Article

citation information:

Mantič, M., Kuľka, J.,

Kopas, M., Faltinová, E., Hrabovský, L. Limit states of steel supporting

structure for bridge cranes. Scientific

Journal of Silesian University of Technology. Series Transport. 2020, 108, 141-158. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.108.13.

Martin MANTIČ[1],

Jozef KUĽKA[2],

Melichar KOPAS[3],

Eva FALTINOVÁ[4],

Leopold HRABOVSKÝ[5]

LIMIT

STATES OF STEEL SUPPORTING STRUCTURE FOR

BRIDGE CRANES

Summary. This paper describes a question of evaluation

necessity of bridge cranes using the method of limit deformation state and

oscillation damping. The solution was performed by means of theoretical

analysis and an experimental verification at the selected bridge crane. The

final result sounds that in the case of a correct strength computing of given

bridge crane, it is not necessary to also check deformation and damping of

oscillation as well.

Keywords: oscillation, damping, energy, experiment,

deflection, time

1. INTRODUCTION

The questions concerning

vibrations of the bridge cranes are analysed in many professional works from

various authors. For example, vibrations of the crane girder, which are

occurring as a consequence of the crane travel on the crane track, are

described by the authors in the works [1-3].

Scientific investigation

of crane oscillations, together with the presentation of possibilities on how

to eliminate these oscillations using a suitable form of the crane control

strategy, is presented in [4-7].

Other methods, which are

determined for the elimination of the crane oscillations by optimisation of the

crane control components and mechanisms, are introduced in [8-10].

Different proposals of a

dynamic model relating to the abovementioned problems are given in [11-14] and

the corresponding experimental methods are in

[15, 16].

Another

interesting approach to the investigation of mechanical vibration, damage of

transport machine parts and generation of failures is presented in [17-27].

Other

experimental studies dealing with the mechanical properties of a layered beam,

which is partially treated with a damping element based on a granular

material, offers [28].

The author of [29], is

focused on the assessment of vibration control performance using enhanced smart

constrained layer damping treatment with edge elements. The non-linear dynamics

of a crane is investigated in the contribution [30].

The commonly used or

standard approach to the solution of a damping process represents the

application of the logarithmic decrement, which enables estimation of the

damping ratio from a time history of the oscillation process.

Analysis of this method

and optimisation of the parameters during the processing and evaluation of the

results is presented in [31, 32].

A new algorithm OMI

(Optimization in Multiple Intervals), which is intended for computation of the

logarithmic decrement concerning the exponentially damped harmonic

oscillations, is described as well as compared with the classic computational

methods in the publications [33, 34].

According to these

articles, it is possible to say that the OMI algorithm is proved to be the best

solution in the computation of the logarithmic decrement and the resonant

frequency for high damping levels. Moreover, it is possible to take into

consideration, a typical causal relation between the wear process and wear

damage of constructional parts, which is introduced for example in [35].

The existing STN 27 0103 [36] informs the

design of steel crane structures according to two groups of limit states.

For

the first group of limit states, which lead to the loss of loading capacity or

the loss of position stability, the following criteria are central to the

design of steel supporting structure:

·

strength and stability,

·

fatigue strength,

·

position stability.

For

the second group of limit states, the following criteria are crucial:

·

static deformation (deflection, displacement, and twisting),

·

dynamic structure response (steel structure frequency, amplitude,

and damping).

The second group of limit states is outlined in the Article

X of the standard only in section 66, which states as follows:

“Deformation and oscillation damping must not affect operational safety

and must not interfere with proper crane function with regard to its work

specifications”. In Annex VIII, the standard recommends how to approach

the bridge crane evaluation.

To a great extent, the STN 27 0103 [36]

overlaps with the German DIN standard 15018 “Krane. Grundsätze

für Stahlwerke. Berechnung“ [37]

in the calculation procedures. This DIN, however, does not specify checking for

the limit state of deformation and damping.

This article lays out the theoretical analysis which

consequently ties into the experimental analysis on a particular bridge crane.

2. OSCILLATION

DAMPING OF A STEEL SUPPORTING STRUCTURE IN A BRIDGE CRANE

A degree of freedom in a

flexible system is conceived as a number of independent coordinates which

determine the location of all the system’s masses.

If the continuous

distribution of the flexible elements is small in comparison with the masses

distributed in the individual points, then the flexible element mass (m) can be

downplayed and only the coordinates of the masses distributed in the points

examined.

Let us propose that the

resistance of the surroundings is directly proportional to the speed in the

following relation:

Fresist = – k.v , where k > 0,

(1)

k – the damping

coefficient (kg.s-1).

The resistance force counters the speed which is

expressed by the minus sign in this formulation. If the acting restoring force

is directly proportional to the displacement, the equation of motion is as

follows:

![]() ,

(2)

,

(2)

c – spring stiffness (N.m-1).

Once the substitution is applied:

where b is the damping coefficient and the ω0 constant is the natural

angular frequency, that is, the angular frequency of the undamped harmonic

oscillator.

After the adjustment, we get the following equation of motion:

![]() .

(4)

.

(4)

The solution to the homogenous second order

differential equation points to the following formulation:

x = eλt, ![]() ,

, ![]() .

(5)

.

(5)

After we apply the function to Equation 4, we

get the following characteristic equation:

![]() ,

(6)

,

(6)

with this solution:

![]() .

(7)

.

(7)

The two ![]() values correspond to the general solution

to Equation 4 in the linear combination:

values correspond to the general solution

to Equation 4 in the linear combination:

![]() (8)

(8)

provided that λ1 ≠ λ2.

According to the extent of the damping, the

following scenarios can play out:

Ø

The damping is large and b2 – ![]() > 0, then both solutions of

the characteristic equation

> 0, then both solutions of

the characteristic equation ![]() are real numbers, and x has no

periodical element. Theoretically, in time t

→

are real numbers, and x has no

periodical element. Theoretically, in time t

→![]() the body gets back to the equilibrium position x = 0. If the damping is this large, the motion is called

aperiodic. Oscillation does not occur at all.

the body gets back to the equilibrium position x = 0. If the damping is this large, the motion is called

aperiodic. Oscillation does not occur at all.

Ø

The damping is such that b2 – ![]() = 0. In such a case, mathematics informs the solution to Equation 4 as the

function x = e-bt as well

as the function x = t.e-bt.

The general solution is their linear combination in the following form:

= 0. In such a case, mathematics informs the solution to Equation 4 as the

function x = e-bt as well

as the function x = t.e-bt.

The general solution is their linear combination in the following form:

![]() . (9)

. (9)

This motion is called critical aperiodic motion.

Ø

Damped oscillatory motion

occurs only when damping is small, if b2

– ![]() < 0. Then:

< 0. Then:

![]() where

where ![]() . (10)

. (10)

The general solution to the equation of motion

is expressed as follows:

![]() .

(11)

.

(11)

Along the lines of this procedure similar to the

harmonic oscillator case, substitution and adjustment bring forward the real

formulation of the general solution:

![]() .

(12)

.

(12)

The angular frequency ![]() is

smaller than the angular frequency at the undamped oscillation of the same

system, and the amplitude which also changes, exponentially decays away over

time:

is

smaller than the angular frequency at the undamped oscillation of the same

system, and the amplitude which also changes, exponentially decays away over

time:

![]() .

(13)

.

(13)

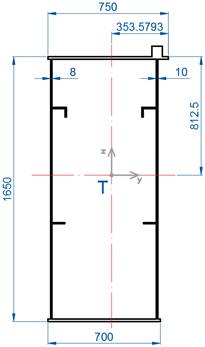

Damped oscillatory motion cannot be considered

periodic because the oscillating point does not reach its original

displacement. The motion here is quasiperiodic, and the T period can only be

conceived as a time interval, past which a mass point passes the equilibrium

position.

The damped oscillation period is:

![]() .

(14)

.

(14)

It is true that T > T0, where T0

is a period of natural oscillations.

If the damping is small, the period practically equals the period of

undamped oscillations. The period increases with growing damping.

The ratio of amplitudes of two consequent

maximum displacements are denoted as ![]() and

called damping.

and

called damping.

![]() .

(15)

.

(15)

The natural damping logarithm is the logarithmic

damping decrement δ.

δ = ln![]() = bT.

(16)

= bT.

(16)

From the dependence of amplitude on time (13),

it is apparent that the oscillation amplitude decreases e-times over a time

interval which equals 1/b. The

inverted value of the logarithmic damping decrement expresses the number of

oscillations, during which the oscillation amplitude changes e-times. The

greater the logarithmic damping decrement, the fewer the number of oscillations

necessary for a particular decrease of the amplitude.

The total mechanical energy of the oscillating oscillator

is proportional to the square of the amplitude. If the energy of the oscillator

with damping in the point in time t = 0

equalled E0, then the

mechanical energy of the oscillator decreases with increasing time according to

the equation:

![]() .

(17)

.

(17)

Friction causes energy dissipation; mechanical energy of

the oscillatory motion changes to thermal energy and the motion gradually

decays. For motion to be maintained in the oscillating system, then energy must

be supplied to it in a suitable way. Experiments confirm that for most

mechanical materials, the value of the dissipated energy during a single

oscillation cycle does not depend on frequency but that it is just the function

of the oscillation amplitude. On the other hand, it is damping that is used in

technical practices to eliminate undesirable vibrations.

Fig. 1. Dependence of amplitude on time at damped

oscillation

3. COMPUTER

AND EXPERIMENTAL APPLICATION ON THE REAL BRIDGE CRANE

Basic data about the

electrical bridge crane under examination:

Capacity Q = 500,000 N

Span of the crane L = 28,200 mm

Crane travel speed vtravel = 0.416 m/s

Lifting speed vlift = 0.0333 m/s

Trolley mass mtrolley = 6,680 kg

Main girder gravity G1 = 294,800 N

Main cross beam gravity G2 = 41,240 N

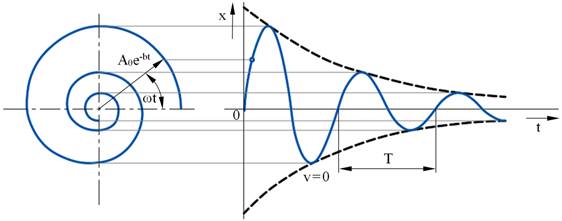

The calculated static values of the cross-section for the main girder

without stiffeners and the rails are illustrated in Fig. 2.

3.1. Calculating damping for the steel supporting crane

structure

According to STN 27 0103 titled “Design of

crane steel structures” – Calculation by limit states, Article X

– Steel supporting structure calculation based on the II. group of the

serviceability limit states – deformation: deformation and oscillation

damping must not affect operational safety and must not interfere with proper

crane function in regard to its work specifications”. The recommended

approach to the bridge crane evaluation is outlined in Annex VIII of the

referenced standard.

The new shape of the girder caused by

deformation is not detrimental to the operation if the deflections are smaller

than the recommended values outlined in [28] and are

caused by a random nominal loading, which includes as follows:

·

rated loading,

·

constant loading,

·

loading brought about by

natural mass, and the movable parts, which move in relation to the movement of

the load.

The new shape of the girder caused by

deformation is not detrimental to the operation if the deflections are smaller

than the recommended values outlined in [28] and are

caused by a random nominal loading, which includes as follows:

·

rated loading,

·

constant loading,

·

loading brought about by

natural mass, and the movable parts, which move in relation to the movement of

the load.

|

|

zT = 812.5 mm A = 55 556 mm2 Jy =

2.2396 x 1010 mm4 Jz = 4.

396 x 109 mm4 |

Fig. 2. Cross-section view of the

main girder in the bridge crane

For the electrical bridge crane (50t x 28.2 m)

with two main girders, along the top of which the trolley travels, the ratio

between the maximum deflection from random nominal loading in relation to

length, based on [37] can reach L/700

at most, that is, maximum deflection can reach:

![]() (18)

(18)

Such a deflection is not detrimental to the

crane operation. A steel supporting structure ought to meet the conditions of

damping while oscillating. For cranes with box girders, it is recommended that

the amplitude, after the nominal load of the oscillating bridge is set aside,

sank in the middle of the bridge within 15 s to 0.5 mm at most. The damping

time for a single-mass substitution system is determined by the following relation:

![]() (19)

(19)

![]() (20)

(20)

where

![]() is the maximum deflection of the girder from

rated loading in (mm),

is the maximum deflection of the girder from

rated loading in (mm),

f is

the frequency of natural oscillations in the girder (s-1),

![]() is

the logarithmic decrement of oscillation damping which depends on the ratio

between the girder height and length.

is

the logarithmic decrement of oscillation damping which depends on the ratio

between the girder height and length.

For the 50t x 28.2 m crane, the bridge girder height is h = 1650 mm (Fig. 2), hence, the ratio h/L = 1650/28200 = 0.0585.

Welded plate box girders are braced with a

compression boom, with a height to length ratio greater than 1:20. Based on [36], the

logarithmic damping decrement ![]() .

.

A girder spring constant can be determined by the following relation:

![]() (Nm-1)

(21)

(Nm-1)

(21)

where

E = 2.1 x 105 MPa is

the elastic modulus,

L = 28 200 mm is

the bridge length,

![]() = 2.2396 x 1010 mm4

is

the axial quadratic cross-sectional moment in relation to the neutral axis.

= 2.2396 x 1010 mm4

is

the axial quadratic cross-sectional moment in relation to the neutral axis.

Then c0

= 10066619.79 Nm-1.

The reduced mass of the girder, trolley, and all

mass oscillating with the girder, once the rated load is set aside, is

determined by the following relation:

![]() (kg)

(22)

(kg)

(22)

where

q – girder mass per length (kg.mm-1),

i – number of girders along which the trolley

travels,

mtrolley – the trolley’s natural mass

without load, including the mass which the trolley retains once the load is set

aside.

To determine the reduced mass of the girders,

the gravity of the individual crane components was relayed from the static

calculation of the equipment, according to which the girder mass where there

are no crane trolley units:

![]() (kg) .

(23)

(kg) .

(23)

The second girder’s mass includes the mass

of the crane travel units, of the switchgear, of the walkway, and of the

trolley wire (relayed from the static calculation):

![]() (kg).

(24)

(kg).

(24)

If we consider that the drawing documentation

for the trolley mass mtrolley

= 6680 kg, then the reduced mass of the girder without the travel units and the

walkway is:

![]() (kg)

(25)

(kg)

(25)

and for the girder with the travel units:

![]() (kg) .

(26)

(kg) .

(26)

The relationships (20) and (21) are used to

determine natural frequencies of the respective beams f1 = 4.847 Hz, f2

= 3.142 Hz.

Damping period of the respective girders

established from the value of the maximum static deformation from the rated

load is as follows:

![]() (mm) .

(27)

(mm) .

(27)

The damping period for the first and the second

girder equals:

![]() ,

,

![]() .

(28)

.

(28)

Because the damping period in both cases is

shorter than 15 s, the steel supporting crane structure meets the conditions

for the oscillation damping according to [36].

3.2. Experimental evaluation of damping in a steel supporting

crane structure

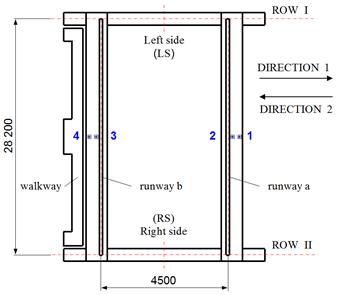

Fig. 3 shows the strain-gauge measurement that

was proposed and made on the electrical bridge crane with box girders. The

proposed methodology enables us to determine the stresses and to identify the

extent of the deflection caused by the suspended load, the amplitude of the

oscillating bridge in the middle of its span after unloading or lifting the

load, and the time of amplitude damping required for reaching a 0.5 mm

oscillation. Furthermore, Fig. 3 shows where the sensors were applied in a

diagram. Strain-gauge sensors were placed on the edges of the top beam flange

along the axis of the bridge symmetry. To measure, we used HBM strain-gauge

sensors, bonding cement (X60), measuring apparatus (Spider8) and the evaluation

software (Catman) also from HBM.

Strain-gauge measurement was made under the

following loading:

·

loading of the crane with a

trolley without load,

·

loading with a 48,000 kg load.

The measuring apparatus was balanced in the

empty trolley mode in the middle of the bridge length. The measured incremental

values of relative deformation were used by the Catman software to evaluate and

visualise time changes of normal stress increments in the points illustrated in

Fig. 3.

The measured time sequences of the relative

deformation were used to calculate normal stresses in the points of the

single-axis stress of the main girder.

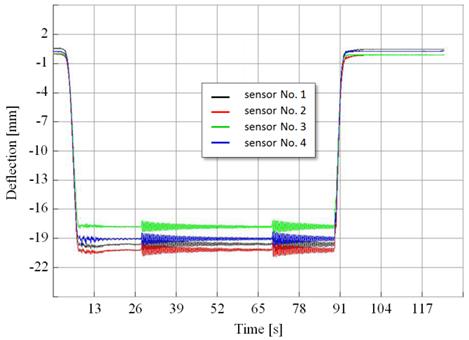

Fig. 4 illustrates the time changes of

incremental stress during intermittent lifting of the 48,000 kg load in the

points of measurements 1, 2, 3 and 4.

Fig. 3. Sensors in position on the crane

Because the load consisted of long slabs, which

could touch the ground at the start of the lift, the dynamic behaviour was

different from the repeated start of lifting if the load is suspended on a wire

rope.

A detailed examination of the time sequences

suggests that the extent of the oscillation amplitude at repeated lifts changes

with the length of the wound wire rope.

The measurement mode ends when the load is

lowered, during which the process of girder completing the oscillation does not

align with the theory of damped oscillation.

It is caused by the fact that the load touched

the ground again with some of its ends, and only then the load was completely

lowered onto the ground.

Damping is also affected by the suppleness of

the wire rope, which significantly reduces the time of damping to the required

amplitude.

With regard to the evaluation of the oscillation

amplitude and the damping time to the permissible 0.5 mm oscillation range

amplitude specified in [36], it is necessary to transform the stress time

sequence in the girders as shown in Fig. 4 into deforming the structure, that

is, into deflection time sequences.

Due to the small 1,390 mm trolley wheelbase and

the 28,200 mm bridge length, concentration of load mass into a point in the

middle of the bridge length.

Deflection in the middle of the girder w:

![]() (29)

(29)

where:

F – weight of half a load Q = 470,880 N,

L – bridge length 28,200 mm,

z – distance from the neutral axis to the top

beam flange,

![]() – measured relative

deformation in the point where the strain-gauge sensor is located,

– measured relative

deformation in the point where the strain-gauge sensor is located,

E – elastic modulus for the girder material,

![]() – stress in the point

where the strain-gauge sensor is located is equal.

– stress in the point

where the strain-gauge sensor is located is equal.

![]() (MPa).

(30)

(MPa).

(30)

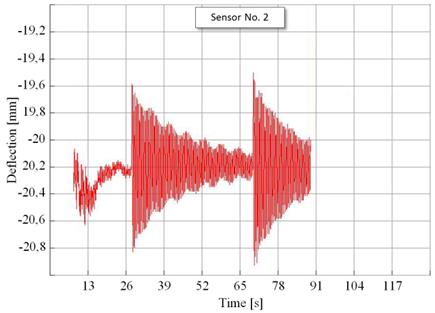

Fig. 5 shows the time sequence of the deflection in the interval between 26

and 91 s for the sensor no. 2 in the time sequence of the crane girder

deflections brought about by the 48,000 kg load established from the

measured values in the measurement points 1, 2, 3 and 4 corresponding to the stress

increments.

The relation (29) considers the cross-section according to Fig. 2, where

the cross-sectional characteristic similarly considers the rail, the top and

the bottom longitudinal stiffening.

Fig. 4. Time dependence of deflections

Fig. 5. Measurement interval for sensor No. 2

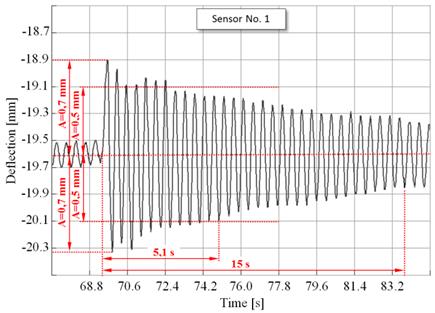

Fig. 6. Time sequence of deflections (Sensor No. 1)

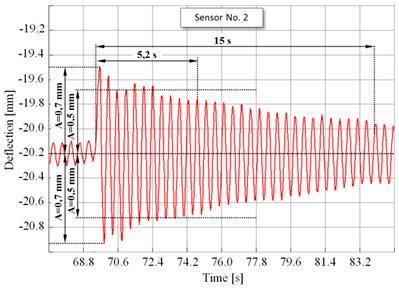

Fig. 7. Time sequence of deflection (Sensor No. 2)

3.3. Strain-gauge measurement evaluation

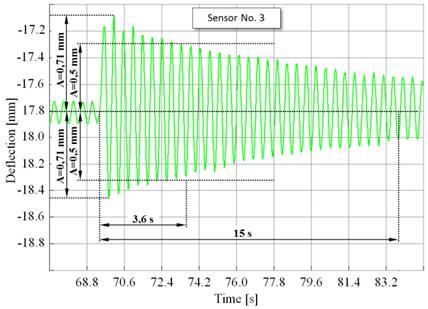

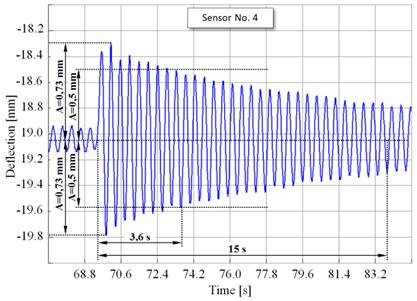

Figs. 6 and 9 show selected intervals of deflection time

sequences established from stresses at lifting from Fig. 4, which can be used

to determine the system dynamic characteristics. It involves determining the

natural angular frequency with respect to damping, natural frequency, and

natural oscillation period while considering the real damping in the girders

and in the mutual relations. The diagrams shown in Figs. 6 to 9 clearly depicts

the following periods of natural girder oscillation for the individual girders:

T1 = 0.4s and T2 = 0.47s. The amplitude sequence of the consecutive cycles

can be used to establish the logarithmic damping decrements, which is, however,

contingent on the potential influence of the oscillation amplitude. It is

necessary to state, however, that the values established by the strain-gauge

measurement are affected by the measure of suppleness, or conversely, the

stiffness of the wire rope, which translates into these quantities.

The values of cycle period established

experimentally are greater than the values acquired by the analytical

calculation. Other quantities are tied to the value by a precisely defined

dependence, and therefore, do not require further commentary.

Fig. 8. Time sequence of deflections (Sensor No. 3)

Fig. 9. Time sequence of deflections (Sensor No. 4)

3.4. Strain-gauge measurement evaluation

Figs. 6 and 9 show selected intervals of deflection time

sequences established from stresses at lifting from Fig. 4, which can be used

to determine the system dynamic characteristics. It involves determining the

natural angular frequency with respect to damping, natural frequency, and

natural oscillation period while considering the real damping in the girders

and in the mutual relations.

The diagrams shown in Figs. 6 to 9 clearly shows the

following periods of natural girder oscillation for the individual girders: T1 = 0.4s and T2 = 0.47s. The amplitude sequence of the consecutive cycles

can be used to establish the logarithmic damping decrements, which is, however,

contingent on the potential influence of the oscillation amplitude.

It is necessary to state, however, that the

values established by the strain-gauge measurement are affected by the measure

of suppleness, or conversely, the stiffness of the wire rope, which translates

into these quantities. The values of cycle period established experimentally

are greater than the values acquired by the analytical calculation. Other

quantities are tied to the value by a precisely defined dependence, and

therefore, do not require further elaboration.

4. SUMMARY AND CONCLUSION

When the structures are evaluated by

serviceability limit states and they are accessible by the operators or the

public, they must be designed to prevent personal discomfort (ex. natural

frequencies of the internal organs that are identical to the frequency of the

structure) caused by the dynamic effects of loading expressed by acceleration

(or speed) and frequency.

The crucial natural frequencies of the structure

and its parts ought to be sufficiently different from the frequencies of the

actuating forces to prevent resonance, which is also especially important from

the perspective of structural fatigue loading.

The standard [36] lists that

there are two limit values of natural frequency and specifically 3 and 5 Hz. It

also states that for the girders with a span L ≤ 10m, the criteria could be deemed met if the specified

extent of the deflection does not exceed 10 or 28 mm. It also points out that

in special cases, a dynamic calculation is needed to show that the resulting

acceleration and the frequency do not cause significant personal discomfort or

failure of the equipment or its parts. Furthermore, the value of relative

internal resistance is affected in no small measure by the losses of overcoming

passive resistance in relations between structural elements, which the

experimental measurement confirmed as well.

It follows that in fact, these relative

quantities of internal resistance are greater; hence, the greater values of the

logarithmic damping decrement. These are the actual reasons why it is

impossible not to take into consideration Section X

and Annex No.VII from the standard [36]. It can be concluded that provided the steel

supporting structure of the bridge crane complies strength-wise, it complies

also in terms of the second limit state of deformation and damping.

Acknowledgements

This article was elaborated in the framework of

the Grant Project VEGA 1/0110/18.

References

1.

He

Wei. 2018. „Vertical dynamics of a single-span beam

subjected to moving mass-suspended payload system with variable speeds”. Journal of Sound and Vibration 418:

36-54. ISSN: 0022-460X. DOI: https://doi.org/10.1016/j.jsv.2017.12.030.

2.

Michaltsos

George, Dimitrios Sophianopoulos,

Anthony Kounadis. 1996. „The effect of a moving mass and other parameters on the

dynamic response of a simply supported beam”. Journal of Sound and Vibration 191(3): 357-362. ISSN: 0022-460X.

DOI: https://doi.org/10.1006/jsvi.1996.0127.

3.

Wu

Jia-Jang. 2005. „Dynamic analysis of an inclined beam

due to moving loads”. Journal of

Sound and Vibration 288(1-2): 107-131. ISSN 0022-460X. DOI: https://doi.org/10.1016/j.jsv.2004.12.020.

4.

Fodor

Szabol, Carlos Vázquez, Leonid Freidovich, Nariman Sepehri. 2016. „Towards oscillation reduction in

forestry cranes”. BATH/ASME 2016

Symposium on Fluid Power and Motion Control. University of Bath, UK. 7-9

september 2016, Bath, UK. ISBN: 978-07918-5006-0. DOI: https://doi.org/10.1115/FPMC2016-1792.

5.

Hussien

Sharifah Yuslinda Syed, Rozaimi Ghazali, Hazriq Izzuan Jaafar, Chong Chee Soon.

2016. „Analysis of 3D gantry crane system by

PID and VSC for positioning trolley and oscillation reduction”. Journal of Telecommunication, Electronic and

Computer Engineering 8(7): 139-143. ISSN: 2180-1843.

6.

Masoud

Ziyad N. 2007. „Oscillation control of quay-side container cranes using

cable-length manipulation”. Journal

of Dynamic Systems, Measurement and Control 129(2): 224-228. ISSN:

0022-0434. DOI: https://doi.org/10.1115/1.2432362.

7.

Hu

Youmin, Bo Wu, Joshua C. Vaughan, WilliamE. Singhose. 2013. „Oscillation suppressing for an energy

efficient bridge crane using input shaping”. 9th Asian Control Conference (ASCC 2013). IEEE Advancing Technology

for Humanity. 23-26 June 2013. Istanbul, Turkey. ISBN:

978-1-4673-5767-8. DOI:

http://doi.org/10.1109/ASCC.2013.6606196.

8.

Chen

Yung-Feng, An-Chyau Huang.

2014. „Oscillation

reduction for overhead cranes with time-varying payload and rope length“.

Journal of the Chinese Institute of Engineers 37(2): 259-267. ISSN: 0253-3839. DOI: https://doi.org/10.1080/02533839.2012.757049.

9.

Singhose

William, Dooroo Kim, Michael Kenison. 2008. „Input shaping control of

double-pendulum bridge crane oscillations”. Journal of Dynamic Systems, Measurement, and Control 130(3). ISSN:

0022-0434. DOI: http://doi.org/10.1115/1.2907363.

10. Kiviluoto Sami, Lasse Eriksson, Heikki

N. Koivo. 2015. „Modelling and control of vertical oscillation in

overhead cranes”. American Control

Conference: 1290-1295. AACC American Automatic Control Council. 1-3 July

2015. Chicago, Illinois. ISBN: 978-1-4799-8685-9.

11. Zrnic Nenad Dj, Vlada M. Gašic,

Srdjan M. Bošnjak. 2015. „Dynamic response of a gantry crane system

due to a moving body considered as moving oscillator”. Archives of Civil and Mechanical Engineering

15(1): 243-250. ISSN: 1644-9665. DOI: https://doi.org/10.1016/j.acme.2014.02.002.

12. Gašic Vlada, Nenad Zrnic,

Aleksandar Obradovič, Srdan Bošnjak. 2011. „Consideration of

moving oscillator problem in dynamic responses of bridge crane”. FME Transactions 39(1): 17-24. ISSN:

1451-2092. DOI: https://doi.org/10.1016/j.acme.2014.02.002.

13. Jaafar Hazriq Jaafar, Z. Mohamed, J.J.

Jamian, Amar Faiz Zainal Abidin,

Anuar Mohamed Kassim, Z. Ab Ghani. 2013. „Dynamic behaviour of a

nonlinear gantry crane system”. Procedia

Technology 11: 419-425. ISSN: 1877-7058. DOI: http://doi.org/10.1016/j.protcy.2013.12.211.

14. Hu Youmin, Bo Wu, Joshua Vaughan,

Willam E. Singhose. 2013. „Oscillation suppressing for an energy

efficient bridge crane using input shaping”. 9th Asian Control Conference (ASCC). Asian Control Association. 23

June 2013 Istanbul, Turkey. ISBN:

978-1-4673-5767-8. DOI: http://doi.org/10.1109/ASCC.2013.6606196.

15. Padula Fabrizio, Antonio Visioli,

Domenico Facchinetti, Alberto Saleri. 2015. „A dynamic inversion

approach for oscillation-free control of overhead cranes”. 20th IEEE International Conference on Emerging

Technologies and Factory Automation (ETFA

2015): 337-343. IEEE Industrial Electronics Society (IES). 08-11 September

2015, Luxembourg City, Luxembourg. ISBN: 978-1-4673-7930-4.

16. Ece Mehmet Cem, Metin Aydogdu, Vedat

Taskin. 2007. „Vibration of a variable cross-section beam”. Mechanics Research Communications 34(1):

78-84. ISSN: 0093-6413. DOI: http://doi.org/10.1016/j.mechrescom.2006.06.005.

17. Grega Robert, Jozef

Krajňák, Lucia Žuľová, Gabriel Fedorko, Vieroslav Molnár. 2017. „Failure

analysis of driveshaft of truck body caused by vibrations”. Engineering Failure Analysis 79:

208-215. ISSN: 1350-6307. DOI: https://doi.org/10.1016/j.engfailanal.2017.04.023.

18. Czech P. 2013. “Diagnosing a car engine fuel

injectors' damage”. Communications in Computer and Information Science 395: 243-250. DOI:

https://doi.org/10.1007/978-3-642-41647-7_30. Springer, Berlin, Heidelberg.

ISBN: 978-3-642-41646-0; 978-3-642-41647-7. ISSN: 1865-0929. In: Mikulski Jerzy

(eds), Activities of transport telematics,

13th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 23-26, 2013.

19. Czech P. 2012. “Determination of the course

of pressure in an internal combustion engine cylinder with the use of vibration

effects and radial basis function - preliminary research”. Communications in

Computer and Information Science 329:

175-182. DOI: https://doi.org/10.1007/978-3-642-34050-5_21. Springer, Berlin,

Heidelberg. ISBN: 978-3-642-34049-9. ISSN: 1865-0929. In: Mikulski Jerzy (eds),

Telematics in the transport environment,

12th International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 10-13, 2012.

20. Haniszewski Tomasz. 2017. „Modeling the dynamics of cargo lifting process by overhead crane for

dynamic overload factor estimation”. Journal of Vibroengineering

19(1): 75-86. DOI: 10.21595/jve.2016.17310. ISSN: 1392-8716.

21. Gąska Damian, Tomasz Haniszewski. 2016.

“Modelling studies on the use of aluminium alloys in lightweight

load-carrying crane structures”. Transport

Problems 11(3): 13-20. DOI: 10.20858/tp.2016.11.3.2. ISSN: 1896-0596.

22. Haniszewski Tomasz, Damian Gaska. 2017.

“Numerical modelling of I-Beam jib crane with local stresses in wheel

supporting flanges - influence of hoisting speed”. Nase More 64(1): 7-13. DOI: 10.17818/NM/2017/1.2. ISSN: 0469-6255.

23. Kosicka E.,

Kozłowski E., Mazurkiewicz D. 2015. „The use of stationary tests for analysis of monitored residual

processes”. Eksploatacja i

Niezawodnosc – Maintenance and Reliability 17(4): 604-609.

DOI: http://dx.doi.org/10.17531/ein.2015.4.17.

24. Mazurkiewicz D. 2014. „Computer-aided

maintenance and reliability management systems for conveyor belts”. Eksploatacja i Niezawodnosc – Maintenance and

Reliability

16(3): 377-382.

25. Mazurkiewicz D. 2010. „Tests of extendability

and strength of adhesive-sealed joints in the context of developing a computer

system for monitoring the condition of belt joints during conveyor

operation”. Eksploatacja i

Niezawodnosc – Maintenance and Reliability 3: 34-39.

26. Czech P. 2011. “Diagnosing of disturbances in

the ignition system by vibroacoustic signals and radial basis function -

preliminary research”. Communications

in Computer and Information Science 239: 110-117. DOI:

https://doi.org/10.1007/978-3-642-24660-9_13. Springer, Berlin, Heidelberg.

ISBN: 978-3-642-24659-3. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Modern transport telematics, 11th International

Conference on Transport Systems Telematics, Katowice Ustron, Poland, October

19-22, 2011.

27. Czech

Piotr. 2011. „An intelligent approach to wear of piston-cylinder assembly

diagnosis based on entropy of wavelet packet and probabilistic neural networks”.

Communications in Computer and

Information Science 239: 102-109. DOI:

https://doi.org/10.1007/978-3-642-24660-9_12. Springer, Berlin, Heidelberg.

ISBN: 978-3-642-24659-3. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Modern transport telematics, 11th International

Conference on Transport Systems Telematics, Katowice Ustron, Poland, October

19-22, 2011.

28. Bajkowski Jacek Mateusz, Bartlomiej

Dyniewicz, Czeslaw I. Bajer. 2015. „Damping properties of a beam

with vacuum-packed granular damper”. Journal

of Sound and Vibration 341: 74-85. ISSN: 0022-460X. DOI: https://doi.org/10.1016/j.jsv.2016.05.006.

29. Balamurugan Varadarajan, Sadagopan

Narayanan. 2002. „Active-pasive hybrid damping in beams with enhanced

smart constrained layer treatment”. Engineering

Structures 24(3): 355-363. ISSN: 0022141-0296. DOI: https://doi.org/10.1016/S0141-0296(01)00101-8.

30. Blackbur D., W. Singhose, J. Kitchen,

V. Patrangenaru, J. Lawrence, T. Kamoi, A. Taura. 2010. „Command shaping

for nonlinear crane dynamics”. Journal

of Vibration and Control 16(4): 477-501. ISSN 1077-5463. DOI: http://doi.org/10.1177/1077546309106142.

31. Tweten Denis. J., Zach Ballard, Brian

P. Mann. 2014. „Minimizing error in the logarithmic decrement method

through uncertainty propagation”. Journal

of Sound and Vibration 333(13): 2804-2811. ISSN: 0022-460X. DOI: https://doi.org/10.1016/j.jsv.2014.02.024.

32. Magalas Leszek B., T. Malinowski. 2003.

„Measurement techniques of the logarithmic decrement”. Solid State Phenomena 89: 247-260. ISSN:

1662-9779. DOI: https://doi.org/10.4028/www.scientific.net/SSP.89.247.

33. Stanislawczyk A. 2006. „Advanced

techniques for determining high and extreme high damping: OMI – a new

algorithm to compute the logarithmic decrement”. Key Engineering Materials 319. ISSN: 1662-9795. DOI: https://doi.org/10.4028/www.scientific.net/KEM.319.231.

34. Magalas Leszek B., Mariusz Majewski.

2015. „Hilbert-twin-a novel hilbert transform-based method to compute

envelope of free decaying oscillations embedded in noise, and the logarithmic

decrement in high-resolution mechanical spectroscopy HRMS”. Archives of Metallurgy and Materials

60(2): 1091-1098. ISSN: 1733-3490. DOI: 10.1515/amm-2015-0265.

35. Lan Qingqun, Manicka Dhanasekar,

Yunendar Aryo Handoko. 2019. „Wear damage of out-of-round wheels in rail

wagons under braking”. Engineering

Failure Analysis 102: 170-186. ISSN: 1350-6307. DOI: https://doi.org/10.1016/j.engfailanal.2019.04.019.

36. STN 27 0103: 1989. Navrhování ocelových konstrukcí

jeřábů. Výpočet

podle mezních stavů. Praha. Úřad pro normalizaci a

měření. [In Slovak: STN 27 0103: 1989. Design of Steel Crane Structures. Calculation According to Limit States. Praha. Czech Office for Standardisation and Measuring].

37. DIN 15 018: 1984. Krane. Grundsätze für

Stahltragwerke. Berechnung. Berlin. Deutsches Institut für Normung.

[In German: DIN 15 018: 1984. Cranes. Steel Supporting Structures. Calculations. Berlin.

German Institute for Standardisation].

Received 11.03.2020; accepted in revised form 12.05.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License