Article

citation information:

Cieśla, M., Opasiak, T. Mining machines elements

packing and securing on platform container. Scientific

Journal of Silesian University of Technology. Series Transport. 2021, 110, 05-21. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.110.1.

Maria CIEŚLA[1],

Tadeusz OPASIAK[2]

MINING

MACHINES ELEMENTS PACKING AND SECURING ON PLATFORM CONTAINER

Summary. The scientific purpose

of this paper was to analyse the problem related to intermodal transportation

of mining components packed in containers or other cargo transport units

coupled with the problem of its proper securing. In this article, the issue of

exposing the load to the effects of inertia forces which might cause

unintentional movement is presented. The methods of securing the heavy load in

cargo transport units are reviewed in the context of cargo immobilisation

possibilities while reducing the load sensitivity to mechanical forces. The

research part of this article presents the methods of packing and securing an

atypical load, which is a part of a mining machine weighing 18t. This paper

presents the results of calculations of inertia forces acting on the

transported cargo, packed on a container platform. Based on the results,

the cross fixing method was selected to secure the cargo and further decisions

were made on the type and quantity of conveyor lashings necessary for the safe

and correct carriage of the atypical load.

Keywords: mining machines securing, lashing selection,

platform container

1. INTRODUCTION

Road transport

vehicles are characterised by widespread availability, flexibility and speed.

Due to the very large diversity of goods and means of transport used, the

method of attachment must be adapted to the needs every time to maintain

maximum safety for both the traffic load, vehicle and other road users.

However, the results of vehicle inspections show that some of the loads carried

are not properly secured on road vehicles. It is estimated that about 25% of

accidents involving trucks result from improper cargo protection [2, 20].

The issue of

freight transport security deserves special attention due to the huge, negative

consequences that entail, for example, losing a heavy load during an emergency

and uncontrolled situation. It is important to determine the impact of

unsecured or incorrectly secured load packages in any transport unit on the

effects in the form of collisions and accidents. More so, it is worth realising

that responsibility for errors arising from unsecured loads, which, according

to the European and global law, concerns all participants in the transport

chain. Shippers, who usually pack goods for shipments are similarly responsible

for the loads’ safety in their supply chains [1, 2, 13, 19]. Human error

[2-4, 6, 14, 21] and the problem of causality [7] in the analysis of accidents

are widely investigated, providing enrichment of knowledge about methods,

procedures and tools allowing incident and accident prevention or prediction [8].

The knowledge

of cargo and packing dynamics has improved over the years [10]. Although there

are many methods and tools supporting cargo security [5, 22], during road

transportation, packed cargo is exposed to other independent random factors.

One is the impact of inertia forces that can cause movement of packaged goods.

The direction of these forces depends on changes in the speed vector of the

vehicle, and in particular, in the direction of the vehicle during braking,

towards the rear of the vehicle during the start-up, or facing transversely to

the vehicle when the transport vehicle is travelling on a curvilinear arc. In

each of the specified cases, the vector of inertia forces takes the direction

of the acceleration vector and its value is proportional to the value of the

vector resulting from the velocity. In addition, the load can be influenced by

the forces resulting from the movement of the vehicle on the road with its

significant inclination and uneven ground. However, there are some studies

focused on non-lashing cargo securing methods [9, 11, 24].

Load

sensitivities for mechanical effects can be reduced by appropriate

immobilisation, that is, by employing suitable fastening elements. These

fastening elements include fastening belts, chain hoists, rope hoists, locking

elements, etc.

By selecting

appropriate methods and tools for securing specific loads, it should be

emphasised, that improper attachment of the load could result in a dangerous

road situation; often resulting in loss of life or health of its participants.

Currently,

legal acts are regulating the requirements for proper protection of loads

during their transportation. Within the European Union, the legal issue of

cargo carriage is regulated by EN-12195. In many countries, this standard has

been obligatory for many years, but still not fully respected by the road

hauliers community. However, it is known that the responsibility for properly

securing the transported cargo lies directly on the carrier. Surprisingly, the

fact remains that dangerous road events still occur, which can be traced to

erroneously secured loads, the reason being lack of knowledge of the problem.

These errors often arise at the loading stage and are often identified for

non-typical loads. Load conditions are extremely important for assessing the

carrier's reliability [12, 15, 23].

This article

presents a practical example of correct safeguarding of an atypical, 18t load

based on the calculated inertia forces acting on the transported cargo that is

placed on the container platform. Securing the load was done with the cross

fixing method.

2.

NECESSITY OF CARGO IMMOBILISATION

Transportation

of machines or other devices, which are usually oversized or extremely

expensive, consists of complex actions involving the movement of cargo and

handling operations (loading, unloading and reloading). Such transportation requires

specialised knowledge and equipment and every part of the process should be

carefully planned [15].

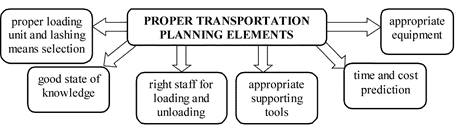

Fig.

1 presents the essential elements of significant transportation process

planning. All elements indicated, affect the quality of the transported goods

and the quality of transport service.

Fig. 1. The basic elements of proper and safe transportation planning

When

planning both recurring and single shipments, a proper loading unit must be

selected and adapted to the type of load and the mode of transport. The

appropriate choice of means of transport (loading unit) for the shipment is

influenced by several factors, such as mode of transport, type of package,

delivery time, density and quantity of the product, requirements for previous

loads, additional equipment, load and securing type or vulnerability to

the external transport conditions. Some of them refer to the conditions of

transporting goods, and others to the packages or transport units used or even

to the requirements for equipment and supplies [16].

Requirements

for equipment, supplies, and loading/unloading technique should be confirmed

with the carrier to maximise optimisation [12]. This information will help the

carrier easily organise the transportation of specific goods. For some

products, the package or transport unit used must be specially designed to

maintain safety in the transport process. Ensuring safe transport depends on

many factors, including the correct selection of packaging or transport unit

and fixing means [17]. The decision, however, depends on the forces acting on

the load.

2.1.

Proper load securing

Securing

of loads during transport is reduced to balance the inertial forces acting on

the load when the vehicle is moving during

acceleration, braking, cornering or overtaking manoeuvres, etc. The

frictional forces that occur between the surface of the cargo floor of the

vehicle and the lower surface of the load are often insufficient to ensure that

the load does not move. Vertical movements of the load during driving due to

bumps and vibrations reduce the frictional force resulting from contact. For

fixing packages or loads on vehicles, elastic belts, ropes or chains, equipped

with mechanical tensioning devices (latches, clamps, stabilisers tensioners)

are used. The carrier responsible for securing the cargo before transport

selects the appropriate number of fixing lashings by him or herself,

considering the mass of the transported load and its external dimensions, which

affects the choice of type and strength parameters of the fastening elements as

the basis of the decision. These principles refer to different types of

cargoes, except liquid cargoes and gas. The most common cargoes, their stowage

and calculation are container cargoes, reefer cargoes, bulk cargoes including

grain and grain products, heavy lift cargoes, timber cargoes, steel cargoes and

ro-ro cargoes [18].

The

appropriate computational analysis is required to determine the forces

transmitted by the load securing elements. This analysis must consider the

following three basic situations that are usually encountered during road

transport:

− braking of the vehicle while

driving straight ahead,

− braking on the curve of the road

when the load on the vehicle is inertia, both in the driving direction and in

the lateral direction outside the arc,

− intensive braking of the vehicle

when driving straight ahead on uneven surfaces,

− vibration of the vehicle causing

reduction of the load pressing the load to the floor of the cargo hold, thus

reducing the friction between the cargo and the cargo area.

These

problems refer not only to the cargo packed inside transport units but also to the

transport units themselves (egg containers) that have to be properly secured [19].

2.2. Forces

acting on packed cargo in transport

The

maximum acceleration

acting on the load while driving is determined by the acceleration product g and the acceleration factor C as defined in the standards [3, 19].

Acceleration factors are regulated by European standards and the IMO, and

differences in values are detailed in Table 1. In addition to the guidelines

contained in the IMO, the United Nations Economic Commission for Europe

recommends using the EN 12195-1 standard in which it has drawn up the European

Commission guidelines on cargo security, and the differences between those

provisions are shown in Fig. 2. Many experts from the European Commission and

scientists worked to elaborate parameters acceptable to obtain the European

standard [1, 3, 19].

Fig.

2. Accelerations acting on the transported cargo in road transport according to

standards

The

German standard, VDI2700, explains the basic forces acting on the cargo, its

proper location and the practical way of installing the fastening devices.

Standard VDI2701 refers to load fixing devices, and the VDI2702 standard

describes the method of calculating the forces required to correctly load the

most common loads with no complicated shapes. Compared to

the EN 12195-1:2010 standard, VDI is more

complex with typical examples and drawings showing how a particular type of

transported cargo should be properly secured, for example, metal circles, large

panes of glass, steel pipes, etc.

Road

Transport Inspection and similar institutions

checks are very accurate at the security control of cargo, which greatly

contributes to the improvement of safety in international transport since the

vehicle with improperly secured load is stopped in the parking lot and cannot

set out on a further route until it is rectified. This

is related to vehicle downtime and the need to supply the driver with

appropriate fastening means.

Tab.

1

Normalised

values of the acceleration factor C depending on

the direction of inertia of the

moving vehicle

|

Direction of inertia force |

Acceleration

factor value C |

|

|

IMO |

EN

12195-1 |

|

|

In the direction of the longitudinal movement,

at the moment of braking |

C=1.0 |

C=0.8 |

|

In the direction of the opposite longitudinal

movement at the moment of starting |

C=0.5 |

C=0.5

(+0.1) |

|

In the transverse direction when driving on

the arc of the road |

||

|

Vertical direction when driving on uneven

roads |

C=1.0 |

C=1.0 |

3. CONTAINER

PACKING AND SECURING OF MINING CONVEYOR

– A CASE STUDY

3.1.

Load characteristics

The

case study in view is based on an order received by a multimodal

transport operator from a global mining machinery and equipment manufacturer

specialising in underground mining, open-pit mining, and bulk cargo transport

and handling. The subject of the order was the transport from Poland to Jakarta

Port in Indonesia of five coal conveyors to carry coal in the open-pit mines.

The whole project was divided into four stages, including multimodal transport.

The transported machines were divided into 122 separate load units due to their

size. Transport took place on standard semi-trailers: tarpaulin of dimensions:

width: 2.48 m, height: 2.70 m, length of 13.6 m and container and cargo units

40 feet plate-type Flat Rack Containers or multi-purpose containers.

The

untypical load analysed in detail in this article is the opencast mine belt

conveyor system of which loading by a reach stacker is shown in Fig. 3. The mass

of the load is mL=18 000 kg, width d=3.2 m, height h=3.0 m and length

l=9.5 m.

3.2.

Selection of cargo securing method

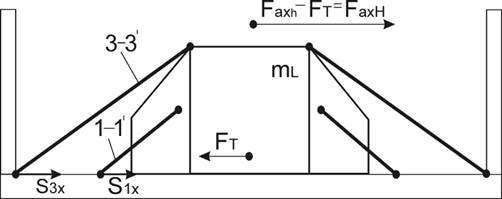

When

attaching an atypical load to an open container

platform, it is important to consider inertia forces acting on the cargo during

its transportation. The theoretically transported cargo can be immobilised by

belt anchorage or appropriate cargo blocking. The load

should be secured by the carrier with elastic fastening elements using

the strap cross fixing method shown in Fig. 4. The surface of the loading platform is made of

painted steel sheet on which wooden supports are laid. Basing on the friction

coefficient table, the coefficient of friction μ=0.20 was calculated for

further estimations. Each of the fastening elements was stressed by a perforce

of Fw=1000 N.

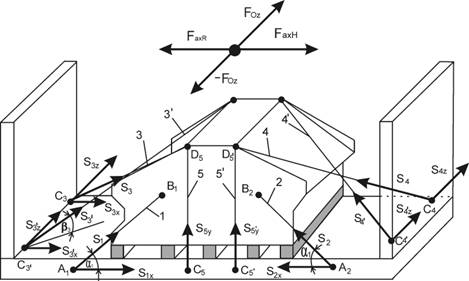

Fig.

3. Belt conveyor drive system for open-pit mine loading process

Fig.

4. Fastening of cargo on a 40 ft Flat Track container

Atypical load should be secured with ten lashing elements in the form of straps (1,

1’, 2, 2’, 3, 3’, 4, 4’, 5, 5’) according to the

scheme in Fig. 5.

Fig.

5. Scheme of belt conveyor system securing method on a container platform

For further

analysis, the following indications were determined according to Fig. 5:

− S1, S1’,

S2, S2’, S3, S3’, S4,

S4’ – tensile forces in fixed lashings no.

1,1’,2,2’,3,3’,4,4’;

− S1x, S1x’,

S2x, S2x’, S3x, S3x’, S4x,

S4x’ – force components of S1, S1’,

S2, S2’, S3, S3’, S4,

S4’, acting respectively in the directions of the axis Ox;

− S3z, S3z’,

S4z, S4z’ – force components of S3,

S3’, S4, S4’ acting respectively

in the directions of the axis Oz;

− S1y, S1y’,

S2y, S2y’ – force components of S1,

S1’, S2, S2’, acting respectively

in the directions of the axis Oy;

− α1, α2

– angles between the lashings S1, S1’, S2,

S2’ and the plane of a container platform;

− β3x, β3’x, β4x, β4’x,–

angles between the axis Ox and the lashings projection on the

platform plane;

− β3z, β3’z, β4z, β4’z

– angles between the axis Oz and the lashings projection on

the platform plane.

3.3. Forces acting on the transported cargo

In the

longitudinal direction, the Fax inertia force acts on the load that

occurs during the braking FaxH and the acceleration FaxR

of the vehicle. While driving along the curvilinear path, centrifugal force Foz

is created, because the uneven surface of the road is a source of inertial

force Fby acting vertically. The values of

the forces of inertia are calculated as the product of the acceleration of

gravity C and derived from the load being transported QL according to the formula:

![]() (1)

(1)

The

values of Cxyz acceleration factors are normalised for the different

directions of inertial forces and the values were shown in Table 1 according to

the European standard.

3.4.

Calculation and selection of lashings for conveyor attachment on a container

platform

The cargo on

the container platform of the vehicle should be protected against slipping

while driving, to ensure the safety of the driver, the traffic and to secure

the load from possible damage. Different methods of fixing cargo on means of

transport are used in transport. The basic ones are: blocking, anchoring using

lashing, increasing the value of friction force of the load on the floor of the

body by the belt lashing method. In practice, combinations of these methods are

usually used. The purpose of this combination is to improve the efficiency of

the loaded cargo.

For

the mounting of the conveyor belt drive system, the cross anchoring method with

belt lashing was used. The cross anchoring method allows

attaching a heavyweight load using only four lashings that secure the load from

moving in both the transverse and the longitudinal directions. However, a

necessary condition for using this kind of protection is that the load has

special handles to fix the lashings used.

The selection

of cross anchoring lashing is to determine the minimum value of the LC lashing

capacity for each of the lashes located at the front (LPp) and the

back (LCt) of the container platform. To determine the lashing

capacity, it is necessary to analyse the inertia forces of the transported load

at the time of the most unfavourable conditions (like roadblock overcoming)

occurring in road transport. During breaking, the inertia force Faxh,

is determined by the following relation (2) (Fig. 6) and is calculated as

follows:

![]() (2)

(2)

where: ax - accelerated deceleration

at braking, mL - load mass.

Therefore,

while braking the Faxh inertia

force acts on the load with 141 264 N.

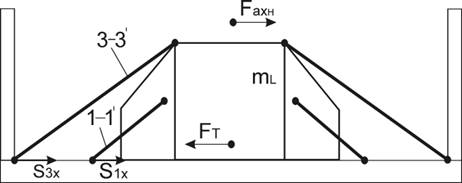

Fig.

6. Diagram showing forces reaction at the moment of braking

At the moment

of braking, the load is secured with 1, 1', and 3, 3’ lashings. In addition to FaxH

inertial force also opposes the FT

frictional force between the surface of the platform container and the wooden

sleepers under load. The friction force FT (3) is directed

opposite to the force causing the load shifting according to the relation (Fig.

7).

![]() (3)

(3)

For wooden

beams and metal substrates, the coefficient of friction is in the range

µ=0.2-0.5. The most unfavourable value was considered, that is,

µ=0.2. In the case of cargo resting horizontally on the platform, the

load force N and the gravity of the load G are equal (N=G). Apart from these

forces, in this case, the load was additionally compressed by the 5 and

5’ belt tension. Then on the force of pressure N, in addition to the

gravity G, there is also the pressing force Pn, derived from the

tension of the belts 5 and 5’. Thus, the load pressure on the substrate,

including the fixing straps, is:

![]() (4)

(4)

where: Pn - additional force pressing

the load to the cargo platform of the container.

Belt

tensioners increase the clamping force by an

additional value of Pn = 5000 N (standard tension force STF). After substituting the appropriate size and calculating the

frictional force, FT has the following

value:

![]() =36 316

N (5)

=36 316

N (5)

The frictional

force, after considering the forces from the load and the pressing straps, is FT=36 316

N. At the moment of braking, after taking into account the force of friction of

the load and the pressing of the belts, the final inertial force FaxH

is applied to the transported load with the following values according to the

following relation:

![]() (6)

(6)

Fig.

7. Scheme of inertia force at the moment of braking

The

resulting value

(6) is inertial force FaxH that acts directly on the load at the time of braking and to

which should be secured with lashing equipment no. 3, 3’ and 1, 1’.

After determining the magnitude of the inertia force acting on the load at the

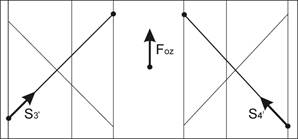

moment of deceleration, the centrifugal force Foz acting on the load

at the moment of travel on the curve is determined according to the relation

(Fig. 8):

![]() (7)

(7)

where: mL - load mass, v - speed of the vehicle with the load, R - radius of the road arc.

Fig.

8. Scheme of the lashings reaction system exhausts to

the centrifugal force on the curve of the road

Fig.

8 shows that at the time

of driving on a curve road, centrifugal force Foz

influences the 3’ and 4’ lashing rods.

To determine the centrifugal force, the most disadvantageous road conditions

are assumed. The calculation assumes that the load can travel at maximum speed

v=80 km/h=22.2 m/s. This speed applies to motorways, expressways and 2-lane

roads outside the built-up areas of Poland. For roads

having the minimum speed curve radiuses are R=250 m. By substituting

these values for the dependence (7), the centrifugal force at the level Foz=35 520

N is obtained. On the other hand, considering the European standard and other

adverse road conditions related to sudden lane change such as avoiding an

obstacle, the centrifugal force is:

![]() (8)

(8)

Taking

into account the frictional force of FT, the final centrifugal force

Foz acting on the considered load is:

![]() (9)

(9)

The

determined values of forces acting on the conveyor drive system on a container

platform are presented in Table 2.

Tab.

2

Values of forces acting on a conveyor drive system packed on a container

platform

|

Direction

of force |

Force

value |

|

In the direction of the longitudinal movement,

at the moment of braking |

|

|

In the direction of the opposite longitudinal

movement at the moment of starting |

|

|

In the transverse direction when driving on

the arc of the road |

|

|

Vertical direction when driving on uneven

roads |

|

Sensors

of vectors of the reaction forces in lashings no. 1, 1’, 2, 2’, 3,

3’, 4 and 4’ are opposed to the return forces during transport

loads on the platform of the container. The inertia

force Foz is directed

forward and its effect is transferred to the cross-lashings no. 4, 4’ and

longitudinal lashings no. 2, 2’. Foz centrifugal force acts transversely to the direction

of travel, and its operation is transferred to the cross lashings no. 3 and 4. When

Foz centrifugal force changes, the reactions will occur in 3’

and 4’ lashings. Tilt angles of lashings are required to determine the

reaction forces. Fig. 9 shows the angles β1,

β2, describing the arrangement of cargo lashing in

the Oxz plane at reaction point C.

Fig.

9. Angles of lashing no. 3 alignment at the C3’ attachment

point

Reactions

considered at points C and C’ are the condition

of the load when the transported load on the container platform is affected by

the forward inertia force FaxH as

a result of the vehicle braking. The reactions at points C and C’ have

the same values (S3x=S3’x) since

the fixing lashing are arranged symmetrically. Strength

S3 was

decomposed into components acting in directions Ox,

Oz.

![]() (10)

(10)

![]() (11)

(11)

Similarly,

the S1 force in the direction of Ox and Oz was decomposed

into the force of the reaction of lashings 1 and 2 at points C1 and

C2.

![]() (12)

(12)

![]() (13)

(13)

The

S3x, S3x’ and S1x, S1x’

reaction forces maintain the charge in equilibrium when the inertial force at

the moment of braking FaxH is acting in the longitudinal direction.

The load remains in balance if:

![]() (14)

(14)

When S1=S1’,

S3=S3’, then the equation takes the following form:

![]() (15)

(15)

After

substituting the relations defined in equation (10) and (12) into equation

(15), we obtain:

![]() (16)

(16)

Equation

(16) presents the state of equilibrium at the moment the vehicle brakes. To

determine the forces in the S3 and

S1 lashings, tensile forces in lashings 3 and 4

arising from the centrifugal force at the moment of the arc or other lane

change manoeuvre must be determined.

When

driving on the arc of the road, lashings 3 and 4 are tensed under the influence

of the centrifugal force Foz, based on the dependence:

![]() (17)

(17)

After substituting dependence (11) and

assuming that S3z=S4z due to the symmetry of the attached

load, the equation (17) takes the following form:

![]() (18)

(18)

After transforming the equation (18) to S3,

we obtain the equation of the force in fixing lashing 3 and simultaneously in

lashing 4.

![]() =52 083.3

N (19)

=52 083.3

N (19)

It is clear from the calculation that the fixing lashings 3

and 4 have a tensile strength of 52,083.3 N. It follows that the forces acting

on the lashings of cross attachment S3,3’=52 083.3 N. If

the load acting on the 3 and 4 lashings is known, the force that tenses the 1

and 1’ lashings can be determined. Due to the symmetry, only S1 may be

calculated. After substituting the force S3 for the equation and the corresponding

transformation, we obtain the force S1,1’=20 290.85 N.

The analysis shows that for

the conveyor drive system transported on the container in the individual

attachment lashings force values appear as presented in Table 3.

Following the analysis,

associated with the forces, selection of appropriate fixing equipment should be

done according to lashing capacity (LC).

Tab.

3

Size of forces calculated on

individual lashings securing conveyor drive system

|

No.

of fixing lashing |

Determination

of tensile force of fixing cable |

Value

of maximum forces in tension [N] |

|

1 |

S1 |

20 291 |

|

1’ |

S1’ |

|

|

2 |

S2 |

|

|

2’ |

S2’ |

|

|

3 |

S3 |

52 083 |

|

3’ |

S3’ |

|

|

4 |

S4 |

|

|

4’ |

S4’ |

|

|

5 |

S5 |

22

500 |

|

5’ |

S5’ |

3.5. Selection of lashings securing transported cargo

To

secure the conveyor on a container, according to the guidelines contained in

the standard, the following fixing lashings should be applied: S1,

S1’ and S2, S2’, lashings

should have a tensile strength of S1,2 =20 291 N,

lashings S3, S3’ and

S4, S4’ should have a tensile strength of

S3,4=52 083 N and lashing S5=22 500

N.

Lashing

straps recommended by the carrier was selected for conveyor attachment. Lashing

straps usually consist of artificial fibres (usually polyester according to EN

12195-2). Each tape harness is labelled with the appropriate information, shown

in Fig. 10, which is lashing capacity (LC) in decaNewtons (daN-

official force unit corresponding to 1 kg), standard tension force (STF) which is obtained when the manual force is applied to the

tensioner (SHF) [3, 19].

|

Breaking

force 4000

kg |

|

LC

1600 daN |

|

SHF

50 daN / STF 400 daN |

|

100%

POLYESTER |

|

LGL

10 m |

|

!

NOT FOR LIFTING ! |

|

IRU

CIT |

|

VAT No. XXXYYY-YYYY |

|

2017 |

|

EN 12195-2 |

Fig.

10. Cargo lashing belt label according to the EN 12195-2 standard

Fixing equipment

in the form of fastening belts should be made following the EN 12195-2

standard. Companies that manufacture these types of fastening belts have the

straps in their assortments in the following ranges:

− lashing

strap width from 25 to 75 mm,

− lashing strap

maximum load from 250 to

10 000 daN,

− safety factor of the

securing straps is 2.

When

attaching an 18t load on conveyor drive system, the following fastening belts

should be used [12]:

a.

for lashings: S1, S1’ and S2, S2’

one-piece belt with manual tensioner was used (Fig. 11)

Fig.

11. Fastening strap used for lashings S1, S1’

and S2, S2’

This

type of lashing strap has the following parameters and implementations used

(Table 4):

− strap width 50 mm,

− lashing capacity LC=2

000 daN.

Tab.

4

Fastening

strap types used for lashings S1, S1’

and S2, S2’ of conveyor securing

|

LC

- lashing capacity |

Implementation possibilities |

||

|

2000 [daN] |

4000 [daN] |

4000 [daN] |

|

|

|

|

|

Two-piece with profile hooks |

|

Two-piece with U-type hooks |

|||

|

Two-piece with carabiners hooks |

|||

|

One-piece with a closed circuit |

|||

b.

for lashings: S3, S3’

and S4, S4’, the following fastening straps

were used (Fig. 12):

Fig.

12. Fastening strap used for lashings S3, S3’ and

S4, S4’

This

type of lashing strap has the following parameters and implementations used

(Table 5):

− strap width 75 mm,

− lashing capacity LC=5

000 daN.

Tab.

5

Fastening

strap types used for lashings S3, S3’

and S4, S4’ of conveyor

securing

|

LC

- lashing capacity |

Implementation possibilities |

||

|

5000 [daN] |

10000 [daN] |

10000 [daN] |

|

|

|

|

|

Two-piece with forged security hooks |

|

Two-piece with profile hooks |

|||

|

One-piece with a closed circuit |

|||

c.

for lashings: S5 and S5’

fastening straps of the following parameters should be used (Fig. 13): strap width - 50 mm, lashing

capacity LC=2 500 daN with different types shown in Table 6.

Fig.

13. Fastening strap used for lashings S5

and S5’

Tab.

6

Fastening

strap types used for lashings S5 and S5’

of conveyor securing

|

LC

- lashing capacity |

Implementation possibilities |

||

|

2500 [daN] |

5000 [daN] |

5000 [daN] |

|

|

|

|

|

Two-piece with profile hooks |

|

Two-piece with U-type hooks |

|||

|

Two-piece with carabiners hooks |

|||

|

One-piece with a closed circuit |

|||

For

load safety, the use of a similar procedure for choosing the form of security

and fixing means selection is recommended, analysing each case separately at

the planning stage of the transport process according to standardisation [1, 3,

19].

4.

CONCLUSIONS

This article

is focused on

intermodal transportation of mining components packed in containers or other

cargo transport units together with the problem of its proper securing. Using

appropriate equipment, method of cargo securing and correct transport unit are

very important elements among the six key factors mentioned as most important

of proper and safe transportation planning. The decision of packaging and

fixing means selection, however, depends on the forces acting on the load. EN

12195-1 standard is usually used for calculation of securing forces which

contains the European Commission guidelines on cargo security. However, many

carriers use the VDI2700 German standard where the basic forces acting on the

cargo, practical way of proper location and installing the fastening devices

are explained. Furthermore, this

article presents a case study of container packing and securing of a mining

conveyor, which was sent from Poland to Indonesia. First, the strap cross fixing method was determined with five

lashings. Thereafter, considering the friction forces of the load and the

lashing pressing forces, final inertial force (FaxH=104 948 N)

while vehicle braking was calculated. It should be

secured with lashing equipment no. 3, 3’ and 1, 1’. While driving

on a curve road, centrifugal force (Foz=53 684 N) influences the 3’ and 4’ lashing rods.

Then, forces acting on the lashings of

cross attachment S3,3’=52 083.3 N were

determined and are the same for lashings 4 and 4’. Basing on this

knowledge, lashing strap of 75 mm width and lashing capacity LC=5 000 daN

was selected for cargo securing. Similarly, forces acting on lashings 1,

1’ and 2, 2’ were determined (S1,1’=20 291 N)

and appropriate strap of 50 mm width and 2 000 daN lashing capacity was

proposed. For lashings 5 and 5’ (S5,5’=22 500 N),

strap with 50 mm width and LC=2 500 daN lashing capacity is proposed. Finally,

various types of usable selected belts with different hook variants were

presented.

References

1.

European Best Practice Guidelines on Cargo

Securing for Road Transport. 2014. European Commission, Directorate-General for

Energy and Transport,

ISBN: 978-92-79-43665-9. DOI: 10.2832/80373.

2.

Grunau Peter. 2015. Cargo Handling and Stowage: A Guide for Loading, Handling, Stowage,

Securing, and Transportation of Different Types of Cargoes, Except Liquid

Cargoes and Gas. BoD–Books on Demand. ISBN: 9783739217574.

3.

IMO/ILO/UN ECE Guidelines for Packing of Cargo Transport Units (CTUs)

(International Maritime Organization. London. 1997. ISBN: 92-801-1443-3).

4.

Jagelcak Juraj, Jozef Gnap. 2011. Different

measures for load securing create barriers in international road freight

transport. Archives of Transport System Telematics. 4(2): 10-17. ISSN:

1899-8208.

5.

Jagelcak Juraj. 2007. „Equation of the Standard EN 12195-1 Stipulates

Unreasonable Demands for Cargo Securing”. Communications – Scientific Letters of the University of Zilina

(Komunikacie) 9(4): 30-33. ISSN: 1335-4205.

6.

Jagelcak Juraj. 2015. Loading and fastening of freight in road transport. 2nd edition.

ISBN: 978-80-554-1083-8.

7.

Jia Junbo. 2007. „Investigations of vehicle securing without lashings

for Ro-Ro ships”. Journal of marine

science and technology 12(1): 43-57.

DOI 10.1007/s00773-006-0240-7.

8.

Mao Li, Runtian Jing. 2009. „Simulation Analysis for Cargo

Mechanical State during Transportation”. In: Logistics: The Emerging Frontiers of Transportation and Development in

China. Edited by Rongfang (Rachel) Liu, Jin Zhang, Changqian Guan. P. 821-827.

DOI: https://doi.org/10.1061/9780784409961.

9.

Nieoczyma Aleksander, Jacek Cabanb, Jan Vrabelc.

2019. „The

problem of proper cargo securing in road transport – case study”. Transportation Research Procedia 40:

1510-1517. DOI: https://doi.org/10.1016/j.trpro.2019.07.209.

10.

Polzin Steven E. 2011. Security considerations in transportation planning: A white paper. P.

12-36. Luxembourg: Publications Office of the European Union.

ISBN: 978-92-79-18270-9. DOI: 10.2832/30955.

11.

Rievaj Vladimir, Ján Vrabel,

František Synak, Ladislav Bartuska. 2018. „The Effects of vehicle load on driving

characteristics”. Advances in

science and technology – research journal 12(1): 142-149. DOI:

10.12913/22998624/80896.

12.

Safe

Packing of Cargo Transport Units (CTUs) –

COURSE, Model course 3.18. International Maritime Organization. London. 2001.

ISBN: 92-801-5116-9.

13.

Saruchera Fanny. 2020. “Determinants of

effective high-risk cargo logistics at sea ports: A case study”. Journal of Transport and Supply Chain

Management 14: a488. DOI: https://doi.org/10.4102/jtscm.v14i0.488.

14.

Sidney W.A. Dekker.

2004. Ten questions about human error: A

new view of human factors and system safety. Human

Factors in Transportation Series. London. CRC Press. ISBN: 0805847456.

15.

Singh Paul, Jay Singh, John Antle, Erin Topper.

2014. ”Load Securement and Packaging Methods to Reduce Risk of Damage and

Personal Injury for Cargo Freight in Truck, Container and Intermodal

Shipments”. Journal of Applied Packaging Research 6(1): Article 6.

DOI: 10.14448/japr.01.0005.

16.

Shtykov Victor Pavlovich. 2014. ”The

carrier's liability for failure to vehicles to transport cargo”. Life Science Journal 11(9): 292-294.

17.

Stajniak Maciej, Adam Koliński. 2016.

”The impact of transport processes standardization on supply chain

efficiency”. LogForum 12(1): 37-46. DOI: 10.17270/J.LOG.2016.1.4.

18.

Stapleton Drew M., Vivek Pande, Dennis O'Brien.

2014. ”EXW, FOB or FCA? Choosing the right Incoterm and why it matters to

maritime shippers”. Journal

of Transportation Law, Logistics, and Policy 81(3): 227-248. ISSN:

1078-5906.

19.

STN EN 12195-1:2011. Load restraint assemblies on road vehicles – Safety – Part 1: Calculation of

securing forces.

20.

Stokłosa

Józef, Grzegorz Koszałka, Leszek Gil. 2012. ”Analiza sił

w elementach mocujących ładunki na pojazdach samochodowych”. Postępy Nauki i Techniki

12:

94-100. [In English: “Analysis of forces in elements used for fastening

loads on road vehicles”].

21.

Strauch Barry. 2017. Investigating human error: Incidents, accidents, and complex systems.

London. CRC Press. ISBN: 978-1-4724-5868-1.

22.

Vlkovský Martin, Teodora Ivanuša,

Vlastimil Neumann, Pavel Foltin, Hanna Vlachová. 2017.

”Optimizating cargo security during transport using dataloggers”. Journal of Transportation Security 10:

63-71. Springer Science+Business Media. DOI: 10.1007/s12198-017-0179-4.

23.

Vlkovsky Martin, Katerina Pochobradska, Pavel

Foltin, Vaclav Zajicek. 2016. ”The cargo securing based on European

standards and its applicability in off-road transport conditions”. 3rd International Conference on Traffic

and Transport Engineering (ICTTE). 24-25 November 2016: 603-607. Belgrade,

Serbia: Scientific research center LDT Belgrade. ISBN: 978-86-916153-3-8.

24.

Zong Cheng-Giang, Zhang Hong-Wei, Huang Chao-Zhi,

Dong Jin-Song. 2017. ”Research on the influence of cargo securing force

with typical road alignments and vehicle working conditions”. 4th International Conference on

Transportation Information and Safety (ICTIS): 27-32. Banff, AB. DOI: 10.1109/ICTIS.2017.8047737.

Received 03.08.2020; accepted in revised form 20.10.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License