Article

citation information:

Kiedrowski, J., Jendro, G.,

Kamiński, A., Fabiś, P. Aerodynamics package for formula student car WT-02. Scientific Journal of Silesian University of

Technology. Series Transport. 2020, 109,

55-60. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.109.5.

Jakub KIEDROWSKI[1],

Grzegorz JENDRO[2],

Arkadiusz KAMIŃSKI[3],

Paweł FABIŚ[4]

AERODYNAMICS

PACKAGE FOR FORMULA STUDENT CAR WT-02

Summary. This paper is a summary

of the design and workmanship of the aero package vehicle Formula Student. Simulation research projects of the

aerodynamic system were conducted. The article proposes different variants of the

aero wings and conducted simulation studies of construction. The aerodynamics

system impact on strength and reliability of selected models was determined.

Keywords: Formula Student, aero pack, MES, simulation

1. INTRODUCTION

Formula Student (FS) is an

international competition between teams of universities and technical faculties

from around the world organised in Europe by IMechE. The idea behind the

competition is to design and execute a racing vehicle in accordance with the

rules of the competition. The creation of the team finished the car in given

time and in line with the need to gain the knowledge, discipline, cooperation,

foresight, and often compromises. Experience and knowledge gained in such

circumstances are invaluable and an important part of training top-notch

engineers. Undoubtedly, this is also a chance to test their skills in the real

world, under the pressure of time and project requirements. Of importance is

not only the designed maximum speed of the car but the balance between a number

of important elements to be taken into speed, economy of operation, aesthetics,

functionality and safety. The victory in the competition is only for those

teams that are able to give a complete project and get it for the highest

number of points. With the FS, students have the chance to establish contacts

with the local industry, and the industry has the opportunity to support the

development of its potential future executives. The basis for the formula

student undoubtedly is the idea of supporting the development of technical

ideas. It shows the importance of creating technical universities. Engineering

studies and profession play a huge role in human development, therefore, are of

great value to society.

2. VEHICLE AERODYNAMICS

During its movement, a car vehicle is loaded with forces

from flowing air. This air is used as a cooling medium for the engine element

and as an element improving for the vehicle's behaviour. Modern road vehicles

use the air washing over it to improve the stability of the vehicle behaviour

in curves. Especially in racing vehicles, so-called aerodynamic packages allows

the increase of the pressure force of the vehicle on the surface, which allows

obtaining higher speeds at bends [1]. General assumptions of the basics of

aerodynamics in relation to motor vehicles are presented in the paper Fuller et

al. [2]. The work applies to road vehicles, but the assumptions also apply to

racing vehicles. Methods of designing and making aerodynamic packages for

high-performance cars and racing cars are presented in [3 and 4]. The works presented

ways of designing racing cars, the impact of shape profiles on their downforce.

3. AERO PACKAGE FOR THE FORMULA STUDENT CAR

The

object of the research is a vehicle racing class Formula Student WT-02 equipped

with a four-cylinder, four-stroke SI engine with a capacity of 600 cm3.

Originally, this engine was powered by a carbureted system, however, in the

course of adapting the engine to the vehicle, it was converted to multi-point

injection system.

During

the project construction, in order to increase the dynamic qualities of the

vehicle, a charging system was applied using a turbocharger. These engine

modifications allowed to obtain 97 kW of power – a sufficient amount to

overcome the additional drag from the aerodynamics package.

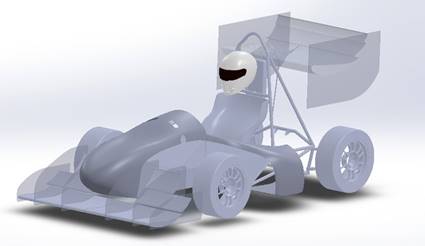

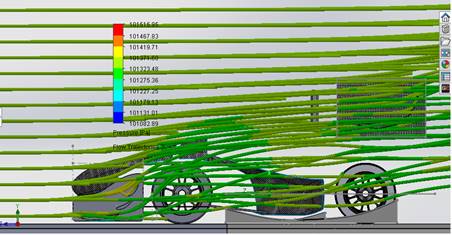

The

car was designed without any aerodynamics systems. During the season, after

race results analysis, the team took the decision to design the aerodynamical

systems. Systems should have front and rear wings and side aileron which

improve air flow to the cooling system and intercooler. These are presented in Fig. 1.

|

Fig.

1. View of car WT-02 with aerodynamical system |

4. PROJECT OF THE

AERODYNAMICAL SYSTEM

Angle

of attack α is

an angle between the chord line of an airfoil and the direction of the fluid

stream. According to literature, the lift coefficient CL increases

with increase of α.

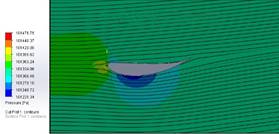

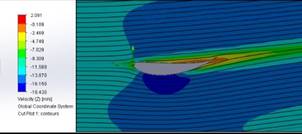

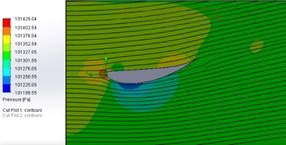

The peak for CL is obtained for α = 10÷15°. Three

airflow simulations were performed respectively for angles 5°, 10°,

15° and for each one of them, pressure and velocity contours were received,

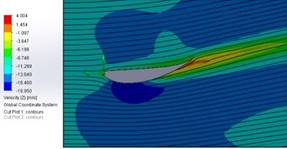

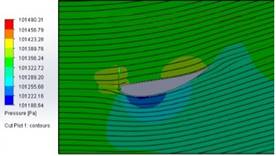

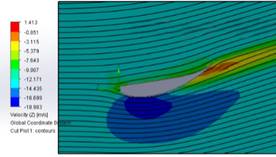

which are presented in Fig. 2-4. The simulation was made for the bottom airfoil

of the rear wing.

Fig.

2. Pressure and velocity contours for α = 5°

Fig.

3. Pressure and velocity contours for α = 10°

Fig.

4. Pressure and velocity contours for α = 15°

It

follows from the above that for angles 10° and 15° under- and

overpressure zones are located in similar places relative to the surface of the

airfoil and the pressure values are comparable. For 5° angle of attack, the

airfoil produces comparable underpressure to other settings but an explicit

overpressure zone is not created, therefore, this is not the most favourable

setting for a single element wing. However, the rear aerodynamic package is a

three-element wing, hence, for better cooperation between airfoils arnd for

guiding a part of the flow to the diffuser, the 5° angle of attack was

applied. The analysis for the rear wing is presented later.

Front

aerodynamic package consists of three airfoils, which are of various sizes and

inclination. The front wing design, in order to generate maximum downforce,

requires utilisation of utmost area, which is indirectly restricted by FSAE

rules. Applied arrangement and sizes of each airfoil are the results of

observations of similar constructions and many time-consuming airflow

simulations.

Fig.

5. Pressure contour for front wing package

From

Fig. 5, it follows that the greatest overpressure is generated over two most

leaning airfoils. The underpressure zone which is forming over the bottom

airfoil is unfavourable (this is the result of low angle of attack) but due to

this setting, a part of airflow is guided beyond the wing (in direction to the

diffuser) and also attached flow is obtained, which accumulates underpressure

underneath the wing. The stationary flap on the upper airfoil cumulates

overpressure above the wing that results in increasing downforce while

maintaining the size of the wing.

Rear

aerodynamic package, as well as front package, contains three airfoils at

various sizes and inclination. For the same reason as before, the bottom

airfoil has a low angle of attack (0°). However, the rear wing is greater

than the front wing because it is less spatially restricted and higher

downforce is preferred on the drive axle.

Fig.

6 presents the simulation of airflow for both wings assembled to the vehicle.

The streams from the front wing are directed on the way to the rear wing to

increase its efficiency.

Fig.

6. Vehicle flow simulation

The

total downforce deriving from the front and rear wing were calculated.

Downforce is a function of vehicle (airflow) velocity and it increases exponentially.

WT-02 car can maximally reach around 690 N of downforce at 100 kph. The D(v)

graph is presented in Fig. 7.

Fig. 7. Downforce vs. flow velocity

5. CONCLUSIONS

The

study simulations of airflows provided significant information about the influence

of airfoils shape and inclination to total achievable downforce. This research

leads to the following conclusions:

1. The increase in

inclination of a single airfoil affects in increasing downforce but it has to

be considered under the cooperation between airfoils on the wing, which is a

major issue.

2. To achieve greater

amounts of downforce, an aero package should be designed simultaneously with

the frame. In the discussed car, this was not done and there was no reasonable

possibility to assembly a diffuser.

3. Even though the aero

package was designed after constricting the vehicle, 150-200 N of downforce was

achieved in Endurance average speeds, which does not stand out from other

Formula Student vehicles performance.

It

seems reasonable to continue the research for the optimisation of the aero

package designand to perform tests on models in wind tunnel.

References

1.

Piechna J. 2000. Podstawy

aerodynamiki pojazdów. [In Polish: Fundamentals of vehicle aerodynamics]. Warsaw: WKiŁ.

2. Moffat J., W. Gater. 2016. Introduction to aerodynamics. School of

Engineering Blackpool and the Fylde Collage.

3. Fuller J., M. Best, N.

Garret, M. Passmore. 2013. “The importance of unsteady aerodynamics to

road vehicle dynamics”. Journal of

Wind Engineering and industrial Aerodynamics 117: 1-10.

4. Kshirsagar V., J.V.

Chopade. 2018. “Aerdynamics of High Performance Vehicles”. International Research Journal of

Engenineering and technology (IRJET) 05(03):

2182-2186.

5. Katz Joseph. 1995. Race car aerodynamics: designing for speed.

Cambridge: Bentley Publishers. ISBN: 978-0837601427.

6. 2017-18 Formula SAE Rules. SAE Interantional. 2016.

7. Milliken William F.,

Douglas L. Milliken. 1995. Race car

vehicle dynamics. SAE International. Warrendale. ISBN: 978-1-56091-526-3.

8. Kurowski Paul. 2013. Engineering Analysis with

SolidWorks Simulation 2013.

SDC Publlications. Mission. ISBN: 978-1-58503-784-1.

9. SOLIDWORKS Education

Edition - Fundamentals of 3D Design and Simulation. Dassault Systèmes SolidWorks

Corporation. Waltham. 2016.

Received 03.09.2020; accepted in revised form 03.11.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License