Article

citation information:

Szczucka-Lasota, B.,

Węgrzyn, T., Łazarz, B., Jurek, A., Wilczyński, K.I. Welding of pins to mobile platforms

arms. Scientific Journal of Silesian University

of Technology. Series Transport. 2020, 109,

177-186. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.109.16.

Bożena SZCZUCKA-LASOTA[1],

Tomasz WĘGRZYN[2], Bogusław

ŁAZARZ[3], Adam JUREK[4],

Krzysztof I. WILCZYŃSKI[5]

WELDING

OF PINS TO MOBILE PLATFORMS ARMS

Summary. There is an increasing

demand for mixed joints made of hard-weldable steels used in the construction

of transport means. An illustration of this is the welding of movable platform

elements such as a pin to arm joints. The pin is made of high-strength

structural steel S690 QL (1.8928) while the arm of the movable platform is

made of DOCOL 1200M steel from the AHSS group (Advanced High-Strength Steel).

Such a joint is not easy to make due to the different chemical composition

of both steels. The difference in thickness of welded elements creates an

additional difficulty. The thickness of the cylindrical pin is 40 mm, whereas

the thickness of the sheet metal used for the platform arm is much smaller and

amounts to 2 mm. Joints of varying thickness and chemical composition tend to

produce cracks in the heat-affected zone as well as in the weld. The purpose of

this article is to determine the most appropriate welding parameters and the

selection of additional materials to obtain correct joint with good mechanical

properties, free of welding defects and incompatibilities.

Keywords: civil engineering, transport, mobile platforms,

welding

1. INTRODUCTION

In

the construction of transport means, there is an increasing demand for welding

of new steel grades, including mixed steel joints that support high structural

strength [2,4,5,6,10,13]. An example of application of hard-welded mixed joints

are elements of movable platforms. This article examines the possibility of

making a correct mixed pin to arm joint of such a platform. High-strength

steels from the AHSS group (for example, DOCOL 1200M steel) are used for the

platforms’ arms, whereas lower strength steels (for example, S690 QL

steel) are used for the pins [11].

This

article focuses on multi-material welding of thin-walled construction of

movable platform arms with a pin of much greater thickness. The purpose of this

paper is to select the most appropriate welding process parameters to ensure

good mechanical properties of the mixed joint made of S690 QL and DOCOL 1200M

steels used in the construction of mobile platforms.

2. MATERIALS AND METHODS

Steel

S690 QL, from the group of high-strength steels, is increasingly used in civil

engineering and transport due to its high strength and high yield strength.

Those steels are primarily used for the loaded parts of welded structures, for

example, crane elements, mobile platforms, tanks or for pins used in the

construction of transport means. The use of S690 QL steel reduces the total

weight of a transport vehicle structure. The tensile strength of this steel is

high, at the level of 900 MPa, the yield strength is at 700 MPa and the

relative elongation is at the level of 15% [11,12]. During the welding of this

steel, a reduction of the mechanical properties of the joint compared to the

parent material can be observed. Therefore, it is recommended to limit the

linear energy during the welding process to the level of 4,5 kJ/cm [1,7,9,14].

DOCOL

1200 M steel from the AHSS group is characterised by very high strength, at the

level of 1200 MPa and a yield strength of 950 MPa. DOCOL 1200 M steel has a

twice lower relative elongation at a value of 7%. Typical applications of DOCOL

1200 M steel include advanced lifting equipment, mobile platforms as well as

truck frames [11,12]. Table 1 presents the mechanical properties of S690 QL and

DOCOL 1200M steels used for elements of moving platforms.

Tab. 1

Mechanical properties of

S690 QL and DOCOL 1200M steels [11]

|

Steel |

The yield point YS, MPa |

Tensile strength UTS, MPa |

Relative elongation A5,% |

|

DOCOL 1200M |

950 |

1250 |

7 |

|

S690 QL |

690 |

900 |

15 |

DOCOL

1200M and S690QL steels are considered as difficult to weld due to appearing

cracks in the weld (less often than in the heat-affected zone) [3]. Welding of

both of these steel grades (separately and in mixed joints) produce

difficulties due to the presence of a dominant martensitic structure in them [3,8,11].

Mixed joints create additional complications due to the differences in chemical

composition and varied plastic properties. Table 2 presents the chemical

composition of DOCOL 1200M and S690QL steel.

Tab. 2

Chemical properties of S690

QL and DOCOL 1200M steels [11]

|

Steel grade |

C% |

Si% |

Mn% |

P+S% |

Ni% |

Al% |

Mo% |

Ti% |

|

DOCOL 1200M |

0.11 |

0.2 |

1.7 |

0.012 |

0.1 |

0.041 |

0.05 |

0.025 |

|

S690

QL |

0.19 |

0.8 |

1.7 |

0.019 |

2.1 |

0.015 |

0.72 |

0.050 |

The

chemical composition of both steels is not similar. Furthermore, it is worth to

note much higher carbon content present in S690 QL steel than in DOCOL 1200 M

steel, which significantly increases its strength, however, worsening the

plastic properties at the same time. To improve the plastic properties of S690

QL steel, an additional higher content of Ni and Mo shall be introduced.

It

was decided to verify the possibility of proper circumferential welding of the

thick-walled pin (40 mm high and 40 mm in diameter) made of S690 QL steel to

the thin-walled arm of the mobile platform (with a thickness of 2 mm) made of

DOCOL 1200M steel. Further, we resolved to produce welds with the use of MAG

(Metal Active Gas) process testing the following gas mixture acting as a

shielding gas: Ar + 18% CO2 and Ar +10% CO2 (according to

the PN-EN 14175 norm).

The

following electrode wires were selected: UNION X90 (EN ISO 16834-A G 89 6 M21

Mn4Ni2CrMo) and UNION X96 (EN ISO 16834-A G 89 5 M21 Mn4Ni2, 5CrMo), their

chemical composition is presented in Table 3.

Tab. 3

Electrode

wires used in the research - chemical composition [1]

|

UNION |

C% |

Si% |

Mn% |

P% |

Cr% |

Mo% |

Ni% |

Ti% |

|

X90 |

0.10 |

0.8 |

1.8 |

0.010 |

0.35 |

0.60 |

2.3 |

0.005 |

|

X96 |

0.12 |

0.8 |

1.9 |

0.010 |

0.45 |

0.55 |

2.5 |

0.050 |

The

chemical composition of both wires is similar; however, it differs slightly

from the chemical composition of the welded steels. The parameters of

peripheral welding of the pin to the platform arm with the use of both

electrode wires were comparable. The diameter of the electrode wire was 1.0 mm,

arc voltage 18 V and welding current 110 A. In both cases, three different

peripheral welding speeds were verified: 25 mm/min, 35 mm/min and 45 mm/min.

According to literature recommendations, the welding speed was changed three

times to assess the linear energy that is most appropriate [11,14]. The source

of a direct current was connected to (+) on the electrode, the thin-walled weld

was single-stitched. Each time before the welding, pre-heating drying to the

temperature of 70°C was applied.

In

addition, a mixed testing joint of the tested sheets (DOCOL 1200 M and S690 QL)

was made with a thickness of 3 mm, to analyse the strength and bending

resistance. Similarly, as before, the diameter of the electrode wire was

1.0 mm, arc voltage 18 V and welding current 110 A. The weld was

single-stitched. Furthermore, in this part of the study two different electrode

wires: UNION X90 and UNION X96, as well as two various argon shielding

mixtures: Ar + 18% CO2 and Ar +10% CO2 (according to

PN-EN 14175 norm) were used. Each time before the welding, pre-heating drying

to the temperature of 70°C was applied.

3.

METHODS, SCOPE OF RESEARCH

The

research included non-destructive testing (NDT):

• visual testing (VT) of prepared welded joints was done

with the use of an eye armed with a magnifying glass at the magnification of

3× – test was done according to the PN-EN ISO 17638 norm,

assessment criteria according to the EN ISO 5817 standard,

• magnetic particle testing (MT) - tests were carried out

according to the PN-EN ISO 17638 norm, with assessment performed according to

the EN ISO 5817 standard, using a magnetic flaw detector of REM-230 type,

• radiographic tests - tests were carried out according to

the PN EN ISO 15614-1 norm. The type of radiation source was SMART 200.

Amongst

the destructive tests, the following assessments of the researched pin to

platform arm weld were performed:

• examination of the microstructure of specimens digested

with the use of Adler's reagent and a light microscope (LM),

• hardness measurement (HPO 250 hardness tester, HV10 test

method).

Additionally,

for a mixed testing MAG joint made of the two 3 mm thick sheets, the following

tests were carried out:

• tensile strength test using a machine (ZWICK 100N5A

strength testing machine),

• bending test (ZWICK 100N5A strength testing machine).

4.

RESULTS AND DISCUSSION

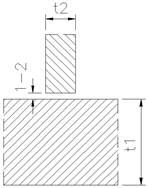

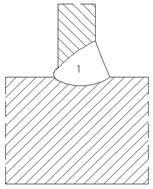

A

mixed butt-type welded joint (BW) from S690 QL steel with the thickness of t1 =

40 mm and from DOCOL 1200 M steel with the thickness of t2 = 2 mm was made. MAG

(135) welding method was applied in the down position (PA) according to the EN

15614-1 norm. The material preparation for single-stitched welding is presented

in Figure 1.

To assess the

weldability of the mobile platform components (pin and platform arm) two argon

mixtures: 82% Ar-18% CO2 and 90% Ar-10% CO2 were

selected to act as shielding gases, and the two electrode wires: UNION X90 and

UNION X96 were applied. Each time before the welding, pre-heating drying to the

temperature of 70°C was applied.

After welding, the

following non-destructive tests (NDT) were carried out: visual (VT),

magnetic-particle (MT) and radiographic.

The results of the

created mobile platform joint are presented in Table 4.

Table 4 data shows

that the type of shielding mixture, as well as the type of electrode wire and

especially the type of linear energy, affect the quality of the produced joint.

For all four cases tested, no cracks in the weld appeared only the welding

speed was at the level of 35 mm/min. Those welds received the quality level B

according to the PN EN ISO 5817 norm. The image quality was W18 according to

the EN ISO 19232-1 norm. Non-destructive testing showed that the less oxidising

argon mixture (90% Ar-10% CO2) is more appropriate as its use allows

to avoid cracks in welds made with a different speed than 35 mm/min.

Fig.

1. (a) Groove shape; (b) Welding method

Tab. 4

Assessment of non-destructive testing of the

movable platform joint

|

Shielding

gas |

Electrode

wire |

Welding

speed 25 mm/min |

Welding

speed 35 mm/min |

Welding

speed 45 mm/min |

|

90% Ar-10% CO2 |

X90 |

No cracks |

No cracks |

Cracks in the weld |

|

90% Ar-10% CO2 |

X96 |

Cracks in the weld |

No cracks |

No cracks |

|

82% Ar-18% CO2 |

X96 |

Cracks in the weld |

No cracks |

Cracks in the weld |

|

82% Ar-18% CO2 |

X96 |

Cracks in the weld |

No cracks |

Cracks in the weld |

4.1. Results of destructive testing

For further testing,

only joints made with the welding speed of 35 mm/min were considered. Joint

hardness distribution was carried out as well. The results are presented in

Table 5.

Tab. 5

Hardness distribution in a mixed joint

|

Wire |

Gas mixture |

DOCOL 1200M |

HAZ-1 |

Weld |

HAZ-2 |

S690 QL |

|

UNION X90 |

90% Ar-10%

CO2 |

395 |

317 |

376 |

386 |

256 |

|

UNION X96 |

90% Ar-10%

CO2 |

396 |

315 |

407 |

384 |

259 |

|

UNION X90 |

82% Ar-18%

CO2 |

398 |

312 |

381 |

380 |

257 |

|

UNION X96 |

82% Ar-18%

CO2 |

398 |

310 |

413 |

381 |

258 |

Analysing the data

from Table 5, it can be noted that the electrode wire UNION X90 is more

appropriate due to the similar hardness value in the whole joint (below 400

HV). Similar hardness in the entire welded joint promotes cracks resistance.

The use of UNION X96 electrode wire is less advantageous. The increased content

of C and Cr in the wire increases the hardness of the weld exceeding the

value of 400 HV. The weld hardness at the level of 413 obtained with the use of

UNION X96 electrode wire is too high and may cause joint cracks that occur when

the welding energy is not selected properly (Table 4). At the same time, it was

observed that the mixture of 90% Ar-10% CO2 is the most suitable to act as a

shielding gas. The weld made in the shield of 82% Ar-18% CO2

characterises with a higher hardness, which might be a result of numerous and

larger non-metallic oxide inclusions in the weld metal due to the more

oxidative nature of the shielding mixture [11].

4.2. Strength

tests

To obtain additional

information regarding the correctness of the joint, it was decided to perform

tensile strength tests. For this purpose, an additional mixed joint made of

other sheets (DOCOL 1200M and S690 QL) with a thickness of 3 mm was carried

out.

The MAG (135) welding

method was applied again in the down position (PA) and according to the

requirements of the EN 15614-1 norm. Once the joints welded with various

parameters were completed, tests of immediate tensile strength were performed.

Joint strength tests were carried out on the ZWICK 100N5A strength testing

machine. The results of the mechanical tests of the welds: S690 QL/DOCOL 1200M

(an average of three measurements) are presented in the Tables 6-7.

Tab. 6

Mechanical properties of the mobile platform joint

(mixed jointS690 QL /DOCOL1200M)

|

Welding

types |

Electrode

wire |

Shielding gases |

Rm, MPa |

Re, MPa |

A5, % |

|

S690 QL / DOCOL 1200M |

Union X90 |

90%

Ar-10% CO2 |

719 |

562 |

7.3 |

|

S690 QL / DOCOL 1200M |

Union X96 |

90%

Ar-10% CO2 |

741 |

589 |

6.9 |

|

S690 QL / DOCOL 1200M |

Union X90 |

82%

Ar-18% CO2 |

723 |

567 |

7.2 |

|

S690 QL / DOCOL 1200M |

Union X96 |

82%

Ar-18% CO2 |

745 |

591 |

6.8 |

The analysis of the

array data shows that the connectors were correctly made. The best plastic

properties were obtained for the joint created with the use of Union X90

electrode wire and the shielding gas mixture containing 90% Ar-10% CO2.

Union X96 wire supports greater joint strength, but at the cost of plastic

properties deterioration. The highest relative elongation value of the mixed

joint was obtained when welding with the use of MAG method, Union X90 electrode

wire and the gas mixture 90% Ar-10% CO2.

Afterwards, the

bending test of the created joints was performed. For the test, a sample with a

thickness of a = 3 mm, width of b = 20 mm, mandrel of d = 22 mm and support

spacing of d + 3a = 31 mm was used, the required bending angle was at the level

of 180°. Five bending measurements were carried out both on the face side

and on the root side of the weld.

Those joints that

obtained the best plastic properties (with the use of UNION X90, UNION X96

electrode wires and 90% Ar-10% CO2 and 82% Ar-18% CO2 gas

mixtures) were subjected to the bending test. The tests results are summarised

in Table 7.

The analysis of Table

7 shows that the joints were correctly made. No cracks or other

incompatibilities were found in the tested samples. However, cracks were

observed in the joints from the root of the weld side where the Union X96

electrode wire was used.

Tab. 7

Mixed joints bending test results

|

Welding

types |

Side deformation |

Side deformation |

Size [mm] |

Comments |

|

Union X90 |

90% Ar-10% CO2 |

Root of the weld |

3 x 20 |

No

cracks, no incompatibilities |

|

Union X90 |

90% Ar-10% CO2 |

Face of the weld |

3 x 20 |

No

cracks, no incompatibilities |

|

Union X90 |

82% Ar-18% CO2 |

Root of the weld |

3 x 20 |

No cracks,

no incompatibilities |

|

Union X90 |

82% Ar-18% CO2 |

Face of the weld |

3 x 20 |

No

cracks, no incompatibilities |

|

Union X96 |

90% Ar-10% CO2 |

Root of the weld |

3 x 20 |

Cracks in weld |

|

Union X96 |

90% Ar-10% CO2 |

Face of the weld |

3 x 20 |

No

cracks, no incompatibilities |

|

Union X96 |

82% Ar-18% CO2 |

Root of the weld |

3 x 20 |

Cracks in weld |

|

Union X96 |

82% Ar-18% CO2 |

Face of the weld |

3 x 20 |

No

cracks, no incompatibilities |

4.3.

Metallographic examination

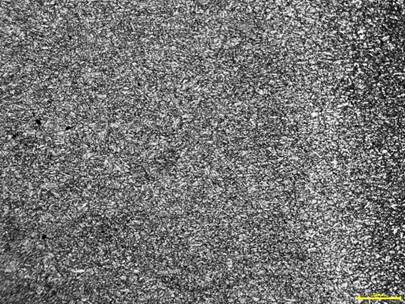

The microstructure

analysis was performed next. Similarly, the structure of those mixed joints

that presented the best relative elongation was analysed. The microstructure of

the cross-section of the S690 QL/DOCOL 1200M joint is presented in Figure 2.

Observations of

specimens digested in the Adler's reagent were performed on the Reichert light

microscope. A typical structure of the pin to arm joint made with the use of

UNION X90 electrode wire and in the shielding mixture of 90% Ar-10% CO2

is shown in Figure 2.

The results of the

structural tests indicate that in the pin to arm platform weld, martensitic and

fine-grained ferrite structures dominate. The results of all the tests

presented in this article were positive, confirming that the selected UNION X90

electrode wire, the gas mixture 90% Ar-10% CO2 and the selected

welding parameters are correct (U = 18 V, I = 110 A, v = 35 mm/min).

5.

CONCLUSION

In the construction

of transport means, there is an increasing demand for the use of mixed joints

made of high-strength steels with steels from the AHSS group. Steels S690 QL

and DOCOL 1200M are increasingly used to construct mobile platforms structures.

Mixed joints created from those steels are prone to welding cracks. This

article presents the selection of welding parameters to welding the pin (S690

QL steel) to movable platform arms (DOCOL 1200M steel). Apart from an

appropriate selection of gas mixture, type of electrode wire and voltage

parameters, it is important to determine the appropriate welding speed. During

the first part of the study, mixed joints made with different linear energy

were performed, promoting the selection of the most appropriate welding speed

(v = 35 mm/min) which did not produce welding defects and incompatibilities.

The possibility of making correct mixed joints was confirmed by non-destructive

and destructive tests. Furthermore, the tests showed that the most appropriate

way to make a mixed joint from S690 QL steel (used for the pin) with DOCOL

1200M steel (used for the platform arm) is the application of the protective

gas mixture 90% Ar-10% CO2 with a UNION X90 electrode wire during

the MAG welding. Those parameters produce joints without welding defects and

incompatibilities and promote comparable hardness of 380 HV on the entire

joint. The strength of the mixed joint obtained with such parameters is high,

at the level of 720 MPa. The change of argon gas mixture to a mixture with a

higher CO2 content (introduction of additional oxygen to the weld

metal) and the change of electrode wire (which increases the content of Fe and

Cr in the weld metal) leads to an increase in the strength of the joint and at

the same time to a decrease in its plastic properties.

Further, the

metallographic structure of the weld (made of Union X90 electrode wire in the

shielding gas mixture of 90% Ar-10% CO2) was assessed, with

dominating martensitic structure and a fine-grained ferrite. This leads to the

conclusion that the welding parameters should be carefully selected to avoid

cracks and other welding defects and incompatibilities.

Fig. 2. The

structure of the mixed joint made of Union X90 electrode wire in the shielding

gas mixture of 90% Ar-10% CO2. Martensite and fine-grained ferrite

are

the dominant phases in the weld

Acknowledgement

This paper is part of the COST

project, CA 18223.

References

1.

Agrawal K.C. 2001. Industrial Power

Engineering and Applications Handbook, 1st ed. Elsevier Inc. ISBN:

978-0-7506-7351-8.

2.

Benato R., F. Dughiero, M. Forzan, A. Paolucci.

2002. “Proximity effect and magnetic field calculation in GIL and in

isolated phase bus ducts”. IEEE Transactions on Magnetics 38(2):

DOI: http://dx.doi.org/10.1109/20.996202.

3. Ferenc K., P. Cegielski, T.

Chmielewski. 2015. Welding technique in practice: A guide by an engineer,

constructor and technologist. 1st ed. Verlag Dashofer.

4.

Giles

Tanya L., Keiichir Oh-Ishi O., Alexander P. Zhilyaev, Srinivasan Swami, Murray

W. Mahoney, Terry R. McNelley. 2009. „The Effect of Friction

Stir Processing on the Microstructure and Mechanical Properties of an Aluminum

Lithium Alloy”. Metallurgical and Materials Transactions 40(1):

104-115. DOI: http://dx.doi.org/10.1007/s11661-008-9698-8.

5. Golański D., T. Chmielewski, B.

Skowrońska, D. Rochalski. 2018. “Advanced Applications of

Microplasma Welding”. Biuletyn Instytutu Spawalnictwa w Gliwicach 62(5): 53-63. DOI: http://dx.doi.org/10.17729/ebis.2018.5/5.

6.

Hamilton C., S. Dymek, A. Węglowska, A. Pietras. 2018. “Numerical

Simulations for Bobbin Tool Friction Stir Welding of Aluminum 6082-T6”. Archives

of Metallurgy Materials 63(3): 1115-1123. DOI: http://dx.doi.org/10.24425/123784.

7.

IEEE Standard for Metal-Enclosed Bus. 2016. In:

IEEE Std C37.23-2015” (Revision of IEEE Std C37.23-2003). IEEE.

DOI: http://dx.doi.org/10.1109/IEEESTD.2016.7470712.

8.

Izairi N., F. Ajredini, A. Vevecka-Pfiftaj, P. Makreski, M. Ristova.

2018. „Microhardness evolution in relation to the

cFigtalline microstructure of aluminum alloy AA3004”. Archives of

Metallurgy Materials 63(3): 1101-1108. DOI: http://dx.doi.org/10.24425/123782.

9.

Jaeschke B., M. Węglowski, T. Chmielewski. 2017.

„Current State and Development Opportunities of Dynamic Power Source for

GMA Welding Processes”. Journal of Manufacturing Technologies

42(1): 23-30.

10. Samardžić

I., M. Dunđer, M. Katinić, N. Krnić. 2017. “Weldability

investigation on real welded plates of fine-grained high-strength steel

S960QL”. Metalurgija 56(1-2):

207-210. ISSN: 0543-5846.

11. Silva A., B. Szczucka-Lasota, T.

Węgrzyn, A. Jurek. 2019. „MAG welding of S700MC

steel used in transport means with the operation of low arc welding

method”. Welding Technology Review 91(3): 23-28. DOI: https://doi.org/10.26628/wtr.v91i3.1043.

12. Skowrońska B., J. Szulc, T.

Chmielewski, D. Golański. 2017. „Selected

Properties of Plasma+MAG Welded Joints of S700 MC Steel”. Welding

Technology Review 89(10): 104-111. DOI: http://dx.doi.org/10.26628/ps.v89i10.825.

13. Spišák

E., J. Majerníková, J. Slota. 2014. “Change of ears

creation of AHSS steels after heat treatment of zinc coating”. Metalurgija 53(4): 473-476. ISSN:

0543-5846.

14. Szymański G., A. Patecki. 1984. „Eddy

current and temperature of the sheath in tree-phase pipe sheathing

system”. IEEB Transaction of Magnetics 20(5): 2004-2006. DOI: http://dx.doi.org/10.1109/TMAG.1984.1063218.

Received 09.08.2020; accepted in revised form 28.10.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License