Article

citation information:

Illes, L., Jurkovic, M., Kalina,

T., Gorzelanczyk, P., Luptak, V. Methodology for optimising the hull shape of a vessel

with restricted draft. Scientific Journal

of Silesian University of Technology. Series Transport. 2021, 110, 59-71. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.110.5.

Ladislav ILLES[1],

Martin JURKOVIC[2],

Tomas KALINA[3],

Piotr GORZELANCZYK[4],

Vladimir LUPTAK[5]

METHODOLOGY

FOR OPTIMISING THE HULL SHAPE OF A VESSEL WITH RESTRICTED DRAFT

Summary. Increasing transport

volumes on Europe's inland waterways is a major reason for improving the

quality and reliability of internationally important waterways. Continued

navigation restrictions due to restricted draft (draught) led to the search for

new design solutions. Such solutions enable navigation even under critical

navigation conditions. Restricted draft is one of the most important

limitations that hinder navigation, especially in the summer. The main

objective of the construction of an inland vessel is to obtain a shape that

will achieve optimum performance with as little resistance as possible. A shape

that will be able to navigate at a limited depth. Presently, there is no

clearly defined methodology as a procedure for optimising the hull. When

solving theoretical problems of shipbuilding character and ship calculations,

it is necessary to consider the basic theory of the ship with special regard to

the latest methodological procedures of related scientific disciplines. This

paper presents a methodology that considers all the basic aspects of

optimisation tasks in ship design and construction.

Keywords: optimisation, methodology, restricted draft,

waterways, vessel

1. INTRODUCTION

Shipping on

European rivers and inland waterways is of considerable economic benefit,

contributing to the carriage of goods and passenger transport. The most

important waterway is the Rhine-Main-Danube Canal, which connects the North Sea

with the Black Sea. However, shipping on some significant critical stretches of

the Danube has been restricted by long-standing problems of limited seasonal

navigation conditions. Sometimes the traffic of large commercial vessels and

pushed convoys is completely paralysed [9,11].

The flow

regime and water level has been developing and changing globally for a long

time. This is due to anthropogenic effects such as water management operation

or land use change near waterways. This has an impact on freshwater resources

and changes in hydrological conditions that form the basis for water resources

and the entire ecosystem [5].

Because of

rapid climate change in recent years, there have been serious seasonal problems

on the Rhine, where it has become necessary to restrict freight transport to

such an extent that it has caused difficulties in the logistics systems of

large companies that mainly source their raw materials and semi-finished

products through shipping [2]. These changes represent a global problem for navigation

on inland waterways, water areas and ports and have become major obstacles to

the further development of water transport [16,19].

Traffic

restrictions due to the low water level can similarly be seen on the Danube

River. In January 2017, the water levels were extremely low, around the lowest

navigable water level (LNWL), when the river froze over, and subsequently, ice

events occurred. Ship traffic on the Upper Danube and the Middle Danube saw a

considerable decline in loaded drafts during this period. After measures to

combat the ice events on the Danube had been concluded and navigation

conditions stabilised, operation at loaded drafts of approx. 2,5 m for barges

in pushed convoys began in early March. Hydrological conditions on the Danube

were unstable during the second quarter, and by late May, loaded drafts were no

more than 2,3-2,2 m. [4]. The summer low-water period began in June, and

successive, intermittent precipitation in the third and fourth quarters did not

lead to a stabilisation of hydrological conditions, hence, loaded drafts

remained between 2, 2 and 2, 3 m from September until the end of the year 2017

[3].

The low water

level lasted for 80 days, resulting in the cessation of navigation and the

associated losses for shipowners [1]. Optimising the shape of the vessel's hull

is one way to improve shipping operations on inland waterways. Particularly,

the improvement of the navigability characteristics of vessels navigating in

shallow waters. Restricted draft is one of the most important limitations that

reduces navigation, especially during summer.

An inland

vessel floating in shallow water achieves a much higher resistance than a

vessel floating in deep water. There are several methods by which these effects

can be eliminated [8,15,21,25,27]. In addition to resistance, wake fraction and

thrust deduction change as well [20,23]. The propulsion efficiency likewise

varies depending on the different propeller load [12]. Optimisation of ship

hull–propeller system is also one of the most important aspects of ship

design and leads to ship cost reduction, improving performance and increasing

the lifespan of the propulsion system. Changes in the stream of water

surrounding the vessel are caused by different flow around the hull compared to

deep water navigation [7]. The low ship underneath below the vessel leads to

increased return flow speed. In the vertical direction, the movement of water

is limited, causing it to be transformed into a horizontal movement. Thus, the

increased reverse flow rate reduces the pressure below and around the hull.

This results in an additional reduction in the draft and, in most cases,

increased wave resistance [13,26].

The specific

effects that change the trajectory of liquid flow around the ship hull in

shallow water require different design requirements compared to seagoing ships.

Inland vessels often navigate in waters with a depth of about 2 m. The main

objective of the design of shallow-water vessels is to achieve the shape of the

hull, with the lowest propulsion power requirements. Navigation optimisation

studies, focusing on the impact of waves on shallow watercraft, have been

conducted in the past [22,24,29].

This paper is

based on the objectives set out in the Danube Strategy and follows up the

scientific publications on the research and development of new and innovative

types of ships and propulsion vehicles designed for the changing conditions of

the Danube navigation. However, the results are general, globally applicable on

inland waterways with similar parameters. The result of this paper is a

methodology of optimising the shape of the ship hull with restricted draft,

which will be the basis for the application part with a specific proposal of

solution.

2. THEORETICAL

BACKGROUND AND METHODS

In

solving the theoretical problems of shipbuilding character and naval

architectural calculations, the basic theory of ship will be applied with

special regard to the latest published results of related scientific

disciplines.

2.1.

Equations describing fluid flow

When

examining fluid flow, the basic laws of physics apply, that is, conservation

law of mass, conservation law of momentum and conservation law of energy. All

these laws, as well as viscous phenomena in real fluid, are reflected in

Navier-Stokes equations that describe both laminar and turbulent flow.

For

incompressible fluids, where ρ = const., and ![]() , the

continuity equation in a

differential form will be:

, the

continuity equation in a

differential form will be:

![]() (1)

(1)

When

a hexahedron represents the liquid particle, its centre of gravity will be

affected by the mass forces X, Y and Z in the corresponding

directions. Surface forces from external pressure will act in the centre of

gravity of the elementary body surfaces.

The

hydrostatic Euler equations in the state of flow will have nonzero values on

the right side. These will be x, y, and z acceleration components

that express forces per unit mass.

Hydrodynamic

Euler equations for the ideal fluid (when viscosity is not considered) are then

obtained by substituting the inertia forces generated by the acceleration of

the fluid particles into the equations:

![]()

![]() (2)

(2)

![]()

whereby

adjusting the accelerations on the right side, we get Euler's partial

differential equations that express the dependence between unit mass, surface

and inertia forces:

![]()

![]() (3)

(3)

![]()

Derivatives

according to x, y and z on the right side of the equations

express the acceleration components along the curved streams. The last

derivative by t is a local component that expresses the change in

velocity over time.

Considering

both the flow viscosity of the fluid, and the corresponding shear forces would

also act on the walls of the elemental hexahedron - in addition to the

compressive forces.

Newton’s

equation expresses these frictional forces mathematically as tangential stress

![]() (4)

(4)

where η

is the coefficient of dynamic viscosity.

By

adding the friction component to the Euler equations of fluid dynamics, we

obtain the Navier-Stokes partial differential equations for all unit actions on

the fluid particle in three basic directions of space, that is, weight,

pressure, friction and inertia. Furthermore, considering the continuity

equation (1), the Navier-Stokes equations expressing the flow of Newtonian

fluid can be further simplified to the form:

![]()

![]() (5)

(5)

![]()

Equations

5 can be interpreted as the specific form of the second Newton's law for the

flow of viscous incompressible fluid per unit mass, on the right with the

product of acceleration and weight, on the left with the sum of mass and

surface (pressure and viscous) forces [6,10].

2.2.

Computational domain and CFD mesh

Computational

Fluid Dynamics (CFD) is the most commonly used software in computer modelling

of fluid flow. Several mesh-based methods have been developed in this area

where the geometry under investigation is replaced by a 2D or 3D mesh and the

flow problem is solved using Navier-Stokes equations. The basic principle of

CFD is to create a computational domain that consists of a geometric model of

the actual and discretised form (mesh), a definition of boundary conditions, a

set of physical properties and calculation methods, and possibly external

geometry boundaries of the flow area (external flow) [17,28].

In

the CFD simulation of navigation, the geometry under investigation consists of

the outer surface of the hull, surrounded by a flow area, mostly of hexahedral

shape. This is a typical case of external flow where the flow takes place in

the surrounding environment and not within the computational geometry. The

investigated physical phenomena take place in a multiphase environment, at the

boundary of two phases (water-air), which considerably increases the

computational complexity of these tasks.

The

resulting mesh is a product of discretisation of real geometry, its arrangement

can be either structured or unstructured.

Structured

mesh consists of rectangular elements (in 2D) and hexahedral blocks (in 3D).

The main advantage of such a mesh is higher accuracy of calculation and less

complex matrix representation of the solved structure within the algorithm.

However, the discretisation of complicated shapes and the creation of

transition areas with different meshing size often give rise to problems that

point to less flexibility in the structured mesh.

In

some cases, an unstructured mesh with sufficient accuracy can be similarly

used. More so, there are tasks that do not allow the application of structured

meshes. Such a mesh consists of triangular elements (in 2D) or tetrahedral,

prismatic pentahedron and pyramidal elements (in 3D). It is ideal for

discretising complex geometric shapes, maintaining good quality in shape

interpolation (small distortions), and densifies without problems. The various

elements are often combined into an optimal structure, for example, in the

boundary layer zone.

Another

possibility is the creation of hybrid structures, which is a suitable

combination of structured and unstructured meshes. It has wide application in

CFD simulations, where the complex surfaces of bodies and their boundary layers

are represented by an unstructured mesh, while the environment is formed by a

high-quality structured mesh. The interface zone between them is a transition

area filled with pyramidal elements (in 3D).

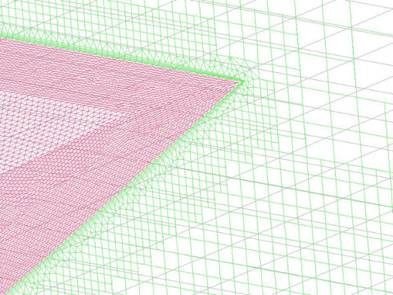

Fig. 1.

Structured (right) and unstructured (left) mesh with boundary layer and

intermediate zone connected to the refined structured mesh

The most serious limitation in CFD analysis is the

number of mesh elements and nodes. In each iteration of the calculation,

the hydrodynamic state of the elements is evaluated individually, and their

excessive number can massively increase computational complexity and machine

time. Hence, it is necessary to keep the number of elements as low as possible,

however, not to the detriment of the accuracy of the calculation.

We call a quality mesh when the elements have the

same size, are geometrically regular and their distribution is also regular in

the discretised area. A suitable choice of element size ensures that the

hydrodynamic properties of the flow are captured; however, velocities are

decisive for dimensions.

In most cases, due to the limited number of

elements, it is not possible to capture the effects in different areas of a

domain while meeting all mesh quality criteria. This problem is solved by local

refinement of the mesh in computationally demanding and geometrically complex

parts of the model. Typical examples are the boundary layer region, leading and

trailing edges, free fluid surfaces, etc.

In terms of the motion state of the investigated

solids at the boundaries of the computational domain, individual areas of the

mesh can be stationary, deformable and dynamic. Generally, dynamic meshes can

be used wherever the domain shape changes over time due to the rotational or

translational movement of its boundary surfaces. During the simulation, the

dynamic mesh and the surrounding mesh zone must be continuously smoothed and

remeshed, placing increased demands on computing power [6,10].

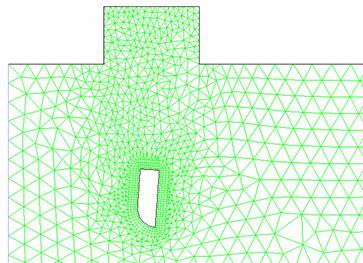

Fig.

2. Dynamic mesh zone around a falling body in a 2D CFD simulation

(ANSYS

Fluent 17.2 Documentation)

2.3.

Methods for solving partial differential equations (PDE) of CFD

Many

numerical methods have been developed to address particular physical problems.

Their application depends both on the suitability of the method for solving the

issue and on the history of development.

By

replacing the geometry of the examined area with a mesh of generated nodal

points, the flow calculation domain is discretised, thus, allowing the flow

equations to be converted into algebraic equations.

Solutions

of differential and integral flow equations by discretisation are carried out

through various methods, of which the following are the most common:

Finite

Volume Method (FVM) - This method in a discretised form retains very reliably,

the principles of conservation laws of balanced physical quantities in the

control volume and is, therefore, the most widely used CFD simulation apparatus

for solving the Navier-Stokes equations.

Finite

Difference Method (FDM) - This method is based on the conservative differential

form of determining equations. It is a traditional and proven method for

numerical solution of partial differential equations. The principle of this

method is to transform derivatives into differences in the mesh nodes of the

flow field.

Finite

Element Method (FEM) - This method uses elements instead of control volumes.

Balancing laws are applied to the elements to determine the quantities of the

flow field at the nodes of the elements. Unlike the previous two methods, this

method also uses interpolation structures to ensure the interdependence of

nodal points.

For

the solution of algebraic equations, an optimal algorithm (scheme) of the

solution is provided, which is the basis for computer software development.

Schemes specify iterative processes and may be explicit or implicit. The

practical solution is performed using a software and the process should

gradually converge to an exact solution. The aim is to achieve a minimum

deviation from the exact result.

The

best-known solution schemes applied in the CFD area are Euler FTFS scheme,

Euler FTCS scheme, Euler FTBS scheme, Upwind scheme, Lax-Friedrichs scheme,

Lax-Wendroff scheme, MacCormack scheme, Runge-Kutta scheme. [18].

2.4.

Models for turbulent fluid flow

Numerical

modelling of turbulent flows is still in the process of research and

development, supported by the latest knowledge of mathematics, physics and

technical computational methods. However, there is no universal model of

turbulence that is generally and effectively applied in all cases. To choose the

most suitable model for a particular calculation case, it is necessary to

consider the possibilities and limitations of individual numerical models.

Turbulent swirls are characterised by length and speed scales and the following

methods are appropriate for different scales:

Direct

Numerical Simulation (DNS) - This method is suitable for direct solution of a

wide range of turbulent vortex sizes, based on Navier-Stokes equations. It does

not model swirls but captures turbulence by solving equations with high

precision, which requires a very fine mesh. Direct numerical simulation

provides a perfect mapping of physical phenomena in a flowing fluid, and its

results are considered equivalent to those of experiments. Many mesh elements

and a time-dependent process with very small steps lead to the technical

unrealisability of simulations in engineering practice.

Large

Eddy Simulation (LES) - This method solves only large-scale swirls that can be

captured by a coarse mesh at larger time steps. For small turbulent swirls,

subgrid models are created and removed by filtration of the turbulent field.

Their right combination allows creating a coarse mesh even in engineering tasks

whose solution is already realistic with today’s computer technology.

However, a major disadvantage of the large vortex method is the need to refine

the mesh along the body walls in three directions. Various modified methods as

well as a RANS/LES hybrid model have been developed to overcome this drawback.

Time-Averaging

Method (RANS - Reynolds Averaged Navier-Stokes Equations) - This method has

relatively low computational capacity requirements and provides acceptable

accuracy. It is being extensively used in engineering simulations. Further, it

consists of parametric modelling of turbulent flow by time-averaged values of

physical quantities using Reynolds method. Several different RANS methods have

been developed for various specific task types, which simplify the modelling of

swirls using added transport equations. There is also a method known as DES

(Detached Eddy Simulation) which is a transition between RANS and LES. It

combines the advantages of both the LES and the RANS numerical modelling

methods.

Some

of the time-averaging methods are based on Reynolds stresses (RSM), others are

based on the Boussinesque hypothesis of turbulent viscosity (for example, k - 𝜀

and 𝑘 - 𝜔).

Results calculated by RANS should be confronted with published results or

validated by experiment. The most common models of turbulence based on Reynolds

averaging and Boussinesque principle, which are also implemented by ANSYS

Fluent program are:Spalart-Allmaras Model, 𝑘 - 𝜀

Models, 𝑘 - 𝜔

Models, 𝑘 - 𝑘𝑙 - 𝜔

Transition Model, Transition SST Model, Reynolds Stress Model (RSM), Large Eddy

Simulation (LES) Models, Wall Adapting Local by Eddy Viscosity (WALE) Model,

Detached Eddy Simulation, Smagorinsky Lilly Models, Dynamic Kinetic Energy

Subgrid Scale Model, Scale-Adaptive Simulation (SAS) Model.

The

appropriate optimisation method must be chosen and the specific optimisation

task will be formulated only after the precise determination of the maximised

and minimised variables (ship parameters) and limiting conditions (waterway

restrictions, economic objectives, etc.). A volume of results of technical

analyses and the way of their processing also have a major impact [14].

3. RESULTS AND

DISCUSSION

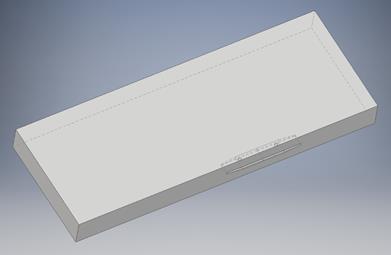

Creation of a

three-dimensional CFD domain for the analysis of navigational characteristics

of vessels is usually started in some solid or surface modelling program.

A solid block with a cavity corresponding to

the negative shape of the hull is created. The flow-around is being

investigated; this is a typical problem of external flow in CFD. Only one half

of the space is modelled because in these cases the boundary condition of symmetry

can be applied in the ship's centre plane (XZ). Such a typical 3D model is

shown in Figure 3, this particular domain was created for a pontoon-type

single-hull test.

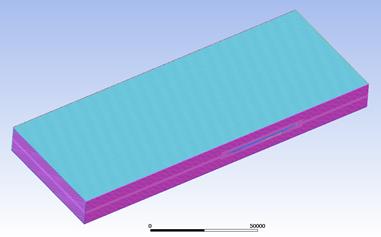

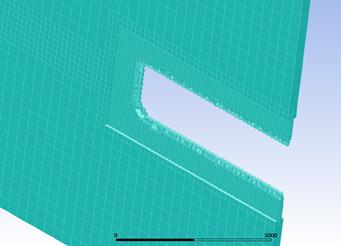

Thereafter, after importing the 3D

model into the CFD system, the three-dimensional domain body is replaced with a

suitable task-specific computational mesh. The mesh is refined in critical

areas, special elements are created in the boundary layer and the transition

areas. Figure 4 is an overall view of the computational grid, showing that the

grid is refined around the body to be flown around and in the free surface area

to better capture the physical effects such as turbulence, streamline

separation and wave motion.

A cross-sectional view of Figure 5

provides a more detailed insight into the internal structure of such a CFD

mesh. It is possible to distinguish individual special types of elements -

prismatic in the boundary layer, pyramidal in the transition area and

structured surroundings formed by hexahedral elements of different sizes.

After

successfully creating the required quality mesh, the computational domain is

configured based on input parameters and specifically for the type of analysis.

When the system is properly configured, the transient analysis is started, only

then the convergence of the calculation is monitored until termination.

Fig.

3. Example of initial 3D model of a CFD domain intended for

vessel flow-around simulation

Fig.

4. Computational mesh of CFD domain with refined zones

Fig.

5. Internal structure of 3D mesh with different zones

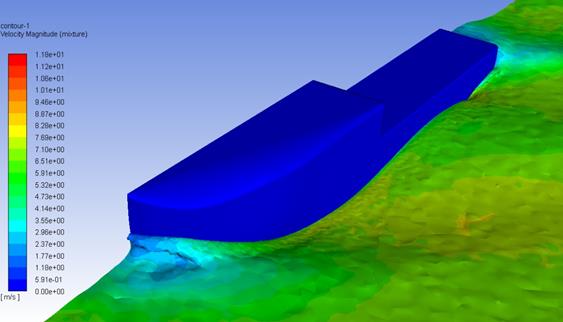

Figure

6 shows the resulting wave field of the vessel. It is an example of CFD

analysis of the hull where the physical properties of the flow-around were

investigated. In addition, the resistance of the hull was determined at certain

constant cruise speeds. It is very important to compare these analysis results

with proven technical indicators of other vessels that have been previously

model-tested. In most cases, this is an adequate result validation method. By

gradual calibration of the CFD task configuration, such as dimensions and

proportions of the computational domain, mesh parameters, boundary layer,

boundary conditions, initialisation parameters, computational model and

numerical methods, it is possible to refine the result and achieve accuracy

with a deviation of ± 5%. Such deviations from the results of other

sources are satisfactory and the accuracy of CFD analysis is sufficient to

perform optimisation tasks.

Fig. 6.

Example output from CFD analysis of flow-around a vessel – wave pattern

The emergence of the question, what is new in the

mentioned methodology, comes to bear at the end of this study. Similar

progressive approaches have been applied for several years in various companies

and institutions specialised in hydrodynamic development and research.

Here, however, it is a question of finding new ways,

for example, researching new principles of hull interaction with multiple

propulsion units, determining their optimal number, thrust and location. Of

course, such innovation requires major changes in the shape of the hull and in

the hydrodynamic parameters of the flow-around. Due to the distribution of

propulsion power to several propulsion units over the entire length of the hull

and the low draft, the introduction of new types of special propulsors should

be considered as well. It is possible to analyse their properties as a single

unit submerged in a basin by CFD analysis.

More important is the simulation of their

interaction with the hull, which is a much more complex problem due to their

increased number and the special hydrodynamically shaped underwater part of the

hull. The classic single-propeller and twin-propeller arrangement is presently

well documented, and the velocity field influenced by the hull flow-around in

the plane of the propeller can be illustrated by the standard wake field

diagram. However, current science still has debts in the complex theory of

distributed propulsion and their interaction with the hull for cases where some

units have to work in the flow field of others, that is, their velocity fields

interact.

This is a rather complex issue that the R&D has

been trying to resolve in the past by model tests when full functional

propulsion units have been mounted on models, scaled in proportions given by

the theory of similarity. However, these tests are very time-consuming and

costly; therefore, are not appropriate at the research stage or for extensive

optimisation processes. Therefore, in recent years, such CFD simulations have

already begun, which have already considered the effect of the propulsors on

the flow-around and the total flow field nearby the hull. Manufacturers of

commercial CFD software have developed tools that allow defining constant flow

velocities at several selected locations of the computational domain, and in

this way, simulate the operation of the propulsors in a simplified way.

Rotating dynamic meshes that can represent the body

shape of the propulsor and its surroundings are available for better accurate

analysis. This means that within one domain we can have 3D models of the hull

and all propulsors, combining static and dynamic meshes. Of course, this method

is computationally demanding, however, it is already practically applicable

with the current computer technology.

4.

CONCLUSION

The methodological process is designed to solve complex shipbuilding

tasks and partial optimisation tasks. Among the basic tasks are, for example,

the design and analysis of the characteristics of the new shapes of the ship's

displacement hulls, considering the long-term proven hulls of inland waterway

vessels.

Another area of application of the methodology is the sizing of the new

arrangements on the session: hull - propulsion, considering long-established

inland navigation systems. Application of the results can similarly be

practised in CFD analysis and comparison of performance parameters of new

conceptual and existing solutions.

This methodology is designed to achieve other specific solutions:

· the development of an

innovative concept for a new generation of inland waterway vessels,

· simple identification of

optimal main ship parameters based on input data, such as navigational

restrictions and economic targets,

· support tools or working

aids for ship planners, such as the implementation of the proposed methodology,

· preliminary input for

economic calculations of shipping establishment and operating costs.

Due to the lower overall complexity, the CFD method

has wide application, which in this particular investigation, is the only real

alternative for optimisation of distributed propulsion. This is just one of the

possible directions for further development of low-draft ships. The ultimate

goal is to put an entirely new, innovative type of inland vessel into service

in the foreseeable future.

References

1.

90th Session of the Danube Commission.

2018. Market observation for Danube

navigation - results in 2017.

Budapest. Danube Commission.

2.

Aguiar F-C., J. Bentz, J-M.N. Silva, A-L. Fonseca, R.

Swart, F-D. Santos,

G. Penha-Lopes. 2018. “Adaptation to climate change at local level in

Europe: An overview”. Environmental

Science & Policy 86: 38-63. ISSN: 1462-9011. DOI: https://doi.org/10.1016/j.envsci.2018.04.010.

3.

Beuthe M., B. Jourquin, N. Urbain, I. Lingemann, B.

Ubbels. 2014. “Climate change impacts on transport on the Rhine and

Danube: A multimodal approach”. Transportation

Research Part D: Transport and Environment 27: 6-11. DOI: https://doi.org/10.1016/j.trd.2013.11.002.

4.

David A., E. Madudova. 2019. “The Danube river

and its importance on the Danube countries in cargo transport”. 13th International Scientific Conference on

Sustainable, Modern and Safe Transport, “TRANSCOM 2019” 40:

1010-1016. 29-31 May 2019. Novy Smokovec, Slovakia.

5.

Doll P., B. Jimenez-Cisneros, T. Oki, N.W.

Arnell, G. Benito, J.G. Cogley, T. Jiang, Z.W. Kundzewicz, S. Mwakalila, A.

Nishijima. 2014. „Integrating risks of climate change into water

management”. Hydrol. Sci. J.

60: 4-13. DOI: 0.1080/02626667.2014.967250.

6.

Douglas J.F., J.M. Gasiorek, J.A. Swaffield, L.B.

Jack. 2005. Fluid mechanics.

Fifth edition, Pearson Education Limited, Harlow. ISBN: 978-0-13-129293-2.

7.

Esmailian E., H. Ghassemi, H. Zakerdoost. 2017.

“Systematic probabilistic design methodology for simultaneously

optimizing the ship hull - propeller system”. International Journal of Naval Architecture and Ocean Engineering

9(3): 246-255. ISSN: 2092-6782. DOI: https://doi.org/10.1016/j.ijnaoe.2016.06.007.

8.

Ferreiro L.D. 1992. “The effects of confined

water operations on ship performance: a guide for the perplexed”. Nav. Eng. J. 104: 69-83.

9.

Galierikova A., J. Sosedova. 2018. “Intermodal

Transportation of Dangerous Goods”. Nase

More 65(3): 8-11. ISSN: 0469-6255. DOI: 10.17818/NM/2018/3.8.

10.

Ganco M. 1983. Fluid

mechanics. Bratislava: ALFA Bratislava. ISBN: 63-745-83.

11.

Habersack H., T. Hein, A. Stanica, I. Liska, R. Mair,

E. Jager, Ch. Hauer, Ch. Bradley. 2016. “Challenges of river basin

management: Current status of, and prospects for, the River Danube from a

river engineering perspective”. Science

of The Total Environment 543(A): 828-845. DOI:

https://doi.org/10.1016/j.scitotenv.2015.10.123.

12.

Harvald S.A. 1977. “Wake and thrust deduction at

extreme propeller loadings for a ship running in shallow water.” RINA Suppl. Pap. 119.

13.

Kim D.H., J.K. Paik. 2017. “Ultimate limit

state-based multi-objective optimum design technology for hull structural

scantlings of merchant cargo ships”. Ocean

Engineering 129: 318-334. ISSN: 0029-8018. DOI: https://doi.org/10.1016/j.oceaneng.2016.11.033.

14.

Kudelas D. 2017. Basics of computer flow modelling

and visualization. Kosice: Faculty

BERG TU, Kosice.

15.

Lackenby H. 1963. “The effect of shallow water

on ship speed”. Shipbuild. Mar. Eng. 70: 446-450.

16.

Lobanova A., S. Liersch, J.P. Nunes, I. Didovets, J.

Stagl, S. Huang, H. Koch, M.R.R. Lopez, C.F. Maule, F. Hattermann, V.

Krysanova. 2018. “Hydrological impacts of moderate and high-end climate

change across European river basins”. Journal

of Hydrology: Regional Studies 18: 15-30. ISSN: 2214-5818. DOI: https://doi.org/10.1016/j.ejrh.2018.05.003.

17.

Macháčková A., P. Kuchta, Z.

Klečková, R. Kocich, J. Szwed. 2016. “Numerical simulation of

the heat treatment of the weld for steam generator”. Metalurgija 55(4): 741-744.

18.

Molnar V. 2011. Computational

Fluid Dynamics - Interdisciplinary Approach with CFD. Bratislava: STU

Bratislava. ISBN: 978-80-8106-048-9.

19.

Nouasse H., A. Doniec, G. Lozenguez, E. Duviella, P.

Chiron, B. Archimede, K. Chuquet. 2016. “Constraint satisfaction

problem based on flow graph to study the resilience of inland navigation

networks in a climate change context”.

IFAC-PapersOnLine 49: 331-336. DOI:

https://doi.org/10.1016/j.ifacol.2016.07.626.

20.

Raven H. 2012. “A computational study of

shallow-water effects on ship viscous resistance”. Proceedings of the 29th Symposium on Naval Hydrodynamics.

Gothenburg.

21.

Raven, H. 2016. “A new correction procedure for

shallow-water effects in ship speed trials”. Proceedings of the 2016 PRADS Conference, Copenhagen.

22.

Rotteveeel E., R. Hekkenberg, A. Ploeg. 2017.

“Inland ship stern optimization in shallow water”. Ocean Engineering 141: 555-569. ISSN:

0029-8018.

23.

Rotteveel E., R. Hekkenberg. 2015. “The

influence of shallow water and hull form variations on inland ship

resistance”. Proceedings of the

12th International Marine Design Conference. “IMDC 2015”. 11-14 May 2015. Tokyo, Japan.

24.

Saha G.K., K. Suzuki, H. Kai. 2004.

“Hydrodynamic optimization of ship hull forms in shallow water”. J. Mar. Sci. Technol 9: 51-62. DOI:

10.1007/s00773-003-0173-3.

25.

Schlichting O. 1934. Ship's resistance to limited water depth: Resistance of ships to

shallow water. Jahrb. der Schiffbautech 35: 127.

26.

Sun H., O.M. Faltinsen. 2012. “Hydrodynamic

forces on a semi-displacement ship at high speed”. Applied Ocean Research 34: 68-77. ISSN: 0141-1187. DOI:

https://doi.org/10.1016/j.apor.2011.10.001.

27.

Tuck E. 1978. “Hydrodynamic

problems of ships in restricted waters”.

Annu. Rev. Fluid Mech 10: 33-46. DOI:

10.1146/annurev.fl.10.010178.000341.

28.

Wang X.M., X.L. Wu, W.Q. Zhou. 2019. “Analysis

of oxygen enriched combustion characteristic of 350 MW utility boiler based on

computational fluid dynamics”. Metalurgija

58(3-4): 223-227.

29.

Zhao L-e. 1984. “Optimal ship forms for minimum

total resistance in shallow water”. Schr.

Schiffbau. DOI: 0.15480/882.930.

Received 04.07.2020; accepted in revised form 19.10.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License