (Figure 2) in FSW, one should expect an increase at

concentration of alloying chemical elements in

13%, the conditional diameter particles of the second

phase was estimated by relation (5). The calculated D values were in the range of 2-3 μm, which coincides with

known data [20, 22]. Given the possible solution in particles of chemical

compounds at studied temperature range (Figure 2) in FSW, one should expect an increase at

concentration of alloying chemical elements in ![]() - solid

solution after cooling alloy. Then, after formation weld and its cooling, in

the layers of alloy with a high degree mixing should change the effect of

hardening from the state of solid solution. To confirm this is used the

Hall-Petch type ratio [25], with Hm as a

characteristic of strength:

- solid

solution after cooling alloy. Then, after formation weld and its cooling, in

the layers of alloy with a high degree mixing should change the effect of

hardening from the state of solid solution. To confirm this is used the

Hall-Petch type ratio [25], with Hm as a

characteristic of strength:

![]() ,

(6)

,

(6)

where Hmi is the expected microhardness of alloy matrix at

absence grain boundaries with large disorientation angles [25], ky is the angular

coefficient. Given the lack of a clear boundary in the structure between the

three zones (Figure 2b), it was decided to analyse only for two areas with

guaranteed temperatures of 330 and 360°C. The result of applying Hm against the corresponding values of d is shown in Figure 4. Execution of

this ratio indicates that level Hm is determined by the grain size of alloy matrix and

the state of the solid solution, with virtually no contribution from

substructure elements, etc. The effect on level Hm from the particles of the second phase is almost

absent, due to their location along the grain boundaries with large angles of

disorientation. The fact is that when

the particles of the second phase have a predominantly location at middle of

grains, conditions of relation (6) will be violated due to transition of the

role of the main structural element from d

to distance between the particles [20, 21, 24]. According to estimates Hm and ky, it is

determined that when temperature changes from 330 to 360°C,

contribution to the total level of microhardness from solid solution (Hm)

decreases from 400 to 110 MPa, and resistance of deformation propagation from

boundaries of grain (ky) will increase more

than twice (from 2,5 to 6 N mm-1,5). Thus, with increasing

temperature at FSW effect of

hardening from the state of solid solution decreases, while the grain

boundaries increases. Comparative analysis Hm for the

equal d but at different temperatures

at FSW shows a violation of the known ratio, when

under normal conditions of deformation decrease temperature increases the

hardening effect, and reduces the degree of softening alloy. Thus, for d = 8 μm, at 330°C, Hm is less

than 700 MPa, and for 360°C on 15% higher (![]() ). For a big d, different relationship is obtained. For example, at d = 28 μm, Hm = 520 MPa

for a temperature of 330°C, and for 360°C, Hm = 480 MPa

(

). For a big d, different relationship is obtained. For example, at d = 28 μm, Hm = 520 MPa

for a temperature of 330°C, and for 360°C, Hm = 480 MPa

(![]() ). Given that with increasing d, the parameters of strain hardening

increase [21], to the known requirements for achieving over superplastic flow, in addition to

maintaining a stable structure with over fine grain, it should further minimise

influence from the state of solid solution.

). Given that with increasing d, the parameters of strain hardening

increase [21], to the known requirements for achieving over superplastic flow, in addition to

maintaining a stable structure with over fine grain, it should further minimise

influence from the state of solid solution.

5. CONCLUSIONS

1.

At temperatures

above phase equilibrium, the partial solution of particles chemical compounds

is a source of supersaturation solid solution by atoms alloying elements under

FSW.

2.

At the formation

of weld, the presence in structure particles of the second phase is a factor in

inhibiting movement grain boundaries at the period of structure formation.

3.

Increasing

temperature during FSW, accompany by decrease contribution from state of solid

solution and increased role of grain boundaries to the overall hardness level

of the weld.

Gratitude

The authors are grateful to the Chief of the

laboratory, Yu. L. Nadezhdin, for his valuable advice on discussing research

results.

а

b

c

d

Fig. 3. General view of the area intensive mixing after FSW (![]() = 1250 min

= 1250 min![]() ) (a)

) (a)

and enlarged image of the selected fragment depending on heating temperature:

(b) -330,

(c) -345 and (d) -360°C. Magnification: a - 100; b-d - 350

Fig. 4. Influence of the size of grain ![]() - solid

solution on microhardness,

- solid

solution on microhardness,

depending on the temperature of the microvolumes alloy at FSW (▲ - 330,

♦ -360°C)

References

1.

Ding J., R. Carter, K. Lawless, et.al. 2006. „Friction stir

welding flies high at NASA”. Ibid 3: 54-59.

2.

Hovanski Yu., P. Upadhyay, J. Carsley, et.al. 2015. „High-Speed

Friction-Stir Welding to Enable Aluminum Tailor-Welded Blanks”. The

Journal of The Minerals, Metals & Materials Society 67: 1045-1053. ISSN:

1047-4838. DOI: https://doi.org/10.1007/s11837-015-1384-x.

3.

MST Technology Co., LTD. 2020. „Friction Stir Welding Applied To

Rail”. Available at:

https://www.aee-fsw.com/news/friction-stir-welding-applied-to-rail-33051203.html.

4.

Bušić

M., Z. Kožuh, D. Klobčar, I. Samardžić. 2016.

“Friction stir welding (FSW) of aluminium foam sandwich panels”. Metalurgija 55(3): 473-476.

5.

Miličić

M., P. Gladović, R. Bojanić, T. Savković, N. Stojić. 2016.

“Friction stir welding (FSW) process of copper alloys”. Metalurgija 55(1): 107-110.

6.

Podržaj P.,

B. Jerman, D. Klobčar. 2015. “Welding defects at friction stir

welding”. Metalurgija 54(2):

387-389.

7.

Klobčar D.,

J. Tušek, M. Bizjak, V. Lešer. 2014. “Micro friction stir

welding of copper electrical contacts”. Metalurgija 53(4): 509-512.

8.

Thomas W.M., E.D.

Nicholas, J.C. Needham, et. al. Patent 5,460,317. United States. Friction welding. Assignee The

Welding Institute Cambridge, United Kingdom. Public date: 10.10.1995. Available at:

https://patents.google.com/patent/US5460317A/en.

9.

Yihua Xiao, Haifei

Zhan, Yuantong Gu, et.al. 2017. “Modeling heat transfer during friction

stir welding using a meshless particle method”. International Journal of Heat and Mass Transfer 104: 288-300. DOI:

10.1016/j.ijheatmasstransfer.2016.08.047.

10.

Dalder E., J.W.

Pastrnak, J. Engel, et.al. 2008. “Friction stir welding of thick-walled

aluminum pressure vessels”. P. 40-44. Available at:

https://app.aws.org/www/wj/2008/04/WJ_2008_04.pdf.

11.

Mola K., A. Dziadon.

2008. “Formation of magnesium – eutectic mixture layered

composite”. Archives of Foundry

Engineering 8: 127-132.

12.

Li X., A. Schert,

M. Heilmaier, et. al. 2016. “The

Al – rich Part of the Fe – Al Phase Diagram”. Journal of Phase

Equilibria and Diffusion 37: 162-173.

13.

Kematick R.J.,

C.E. Myers. 1992. “Thermodynamics and Phase Equilibria in the Al-Mn

System”. Journal of Alloys and Compounds 178: 343-349.

14.

Villegas J.F., J.V. Dominguez,

G.V. Ochoa, et.al. 2017. “Thermo-mechanical

modeling of friction-stir welding tool used in aluminum alloys joints”. Contemporary Engineering Sciences 10(34):

1659-1667. DOI: 10.12988/ces.2017.711156.

15.

Li Dongxiao, Yang

Xinqi, Cui Lei, et.al. 2015. “Investigation of stationary shoulder

friction stir welding of aluminum alloy 7075-T651”. Journal of Materials Processing Technology 222: 391-398. DOI:

10.1016/j.jmatprotec.2015.03.036.

16.

El-Sayed M.M, A.Y.

Shash, T.S. Mahmoud, et. al. 2018. “Effect of friction stir welding

parameters on the peak temperature and the mechanical properties of aluminum

alloy 5083-O”. Improved Performance

of Materials 72: 11-25.

DOI: 10.1007/978-3-319-59590-0_2.

17.

Dawes C.J. 1995.

“An introduction to friction stir welding and its development”. Weld. and metal fabr. 1: 13-16.

18.

Wilkinson D.S., C.H. Caceres.

1984. “On the mechanism of strain-enhanced grain grown

during super plastic

deformation”. Acta Met. 32:

1335-1345.

19. Partridge P.G., D.S. Mc Darmaid, A.W. Bowen. 1985.

“A deformation model for anisotropic super plasticity in to phase alloys”. Acta Met. 33: 571-577.

20.

Xiao-guo Wang, Qiu-shu Li, Rui-rui Wu, et al. 2018. “A Review on Superplastic Formation Behavior

of Al Alloys”. Advances in

Materials Science and Engineering 7606140. DOI:

https://doi.org/10.1155/2018/7606140.

21.

Ruano O., O.D. Sherby.

1988. “On constitutive equations for various diffusion-controlled creep

mechanisms”. Revue de Physique Appliquee 23:

625-637.

22.

Sakai G., Z.

Horita, T.G. Langdon. 2005. “Grain refinement and superplasticity in an

aluminum alloy processed by high-pressure torsion”. Materials Science

and Engineering A 393: 344-351.

23.

Robiller G., Ch. Straβburger. 1969. “Zum Bauchinger–effektunlergiester stahle”. Materialprufung 1: 89-95.

24.

Smith C.S. 1948. “Grains, phases and interfaces: an interpretation

of microstructure”. Trans. ASME

175: 15-67.

25.

Christ B.W., G.V. Smith.

1967. “Comparison of the hall-petch parameters of zone-refined iron

determined by the grain size and extrapolation methods”. Acta Metallurgica 15: 809-816. DOI:

https://doi.org/10.1016/0001-6160(67)90362-8.

Received 07.04.2021; accepted in revised form 24.05.2021

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License