Article

citation information:

Puškár, M., Kopas, M., Šoltésová,

M., Lavčák, M. System for analysis and correction

of motor management. Scientific Journal

of Silesian University of Technology. Series Transport. 2021, 111, 129-136. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.111.11.

Michal PUŠKÁR[1],

Melichar KOPAS[2],

Marieta ŠOLTÉSOVÁ[3], Matúš LAVČÁK[4]

SYSTEM

FOR ANALYSIS AND CORRECTION OF

MOTOR MANAGEMENT

Summary. The innovative system, which was developed for analysis and correction of motor

management, is determined

for the solution of practical

problems concerning the operation of the piston combustion

engines. Programming of the ignition

curves and fuel maps without relevant

feedback, namely, without information obtained from the engine operation, increases the risk of detonation combustion, which can destroy

the combustion engine. However, the main application area of this system is the development of

an algorithm, which is specified

for control of the combustion

process based on the HCCI technology (Homogenous Charge Compression Ignition). Nowadays, the functional principle of the HCCI engine is one of the most effective possibilities on how to reach higher

operational efficiency of

the gasoline engine, that is, closer

to the efficiency level of

the diesel driving units.

Keywords: system, analysis, correction, motor management

1. INTRODUCTION

Presently,

many production companies around the world offer a wide range of electronics,

including programmable electronic control units determined for installation in

various models of piston combustion engines [1-3]. The programmable electronic

control units enable to perform very detailed simulation of the engine ignition

curve using either the 2-dimensional or the 3-dimensional simulation method.

Application of the 2-dimensional method means that the actual value of the

ignition advance angle is a function of the engine operational speed. The

second possibility, that is, application of the 3-dimensional method, means

that the angle of advanced ignition is not only a function of the engine speed,

but also depends on the actual position of the throttle installed in the input

pipe [4]. The throttle position determines the real amount of the fuel-air

mixture that is delivered into the combustion engine.

However,

a relevant problem occurs in the real operation of the combustion engine. This

problem is that the values programmed during the simulation process (that is,

the values of advanced ignition at various engine speed levels), do not usually

correspond with reality. The individual impulses obtained from the measuring

sensor changes with the given type of combustion engine. For example,

variability of the impulse shape, which is typical for the input impulses as

well as their delay, especially at higher engine speed levels (above 10,000

rpm); cause significant deformation of the output data correctness [5-7].

Based

on this, an innovative system, which enables tuning the universal control unit

to the concrete type of the engine-working regime, was developed by our

research team. Further, this system defines the correction curve for the input

values during the programming of the ignition curves and fuel maps.

2. ANALYSIS OF IGNITION IMPULSE

First, it is

necessary to note the measuring of impulse produced by the impulse generator.

This generator is connected with the engine crankshaft. The measuring process

is based on the application of an oscilloscope. The main task of the measuring

procedure is the collection of real data, which describe the analysed

parameter. In the case that the values obtained from the measuring procedure

are utilised within the engine control process, hence, it is necessary to

ensure that the installed measuring apparatus fulfils the required metrological

characteristics.

Fig. 1. Generator

of impulses for combustion engine

Of course, this

requirement is equally valid for the application of the above-mentioned

oscilloscope. It is necessary to emphasise an important fact that every

deviation, which occurs during the measuring activity, has a negative impact on

the measuring process and it causes an incorrect function of the engine control

unit. There are two main constructional parts of the impulse generator: the

sensor of impulses and the rotor, which is directly connected with the

crankshaft (Figure 1).

The value of basic

advance is given by the setting of the generator. It corresponds to the

"base advance" angle. Figure 1 illustrates the top dead centre

position [6]. It is recommended to verify whether a real advance in the given

engine is following the advance, which was determined using a stroboscopic

lamp.

The sensor of

impulses is a very important part of the electronic ignition system. It is

necessary to apply such kind of sensor, which can satisfy the ascending edge

condition (that is, the change of voltage) within the interval from 0 to 1.5 V.

This requirement fulfils the inductive sensor of rotation [8-11].

An ignition spark

is generated by the system of ignition and the spark-coil according to the

impulses from the rotational sensor.

Fig. 2.

Signal obtained from impulse sensor (part above) and in CDI (part below)

Figure 2

illustrates a shape of the impulse coming from the sensor of impulses in such

form, which is presented from the oscilloscope. A specific position of the

rotor, namely, the position opposite the sensor, is situated at 32º before reaching the top dead centre. This situation

illustrates the left circle in Figure 2, whereby generation of the impulse

starts just in this moment. Amplitude of the impulse is increasing in the

negative direction regarding the central axis. After one half of amplitude

begins a rapid reversing in such a moment, when the rotor is not in

interference. The impulse amplitude further continues in the previous direction

to reach the maximum negative value, and consequently, it is returning back to

the central line. The impulse amplitude passes through the central line at

approx. 7º before the level of the top

dead centre. The above-described deviation creates a specific interval, which

is called “the trigger interval”, whereby this oscillation lasts

during approx. 25º within rotation of the

engine crankshaft. Finally, the positive amplitude occurs after crossing the

projection lug in the rotor. The lug is visible in Figure

The signal

obtained from the sensor is the input signal to the control unit to be

processed [12, 13]. The bottom part of Figure 2 illustrates the signals

modified in the universal programmable control unit CDI. Further presented in

the given figure is a mutual comparison of the processed signals and the

scanned signals. It is visible from the same figure that the final version of

the signal, which is processed in the control unit CDI, has the values situated

only in the positive part of the axis, namely, with three main amplitudes. It

is also evident that this signal is periodically repeating after each

revolution of the rotor, that is, after every 360º.

3. PRINCIPLE OF THE MEASURING METHOD

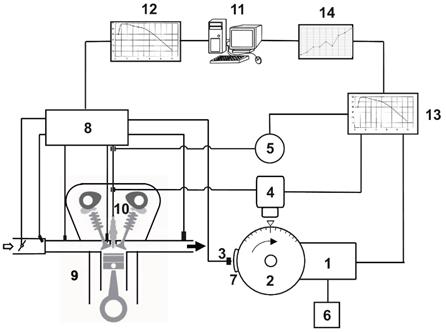

The described system, which is

determined for analysis and correction of motor

management (Figure 3), consists of the electric motor, sensor of

impulses, stroboscopic lamp, speed indicator and speed regulator. The rotor of

the electric motor is connected with the disc protractor. The disc protractor

generates an electric signal through a lug shaped in the form of a sector of a

circle.

Fig. 3.

System for analysis and correction of motor

management

(1, 2 –

high-speed electric motor with disc protractor; 3 – impulse sensor; 4 –

generator of stroboscopic effect; 5, 6 – speed indicator with speed regulator; 7

– sector of circle, which generates impulses; 8 – control unit; 9

– combustion engine; 10 – spark plug; 11 – PC;

12 – input curve; 13 – real curve; 14 – correction curve)

The generated electric signal is

detected by the impulse sensor, which is jointed to the engine control unit.

The stroboscopic lamp is emitting a light ray oriented to the disc protractor

just at the moment of simulated ignition of the fuel-air mixture. The speed

indicator and the stroboscopic lamp are connected to the cable of the engine

spark plug. The speed regulator enables utilising the whole spectrum of the

engine speed. The time behaviour of the real ignition curve is recorded on the

disc protractor using the stroboscopic method. Consequently, there is utilised

the principle of comparison between the real ignition curve and the input

ignition curve, which is installed into the engine control unit by a personal

computer (PC). The result of this procedure is the correction curve, which

serves for modification of the input data.

The main advantage of this solution

is that it enables obtaining the correction curve relatively fast with a

satisfactory accuracy. The question of deviations concerning the real output

values of the ignition curve as well as the importance of the fuel map are

especially relevant in the high-speed engine operational area and they have a

significant influence on the operational stability of the HCCI

combustion process.

4. APPLICATION OF THE PRESENTED SYSTEM

The presented measuring method was

practically verified in the case of the experimental combustion engine. There

was applied the control unit (CDI) during the whole measuring process.

Regulation of the advanced ignition is based, in this case, on two adjustable

ignition curves within the interval from 0 to 90° at the engine speed level

from 100 to 15,000 rpm. It is possible to set all the functions and various

operational ignition regimes using a PC equipped with a special software

application called the Ignition Control. This application also enables to

obtain online visualisation of the most important engine operation values, that

is, the values of advanced ignition, engine speed as well as the inputs in

digital and analogue forms. The ignition system is connected to the PC using an

interface - USB cable [14-16].

There was programmed and implemented

into the control unit, the input ignition curve through the PC. This ignition

curve is a part of the control algorithm, which is utilised for control of the

combustion process. After the start, the speed of the electric motor with the

disc protractor was set on the required initial value using the speed regulator.

The stroboscopic lamp is emitting a light ray to the disc protractor at the

moment of simulated ignition of the fuel-air mixture. The result is a light

effect of a seeming stopping of the disc protractor in the simulated ignition

position. The disc protractor indicates the advanced ignition value, and at the

same time, the speed indicator offers the corresponding engine speed value. It

is obtained, in this way, one operational point of the real ignition curve. The

speed regulator allows performing of a sequential change of the engine speed

within the above-mentioned speed interval, and thus, it is possible to

investigate the whole behaviour of the real ignition curve. The real ignition

curve was compared with the programmed ignition curve using the PC and this

process of comparison resulted in the correlation curve. The correlation curve

serves for the input data modification.

5. CONCLUSIONS

The

innovative measuring process described in this article enables to perform very

precisely, a tuning procedure concerning the ignition control unit for each

kind of combustion engine. This measuring methodology represents a significant

contribution to the operational safety of the combustion engine. Namely, it

reduces the risk of detonation combustion due to the elimination of

incorrect outputs. In this way, it also significantly increased the global

operational reliability of the combustion engine, especially during the

application of the HCCI technology. This technology

utilises the principle of self-ignition of the homogenous fuel mixture using

the compression stroke. The homogenous fuel mixture is combusted in the whole

combustion volume at the same time, that is, there is combusted almost the

whole fuel mixture. Therefore, exploitation of the fuel is very effective,

however, there are some serious problems concerning the application of the HCCI technology. The most relevant of them are high

compression pressures, excessive heat release and demanding control of the

self-ignition process. Development of an algorithm, which is determined for the

operational control of the combustion process, is one of the main conditions

that are necessary for the practical and reliable application of the HCCI technology. The system described in this article

represents a significant contribution for better feedback regarding the control

components of motor management.

Acknowledgements

This work was supported

by the Slovak Research and Development Agency under Contract No. APVV-19-0328.

This article was written

in the framework of the Grant Projects: VEGA 1/0318/21 “Research and

development of innovations for more efficient utilization of renewable energy

sources and for reduction of the carbon footprint of vehicles” and KEGA 006TUKE-4/2020

“Implementation of Knowledge from Research Focused on Reduction of Motor

Vehicle Emissions into the Educational Process.”

References

1.

Puskar Michal,

Peter Bigos, Michal Kelemen,

Roman Tornhajzer, Martin Sima.

2014. „Measuring method for feedback provision during development of fuel

map in hexadecimal format for high-speed racing engines”. Measurement 50: 203-212. DOI: 10.1016/J.MEASUREMENT.2014.01.005.

2.

Brestovic Tomas, Natalia Jasminska, Maria Carnogurská,

Michal Puskar, Michal Kelemen, Milan Filo. 2014.

„Measuring of thermal characteristics for Peltier thermopile using

calorimetric method”. Measurement 53: 40-48. DOI: https://doi.org/10.1016/j.measurement.2014.03.021.

3.

Wierzbicki Sławomir. 2019. “Evaluation of the effectiveness

of on-board diagnostic systems in controlling exhaust gas emissions from motor

vehicles”. Diagnostyka 20(4): 75-79.

4.

Czech Piotr. 2013. „Intelligent

Approach to Valve Clearance Diagnostic in Cars”. Communications

in Computer and Information Science 395: 384-391.

DOI: https://doi.org/10.1007/978-3-642-41647-7_47.

Springer, Berlin, Heidelberg. ISBN: 978-3-642-41646-0; 978-3-642-41647-7. ISSN:

1865-0929. In: Mikulski Jerzy (eds), Activities of transport telematics,

13th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 23-26, 2013.

5.

Puskar Michal,

Tomas Brestovic, Natalia Jasminska.

2015. „Numerical simulation and experimental analysis of acoustic wave

influences on brake mean effective pressure in thrust-ejector inlet pipe of

combustion engine”. International

Journal of Vehicle Design 67(1): 63-76. DOI:

https://doi.org/ 10.1504/ijvd.2015.066479.

6.

Czech Piotr. 2011. „Diagnosing

of disturbances in the ignition

system by vibroacoustic signals

and radial basis function - preliminary research”. Communications

in Computer and Information Science 239: 110-117.

DOI: https://doi.org/10.1007/978-3-642-24660-9_13.

Springer, Berlin, Heidelberg. ISBN: 978-3-642-24659-3. ISSN: 1865-0929. In:

Mikulski Jerzy (eds), Modern transport telematics, 11th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 19-22, 2011.

7.

Czech Piotr. 2013. „Diagnosing

a car engine fuel injectors' damage”. Communications in Computer

and Information Science 395: 243-250. DOI: https://doi.org/10.1007/978-3-642-41647-7_30. Springer, Berlin,

Heidelberg. ISBN: 978-3-642-41646-0; 978-3-642-41647-7. ISSN: 1865-0929. In:

Mikulski Jerzy (eds), Activities of transport telematics, 13th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 23-26, 2013.

8.

Dodok Tomas, Nadezda

Cubonova, Miroslav Cisar,

Ivan Kuric, Ivan Zajacko.

2017. „Utilization of strategies to generate and optimize machining

sequences in CAD/CAM“. 12th

International scientific conference of young scientist on suitable, modern and

safe transport 192: 113-118. May 31-June 02, 2017. High Tatras,

Slovakia. DOI: 10.1016/j.proeng.2017.06.020.

9.

Kuric Ivan, Miroslav Cisar, Vladimir Tlach, et al.

2018. „Technical Diagnostics at the Department of Automation and

Production Systems“. 2nd

International Conference on Intelligent Systems in Production Engineering and

Maintenance (ISPEM) 835: 474-484. Sep 17-18,

2018. Wroclaw, Poland.

10.

Puskar Michal,

Andrej Jahnatek, Ivan Kuric,

et al. 2019. „Complex analysis focused on influence of biodiesel and its

mixture on regulated and unregulated emissions of motor vehicles with the aim

to protect air quality and environment”. Air Quality Atmosphere And Health 12(7):

855- 864.

11.

Brezinova Janette., Anna Guzanova. 2012. „Possibilities of utilization high

velocity oxygen fuel (HVOF) coatings in conditions of

thermal cycling loading“. Metalurgija 51(2): 211-215.

12.

Zivcak Jozef,

Martin Sarik, Radovan Hudak.

2016. „FEA simulation of thermal processes

during the direct metal laser sintering of Ti64

titanium powder“. Measurement 94:

893-901. DOI: 10.1016/j.measurement.2016.07.072.

13.

Toth Teodor,

Radovan Hudak, Jozef Zivcak. 2015. „Dimensional verification and quality

control of implants produced by additive manufacturing“.Quality innovation prosperity - Kvalita inovacia prosperita 19(1):

9-21. DOI: 10.12776/QIP.V19I1.393.

14.

Homisin Jaroslav, Peter Kassay, Michal Puskar, Robert Grega,

Jozef Krajnak, Matej Urbansky, Marek Moravic. 2016. „Continuous tuning of ship propulsion

system, by means of pneumatic tuner of torsional oscillation. Transactions of the Royal Institution of

Naval Architects Part A: International Journal of Maritime Engineering 378.

DOI: 10.3940/RINA.IJME.2016.A3.378.

15.

Puskar Michal,

Andrej Jahnatek, Jaroslava Kadarova, et al. 2019. „Environmental study focused

on the suitability of vehicle certifications using the new European driving

cycle (NEDC) with regard to the affair “dieselgate” and the risks of NOx emissions

in urban destinations“. Air Qual Atmos Health 12: 251-257.

DOI: https://doi.org/10.1007/s11869-018-0646-5.

16.

Puskar Michal,

Michal Fabian, Jaroslava Kadarova,

Peter Blistan, Melichar Kopas. 2017. „Autonomous vehicle with internal combustion

drive based on the homogeneous charge compression ignition technology“. International Journal of Advanced Robotic

Systems 14(5): 1-8. DOI: 10.1177/1729881417736896.

Received 19.02.2021; accepted in revised form 02.05.2021

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License