Article

citation information:

Synák, F., Rievaj, V.,

Kučera, M., Šebök, M., Skrúcaný, T. Effect of repeated

vehicle braking on the warming of selected parts of the vehicle. Scientific Journal of Silesian University of

Technology. Series Transport. 2020, 107, 183-196. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.107.14.

František SYNÁK[1],

Vladimír RIEVAJ[2], Matej

KUČERA[3],

Milan ŠEBÖK[4], Tomáš SKRÚCANÝ[5]

EFFECT

OF REPEATED VEHICLE BRAKING ON THE WARMING OF SELECTED PARTS OF THE VEHICLE

Summary. The friction brakes convert a significant part of a

vehicle’s kinetic energy into thermal energy. Some of its parts is

distributed to the places around the brakes, and another part is accumulated in

several vehicle components. This article is focused on the measurement of

temperature increase of selected vehicle components during re-deceleration.

These components include brake discs, brake pads, calliper, wheel rim and tire

side in the area of its bead and tread. The measurements were performed during

the repeated braking of a fully-loaded vehicle according to ECE Regulation No

13 - type I.

Keywords: repeated braking, temperature, brake, heat,

road safety

1. INTRODUCTION

The purpose of friction brakes during vehicle motion is to convert part

of the vehicle’s kinetic energy to another energy [1], and thus, enable the

vehicle to stop or slow down [2]. In the vehicle’s friction brakes,

specifically, where the brake pads contact the friction disc, kinetic energy is

primarily converted into thermal energy [3, 4]. Heat is further distributed to

the other parts of the vehicle as well as to ambient air [5].

Heat accumulated in the friction disc and brake pads can increase the

coefficient of friction to some extent [6]. However, after exceeding a certain

heat value, which is usually 350°C for constant temperature and 800°C

for peak temperature, permanent adverse changes in a material can occur [7]. As

a result of too high temperatures, a vitreous layer can occur, so the

coefficient of friction between the disc and pad is decreased. The disc can

also change its shape, it can be corrugated [8]. Furthermore, concerning the

brake pad, it can lead to separation or destruction of friction lining

resulting in the loss of brake control [9].

Heat from the brake pads also runs to the brake calliper. There is a

piston mounted which is extruded by brake fluid [10]. Therefore, brake fluid is

similarly being heated. An important parameter of brake fluid is its boiling

point. Since it is a hydroscopic fluid, it absorbs moisture through the rubber

gaskets and hose’s sides. The moisture accumulated in the brake fluid

reduces its boiling point [11]. If the brake fluid is heated at boiling point,

the water contained is being transformed into steam. Instead of fluid, steam is

compressible, thus, heating the brake fluid above its boiling point can weaken

the brake control. Wet boiling point, that is, the brake fluid’s boiling

point in a vehicle, usually varies about 170°C [12].

The cycle of heating further includes the rims of wheels as well as tire

beads. The tire bead is the only place where the rim has a connection with the

tire [13]. In the case of excessively high temperatures, there could be a lack

of connection between the rim and tire bead, and it would adversely affect the

vehicle features [14]. Heating of tire disc and rim causes heating of air in

the tire, and it can have an effect on the increase of pressure in the tire

[15].

This article focuses on the impact of vehicle intense deceleration on

the temperature of brake disc and pads, brake calliper, rim of a wheel as well

as on tire beads and sides. The measurements were performed during a vehicle

driving according to the amended methodology of ECE Regulation No 13 - type I

testing. This regulation sets the conditions of brake efficiency testing

during re-deceleration [16]. The results, therefore, reflect the testing status

under legislative conditions.

Significant consideration was given to the warming of brakes during

repeated braking in scientific publications [28, 29, 30]. However, this

research is predominantly focused only on the brake disc itself, or even on the

brake pad [8, 31, 32]. Therefore, the purpose of this article is to measure the

temperature of the other vehicle parts that are being warmed during repeated

braking. Since some of the components are not part of the braking system, yet they

are affected by it and determine the efficiency of braking.

Such research can likewise be done via mathematical modelling as seen in

the publications [6,8,32,33]. The results published in this article were

gathered trough real measurements, although it can be said that the results

from mathematical modelling are not too diverse from those gathered via real

measuring [32].

It can be expected that particular components of the brake disc will

have different temperatures depending on their distance from the centre [31]. To

achieve sufficient accuracy, the brake disc’s temperature will be

measured in the centre of its friction surface [34, 36]. Such accuracy supports

the fact that the measurement in this article is focused on the vehicle

operation, and not on the material from which the components are made

[35].

It is assumed that the components at which the temperature is measured,

will reach a limit temperature but they will not be destructed or permanently

damaged.

2. METHODOLOGY

2.1. Measurement procedure

The general binding ECE Regulation

No 13H describes uniform provisions concerning the approval of passenger cars

in terms of deceleration. Besides other tests, the regulation also provides

type I testing. While testing, the service brakes are tested by being

decelerated 15 times and released with the vehicle loaded under conditions

listed in Tab. 1.

Tab. 1

Test conditions

according to ECE 13, type I

|

V1 (km.h-1) |

V2 (km.h-1) |

Δt (s) |

n |

|

80% Vmax ≤ 120 |

0,5 V1 |

45 |

15 |

where:

V1 is initial speed at the beginning

of deceleration,

V2 is speed at the end of

deceleration,

Vmax is maximum vehicle speed,

n is number of deceleration,

Δt is duration of braking cycle, that

is, time taken between the beginning of one deceleration and the following

beginning of another deceleration [16].

If parameters of a vehicle are not

able to keep the prescribed duration, the regulation permits to make this time

longer. There must always be at least 10 s available for the initial speed of

braking stabilisation.

To enable the temperatures to be

distributed in the required measurement points at the measurement accuracy

acceptable, it was necessary to keep the wheels stable during temperature

measurements [17]. The methodology according to ECE No 13, I has been adjusted

to this situation and, similarly to the situation at which mechanical energy

that is transformed into heat during deceleration would have reached the same

value as for unadjusted methodology. Therefore, the zero speed and the

following relation were needed (1):

![]() (1)

(1)

where:

ΔEKEHK is the difference of kinetic energies at

the beginning and at the end of one braking cycle according to ECE No 13 H,

ΔEKMSR is the difference of kinetic energies at

the beginning and at the end of one surrogate braking cycle.

Equation 1 can be detailed as

follows (2):

![]() (2)

(2)

where:

m is vehicle mass,

V1 is initial speed at the beginning

of braking according to ECE No 13 H,

V2 is speed at the end of braking

according to ECE No 13 H,

VA is initial speed wanted at the

beginning of surrogate braking cycle,

VB is speed at the end of the

surrogate braking cycle. VB

= 0 [18].

After having the values substituted

(3):

![]() (3)

(3)

After having the initial speed

wanted VA (4):

![]() (4)

(4)

To maintain the amount of energy

transformed, the initial braking speed of 103.9 km.h-1 was

calculated.

Time is very important for the

distribution of heat. To maintain the time of mechanical energy transformation

to thermal energy, it is necessary to maintain the same time of deceleration

(5):

![]() (5)

(5)

where:

b is deceleration required according

to ECE No 13 H, 3m.s-2,

Dv is speed difference at the

beginning and at the end of deceleration [m.s-1],

t is time needed for achieving the

change required while deceleration b [19].

Deceleration time can be calculated

via Equation 6, by substituting the values according to ECE Regulation No 13, Equation

5:

(6)

(6)

After having the time of

deceleration t (7):

(7)

(7)

The deceleration was repeated 15

times at the initial driving speed of 103.9 km.h-1 up to the final

stopping. Duration of one deceleration was 5.56 s.

Fig. 1 depicts the actual course of

driving speed depending on time.

Fig. 1. Course of driving speed depending on time

2.2 Introduction of parameters into

the dynamometer

The measurements were performed at

the cylinder test station MAHA MSR 1050. Measuring under laboratory conditions

was provided with higher accuracy when compared to road traffic measuring [20].

Fig. 2 shows the vehicle during its measuring at the cylinder test station MAHA

MSR 1050.

Fig. 2. Vehicle used for measuring and MAHA MSR 1050

The cylinders of the cylinder test

station can both be decelerated and accelerated. To have the cylinder values at

the level of a situation in which a vehicle is real-road driving, it is

necessary to introduce these values into the cylinder test station’s

control computer. The values are achieved by the coasting deceleration

measurement of vehicle resistance under the conditions of Standard EN 30 0556.

Such measurement relies on a vehicle with prescribed laden mass which is

accelerated up to the speed about 110 km.h-1; disconnection between

the engine and wheels and on the recording of vehicle coasting. Fig. 3 depicts

the vehicle deceleration during measurement.

Fig. 3. Vehicle deceleration during coasting deceleration

measurement

The recorded vehicle speed that

depends on the time of disconnection between the engine and wheels is further

introduced into the cylinder test station’s computer. Based on these

values and measurement results, the computer sets the values of deceleration or

acceleration directly at the cylinders during particular driving modes. Thus,

the cylinder test station can fully provide a road driving simulation.

2.3. Vehicle used for measurements

The measurements were performed with

the Kia Ceed. Its technical parameters are given in Tab. 2.

Tab. 2

Technical

parameters Kia Ceed [21]

|

Engine |

1.6 CVVT |

|

Year of construction |

2007 |

|

Engine power |

92 kW/6200 min-1 |

|

Engine torque |

154 Nm/4200 min-1 |

|

Transmission |

5 gearbox, manual |

|

Type of bodywork |

Hatchback |

|

Overall mass |

1,730 kg |

|

Front brakes |

disc, air-cooled, ribbed |

|

Outer diameter of brake

disc |

280 mm |

|

Size of brake pads l x w x

d |

130 x 58.1 x 16.7 mm |

2.4. Device used for temperature

measurement

The temperatures of selected vehicle

parts were measured via FLIR E60 Thermal Imaging Camera shown in Fig. 4.

Fig. 4. Device used for temperature measurement [22]

Table 3 shows the technical

parameters of the device used.

Tab. 3

The

technical parameters of FLIR E60 [23]

|

Ir resolution (array size) |

76,800 (320 x 240) |

|

Temperature range |

-20 to 650°C |

|

Accuracy |

±2% rdg. or 2°C |

|

Thermal sensitivity |

<0.05°C (50mK) |

|

Frame refresh |

60 Hz |

|

Field of view |

25° x 19°; Optional lenses available |

2.5. Measurement course

The vehicle brakes were heated up to

the operational temperature by deceleration repetition [24, 25, 26]. Then, the

pedometer sensor was fitted to the brake pedal and its screen was located in

the driver’s field of view to enable them to see the value of brake pedal

force at every moment (Fig. 5).

Fig. 5. Pedometer sensor CORSYS

The brake pedal force at which the

deceleration had achieved the parameters calculated was known. After having the operational temperature

of brakes [27], the pictures by the thermographic camera were taken and the

vehicle was accelerated up to the speed of 103.9 km.h-1. Afterwards,

using the fifth transmission gear, the driver depressed the brake pedal sharply

in that force as had been measured during prescribed deceleration. When

the engine had its speed under 900 min-1, the driver depressed

the clutch to avoid the engine’s switching off. Then, the

thermographic camera took the pictures when the wheels were stabilised and the

driver again accelerated the vehicle up to the speed of 103.9 km.h-1.

The whole cycle was repeated 15 times and the time of one cycle was 45 s.

3. RESULTS

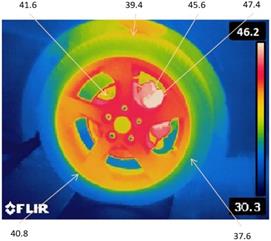

Fig. 6 shows the temperatures of

measured points before the beginning of the measurement. The temperature is

given in °C.

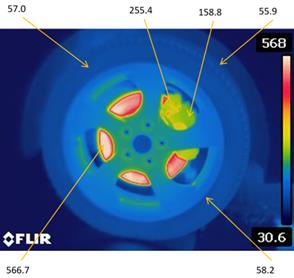

As seen from the comparison of both Figs.

6 and 7, before measuring and after heating, the highest temperature was on the

wheel disc, in the area of its nave. After the fifteenth measurement, the

highest temperature could be seen in the area of the brake disc.

The tables below show the

temperatures of the components’ surface after particular measurements.

The results from 1st up to 7th measurement are given in Tab.

4, while Tab. 5 shows the measurements from 8th and 15th.

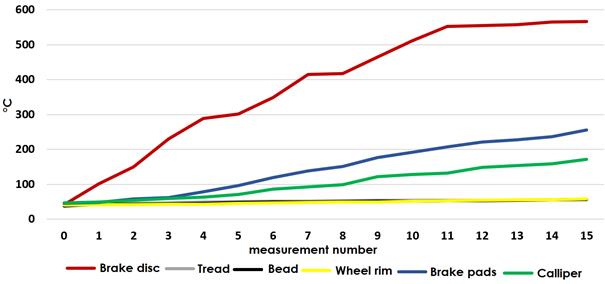

For better transparency, Fig. 8

shows the measurement results in the form of a graph.

As seen from the Fig. 8, the highest

growth in temperature, from 41.6°C up to 566.7°C, relates to the

surface of the brake disc. Such result is predominantly due to the brake

disc’s feature of absorbing thermal energy that is converted from kinetic

energy and shifting such energy further. The brake pad has the same

feature even though it had lower temperatures. This resulted from

the measurement methodology since the temperature was measured opposite to

the side when there is a connection with the friction area of the brake disc.

The same course of temperature can also be seen in the surface of the brake

calliper.

Fig. 6. Initial temperatures

Fig.7 shows the temperatures of

particular components after the final (15th) measurement

Fig. 7. Temperatures after the final measurement

Tab. 4

Measurement

results no. 1-7

|

Measurement |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

Brake disc [°C] |

41.6 |

100.9 |

149.4 |

230.2 |

288.5 |

301.4 |

348.1 |

415.2 |

|

Tire tread [°C] |

39.4 |

44.2 |

45.2 |

46.9 |

48.7 |

50.2 |

51.4 |

52.4 |

|

Tire side [°C] |

37.6 |

43.1 |

43.4 |

43.9 |

45.8 |

48.0 |

48.7 |

49.8 |

|

Rim [°C] |

40.8 |

41.5 |

41.6 |

42.8 |

43.2 |

45.2 |

46.5 |

48.1 |

|

Brake pad [°C] |

45.6 |

47.6 |

57.9 |

61.5 |

78.1 |

96.3 |

119.9 |

139.0 |

|

Calliper [°C] |

47.4 |

48.8 |

54.5 |

59.1 |

63.1 |

70.8 |

86.0 |

92.1 |

Tab. 5

Measurement

results no. 8-15

|

Measurement |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

|

Brake disc [°C] |

417.3 |

464.4 |

512.2 |

552.5 |

555.0 |

557.1 |

565.1 |

566.7 |

|

Tire tread [°C] |

53.2 |

53.9 |

54.2 |

54.6 |

54.7 |

55.0 |

55.3 |

55.9 |

|

Tire side [°C] |

50.7 |

51.3 |

52.2 |

52.7 |

53.2 |

54.5 |

55.9 |

57.0 |

|

Rim [°C] |

48.7 |

49.6 |

52.3 |

53.7 |

54.9 |

55.2 |

55.7 |

58.2 |

|

Brake pad [°C] |

151.3 |

177.2 |

192.1 |

206.7 |

221.3 |

227.9 |

237.1 |

255.4 |

|

Calliper [°C] |

99.0 |

121.9 |

127.9 |

132.5 |

148.8 |

154.3 |

158.8 |

171.1 |

Fig. 8. Measurement results

4. Discussion and Conclusion

While the vehicle is decelerating,

its kinetic energy is predominantly converted into thermal energy that leads to

significant heating of particular components of the wheel and brake system.

Therefore, the parts of the vehicle heated during deceleration must be

constructed from high-temperature resistant materials to ensure the vehicle’s

ability to decelerate.

Using certified brake components

reduces the probability of failure in the braking system during natural

deceleration.

However, it is necessary to replace

brake fluid on a regular basis, since the fluid’s boiling point is

reduced over time. During the measurements mentioned in this article, the

temperature of the calliper was 171°C. It can be presumed that the brake

fluid may have a similar temperature. The value measured, thus, highlights the

need for regular review of the brake fluid’s boiling point, or as the

case may be its replacement every 3 years.

Concerning the brake disc

temperature, the temperatures measured in the publication [7] were similar to

the temperatures measured in this article. In the publication [7], a numerical

solution of the heat-friction problem for a brake pad–brake disc system

during repeated intermittent braking was obtained using the finite element

method. During simulations, the disc’s temperature was about 600°C, which

is similar to our measurements. However, in our case, there were 15

decelerations made, while in the case [7], there were only 10 with substantially

shorter duration of particular braking. Likewise in our measurements, an increase

in temperature after exceeding 500°C was significantly less precipitous.

Thus, there is an assumption that after reaching a certain temperature in the

brake disc and brake pad, the temperature ceases to rise considerably. However,

it can also lead to the damage of these brake components by the longer

influence of high temperatures. This could correspondingly affect the increase

in the temperature of the brake fluid [37].

The brake disc’s temperatures

of nearly 500°C were also reached during the measurements given in

[3]. Through mathematical modelling, there were performed 10 consecutive

decelerations during a period of about 150 s.

The brake disc’s temperatures

of over 500°C were also reached in the publication [36], where during

simulations, the decelerations were not repeated but continuous.

Higher temperatures in the brake

disc and brake pads, as seen in this research, were also measured in the

publication [35], specifically 650°C. In this case, components of

trucks’ braking system were tested and they are of higher strains.

In the other publications explored

[19, 28, 38], there were lower values in temperature measured during

measurements. The reason lies in the fact that in most cases, the braking is

not repeated as much as 15 times, or the decelerations are not performed at such

high driving speeds. Additionally, concerning the high values measured in this

article, another reason can demonstrate those as the vehicle decelerated was

fully loaded and the braking intensity was fairly high. Since the braking was

made until the vehicle stopped, cooling by air flowed was significantly

restricted at low speeds.

The temperatures measured had

comparably high values, however, not so high as to cause damages in vehicle

components. These values highlight the necessity to cover all those features of

particular components that are required by the relevant legislation.

Acknowledgements

This contribution was prepared based on the grant:

VEGA no. 1/0436/18 - Externalities in road transport, an origin, causes and

economic impacts of transport measures.

References

1.

Kapusta J., A. Kalašová. 2015.

„Motor vehicle safety technologies in relation to the accident

rates“. Communications in Computer and Information Science:

172-179.

2.

Shyrokau B., D.W. Wang, K. Augsburg, V. Ivanov. 2013. „Vehicle dynamics with

brake hysteresis”. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of

Automobile Engineering 227(2): 139-150. DOI: 10.1177/0954407012451961.

3.

Ondruš J., J. Vrábel, E. Kolla. 2018. „The influence of

the vehicle weight on the selected vehicle braking characteristics“. Transport

means 2018. Part I: proceedings of the international scientific conference:

384-390. ISSN: 1822-296X 384-390.

4.

Hong Y., T. Jung, C. Cho. 2019. „Effect

of heat treatment on crack propagation and performance of disk brake with cross

drilled holes“. International journal of automotive technology

20(1): 177-185. DOI: 10.1007/s12239-019-0017-8.

5.

Vrábel J., J. Jagelčák, J.

Zámečník, J. Caban. 2017. „Influence of emergency

braking on changes of the axle load of vehicles transporting solid bulk

substrates“. 10th International Scientific Conference on

Transportation Science and Technology (TRANSBALTICA) 187: 89-99. DOI:

10.1016/j.proeng.2017.04.354.

6.

Grzes P. 2019. „Maximum temperature of the disc during repeated braking

applications“. Advances in mechanical engineering 11(3). ISSN:

1687-8132. DOI: 10.1177/1687814019837826.

7.

Adamowicz A. 2016. „Effect of convective cooling on temperature and

thermal stresses in disk during repeated intermittent braking“. Journal

of friction and wear 37(2): 107-112. DOI: 10.3103/S1068366616020021.

8.

Yevtushenko A.A., P. Grzes. 2010. „The

FEM-modeling of the frictional heating phenomenon in the pad/disc tribosystem

(a review)“. Numerical heat transfer part A-applications 58(3):

207-226. ISSN: 1040-7782. DOI: 10.1080/10407782.2010.497312.

9.

Ferodo. „Friction material data sheets“. Available at:

https://www.ferodo.com/support/commercial-vehicles/cv-friction-material-data-sheets.html.

10.

Janoško I., T. Polonec, R. Simor. 2010.

„Electronic encyklopedia of construction engines and vehicles“. 41st

International Scientific Conference of Czech and Slovak University Departments

and Institutions Dealing with the Research of Internal Combustion Engines: 232-238. ISBN:978-80-7372-632-4.

11.

Caban J., P. Droździel, J. Vrábel, B. Šarkan, A. Marczuk,

L. Krzywonos. 2016. „The research on ageing of glycol-based brake fluids

of vehicles in operation“. Advances in Science and Technology Research

Journal 10(32): 9-16.

12.

Avantor. „Safety data sheet“.

Avaliable: https://www.avantorsciences.com/stibo/search/sdsmix000168_us_en.pdf.

13.

Kadhem A., Y. Sadiq, M. Enad. 2018. The

effect of steel wire pre-tension on the tensile properties of bead ply in

rubber tires. 2nd International Conference on Engineering

Sciences-University-of-Kerbala

(ICES-UoK) 433. DOI: 10.1088/1757-899X/433/1/012077.

14.

Čulík K., A.

Kalašová, V. Harantová. 2019. „Creating a virtual

environment for practical driving tests. Communications in Computer and

Information Science 91049: 95-108. DOI: 10.1007/978-3-030-27547-1_8.

15.

Ivanov R. 2016. „Tire wear

modeling“. Transport Problems 11(3): 111-120. DOI:

10.20858/tp.2016.11.3.11.

16.

Regulation No 13-H of the Economic Commission

for Europe of the United Nations (UN/ECE) - Uniform provisions concerning the

approval of passenger cars with regard to braking [2015/2364].

17.

Wernik J. 2014. „Investigation of heat

loss from the finned housing of the electric motor of a vacuum pump“. Applied

sciences – Basel 7(12). DOI: 10.3390/app7121214.

18.

Ondruš J., E. Kolla. 2017.

“Practical use of the braking attributes measurements results”. 18th

International Scientific Conference on LOGI 134. DOI:

10.1051/matecconf/201713400044.

19.

Adamowicz, A. 2016. „Finite element

analysis of the 3D thermal stress state in a brake disk“. Journal of

theoretical and applied mechanics 54(1): 205-218. ISSN: 1429-2955.

20.

Stopka O., A. Šarkan. 2018.

„Quantification of road vehicle performance parameters under laboratory

conditions“. Advances in Science and Technology Research Journal

12(3): 16-23.

21.

Cars-Data. „Kia Ceed 1.6 CVVT“. Available at: https://www.cars-data.com/en/kia-ceed-1.6-cvvt-x-ecutive-specs/18902.

22.

Flrir. „Flir E60”.

Available at: https://www.flir.com/support/products/e60/#Specifications.

23.

Janura R., M. Gutten, D. Korenčiak,

M. Šebok. 2016. “Thermal processes in materials of oil

transformers”. International Conference on Diagnostic of Electrical

Machines and Insulating Systems in Electrical Engineering (DEMISEE): 81-84.

ISBN: 978-1-5090-1249-7.

24.

Sicinska K. 2019. “Age of a

passenger car and its influence on accidents with fatalities in Poland”. Transport

Problems 14(1): 105-11. DOI: 10.20858/tp.2019.14.1.10.

25.

Figlus T., L. Kuczynski. 2018.

“Selection of a semi-trailer for the haulage of long oversize loads,

taking into account an analysis of operational damage”. XI International Science-Technical

Conference Automotive Safety, IEEE Proceedings Paper. ISBN:

978-1-5386-4578-9.

26.

Koziol M., T. Figlus. 2017.

“Evaluation of the failure progress in the static bending of gfrp laminates

reinforced with a classic plain-woven fabric and a 3D fabric, by means of the

vibrations analysis”. Polymer

Composites 38(6): 1070-1085. DOI: 10.1002/pc.23670.

27.

Zhao S.D., Y. Yin, J.S. Bao, X.M. Xiao, et

all. 2019. “Analysis and correction on frictional temperature rise

testing of brake based on preset thermometry method”. Industrial

lubrication and tribology 71(7): 907-914. DOI: 10.1108/ILT-10-2018-0376.

28.

Wallis L., E. Leonardi, B. Milton, P. Joseph. 2002. “Air flow and

heat transfer in ventilated disc brake rotors with diamond and tear-drop

pillars”. Numerical Heat Transfer, Part A 41(6-7): 643-655.

29.

Talati F., S. Jalalifar. 2008. “Investigation of heat transfer

phenomena in a ventilated disk brake rotor with straight radial rounded

vanes”. Journal of Applied Sciences

8(20): 3583-3592.

30.

Belhocine A., M. Bouchetara. 2012.

„Thermal behavior of full and ventilated disc brakes of vehicles“. Journal

of mechanical sciented and technology 26(11): 3643-3652. DOI:

10.1007/s12206-012-0840-6.

31.

Adamowicz A., P. Grzes. 2011. „Influence

of convective cooling on a disc brake temperature distribution during

repetitive braking”. Applied thermal engineering 31(14-15):

2177-2185. DOI: https://doi.org/10.1016/j.applthermaleng.2011.05.016.

32.

Yevetushenko A., P. Grzes. 2011.

“Finite element analysis of heat partition in a pad/disc brake

system”. Numerical heat transfer, Part A: Applications 59(7). DOI:

https://doi.org/10.1080/10407782.2011.561098.

33.

Grzes P. 2017. “Determination of the

maximum temperature at single braking from the FE solution of heat dynamics of

friction and wear system of equations”. Numerical heat transfer part A

– Applications 71(7): 737-753. DOI: 10.1080/10407782.2017.1308711.

34.

Soderberg A., S. Andersson. 2009.

“Simulation of wear and contact pressure distribution at the pad-to-rotor

interface in a disc brake using general purpose finite element analysis

software”. Wear 267(12): 2243-2251. DOI:

10.1016/j.wear.2009.09.004.

35.

Gigan G., T. Vernersson, R. Lundén,

P. Skoglund. 2015. “Disc brakes for heavy vehicles: an experimental study

of temperatures and cracks”. Journal of Automobile engineering.

229(6): 684-707. DOI: 10.1177/0954407014550843.

36.

Adamowicz A., P. Grzes. 2011.

“Analysis of disc brake temperature distribution during single braking

under non-axisymmetric load”. Applied Thermal Engineering 31(6-7):

1003. DOI: ff10.1016/j.applthermaleng.2010.12.016ff.

37.

Kuranc A., G. Zajac, J. Szyslak, T.

Slowik, J. Vrábel, B. Šarkan, et all. 2018. “Boiling point of

the brake fluid based on alkyl ethers of alkylene glycols in vehicles being in

use”. Przemysl Chemiczny 97(12): 2102-2105. DOI:

10.15199/62.2018.12.17.

38.

Afzal A., M.A. Mujeebu. 2019. “thermo-mechanical

and structural performances of automobile disc brakes: a review of numerical

and experimental studies”. Archives of Computational Methods in

Engineering 26(5): 1489-1513. DOI: 10.1007/s11831-018-9279-y.

Received 15.02.2020; accepted in revised form 11.05.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License