Article

citation information:

Dižo, J., Blatnický, M., Droździel,

P., Semenov, S., Mikhailov, E., Kurtulík,

J. Strength

analysis of an off-road lorry frame. Scientific

Journal of Silesian University of Technology. Series Transport. 2021, 110, 23-33. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.110.2.

Ján DIŽO[1],

Miroslav BLATNICKÝ[2],

Paweł DROŹDZIEL[3],

Stanislav SEMENOV[4], Evgeny MIKHAILOV[5],

Jakub KURTULÍK[6]

STRENGTH

ANALYSIS OF AN OFF-ROAD LORRY FRAME

Summary. The lorry frame is the

main carrying part of a lorry, composed of several components. These components

are connected by joints into one structural unit and it forms the lorry

chassis. The contribution of this article is focused on the strength analyses

of a backbone frame, which is used on an off-road lorry chassis. Strength

analyses are carried out utilising the finite element method. This article

presents a created three-dimensional model of the frame and definition of

boundary conditions (loads, the definition of degrees of freedom) needed for

simulation computations. Results of the numerical calculations are the main

parts of this article. Attention is mainly centred on the distribution of

stresses of the frame under defined loads and its deformations.

Keywords: frame, off-road truck, strength analysis,

finite element method

1. INTRODUCTION

A lorry is a

vehicle whose structure is built to transport goods. However, these vehicles

are used to tow trailers of various kinds as well. Tractors of semitrailers belong to this

group of vehicles.

The chassis of

a lorry is the bottom as well as the carrying part of the vehicle, onto which

the cabin, body and drive-train are mounted. This unit is called the vehicle

underbody. Generally, it is composed of these units [23,36]:

- a frame – the basic carrying part of a lorry chassis,

it is loaded by many kinds of loads reliable fixation of the manipulator to a

chassis without its damage,

- a suspension system – a system of mechanisms, which

transmit loads generated during driving and also as results of dynamic forces,

- axles – it is composed of a pair of wheels with

significant participation on the wheel/road contact,

- a braking system – a system of mechanisms, which serve

for slowing down or stopping of the lorry and ensuring of a lorry in a parking

position,

- a

steering system – a system of mechanisms, which allows changing the

driving direction by means of a steering wheel, a system of linkages and

levers.

Sufficient

rigidity of the main carrying structure of a lorry chassis significantly

affects its driving properties as well as loading of the frame and various

lorry bodies [23,36].

2. THE LORRY

FRAME DESIGN

The

frame is the main carrying part of the lorry, which consists of several

elements. These elements are connected by welds joints, screw connections or

rivet joints to one unit. The main task of a lorry frame is its carrying

ability. The lorry frame design considers among others the power drive-train

type [1-3,13,16,19,34]. Therefore, the frame design

has to ensure sufficient rigidity and be as light as possible [6,24,27,33]. More so, it has to ensure that the centre of

gravity of the lorry be as low as possible, which affects the driving stability

of the lorry. The chassis of the lorry has to allow proper guidance and

ensure sufficient driving comfort.

In

the case of standard lorries, a ladder frame is

usually used to meet the abovementioned requirements in the best way. However,

there are such operational conditions of lorries that

operate in rough terrain conditions, for example, in the building industry as a

tipper, concrete mixer, and likewise in forestry, agriculture, army, rescue

services, etc. In these operating conditions, a lorry is submitted to the

combined loads, which cause in addition to bending loads also torque [17,18,30]. From the frame strength point of view, a ladder

frame structure is no longer able to withstand such difficult combined loads

reliably in comparison with operation on a metalled road. Hence, a backbone

chassis was developed.

The

backbone chassis of a lorry is a type of vehicle chassis, which instead of a

two-dimensional ladder structure, consists of a tubular backbone (usually

circular cross-section). It connects the front and rear axles (lorries are often multi-axle) as well as the suspension

system. The backbone chassis is the most used by the Tatra

Trucks company, which has applied this frame design to its off-road lorries for

many years [22,33].

3. THE

BACKBONE CHASSIS

As

mentioned above, the backbone chassis is the typical characteristic of Tatra off-road lorries. These

lorries are developed mainly for heavy off-road conditions, allowing high passability through terrains, high level of driving

comfort, high speeds over difficult terrain, high levels of vehicle stability

in turns and on slopes, minimum maintenance requirements, minimum possibility

of drive-train damages, etc. [22,33].

The

backbone chassis consists of these units:

- a central load-carrying tube,

- axles with independently suspended swinging half-axles

bolted together into a single unit.

The

central load-carrying tube can withstand high torsion and bending loads,

protecting lorry bodies from transmitted loads; its modular system enables the

assembly from two to multi-axle lorries with the

optional all-wheel drive. Further, the shafts of a drive-train system are

situated in the central tube, which protects them from external effects. Such a

technical solution provides high durability together with low maintenance costs

[22].

Off-road

lorries Tatra equipped with

the backbone chassis use independently suspended half-axles. In the basic

version, they are always driven and combined with locks. Differentials are

placed outside the axles in the central loading tube. Axles are equipped with a

pneumatic drum brake system. There are several load-bearing capacity versions

of this chassis. Lighter versions are equipped with a mechanical suspension

system, which consists either of torsion rods for versions with a single

steered front axle or of leaf springs for versions with two steered axles.

Heavier versions are equipped with a pneumatic suspension system, which

provides completely different driving characteristics. All kinds of suspension

systems are combined with telescopic dampers or torsion rods [22,33].

Figure

1 shows the Tatra off-road lorry whose frame is

analysed below.

Fig. 1. Tatra off-road lorry [33]

4. STRENGTH

ANALYSIS OF THE BACKBONE CHASSIS FRAME

The

main purpose of the strength analysis of the frame is to determine the stress

distribution on the frame structure to identify critical locations with stress

concentration [9].

The

analysed frame is the main carrying part of the Tatra

off-road lorry (Fig. 1), which is built to transport goods up to the load

capacity of 15,700 kg. The total weight of the vehicle is 26,000 kg.

Fig. 2. A

three-dimensional model of the analysed frame

The

central load-carrying tube is thick-walled. It is combined with cross walls and

two longitudinal U profiles.

Profiles

and other components are made of structural steel S355J0

whose mechanical properties are listed in Tab. 1.

Tab.

1

Basic mechanical properties

of structural steel S355J0

|

Material |

Yield strength |

Ultimate strength |

Density |

Young’s modulus |

|

Structural steel |

355 |

470-630 |

7850 |

210,000 |

Strength

analyses of the frame were carried out in the ANSYS

software package [4,35]. It works based on the

finite element method (FEM) [26,28,31]. In this

software, it is possible to perform static analyses [11], modal [14,32] and other types of analyses of individual components [10,14,32],

structural unit and even entire mechanical systems [7,12].

The

realisation of analyses consists of several defined steps. First, the volume

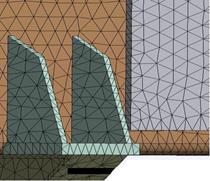

geometry was created and contact couples between parts of the model were

defined. Afterwards, the FEM mesh was generated. Figure 3 depicts a mesh

model of the frame.

The

mesh model composed by quadratic tetrahedron elements with a size of

10 mm. Number of elements was 789,491 and number of nodes 1,484,614.

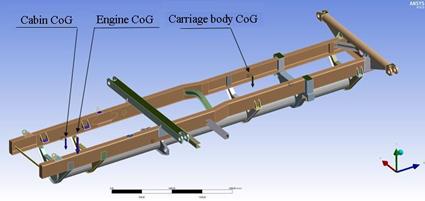

Another

step in analysing the frame was the definition of boundary conditions. Loads were

defined in the centres of gravity (CoG) as following

(Fig. 4):

- an empty tipping body: 25,000 N a central load-carrying

tube,

- a fully loaded tipping body: 157,000 N,

- an engine: 13,500 N,

- a cabin: 4,500 N.

The

strength analyses were performed for two loading states, that is, for an empty

carriage body and a fully loaded carriage body. When the empty carriage body is

considered, only the net weight of the tipping body acts on the analysed

structure.

|

|

|

|

a) |

b) |

Fig. 3. (a) A

mesh model of the analysed frame, (b) FEM mesh detail

Fig. 4. Acting

loads on the analysed frame

Results

of strength analyses for the empty tipping body are shown in Fig. 5

and 6.

Fig. 5.

Distribution of von Misses stresses in the frame structure – the empty

tipping body

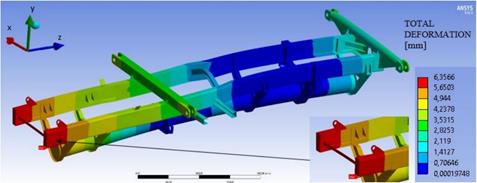

Fig. 6. Total

deflection of the frame structure – the empty tipping body

As

can be seen, the greatest value of the reduced stress (calculated according to

the von Misses hypothesis) is identified in the locations of torsion rods

joints in the plate and the location of the plate mounting to the central

tube. The reduced stress reached a value of 140.98 MPa (Fig. 5).

The

total deflection achieved in the frame structure for the first load case, that

is, for the empty tipping body, is 4.12 mm. It is detected in the

front part of the frame (Fig. 6).

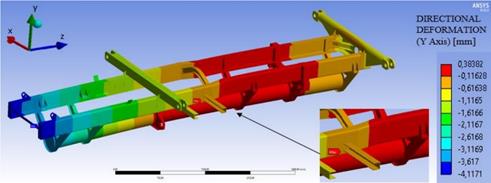

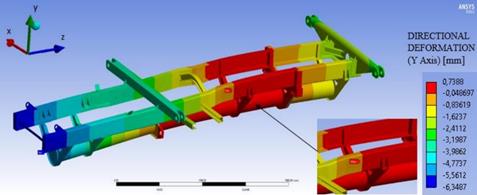

Fig.

7. Vertical deflection of the frame structure – the empty tipping body

Figure 7

shows the deflection of the frame structure for the first load case in the vertical

direction (y-axis). It shows that the

most loaded part of the frame is identified in the tipping body location,

between the location of rear leaf springs mounting and the torsion rods plate.

A part of the longitudinal profiles as well as triangular cross walls are

also loaded.

The

second loading case is considered for the fully loaded tipping body as

aforementioned. Results of strength analyses are shown in Fig. 8 and

Fig. 9.

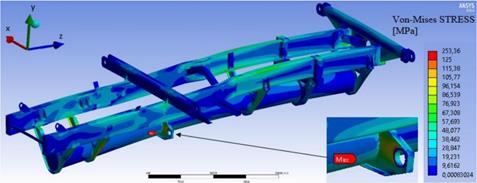

Based

on the reached results, the greatest value of the reduced stress is similarly

detected in the same location as in the case of the empty tipping body.

However, in the second loading case, this stress reached the value of

253.36 MPa (Fig. 8).

The

total deflection of the frame structure for the second loading case reached the

value of 6.36 mm (Fig. 9). It is also detected in the front part of

the frame structure.

The

maximal value of 0.74 mm of the vertical deflection (y-direction) of the frame structure was identified in the rear leaf

springs mounting location (Fig. 10).

Fig. 8.

Distribution of von Misses stresses in the frame structure

– the fully loaded tipping body

Fig. 9. Total

deflection of the frame structure – the fully loaded tipping body

Fig. 10.

Vertical deflection of the frame structure – the fully loaded tipping

body

From

shown results of the strength analyses of the frame structure for the first and

second loading cases, it is obvious, that the value of the reduced stress

calculated according to the von Misses hypothesis increased from the value of

140.98 MPa (the empty tipping body) to the value of 253.36 MPa (the fully

loaded tipping body).

The

determined value of the total deflection in the critical location of the frame

structure increased from the value of 4.12 mm (the empty tipping body) to the

value of 6.36 mm (the fully loaded tipping body).

The

value of the vertical deflection (y direction) also increased, namely from the

value of 0.38 mm (the empty tipping body) to the value of 0.74 mm.

The

yield of strength (Re) of the steel S355J0 used for

the frame structure production is 355 MPa. The maximal value of the

determined value is 253.36 MPa. Thus, the performed static analyses of the

frame structure have shown that it meets the requirements of rigidity and

safety material within the safety factor of 1.4.

However,

the tipping lorry Tatra is designed for heavy

off-road operational conditions. Therefore, the chassis including the frame is

loaded with dynamic loads. Their characteristics, such amplitude and frequency

are stochastic and they will cause different loads in comparison with performed

static analyses [5,20,21]. Hence, future research in

this field should be focused on obtaining input data, which will simulate more

realistic loading of the frame structure. There are mainly loads in the

location of axles mounting, where wheel forces will act on the frame. Further,

efforts will be made to creating a virtual multibody model (MBS model) of the

lorry chassis. It is possible to expand the MBS model using the presented FEM

model of the frame [15,25,37], input dynamic loads to

the structure and investigate its behaviour under these defined loads.

5. CONCLUSION

The

solution of the presented problem consists of obtaining input data from a

customer. Based on these data, the engineering design and functional solution

of the manipulator were created. The important task was the design of the

compressor setting, which has to meet all requirements in term of its

dimensions and the possibility of compensation of all inaccuracies. Safety of

the device, protection of health and operator and ergonomic parameters were

other important aspects of the design. Compliance with the relevant standards

and internal regulations of the customer was a matter of course. Designs of the

rotating part of the manipulator, the control panel, the travel and the

pneumatic parts of the manipulator were realised together with the compliance

of the customer-required components from precisely specified manufacturers. The

next step in solving this problem would be the design of the pneumatic brake,

the selection of air treatment equipment, the creation of the pneumatic circuit

diagram, the FEM simulation of the steel plate, the adjustment mechanism and

the RPS pin console.

Source of

funding

This work was supported by the Cultural and

Educational Grant Agency of the Ministry of Education of the Slovak Republic in

the project No. KEGA 023ŽU-4/2020: Development of advanced virtual models

for studying and investigation of transport means operation characteristics.

References

1.

Barta Dalibor, Martin Mruzek,

Martin Kendra, Paweł Kordos,

Leszek Krzywonos. 2016. “Using of non-conventional

fuels in hybrid vehicle drives”. Advanced

in Science and Technology – Research Journal 10(32): 240-247. ISSN:

2299-8624. DOI: 10.12913/22998624/65108.

2.

Barta Dalibor,

Martin Mruzek, Robert Labuda,

Tomas Skrucany, Leszek Gardynski. 2018. “Possibility of increasing vehicle

energy balance using coasting”. Advances

in Science and Technology – Research Journal 12(1): 228-235. ISSN:

2299-8624. DOI: 10.12913/22998624/86215.

3.

Figlus Tomasz, Łukasz Kuczyński.

2018. “Selection of a

semi-trailer for the haulage of long oversize loads, taking into account an

analysis of operational damage”. XI International

Science-Technical Conference Automotive Safety. IEEE Proceedings Paper. DOI: 10.1109/AUTOSAFE.2018.8373342.

4.

Fomin Oleksij,

Juraj Gerlici, Alyona Lovska, Kateryna Kravchenko, Yuliia Fomina, Tomas Lack. 2019.

“Determination of the strength of the containers fittings of a flat wagon

loaded with containers”. 9th

International Scientific Conference on Research and Development of Mechanical

Elements and Systems IRMES 2019. University of Kragujevac. 5-7 September, Kragujevac,

Serbia. ISSN: 1757-8981.

DOI: 10.1088/1757-899X/659/1/012056.

5.

Fomin Oleksij,

Juraj Gerlici, Alyona Lovskaya, Kateryna Kravchenko, Oleksii Burlutski, Vladimir

Hauser. 2019. “Peculiarities of the mathematical modelling of dynamic

loading on containers in flat wagons transportation”. MATEC Web of Conferences 254. ISSN: 2261-1009. DOI:

10.1051/matecconf/201925402039.

6.

Gardynski Leszek,

Jacek Caban, Dalibor Barta. 2018. “Research of composite materials used in

the construction of vehicle bodywork”. Advanced in Science and Technology – Research Journal 12(3):

181-187. ISSN: 2299-8624. DOI:

10.12913/22998624/92096.

7.

Gerlici Juraj,

Tomas Lack, Jozef Harusinec.

2014. “Development of test stand prototype for rail vehicles brake

components testing”. Communications

– Scientific Letters of the University of Zilina

(Komunikacie) 16(3): 27-32. ISSN:

1335-4205.

8.

Gerlici Juraj,

Tomas Lack, Jozef Harušinec.

2012. “Test stand properties analysis for wheels tread wear in accordance

to the laboratory simulated railway operation”. Proceedings of the 13th Mini Conference on Vehicle System

Dynamics, Identification and Anomalies VSDIA 2012:

157-165. Budapest University of Technology and Economics. 5-7 November,

Budapest, Hungary. ISBN: 978-963313102-2.

9.

Gülenç B., H. Kocaman, B. Çevik, A. Durgutlu, T. Fındık.

2016. “The effect of cold and hot reformation process to mechanical

properties of deformed automobile chassis material”. Mechanika 22(5): 376-379.

10.

Handrik Marian, Peter Kopas, Vladmimir Baniari, Milan Vasko, Milan Saga.

2017. “Analysis of stress and strain of fatigue specimens localized in

the cross-sectional area of the gauge section testing on bi-axial fatigue

machine loaded in the high-cycle fatigue region”. Procedia Engineering 177: 516-519. ISSN: 1877-7058. DOI: 10.1016/j.proeng.2017.02.254.

11.

Jakubovicova Lenka,

Alzbeta Sapietova, Jan Moravec. 2018. “Static analysis of transmission tower

beam structure”. MATEC Web of Conference 244.

ISSN: 2261-236X. DOI:

10.1051/matecconf/201824401011.

12.

Jakubovicova Lenka,

Peter Zavadinka, Jan Jakubovic.

2016. “Transport duty cycle measurement of hybrid drive unit for mixing

drum”. Advanced Mechatronics

Solutions 393: 219-224. ISSN: 2194-5357. DOI:

10.1007/978-3-319-23923-1_33.

13.

Kalincak Daniel, Lubos Bartik, Juraj

Grencik. 2012. “The hybrid traction – the

way of fuel utilization improvement”. Facta Universitas – Series Mechanical

Engineering 10(2): 163-170. ISSN: 0354-2025.

14.

Klimenda Frantisek, Josef Soukup, Milan Zmindak, Blanka Skocilasova. 2018.

“Dissemination of shock waves in thin isotropic plates”. MATEC Web of Conferences 254. ISSN: 2261-236X. DOI: 10.1051/matecconf/201925405005.

15.

Kostrzewski Mariusz.

2018. “Analysis of selected acceleration signals measurements obtained

during supervised service conditions – study of hitherto approach”.

Journal of Vibroengineering

20(4): 1850-1866. ISSN: 1392-8716. DOI: 10.21595/jve.2018.19367.

16.

Kozioł, Mateusz, Tomasz Figlus. 2015. “Failure Progress of 3D Reinforced GFRP Laminate during Static Bending, Evaluated by Means of

Acoustic Emission and Vibrations Analysis”. Materials 8: 8751-8767. DOI: 10.3390/ma8125490.

17.

Kravchenko Alexander, Olga Sakhno, Alexander Lukichov. 2014.

“Research of dynamics of tire wear of trucks and prognostication of their

service life”. Transport Problems

7(4): 85-94. ISSN: 1896-0596.

18.

Kravchenko Alexander, Olga Sakhno, Alexander Lukichov. 2014.

“Trucks tires resource controlling by control of process of their

wearing-out”. Transport Problems

9(1): 83-93. ISSN: 1896-0596.

19.

Labuda Robert, Dalibor Barta, Andrej Kovalcik. 2010. “Effective use of the braking effect of

vehicle drivetrain at deceleration”. XLI.

International Scientific Conference of Czech and Slovak University Departments

and Institutions Dealing with the Research of Internal Combustion Engines (KOKA 2020): 206-211. Technical University Liberec.

06-07 September, Liberec, Czech Republic.

20.

Leitner Bohus,

Lucia Figuli. 2018. “Fatigue life prediction of

mechanical structures under stochastic loading”. MATEC Web of Conferences 157. ISSN: 2261-1009. DOI: 10.1051/matecconf/201815702024.

21.

Leitner Bohus.

2010. “A new approach to identification and modelling of machines dynamic

systems behaviour”. Proceedings of

the 19th International Scientific Conference on Transport Means

TRANSPORT MEANS 2010: 17-20. Kaunas University of Technology. 21-22

October, Kaunas, Lithuania. ISSN: 1822-296X.

22.

Leitner Bohuš.

2014. “Fatigue damage analysis and fatigue life prediction of lorry frame

under random excitation”. 18th

International Conference on Transport Means Transport Means 2014: 9-14.

Kaunas University of Technology. 23-24 October, Kaunas, Lithuania. ISBN: 1822-296X.

23.

Liščák Štefan,

Rostislav Matějka, Vladimír Rievaj, Marián Šulgan. 2006. Chassis of road vehicles (In Slovak). Žilina: University of Žilina.

ISBN: 80-8070-588-7.

24.

Melaika M., S. Nagurnas, R. Pečeliūnas,

N. Višniakov, G. Garbinčius.

2013. “Investigation on distribution of stresses in steel and aluminium

alloy arms of a car suspension system”. Mechanika 19(6): 632-640.

25.

Melnik Rafal,

Bogdan Sowinski. 2017. “Analysis of dynamics of

a metro vehicle model differential wheelsets”. Transport Problems 12(3): 113-124. ISSN: 1896-0596. DOI: 10.20858/tp.2017.12.3.11.

26.

Ren Yuan, Yongchang Yu, Binbin Zhao, Chuanhui Fan, He Li. 2017. “Finite element analysis and optimal

design for the frame of SX360 dump trucks”. Procedia Engineering 174: 638-647. ISSN:

1877-7058. DOI: 10.1016/j.proeng.2017.01.201.

27.

Savkin Alexey Nikolaevich, Alexander Gorobtsov,

KA Badikov. 2016. “Estimation of truck frame

fatigue life under service loading”. Procedia

Engineering 150: 318-323. ISSN: 1877-7058. DOI:

10.1016/j.proeng.2016.07.020.

28.

Stastniak Pavol,

Lukas Smetanka, Marian Moravcik.

2018. “Structural analysis of a main construction assemblies of the

new wagon prototype type Zans.” Manufacturing Technology 18(3): 510-517.

ISSN: 1213-2489. DOI: 10.21062/ujep/130.2018/a/1213-2489/MT/18/3/510.

29.

Suchanek Andrej, Jozef Harusinec, Maria Loulova, Peter Strazovec. 2018.

“Analysis of the distribution of temperature fields in the braked railway

wheel”. MATEC Web of Conference 157. ISSN: 2261-1009.

DOI: 10.1051/matecconf/201815702048.

30.

Suda Yoshihiro, Juraj Grencik. 1996. “The

mechanism of enhanced curving performance of unsymmetric

suspension trucks under acting traction/brake torque”. Vehicle System Dynamics 25 (SUPPL): 629-640. ISSN: 0042-3114. DOI: 10.1080/00423119608969225.

31.

Supardjo, Agus

Dwi Anggono,

Tri Widodo Besar. 2018. “Finite element

analysis of truck frame by using CATIA V5”. Proceeding

of the 4th International Conference on Engineering, Technology and

Industrial Application ICETIA 2017. Universitas Muhammandiyah

Surakarta. 13-14 December, Surakatra, Indonesia.

ISSN: 1551-7616. DOI: 10.1063/1.5042949.

32.

Svoboda Martin, Vaclav Schmid,

Josef Soukup, Milan Sapieta.

2018. “Modal analysis of the vehicle model”. Springer Proceedings in Mathematics & Statistics 249: 351-362.

ISSN: 2194-1009. DOI: 10.1007/978-3-319-96601-4_32.

33.

Tatra vehicle design.

Available at:

https://www.tatratrucks.com/why-tatra/tatra-vehicle-design/tatra-vehicle-design-1/.

34.

Varjan Pavol,

Jozef Gnap, Pavol Ďurana, Mariusz Kostrzewski. 2019.

“Research on the relationship between transport performance in road

freight transport and revenues from excise duty on diesel fuel in selected

European countries”. Transportation

Research Procedia 40: 1216-1223. ISSN: 2352-1457. DOI: 10.1016/j.trpro.2019.07.169.

35.

Vatulia Glib, Anatoliy Falendysh, Yevhen Orel, Mikhailo Pavliuchenkov. 2017. “Structural improvements in a

tank wagon with modern software packages”. 10th International Scientific Conference on

Transportation Science and Technology TRANSBALTICA

2017: 301-307. Vilnius Gediminas University of

Technology.

04-05 May, Vilnius, Lithuania. ISSN: 1877-7058. DOI:

10.1016/j.proeng.2017.04.379.

36.

Vlk František.

2006. Chassis of engine vehicles (In

Czech). Brno: František Vlk

Publishing. ISBN: 80-239-6464-X.

37.

Weyssenhoff Andrzej, Michal Opala, Seweryn Koziak, Rafal Melnik.

2019. “Characteristics and investigation of selected manufacturing

defects of passenger car tires”. Transportation

Research Procedia 40: 119-126. ISSN: 2352-1457. DOI: 10.1016/j.trpro.2019.07.020.

Received 17.08.2020; accepted in revised form 12.11.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License