Article

citation information:

Hrabovský, L. Tension force equalizer

in a rope system using a proximity sensor. Scientific

Journal of Silesian University of Technology. Series Transport. 2021, 110, 35-44. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.110.3.

Leopold

HRABOVSKÝ[1]

TENSION

FORCE EQUALIZER IN A ROPE SYSTEM USING A PROXIMITY SENSOR

Summary. Different values of

tension forces in the load-bearing ropes of elevators, which push the rope into

the grooves of the traction discs with different pressure, are the cause of

uneven wear of the grooves of the traction discs under operating conditions.

Current technical standards in the EU stipulate that the load suspended on

load-bearing ropes be evenly distributed to all ropes used, using one of the

many construction designs for tension force equalizers in the rope system. The

main subject and primary objective of this paper are to present the

construction design, 3D model and produced device of one of four produced

prototypes, which were constructed in the “Research and Testing

Laboratory”, and allow setting of differing values of tension forces in

the system of ropes of a traction elevator, to values of the same size.

Laboratory measurements were performed on the produced device, which enables

the detection of tension forces in ropes and the magnitude of these forces in

the required period to be graphically displayed on a PC. The prototype

tension force equalizer can show the functionality and practical applicability

of the procedure of balancing the levels of tension forces, which are of

unequal strengths at the start of the laboratory measurement.

Keywords: tension force equalizer, rope elevator,

load-bearing rope,

ring load cell

1. INTRODUCTION

In practice,

the elevator car must be allowed to travel as high as possible in the elevator

shaft. This is ensured by installing the load-bearing rope bracket at the

shortest possible distance from the ceiling of the elevator shaft. The minimum

distance of the upper surface of the bracket from the ceiling of the elevator

shaft places a fundamental requirement on the design height of tension force

equalizers, which are installed at the ends of the threaded parts of the suspension

bolts. Mobile tension force equalizers have relatively large heights and their

use to balance varying tension forces to the same magnitude in a rope system is

not always suitable in cases where there is a lack of operating space and the

construction height is limited.

This paper

presents a sequence of activities and a description of the operations, which

when using a tension force equalizer, result in the weight of the load (in the

more loaded branch of the rope system of the elevator) in the final phase of

the experiment being evenly distributed in all cross-sections of the

load-bearing ropes.

The principles

of tension force equalizers suitable for use in cases of restricted operating

spaces and low ceiling height in the elevator shaft are introduced in [3,5].

2. Construction Design of

the Described Device

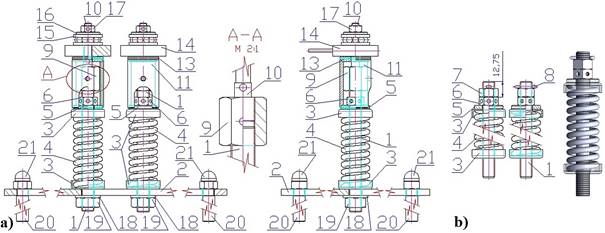

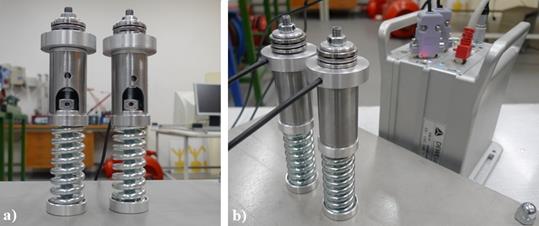

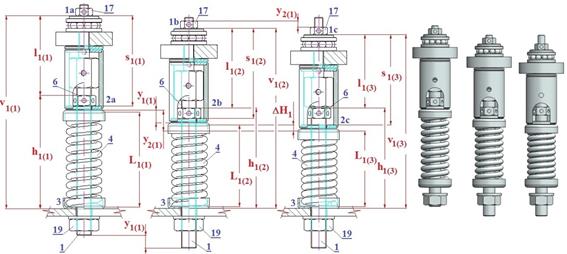

A 2D

construction design (created in AutoCAD) is presented in Fig. 1a. Fig. 2 shows

a 3D model created in the SolidWorks 2012 x 64 SP 5.0 environment, one of four

variants of a tension force equalizer in a rope system, which was designed and

assembled at the Institute of Transport, Faculty Mechanical Engineering, VSB -

Technical University of Ostrava, based on a requirement for its production by LIFTCOMP,

a. s.

Fig. 1. a) 2D construction design for a tension force equalizer

in a system of ropes, b) terminal point of the suspension bolt in practice

The shanks (f 10 or 12 mm) of the suspension eyebolts 1 [1] pass

through (f 11 or 13.5 mm) in the bracket, which under laboratory

conditions is replaced by a steel plate (300 x 200 x 5 mm) 2, Fig. 1a. A bowl 3

and a compression coil spring 4 [7] are slid on the threaded part of each of

the eyebolts 1, which are threaded through the holes in the plate 2. A bowl 3,

a washer 5 and a hexagonal nut 6 are mounted on the upper end face of the coil

spring 4. In practice, unscrewing the nut 6 is prevented by the lock nut 7 and

the cotter pin 8 (Fig. 1b).

Holes (2.5 mm)

are drilled in the shank of the suspension bolts 1, their horizontal axes are

spaced at least 4.5 mm from the end faces of the shanks of the suspension bolts

1 (Fig. 1b). The minimum distance between the upper surface of the nut 6 and

the upper surface of the shank of the hinge screw 1 (after removing the cotter

pin 8 from the hole in the shank of the hinge screw 1 and unscrewing the lock

nut 7) is Lmin = 12.75 mm, Fig. 2b. The space Lmin

[m] is sufficient to

install the tension force equalizer.

A nut 9 (M10),

which has a hole (3 mm) formed on one of its vertical surfaces in the middle of

its height of 20 mm, is screwed onto the threaded part of the shank of the

suspension bolts 1. A threaded part (length 10 mm) of the pin 10 is screwed

onto the internal thread M10 of the opposite hole in the nut 9. A tubular part

11 is threaded on the pin 10 to form concentric holes (3 mm in the nut and 4 mm

in the tubular part 11). In the upper and lower part of the tubular part 11

(with an inner/outer diameter of 20/26 mm), an inner fitting is formed, the

so-called inner f 24 mm to a depth of 2 mm. The tubular part 11 is

threaded at the bottom onto the outer diameter (f 24 mm) of the washer 12 (height 3 mm). A ring 13

(with an inner hole of f 8 mm for the pin 10) is threaded on the inner fitting

(f 24 mm, depth

2 mm). A tension force sensor (Ring Load Cell) 14 (with an inner/outer diameter of 7/38 mm) is

threaded on the pin 10.

An axial

bearing (type 51100 ČSN 024730) 15 and a ring 16 (with an inner hole 6 mm

for the pin 10, with an outer 10 mm lower part 5 mm long, which is pushed into

the hole of the upper ring of the axial bearing 15 are mounted on the shaft of

the pin 10. Part of the height of the 2-mm ring 16 is 20 mm). An M6 nut 17 is

screwed onto the thread M6 in the end part of the pin 10.

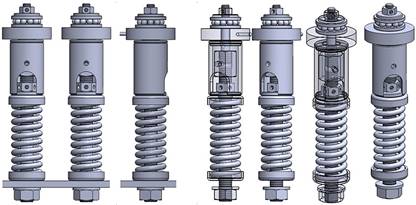

Fig. 2. 3D

model a tension force equalizer in a

system of ropes

The test device, Fig. 1 and Fig. 4, uses compression

coil springs 4 [7] with wire diameter d = 4 mm, outer diameter D1

= 24 mm, length in free state L0 = 63 mm, length in

retracted state L8 = 48.5 mm, total number of turns z =

10.5., number of active coils n = 8.5, spring force in retracted

state F8 = 549 N and stiffness (spring force when compressed

by 1 mm) c = 37.88 N/mm.

3. Aspects Equalizing Tension Forces in a Rope System

The load capacity Q [kg] of a passenger elevator is determined according to the

table in ČSN EN 81-20 [2]. The basic indicator for determining the load

capacity of a passenger elevator is the floor area of the cage, from which the

load capacity and the number of people who can use the elevator at one time are

calculated.

Elevator

cages must be suspended on either steel ropes, gall or roller chains. Steel

wire ropes must meet the requirements [2]: the nominal diameter must be at

least 8 mm; the nominal tension strength of the wires must be 1570 N·mm-2

or 1770 N·mm-2 for ropes with wires of the same tension

strength, or 1370 N·mm-2 for outer wires and 1770 N·mm-2

for inner wires for ropes with two nominal tension strengths; at least two

ropes must be used. The safety factor ks

[-] (is the ratio between

the guaranteed load capacity of the rope NL [N] and the maximum force FL [N] in this rope when the cage with

the rated load is at the lower end station) must not be less than 12 for a

drive with friction discs with three or more supporting ropes; 16 for a drive

with friction discs with two support ropes.

If the load capacity

of the lift is Q [kg],

the actual weight of the cage P [kg],

the height of the lift of the cage H [m], the rope gear r [-], the weight of the rope mL [kg·m-1],

the number of load-bearing ropes nL [-], then the greatest force FL [N] acting in one rope can be expressed

according to (1).

(1)

(1)

If the

coefficient of the minimum breaking force ku

[-] and the minimum breaking force of the rope is NL

[N], then the safety factor of the rope ks

[-] can be expressed by the relation (2).

![]() (2)

(2)

By

modifying the relationships (1) and (2), it is possible to calculate the

required number of load-bearing ropes nL [-], relationship (3).

(3)

(3)

Fig. 3. Laboratory

model of described variants of a tension force equalizer in

a system of ropes, a) front view, b) rear view

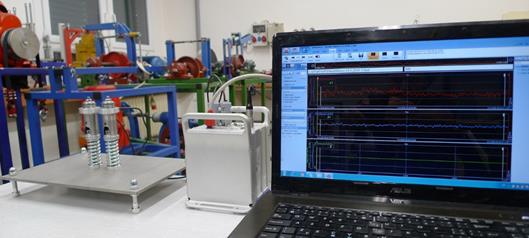

The

principle, presentation and verification of the correct functionality of

equalizing tension forces in the system of ropes (which consists of two or more

ropes) is performed on devices assembled in the Research and Testing Laboratory

of the Institute of Transport, VSB-Technical

University of Ostrava, the equalizers tension forces in the rope system,

Fig. 3 and Fig. 5. The executed device is designed so that it has (for

reasons of reduction of economic costs used for the building of the laboratory

model and the purchase of a larger number of tension force sensors 14) only two

suspension bolts 1.

The cable ends

of both tension force sensors 14 are soldered to the connectors of the

“D Sub” connector plug. The connector plugs are plugged into

two of the four sockets in the DEWESoft DS-NET [6] measuring system. The DEWESoft

DS-NET measuring apparatus is connected to a PC with a network cable (with an

“RJ45” connector at both ends). In the DEWESoft X2 SP5 software

environment in the PC, the curves of the applied forces FL(i) [N] (initially different tension force magnitudes to tension

forces balanced to equal magnitudes) in the suspension bolts 1 were displayed

(detected by force sensors 14), Fig. 5.

The

different magnitudes of the initial values of the tension forces FL(i) [N] in the load-bearing ropes are derived by the different tightening of the

nuts 19, Fig. 1 and Fig. 4. Varied tightening of the nuts 19 causes a different

deformation (that is, compression H1(i)

[m]) of the compression springs 4.

Compression H1(i) [m] of the compression springs 4 is of the same magnitude as the vertical

displacement y1(i)

[m] of the nut 19. The magnitude of the

displacement y1(i)

[m] of the nut 19 can be expressed by the

relation (4), where ds [m] is the mean thread diameter of the hinge screw 1, a [deg] is the pitch angle of the thread of the suspension bolt 1, b [deg] is the angle of rotation of the nut

19, P [m] is the pitch

of the thread of the suspension bolt 1 and the nut 19.

![]() (4)

(4)

The lengths L1(i)

[m] (L1(2) on Fig.

4) compressed springs 4 (loaded by

forces FL(i) [N]) can be expressed

according to (5).

![]() (5)

(5)

Compressive

forces F1(i) [N]

acting in the springs 4; equal to the values of tension forces FL(i)

[N] in the load-bearing

ropes (6); are transmitted to the lower surfaces of the tension force sensors

14 via the washers 5, the tubular parts 11 and the rings 13.

Fig. 4. Visualisation

of the action of balancing differing tension force magnitudes in

the ropes to a unified value.

![]() (6)

(6)

Compressive

forces Fc(i) [N],

which are the same magnitude as the compressive forces F1(i) [N], are applied to the upper

surfaces of the tension force sensors 14 (tension forces FL(i) [N] (1) are transmitted from the

load-bearing ropes via pin 10) (assuming tightened nuts 6).

If the nuts 17

are tightened, the distance l1(i) [m] is shortened (from the initial value l1(2) [m] to the value l1(3) [m], Fig. 4) and there is a vertical

displacement (relative to the upper surface of the suspension bracket, section

“3” in Fig. 4) of the suspension bolt 1 (provided that the nut 19

is not screwed onto the threaded part of the suspension bolt 1). In practice,

each of the suspension bolts 1 is subjected to a proportional part of the load

(ideally FL(1) = FL(2) = FL [N] (1)) and these loads (tension

forces in ropes FL(i) [N])

compress the springs 4. Further, if the magnitudes of the forces in the ropes FL(i)

[N] are not the same, the

springs 4 are deformed differently. The spring 4 which is most compressed H1(i)

[m] (that is, which has the

smallest height L1(i) [m])

generates the highest compressive force F1(i) [N] (6).

By tightening

the nut 17 of the least compressed H1(i) [m] spring 4, in the practical use of

the elevator, the vertical screw 1 is first shifted vertically, to which is

attached (least loaded by the force FL(i) [N] (6)) load-bearing rope. In this

load-bearing rope, the tensile force FL(i) [N] increases (because by shortening

the length of the rope, this rope is loaded with a larger proportion of the

load distributed into the rope system) and the spring 4 is compressed.

4.

Action of the laboratory model of the tension force equalizer

Tightening the

nut 17 of the least compressed H1(i) [m] spring 4 in the laboratory model (Fig. 3) results in (as

a result of the vertical shift y2(i) [m] (4) (Fig. 4) of nut 17, where ds [m] is the mean thread diameter of the

hinge screw 10, a [deg] is the pitch angle of the thread of

the suspension bolt 10, b [deg] is the angle of rotation of the nut

17, P [m] is the pitch

of the thread of the suspension bolt 10 and the nut 17) the transfer of the derived compressive force F2(i)

[N] on the spring 4, which,

due to increasing compressive forces F2(i) [N], is compressed (relative to the

uncompressed length L1(i) [m] of the spring 4 compressed by the force F1(i) [N]) after the completion of the

tightening phase of the nut 19 by the total size y2(i) [m] (7), and with respect to the

uncompressed length L0 [m]

of the spring 4 compressed by the total size sp(i) [m] (8).

![]() (7)

(7)

The increase

in compression DH(i) [m] of the spring 4 (at the moment of terminating

the tightening of the nut 17) is equal to the vertical shift y2(i)

[m] of the nut 17 being

tightened.

The total

compression sp(i) [m]

(8) of the spring 4 is equal to the sum of the vertical shift y1(i)

[m] of the nut 19 being

tightened and the vertical shift y2(i) [m] of the nut 17 being tightened.

![]() (8)

(8)

The resulting

lengths Lv(i) [m] (L1(3) on Fig. 4) of the compressed springs 4 (weighted with the

forces F2(i) [N]) can be expressed

according to (9).

![]() (9)

(9)

By tightening

the nut 17, the distance l1(i) [m] (l1(3) on Fig. 4) is shortened. For the

distance l1(i) [m]

according to Fig. 4, (10) applies.

![]() (10)

(10)

Given the

unchanging heights of the machine parts 6, 11 to 16 (Fig. 1a), when the nut 17

is tightened, a vertical shift of the nut 6 takes place (since the pin 10 is of

a constant and unchanging length) as well as the compression of spring 4 by a

value of y2(i) [m].

Fig. 5. Physical

execution of the model on a tension force equalizer in a system of ropes

If the nut 6

is rotated in the desired direction, at some point, the nut 6 rests on the

washer 5. By further turning the nut 6, the spring 4 is compressed by the value

H3(i) [m].

Compressing the spring 4 by the value H3(i) [m] produces a tension force F3(i

[N] in the suspension screw

1 and the pin 10, which is transmitted to the upper surface of the force sensor

14. Vertical displacement y3(i) = H3(i) [m], derived by turning the matrix 6,

causes the points “1c - 2c” to be delayed, that is, extension of

the length l1(i) [m],

which is given by the sum of the heights of the machine parts 6, 11 to 16,

and reduction of the compressive force F1(i) [N] acting on the force sensors 14.

Sizes of compressive forces F1(i) [N] acting on the force sensors 14, which are mounted on the

suspension bolts 1 of all load-bearing ropes for the given traction lift,

are displayed on the PC monitor. By gradually turning the nuts 6, the

tension forces in the ropes are balanced.

5. Experimental Tests

Cables

terminated with connectors of both tension force sensors 14 of the tension

force equalizer (Fig. 3b) for the test device (Fig. 5) were connected to the

measuring apparatus.

The data

(detected by the force transducers 14) was transferred to the PC via network

cable.

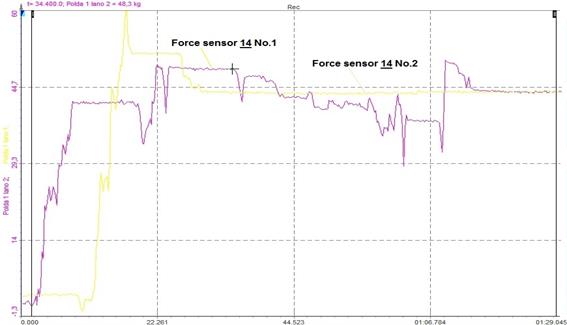

In the

DEWESoft X2 SP5 software environment, the waveforms of the detected compressive

force magnitudes FL(i) [N],

(Fig. 6) were displayed on the PC monitor.

Tab. 1 shows

the theoretically calculated compression force magnitudes Fl(i) [N] according to the relationship

(6), during the compression H1(i) [N] of springs 4 for both tension force equalizers.

Tab. 1

simultaneously gives the tensile force magnitudes FL(i) [N] that were detected by the tension

force transducers 14 during the gradual compression of the springs 4 and

subtracted from the PC monitor.

Fig. 6 shows

the waveforms of the measured forces FL(i) [N] detected by the force transducers

14. From Fig. 6, it is clear that the initially different magnitudes of tensile

forces in the ropes FL(i) [N] can be set to magnitudes of the same size by the tensile

force compensator, using the procedure described in the section

“Action of the laboratory model of the tension force equalizer”.

Tab.

1

Theoretically calculated and measurement-obtained

compression forces

|

F1(1) |

F1(2) |

H1(1) |

H1(2) |

L1(1) |

L1(2) |

FL(1) |

FL(2) |

|

N |

mm |

N |

|||||

|

75.76 |

151.52 |

2 |

4 |

61 |

59 |

78.16 |

147.93 |

|

151.52 |

227.28 |

4 |

6 |

59 |

57 |

157.37 |

232.44 |

|

227.28 |

303.04 |

6 |

8 |

57 |

55 |

223.28 |

310.34 |

|

303.04 |

378.80 |

8 |

10 |

55 |

53 |

305.63 |

365.88 |

|

378.80 |

454.56 |

10 |

12 |

53 |

51 |

382.35 |

462.11 |

|

454.56 |

530.32 |

12 |

14 |

51 |

49 |

467.71 |

526.59 |

Fig.

6. The

holding force of the electromagnet depending on

the distance from ferromagnetic plate

6.

CONCLUSION

Construction

designs and principles of operation of technical devices as well as the

sequence of work procedures, by which the total weight of the load can be

evenly distributed into the partial cross-sections of load-bearing ropes,

which form the system of ropes in traction elevators, are presented in several

researches. These technical devices are called “elevator rope tension

force equalizers”.

The possible way of achieving uniform load

distribution into two or more carrier ropes in the traction lift using a tension force equalizer in a rope system with a proximity

sensor is given in this paper.

This device is portable and is mounted on suspension

bolts only when it is necessary to set the same tensile forces in carrier

ropes. After carrying out its activities, it is possible to remove the device

from the suspension bolts and move it to another traction rope lift.

In

contrast to the known principle of the hydraulic compensator [8], the described

device can be provided with strain gauge load cells that can detect

instantaneous tensile forces in carrier cables, record them and use them for

certificate processing purposes.

This paper

presents a technical design of a mobile, mechanical equalizer, which uses a

tensile force sensor (transducer) to detect tension forces in the ropes.

More so, this

paper presents a construction design and specifications of individual basic

components from which the equalizer is assembled. A 3D model of the tension

force equalizer in a system of ropes was presented as well.

The described device can

adjust the tension forces in the cross-sections of load-bearing ropes, either

during the installation of new elevators or reconstructions and upgrades of

existing elevators. This tension equalizer helps to extend the life of elevator

parts, that is, the load-bearing ropes and the rope friction disc.

The actual prestressing in the

ropes is measured by a sensor, which allows even distribution of the weight of

the load, and thus, distribute it appropriately into the partial cross-sections

of the load-bearing elevator ropes used. The measurement of the magnitude of

tension forces in ropes and their equalization can similarly take place even

during the operation of the elevator car. Tension compensation in load-bearing

ropes of elevators can be achieved using a mobile device to which the cross-sections

of the load-bearing ropes are attached.

The main

advantage of the device is the continuous measurement of the tension of all

ropes of the elevator system during the operation of the elevator. Other

advantages include a non-destructive method of monitoring the tension in the

ropes, that is, a method that does not require interruption of the final length

of the load-bearing rope on which the elevator car is suspended. Further

advantages are the simplicity of installation, affordability, low weight, the

possibility of various forms of measurement and the fact that the device has

its own battery power source.

Acknowledgements

This work was supported by the Ministry of Education,

Youth and Sports of the Czech Republic from the Specific Research Project

SP2020/90.

References

1.

Molnár

Vieroslav, Gabriel Fedorko, Jozef Krešák, Pavel Peterka, Jana

Fabianová. 2017. „The influence of corrosion on the life of steel

ropes and prediction of their decommissioning”. Engineering Failure Analysis 74: 119-132. ISSN: 1350-6307.

DOI: 10.1016/j.engfailanal.2017.01.010.

2.

Zajicek

Jiri. 2015. ČSN EN 81-20 „Bezpečnostní předpisy pro

konstrukci a montáž výtahů - Výtahy pro dopravu

osob a nákladů - Část 20: Výtahy pro dopravu

osob a osob a nákladů”. [In Czech: ČSN EN 81-20 „Safety

rules for the construction and installation of lifts - Lifts for the transport

of persons and goods - Part 20: Passenger and goods passenger lifts”]. 2015.

3.

wurtec. Available at: https://www.wurtec.com/cs/content/permanent-overload-sensor-system-rc-donut.

4.

Meatest.

Available at: https://www.meatest.com/cs/produkty-8438-prstencovy-snimac-tahove-a-tlakove-sily-detail-67.

5.

Rope Tension Adjustment Kit. Available at: https://www.youtube.com/watch?v=3bfKXDsEFy8.

6.

SENSING. Available at:

https://sensores-de-medida.es/medicion/sensores-y-transductores/celulas-de-carga/celulas-de-carga-tipo-arandela/.

7.

UVB

TECHNIK. Available at: http://www.uvbtechnik.cz/data/files/katalog-tlacnych-pruzin-31.pdf.

8.

Brugg

Lifting. Available at: https://brugg-elevator.com/static/document/RLE_Manual. pdf.

Received 26.07.2020; accepted in revised form 30.10.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License