Article

citation information:

Galik, J., Kohar, R., Brumercik, F., Hudec, J.,

Patin, B. Increasing

the safety of a device using the TRIZ methodology. Scientific Journal of Silesian University of Technology. Series

Transport. 2021, 111, 43-56.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.111.4.

Jan GALIK[1],

Robert KOHAR[2],

Frantisek BRUMERCIK[3],

Juraj HUDEC[4],

Branislav PATIN[5]

INCREASING THE

SAFETY OF A DEVICE USING

THE TRIZ METHODOLOGY

Summary. The safety of

machinery is a very important aspect for its correct functioning in the

conditions of modern production or assembly. According to the standards,

manufacturers of special-purpose machines and devices are obliged to provide

their equipment with a certificate of conformity (CE). This article describes

the concerns of insufficient safety of a device. Insufficient coverage of part

of the line meant that the certification did not take place, and the safety

requirements were not met. The TRIZ method was used to resolve this technical

discrepancy, providing designers with "instructions" on how to

proceed, solve complex problems at the level of discrepancies and create

solutions. By agreement of the designers, a solution that was not economically

and implementation-intensive was created. All doors and windows within the

fencing have been reinforced, thus achieving a greater degree of security.

The resulting solution was subjected to simulations in the Ansys Workbench

program, and the FEM analysis led to certain conclusions. The results were then

moved to the structural engineer to assess the solution, who then approved the

solution and successful certification of part of the device, respectively, in

the assembly line.

Keywords: special-purpose

machines, safety, TRIZ

1. INTRODUCTION

Companies

operating in the engineering industry are very complex units, containing

various types of production and assembly technologies. With the increasing

degree of automation, the complexity of decision-making processes within

production or assembly increases. An important factor is the degree of

automation of machinery and equipment, whether manual, semi-automated or

automated equipment [1-3]. A large range of robotic devices can be observed in

production. There are different classes and types of robots suitable for

different activities. Inter-operational robots usually have the task of moving

parts, rotating them, storing them, etc. Production robots have the task of

either assisting man with manipulation or functioning independently in the

production process in place of the man [4]. A great help in assembly logistics

is, for example, AGV tractors [5].

The

devices consist of various programmable modules and control units [6]. These

modules ensure security and are included in the price offers as an option to

purchase the device [7]. The company was approached by a new customer with a

problem related to the line, specifically the robotic workplace. The essence

was to increase the safety of a device, and the problem was that the inspection

of the device in obtaining a CE certificate was not successful [8]. The TRIZ

methodology is often used within the company, which provides its view of the

solved problem [9-11]. The company proposed a solution right at the

certification regarding the inclusion of light gates, which would work as

interrupters of the device. They would react to possible damage to the fence;

thus, increase the level of security [12, 13]. Although the Slovak Technical

Inspectorate is the certifier, it was not enough as a solution that would

increase the strength of the fencing was needed [14]. After determining the

solution and limiting conditions, the results had to be substantiated by FEM

analysis. Ansys Workbench was available from the available software [15, 16].

The specific case was solved in cooperation with the company

HJ Design s.r.o.

1.1. Workplace safety

Devices safety is a relevant element

in the proper functioning of equipment as a whole. The Safety Act defines that

the employer is obliged to ensure that the work device he/she provides to the

employee complies with the minimum safety requirements required of it. The

safety of the work device can also be understood as a safe installation and

inspection at the required location. Installation and proper use mean the

assembly of a functional unit, located in the employer's premises, its proper

functioning and connection, for example, for electrical installation, pressure

distribution (compressed air, nitrogen, etc.), hydraulic distribution, air

conditioning, and distribution of waste materials [17-19]. The safety of the

devices is verified by the customer's requirements, within the standards, while

the electrical safety of the device must be subject to both the STN 331600 and

STN 331610 standards [20]. A large number of requirements for new equipment is

considered by designers during the design process [21].

An

important aspect is the degree of automation of the device (assembly line,

etc.). From this viewpoint, we know from the human operation, semi-automatic

and automatic workplaces. As part of security, different automated devices are

also treated differently. Standards EN ISO 10218-1 and EN ISO 10218-2 deal

mainly with the environment of industrial robots [22]. These standards point

out the possible risks associated with robots and the conditions for

eliminating these risks. It is necessary to follow the established rules such

as no entry of unauthorised persons into the range of the robotic arm, robot

speed below 250 mm/s, entry into space only without automatic mode, the control

panel must be held in the hand and the robot is not controlled externally and

so on [23].

Based on

the analysis of possible risks and the determination of restrictive conditions,

several safety elements are used in the production cell, namely: fencing,

protection of access doors, and emergency stop [24]. Fencing has the function of protecting

the surroundings against possible robot-surroundings collisions. In the event

of an impact, fencing should absorb a larger part of the energy; thus, protect

the environment against the action in our case of the robotic arm. As part of

the requirements, or in an agreement between the customer and the manufacturer,

a way of fencing with the BOSCH REXROTH AG modular system was specified, which

uses modular types of aluminium profiles and a whole range of various

additional modules and design improvements [25, 26]. The construction created

by the designer seemed to be sufficiently strong, which according to them,

needs no additional modification. To protect the operator, it is possible to

use either fencing or frequently used polycarbonate boards.

The

construction uses a security lock as one of the other security elements. With a

higher degree of automation, the door parts of the fence must be protected thus

[27]. They tend to combine modules such as a handle (mechanical system) and

sensors (electrical system) to create a mechatronic system. There are different

variants of security locks, most of which are designed as modular systems,

where a specific lock can be extended by an additional module [28]. Currently,

there are many companies (Euchner, Sick, Troax, and others) that think this way

because modular systems save energy, costs, and time [29]. The protection

elements can also include the use of a T switch, which serves as a safety

mechanism. Upon pressing it, the operation of the device is immediately

interrupted, often of the entire line.

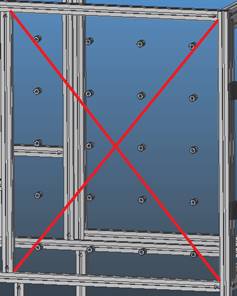

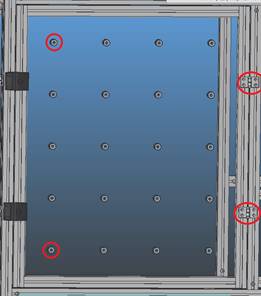

Fig.

1. Fencing of a robotic workplace Fig.

2. Fencing of a robotic workplace

The

problem arose on the part of the assembly line where the robotic arm is

installed behind the safety fencing (in the cage). According to the standards,

and the technical inspection, the given device is unsatisfactory from a safety

perspective; it is necessary to correct the current state, and only then can

the device obtain a CE certificate. The technical inspection does not give an

official permit for the operation of such equipment. Certificates according to

Act 124/2006 Coll. discuss the safety of technical equipment [20]. In Figures 1

and 2, it is possible to see three walls of the fences in the robotic workplace

in which a collision can occur. The result can be a fatal collision with the

person standing next to it.

Due

to various factors, a specific workplace creates danger for human operators,

which is an unacceptable situation from the position of safety and health at

work. The standard STN EN ISO 14121-1: 2008 deals with the assessment of risks

in all phases of the life of machinery. The functional safety of the machine is

discussed in STN EN ISO 13849-1: 2008 [30]. According to these standards,

equipment put into operation is not completely in order. The biggest problem is

that due to the spatial possibilities and the robotic arm used, there is still

the possibility of a collision with the protective fencing.

The

robotic arm used is from Mitsubishi, type RV-7FM-D1-S15, while cooperating with

the robotic controller type CR750-07VD1-1-S15. As part of the purchase of the

device from a subcontractor, it was possible to purchase a module to protect

the device from damage (possible collision) [31]. The function of this module

is to protect the device and prevent the robotic arm from moving out of its

confinement. Due to an insufficient budget, the purchase of this option was

rejected. Based on the customer's request, the concept of increasing the safety

of the robotic device was proposed. The TRIZ methodology proved to be very

reliable, not only in the phase of the ideological (conceptual) solution but

also in solving various technical problems and contradictions.

2. TRIZ METHODOLOGY AND PROBLEM SOLVING

Based on previous experience, the

TRIZ method has proved its worth in solving various problems, providing good

solutions to problems where technical or physical contradictions arise in

proposed solutions. The term contradiction can be understood that by increasing

the value of one parameter, we achieve a decrease in the value of another

parameter, which is important to us. This method is innovative and provides the

key to overcoming contradictions through various solutions [7, 32, 33].

The main problem solved was

insufficient safety of the working robot. Safety had to be increased, so the

question was "How?". When considering this problem, another condition

was encountered, and it sounded at least interfering with the existing

construction of the workplace [34, 35].

Using the TRIZ methodology, a key

technical discrepancy was determined, which arose from the relationship between

the stability of the building (fencing) - 13 and the adaptability of the

building (fencing) - 35 (Figure 3). By increasing the stability of the fence,

we can strengthen the fence, however, this makes it unable to adapt to a

possible impact. By increasing the adaptability, we can achieve low stability

of the building, that is, the fencing may withstand the impact; however, there

will be a deviation from the cage, which is unacceptable for technical

inspection (light gates - Section 1). According to Altshuller’s table,

the problem (contradiction) can be solved by several possible approaches,

namely flexible coatings or membranes (35), recycling and regeneration (34),

separation of the part (2), or change of physical or chemical properties (30).

The solution principle with flexible

coatings or membranes can be used to increase the safety of the device (35). An

example would be the use of impacting a panel of doors and walls covered with a

durable coating. Based on available resources, this principle cannot be used to

solve this situation, thus, a simple and effective solution is needed.

Fig. 3. Technical discrepancy of construction

in the Altshuller matrix

Another solution provided was the

use of recovery and recycling (34). This solution option is used, for example,

when one part of the whole (no longer needed part) evaporates, resp. disappears

during operation, or a regeneration and recovery process may occur. In our

case, the team of designers did not figure out how to solve the problem in this

way.

The third principle of solving our

problem is to separate the influencing part from the whole, to separate it (2).

An example is a compressor room, which due to noise from compressors and

vibrations, is separated from the consumer of compressed air while the person

only has a compressed air connection located next to him/her. There were no

ideas or feedback from the team to use this principle.

The last usable principle from the

Altshuller table was the principle of changing the physical state (30), for

example, a change to a gas or liquid, or a change in other physical properties.

Upon closer examination and consultation of the design team regarding this

principle, it was concluded that there is a possibility to increase the

flexibility of the fence, and at the same time, reinforce the fence with the

least possible intervention and the lowest possible production costs -

assembly. Based on another consultation, several variants of resolving the

situation were created.

Based on the information available

so far, several ideas have emerged on how to strengthen the structure and

create a stronger fence of the robotic arm, which would withstand a possible

collision. Thus, it has to be a simple, economically undemanding solution that

can be quickly implemented. Given the solution to the discrepancy from the

previous section, the design team tried to provide the necessary solutions to

the situation.

The first proposal was to simply

reinforce a given existing structure so that the existing window of the

structure and the door could be easily divided by a profile. This would create

reinforcement and require smaller plexiglass, which can effectively increase

the strength of the construction of all three walls-doors. From an economic

standpoint, it would be necessary either to buy new plexiglass or cut old

plexiglass to the required dimensions.

The second solution to the situation

was to double the plexiglass structure. Plexiglass would be attached to the

aluminium frame (BOSCH) via auxiliary plates, slotted nuts, and screws. The

advantage would be the creation of the second stage of fencing, which should

protect the environment from a possible collision with the robotic arm.

The third variant provided deals

with the doubling of plexiglass, and the two segments will be interconnected.

The design will create a second part of the fence, independent, but at the same

time connected to the first part, which will increase the strength of the

primary glass and, if possible, make the glass become a stronger and more rigid

unit.

2.2. Solution

The contracting authority had the

decisive word for the approval of the final solution. The provided solution

variants were subjected to a decision-making process by the customer. However,

a few pitfalls arose concerning the implementation of the first variant, and

the client disagreed with the dismantling of the assembled fencing. In the

second variant of the solution, there was no connection between the first and

second glass, which gave the impression that the added glass is only a kind of

"second safety glass", which in essence may not be enough in the

event of a possible collision.

The construction team agreed on the

use of the change in the physical properties of the structure (TRIZ) by

creating two segments of the protective fence and interconnecting them. The

third variant was chosen for the solution using the TRIZ method, which gave us

a strong solution to the technical conflict. A second glass was used, attached

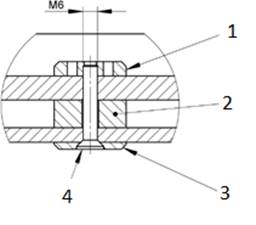

to the first using manufactured spacer rings (2), washers (3), nuts (1), and

screws (4) (Figure 4).

Fig. 4. Designed fencing reinforcement

To verify the data, and create the

basis for the technical inspection, it was necessary to verify the proposed

solution. The simulation took place in the Ansys Workbench program, addressed

in the following section (Section 3).

3. CONSTRAINTS AND FEM SIMULATION

This section deals mainly with

proving the effectiveness of solving the problem. Step one was the definition

and modelling of design modifications, coming to new conclusions, and

determining the key points of the design and possible variants of robot

failure. The situation of the device is as follows:

-

the device is

bounded on three sides by insufficient fencing;

-

two of these sides

are large openable windows for possible maintenance;

-

the filling

consists of a 10 mm thick polycarbonate board;

-

one side is a

solid (non-openable) polycarbonate sheet.

The design team agreed to modify the

equipment fencing as follows:

-

adding spacer

rings, nuts, washers, and screws to each endangered fencing wall and doubling

the protection by adding another polycarbonate panel (t = 6 mm);

-

addition of

security elements for locking the door (component made of polyamide PA6);

-

prescription of

the exact layout of individual spacer rings, locks, and hinges.

The simulation was performed in the

Ansys Workbench program.

3.1. Forces locations

Within the design

team, we wanted to determine the place of impact and the magnitude of the force

as the most critical points of the structure, that is, where the given fencing

elements will be most loaded. The most critical from this point of view was the

centre of the largest wall of the fence and the edges of the opening doors

Figures 5 and 6).

Fig.

5. Impact Glass (LH) Fig.

6. Impact to distant opera points

(reaction

in hinges)

The maximum load capacity can be

read from the graph and from the data on the robotic arm [36] where the

dependence of the distance of the centre of gravity of the robotic arm from the

distance of the centre of gravity of the manipulated load is plotted. If we

consider the problem as static, then we use the safety factor k = 3. If the arm

is the most loaded, that is, with the largest possible manipulated load (7 kg),

at max. distance r = 0.24 m, the force (formula 2) at the maximum speed on the

axis J6 (12.566 rad / s) is as follows:

![]() (1)

(1)

![]() (2)

(2)

The resulting impact force at safety

k = 3 could be obtained in the worst possible variant around 800 N when solved

as a static problem. The simulation was performed only by loading the specified

specific critical variants selected based on the previous risk analysis.

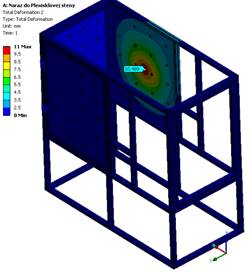

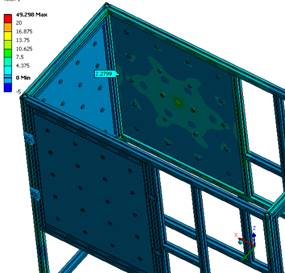

3.2. Forces on the side window (LH)

The method of impact can be seen in

Figure 5, where the robotic arm would in the worst possible conditions, strike

directly into the centre of the wall with the reinforcement already engaged.

The centre of the polycarbonate plate from the edges of the Al profiles has the

coordinates of the x-axis = 493.75 mm; y-axis = 596.5 mm.

Fig. 7. Total deformation (LH) Fig.

8. Von Mises Stress (LH)

The resulting deflection and

stresses on the largest side of the protective fence are still within the

permissible stresses (49.3 MPa, Figure 8) because the maximum value of tensile

strength for the polycarbonate board is 60 MPa (70 MPa) [37]. The deflection

itself (Figure 7) is no longer large (11 mm) under the action of such a large

force on such a large area with such a thick glass. The assumption that a given

impact phenomenon occurs is small, with the robotic arm moving with much

smaller loads during line handling.

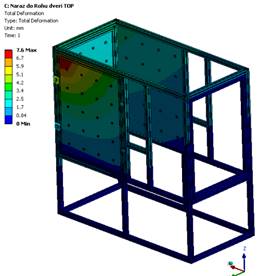

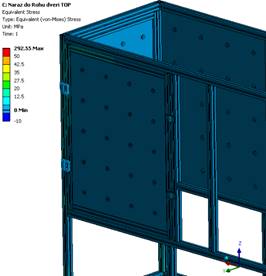

3.2. Forces on the side door (RH)

In Figure 6, it is possible to see

the critical points of application forces on the right side of the door. Hinges

and locks are important parts as the fencing door must remain in place for

safety, and protect its surroundings. Figure 6 shows possible points of

collision within the RH side and are the centres of the spacer rings. With the

correct placement, the impact in both variants should have approximately the

same course, therefore, the variant of the impact into the upper spacer ring

with the coordinates of the x-axis = 110.25 mm was chosen; y-axis = 981.7 mm

(from the edge of the Al profile). The entire closing of the door on this side

of the protective cage was solved using two locks made of PA6 and two hinges

made of Al from BOSCH.

Fig. 9. Total deformation (RH). Fig.

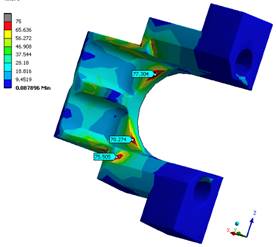

10. Von Mises stress (RH)

In Figure 9, a maximum deviation of

7.6 mm was obtained, which is still at an acceptable value. According to the

simulation, Figure 10 shows a voltage of 292.55 MPa, which is an unacceptable value.

The given value, however, came out in the radii of the polyamide lock during

the testing, which the FEM method can cause stress concentrators to form within

the rounding (Figure 11). As for the reactions in the hinges, the largest

reaction in the hinge came out as 400.5 N in Figure 15. The most stressed was

the upper lock, which had the above-mentioned unacceptable value of von Mises

voltage. The yield strength of polyamide PA6 is 76 MPa [38].

When using the FEM method, it is

necessary to remove any rounding’s, as this rounding’s create

stress concentration. Most of the lock component is coloured in a less

pronounced green colour, which is a value of up to 47 MPa. The given value and

the colouring of the whole part indicate that the given part (tongue) should

withstand a possible collision with the robotic arm [39, 40]. The response in

the lock was calculated in the simulation to the value of 824.23 N, which the

lock bolts withstood in the verification calculation without major problems.

The simulation proved the necessary

results for the certification of the device. The report was forwarded to the

structural engineer for the safety assessment of the proposed fencing. The

structural engineer affirmed the report, which was subsequently submitted to the

technical inspection.

Fig. 11. The lock and von Mises

Stress

4. CONCLUSION

The essence of this article was to

introduce the reader to the solution to a security problem. In our case, a

systematic approach and the use of one of the known innovative methods –

TRIZ managed to get a suitable solution. The methodology is still used in large

design offices, where the team of designers also have an expert in this

methodology. The methodology can be used, not only for solving serious

innovative tasks but also for various technical problems, where the solution

lies in the correct definition of the problem. Further, this article gives an

example of how the design team proceeded to design safer fencing.

As part of solving a specific

problem of increasing safety, the team came up with a simple and effective

solution to increase the strength of the fence, without much intervention. The

provided solution was then simulated in the Ansys Workbench software, and

certain conclusions were drawn from it. Based on these conclusions, a report

was prepared for the structural engineer, who approved the results. Upon the

conclusions drawn, the technical inspection evaluated the proposed solution as

sufficient and, the equipment obtained a CE certificate after implementing the solution.

Source

of funding

This study was supported by the Cultural and

Educational Grant Agency MŠVVaŠ, under contract no. 015ŽU-4/2020

“Inovácie edukačného procesu s využitím

nových technológii v CAD”.

References

1.

Indri Marina, Luca

Lachello, Ivan Lazzero, Fiorella Sibona, Stefano Trapani. 2019. „Smart

Sensors Applications for a New Paradigm of a Production Line”. Sensors

19(3): 650. DOI: https://doi.org/10.3390/s19030650.

2.

Vaičekauskis

M., R. Gaidys, V. Ostaševičius. 2013. „Influence of boundary

conditions on the vibration modes of the smart turning tool”. Mechanika 3: 296-300.

3.

Rimkevičienė

J., V. Ostaševičius, V. Jūrėnas, R. Gaidys. 2009.

„Experiments and simulations of ultrasonically assisted turning

tool”. Mechanika 1: 42-46.

4.

Fomin Alexey, Wsevolod

Ivanov. 2019. „Development of a Mixing Mechanism with a Complex Motion of

the End-effector”. Strojniski Vestnik – Journal of Mechanical

Engineering 65(5): 319-325. ISSN: 2536-2948. DOI:

https://doi.org/10.5545/sv-jme.2018.5965.

5.

Khashayar Asadi,

Akshay Kalkunte Suresh, Alper Ender, Siddhesh Gotad, Suraj Maniyar, Smit

Anand, Tianfu Wu. 2020. „An integrated UGV-UAV system for construction site

data collection”. Automation in Construction 112: 103068. ISSN:

0926-5805. DOI: https://doi.org/10.1016/j.autcon.2019.103068.

6.

Belorit Michal,

Slavomir Hrcek, Tomas Gajdosik, Jan Steininger. 2017. „ Description of

the bearing check program for countershaft gearboxes”. ICMD 2017: 58th

International Conference of Machine-Design-Departments: 32-35. The Faculty

of Engineering, Czech University of Life Sciences Prague, Prague, Czech

Republic. 06-08 September 2017.

7.

Bistak Marek,

Stefan Medvecky, Slavomir Hrcek. 2017. „ The Above-ground

Weighbridge”. TRANSCOM 2017: 12th international scientific conference

of young scientists on sustainable, modern and safe transport: 52-57.

University of Zilina, Zilina, Slovak Republic. 31 May-02 June 2017. High Tatras

Slovak Republic.

8.

European Union,

EU. „CE marking”. Available at:

https://europa.eu/youreurope/business/product-requirements/labels-markings/ce-marking/index_en.htm.

9.

Terninko John,

Alla Zusman, Boris Zlotin. 1998. Systematic

Innovation: An Introduction to TRIZ (Theory of Inventive Problem Solving). Boca Raton, Florida: CRC Press.

ISBN-13: 978-1138440562.

10. Jiwen Chen, Xin Li, Hongjuan Yang, Chen Wang. 2019. „Innovative Design of a Vertical and Transverse

Elevator in Double Shafts, Based on TRIZ Theory”. Strojniski Vestnik – Journal of Mechanical

Engineering 65(5): 297-310. ISSN: 2536-2948.

DOI: https://doi.org/10.5545/sv-jme.2018.5937.

11. Leber Marjan, Majda Bastic, Borut Buchmeister. 2014. „The Trends in Usage and Barriers of Innovation

Management Techniques in New Product Development”. Strojniski Vestnik – Journal of Mechanical

Engineering 60(6): 382-388. ISSN: 2536-2948. DOI: https://doi.org/10.5545/sv-jme.2013.1611.

12. Mierczyk Zygmunt. 2012. „Lasers in the dual use technologies”. Bulletin of the Polish Academy of Sciences:

Technical Sciences 60(4): 691-696. ISSN: 2300-1917. DOI: https://doi.org/10.2478/v10175-012-0080-z.

13. Tian Xu, Jizhuang Fan, Qianqian Fang, Jie Zhao. 2019. „Robotic arm collision rteaction strategies for safe human-robot interaction without torque sensors”. Journal of

Mechanics in Medicine and Biology 19(7): 1940034. ISSN: 1793-6810.

DOI: https://doi.org/10.1142/s0219519419400347.

14. Liptakova Tatiana, Jozef Broncek, Martin Lovisek, Jan

Lago. 2016. „Tribological and corrosion properties of Al-brass”. 33rd

Danubia Adria Symposium on Advances in Experimental Mechanics: 5867-5871.

20-23 September, 2016. Portroz, Slovenia. ISSN: 2214-7853.

15. Zhen Xiao, Qun You Zhao, Fen Lin, Min Ming Zhu, Ji Yao

Deng. 2018. „Studying the Fatigue Life of a Non-pneumatic Wheel by

Using Finite-Life Design for Life Prediction”. Strojniski Vestnik - Journal of Mechanical

Engineering 64(1): 56-67. ISSN: 2536-2948. DOI:

https://doi.org/10.5545/sv-jme.2017.4695.

16. Steininger Jan, Slavomir Hrcek, Branislav Krchnavy.

2017. „ The design of universal loading device for a grinding

machines”. TRANSCOM 2017: 12th international scientific conference of

young scientists on sustainable, modern and safe transport: 869-874.

University of Zilina, Zilina, Slovak Republic. 31 May-02 June 2017.

17. Skyba Rudolf, Slavomir Hrcek, Lukas Smetanka, Maros

Majchrak. 2019. „Strength analysis of slewing bearings”. TRANSCOM

2019: 13th International Scientific Conference on Sustainable, Modern and Safe

Transport: 52-57. University of Zilina, Zilina, Slovak Republic. 31 May-02

June 2017.

18.

Stanczyk

Marcin, Tomasz Figlus. 2019. „The Effect of Selected Parameters of Vibro-Abrasive

Processing on the Surface Quality of Products Made of 6082 Aluminium

Alloy". Materials 12(14): 4117.

ISSN: 1996-1944. DOI: 10.3390/ma12244117.

19.

Figlus

Tomasz, Mateusz Koziol, Lukasz Kuczynski. 2019. „The Effect of

Selected Operational Factors on the Vibroactivity of Upper Gearbox Housings

Made of Composite Materials". Sensors 19(19): 4240.

ISSN: 1424-8220. DOI: 10.3390/s19194240.

20. Narodny

inspektorat prace. Kontrola pevne instalovanych pracovnych prostriedkov a

skusky tvarniacich strojov. [In Slovak:

National Labor Inspectorate. Inspection of permanently installed work

equipment and testing of forming machines]. Available at:

https://www.ip.gov.sk/kontrola-pevne-instalovanych-pracovnych-prostriedkov-skusky-tvarniacich-strojov/.

21. Wasim Ahmed Khan, Abdul Raouf. 2005. Standards for

Engineering Design and Manufacturing (Mechanical Engineering). Boca Raton,

Florida: CRC Press.

ISBN-13: 978-0824758875.

22. Jankech Peter, Peter Fabian, Jozef Broncek, Yuriy

Shalapko. 2016. „ Influence of Tempering on Mechanical Properties of

Induction Bents below 540°C”.

Acta Mechanica et Automatica 10(2): 81-86.

ISSN: 2300-5319. DOI: https://doi.org/10.1515/ama-2016-0013.

23. Daily Automation. „EN

ISO 10218 – Priemyselne roboty a ich integracia do priemyslu”. [In Slovak: Daily automation. „EN ISO 10218 – Industrial robots and their integration in industry”]. Available at:

https://www.dailyautomation.sk/priemyselne-roboticke-systemy-a-ich-integracia-do-priemyslu/.

24. Sarkan Branislav,

Andrzej Kuranc, Lubos Kucera. 2019.

„Calculations of exhaust emissions produced by vehicle with petrol engine

in urban area”. IV International

Conference of Computational Methods in Engineering Science – CMES'19.

Lublin University of Technology, Lublin. 21-23 November 2019. Kazimierz Dolny,

Poland. DOI: 10.1088/1757-899X/710/1/011001.

25. Kucera Lubos, Igor Gajdac, Peter Kamas. 2014. „ Computing

and Design of Electric Vehicles Modern methods of construction design”. ICMD 2013: 54th International Conference of

Machine-Design-Departments: 105-111. Faculty of Mechanical Engineering,

Technical University of Liberec, Liberec, Czech Republic.

10-12 September 2013. ISBN: 978-3-319-05202-1.

26. Galbavy Marian, Jaroslav Pitonak, Lubos Kucera. 2014.

„Powershift Differential Transmission with Three Flows of Power for

Hybrid Vehicles Modern methods of construction design”. ICMD 2013:

54th International Conference of Machine-Design-Departments: 27-33. Faculty of Mechanical

Engineering, Technical University of Liberec, Liberec, Czech Republic. 10-12

September 2013. ISBN: 978-3-319-05202-1.

27. Drbul Mario, Pavol Martikan, Jozef Broncek, Ivan

Litvaj, Jaroslava Svobodova. 2018. „Analysis of roughness profile on

curved surfaces”. ITEP´18 -

Innovative Technologies in Engineering Production. Faculty of Mechanical

Engineering, University of Zilina, Slovak Republic. 11-13. September 2018. ISSN:

2261-236X.

28. Euchner. EUCHNER – More than safety.

Available at:

https://www.euchner.de/de-de/produkte/multifunctional-gate-box-mgbs/komplettsets-mgbs-p-l-h/.

29. Kucera Lubos, Tomas Gajdosik. 2014. „ The

Vibrodiagnostics of Gears Modern methods of construction design”. ICMD

2013: 54th International Conference of Machine-Design-Departments: 113-118.

Faculty of Mechanical Engineering, Technical University of Liberec, Liberec,

Czech Republic. 10-12 September 2013. ISBN: 978-3-319-05202-1.

30. Steininger Jan, Slavomir Hrcek, Tomas Gajdosik, Marian

Stopka. 2017. „The optimization procedure of the inner geometry in

the spherical roller bearings with regard to their durability”. ICMD

2017: 58th International Conference of Machine-Design-Departments: 50-55. Faculty of Engineering,

Czech University of Life Sciences, Prague, Czech Republic. 06-08 September 2017.

31. Orman Lukasz J., Norbert Radek, Jozef Broncek. 2017. „Sintered Mesh Layers for the Production of Efficient Phase

– Change Heat Exchangers”. 10th Conference on Terotechnology:

189-193. Faculty of Materials Engineering and Metallurgy, Silesian

University of Technology, Katowice, Poland. 18-19 October 2017.

ISBN: 978-1-945291-80-7.

32. Mind Tools. „TRIZ - Creativity Techniques

From MindTools.com”. Available at:

https://www.mindtools.com/pages/article/newCT_92.htm.

33. Syed Ahmad Helmi, Arman Bin Alias, Muhammad Hisjam.

2018. „Improved design solution for motion resistance problem

through integration of robust design and theory of inventive problem solving

(TRIZ) principle”. 4th International conference on industrial,

mechanical, electrical and chemical engineering. Surakarta, Indonesia.

9-11 October 2018. ISBN: 978-0-7354-1827-1.

34. Kaplan Stan. 1996. An Introduction to TRIZ.

Farmington Hills, Michigan: Ideation Intl Inc. ISBN: 1-928747-0-00.

35. Broncek Jozef, Mário Drbúl, Michal

Stupavský, Norbert Radek. 2017. „ The application of new rules of

GPS in structural product requirement”. 58th International Conference of Machine-Design-Departments: 50-55.

Faculty of Mechanical Engineering, University of Zilina, Zilina, Slovak

Republic. 06-08 September 2017.

36. Mitsubishi Electric Corporation. „RV-4/7/13/20FM-D-SE Series Standard Specifications

Manual”. Available

at:

https://eu3a.mitsubishielectric.com/fa/en/dl/11035/e40e9916-473a-11ea-9f1a-b8ac6f83a177_bfp-a3322k.pdf.

37. Polycarbonate. Available at:

http://polymerdatabase.com/Commercial%20Polymers/PC.html.

38. PA6G - liaty polyamid TechPlasty. Available at:

https://www.techplasty.sk/material/polyamid/pa6g-liaty-polyamid.

39. Jambor Michal, Daniel Kajanek, Stanislava Fintova,

Jozef Broncek, Branislav Hadzima, Mario Guagliano, Sara Bagherifard. 2020.

„Directing Surface Functions by Inducing Ordered and Irregular

Morphologies at Single and Two‐Tiered Length

Scales”. Advanced Engineering Materials 2001057. DOI: https://doi.org/10.1002/adem.202001057.

40. Weis Peter, Lubos Kucera, Peter Pecha, Martin Mocilan.

2017. „Modal analysis of gearbox housing with applied load”. TRANSCOM

2017: 12th international scientific conference of young scientists on

sustainable, modern and safe transport: 953-958. University of Zilina, Zilina, Slovak Republic. 31

May-02 June 2017.

Received

08.02.2021; accepted in revised form 20.04.2021

![]()

Scientific Journal of Silesian University

of Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License