Article

citation information:

Andrearczyk, A., Bagiński, P. Vibration analysis of a

turbocharger with an additively manufactured compressor wheel. Scientific Journal of Silesian University of

Technology. Series Transport. 2020, 107,

05-17. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.107.1.

Artur

ANDREARCZYK[1], Paweł BAGIŃSKI[2]

VIBRATION

ANALYSIS OF A TURBOCHARGER WITH AN ADDITIVELY MANUFACTURED COMPRESSOR

WHEEL

Summary. This article presents the vibration analysis of a

turbocharger, whose compression wheel was manufactured using a high-precision

additive manufacturing technology. Currently, there are advance studies around

the world for the development of parts of innovative fluid-flow machines using

additive manufacturing techniques. The experimental research was carried out

under conditions of reduced flow temperatures. The tests and the analysis were

performed on a wheel manufactured using a 3D printing technology and on a

conventionally used aluminium wheel. Apart from an FFT analysis of the

vibration signal during machine operation, a machine run-up test was conducted

(up to a speed of 105,000 rpm). The results showed the positive impact of the

use of a plastic wheel on the dynamics of the system at a certain speed range,

which might contribute to the development of a new method to optimise the

geometry of flow systems in small high-speed turbomachines. A modified

automotive turbocharger was subjected to experiments on a test stand.

Keywords: additive manufacturing, compressor wheel, vibration

analysis, polymer

1. INTRODUCTION

The use of additive

manufacturing (AM) technology to accelerate the development of prototypical

solutions in machines and reduce their cost has been on the increase in recent

times. Presently, research on the use of 3D printers for the development of new

prototypes and the optimisation of already existing parts is being carried out.

Since AM technology is widely used and many trials conducted to implement

different materials in diverse fields of science and engineering [1, 2], a

number of studies on the physical properties of the materials used in this

technology need to be carried out. This is important as they make possible

better specification of the field of application of this technology.

Vibration analysis during

machine operation is essential in determining the dynamics of the system and is

mainly carried out for diagnostic purposes [3, 4], more so, it is performed for

the accurate identification of faults and causes of machine instability [5, 6,

7, 8, 9]. This study is based on an automotive turbocharger machine. There are

a number of articles on vibration analyses performed on these types of machines

[10, 11, 12], thus, making the determination of their technical conditions

quick and precise, revealing the reasons behind these conditions. Article [13],

based on the analysis of the vibration spectrum of a turbocharger, describes a way to measure the speed of rotation using the

signals tested. This literature review indirectly contributed to the selection

of a turbocharger as a research object.

So far, in the field of

AM technology, vibration tests have been carried out on 3D printers to improve

the quality of the elements manufactured or to speed up the printing process.

It was only in the article [14] that the vibration properties of 3D-printed

elements were investigated using the modal analysis to determine the natural

frequencies of a research object. Given that there are no studies on the

influence of the use of additively manufactured components on the dynamics of

machines, a decision was made to perform vibration analysis on a turbocharger,

whose compressor wheel was manufactured using a selected 3D printing

technology.

This article describes

the experimental tests that were carried out on a test stand used to determine

the characteristics of turbocharger compressors and presents some of the

selected results of the vibration analysis of the turbocharger with an

aluminium (original) compressor wheel and a polymer one (3D-printed), which has

been tested at high rotational speeds under various operating conditions. This

article is a continuation of research on the use of 3D printing technology in

the experimental verification of the optimised rotor discs that are mounted in

turbomachines. Previous work established that the results of flow calculations

are consistent with the experimental results obtained for aluminium and polymer

discs. The aim of this work was to compare the dynamic properties of a

conventional turbocharger when using a disc made of aluminium or polymer.

2. MANUFACTURING

TECHNOLOGY

The Institute of

Fluid-Flow Machinery, Polish Academy of Sciences (IMP PAN) uses three different

AM technologies. Based on criteria such as printing precision, printing time

and cost of mass production, the MultiJet Printing (MJP) technology used in a

printer produced by the 3D Systems Company (model HD 3500 Max) was selected.

This technology makes achieving very high printing precision (the thickness of

a single layer printed by the device is 16 µm with an accuracy of up to 1

µm) possible. The producer offers a range of materials that have

different mechanical properties. The material sold under the trade name VisiJet

M3 X in the form of a fluid polymer resin was chosen to manufacture the

compressor disc as it has the best properties. The studies carried out on its

mechanical properties showed that the tensile strength is about 54 MPa [15].

The manufacturing

process, which is based on MultiJet Printing technology, is characterised by

putting layers of material through printhead jets that are distributed over the

entire printing platform. The MJP method is based on the inkjet approach to

create 3D elements and photo-cure the printed photopolymer layers using

ultraviolet light.

However, this method

should not be used at high ambient temperatures as it may cause errors during

the printing process. MultiJet Printing is one of the most precise 3D printing

technologies; it uses piezoelectric nozzles located in a printhead to deposit

thin layers of photocurable resin and wax (support material). MJP is used to

create parts with complex shapes, that is, parts with large amounts of details

and complex geometries. The use of the support material (wax) is a huge

advantage of this method as it dissolves at a temperature of 60°C leaving

no trace on the printed element. According to the producer, the selected

building material plasticises at a low temperature (88°C).

3. RESEARCH OBJECT AND

MEASURING EQUIPMENT

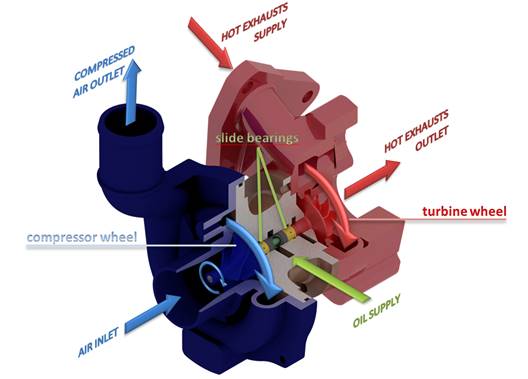

As earlier mentioned, a

turbocharger was selected for the experiments. It is a machine widely used in

the automotive industry. In combustion engines, the compressor rotor supplies

additional air to the combustion chamber through the intake manifold. Nowadays,

one of the most important components of a modern engine is the turbocharger. It

is a rotating machine, which consists of a turbine and a compressor, both

mounted on a common shaft. The operating principle and main components of the

turbocharger are shown in Fig. 1. The following factors influenced the choice

of this machine: the nature of its operation (in terms of dynamics) as

documented in the literature, its high rotational speed, its construction, the

easy assembling and disassembling of the components. The machine casing is

divided into three sections, which perform different functions, even though the

machine has only one shaft. In the supply section of the machine (red colour),

there is a spiral casing that supplies exhaust to the turbine blades to set it

in motion and transmit the torque to the compressor disc via the shaft. The

central section of the machine (green colour) supply oil to the slide bearings

and the thrust bearing, necessary for their lubrication. The supercharging

section of the machine (blue colour) is for the pressure charging of the

engine. This section was chosen for experimental purposes as it is a cool

section (from the viewpoint of the operating temperature) and the rotor disc

can be easily disassembled.

The compressor disc is

the part of the turbocharger that has been manufactured using MJP technology.

The printed polymer disc and the original aluminium disc are shown in Fig. 2. A 3D

laser scanner was used to reproduce the original geometry of the aluminium disc

and a cloud of points was obtained this way, which was then used to create

a model for use in a 3D printer. The geometric dimensions of the two discs were

checked and no manufacturing inaccuracies were detected. The polymer disc has

the same dimensions as the aluminium disc and they are as follows: diameter

near the split blades – 42.5 mm, diameter near the supply of the

compressor (that is, near the non-split blades) – 30 mm. The discs used

in the experiments are shown in Fig. 2.

Conventional

turbocharger test stands use engine exhaust, as in the case of this paper [16].

Due to the properties of the material from which the tested disc was made,

particularly due to its maximum operating temperature (88°C), it was

necessary to carry out this study on the test stand at reduced supply

temperatures. Compressed air (which could be heated to a temperature

between 30°C and 150°C, respectively) was used instead of engine

exhaust.

Fig. 1.

Design and operation of a turbocharger divided into three sections:

compressor section (blue colour), lubrication system (green colour)

and turbine section (red colour)

Fig. 2. Compressor wheel

manufactured using the MJP method (left)

and the original one (right)

Heating was used to

maintain the appropriate temperature at the turbine outlet. Due to the

expansion of the air, the temperature of the medium could have dropped

significantly (even below zero degrees Celsius), which could have caused damage

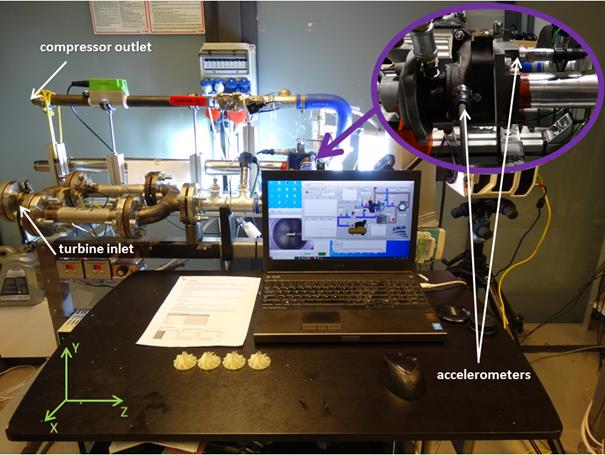

to the machine. The test stand [17] was equipped with all the necessary

elements such as a lubrication system, a heating system, sensors and valves

used to regulate the rotational speed of the device. Furthermore, the oil

supply pressure to the bearings has a considerable impact on the machine

vibrations. In a combustion engine, the oil pressure is regulated by the engine

speed. Since the test stand was not equipped with such a system, an oil pump

was used for this purpose, which maintained the oil pressure in the range of

2.5-4 bar (using an inverter), depending on the current speed of the

compressor. The test stand, as well as the marked sensors required to perform

measurements, are shown in Fig. 3.

Fig. 3. Turbocharger

test stand

Vibration sensors were mounted in the X- and

Z-direction (Cartesian coordinate system shown in Fig. 3). Besides vibrations, other parameters were also

measured (such as temperatures on both sides of the turbocharger, supply

pressure and flow rate) to test the operating parameters, but were not

discussed in this paper. Accelerometers produced by the PCB Piezotronics

Company were used to measure vibrations.

4. RESULTS OF THE EXPERIMENT

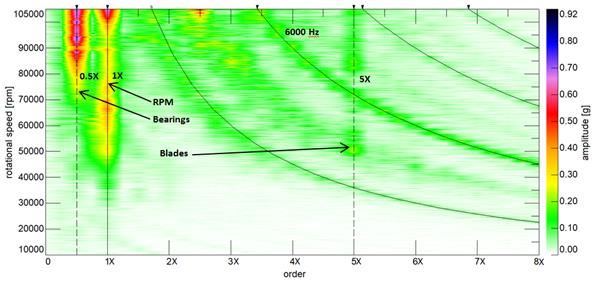

The first part of the

experiment involved testing the compressor using different compressor wheels.

During the tests, a throttle valve was used to regulate the mass flow, thus, a

study of the different operating states of the machine was obtainable. The

tests were conducted with discs made of two different materials. The aluminium

disc had a mass of 16.18 g and the polymer disc, 7.26 g. First, a run-up test

of the machine was carried out with the results shown in Figs. 4 and 5,

respectively.

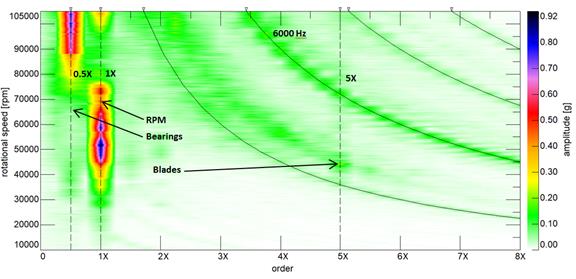

Fig. 4. Colourmap from run-up test conducted with aluminium compressor

wheel

(speed range: from 10,000 rpm to 105,000 rpm)

During

the run-up test performed with the aluminium disc, an increased vibration level

associated with 1X was observed at speeds above 50,000 rpm and was highest at a

speed of 105,000 rpm (Fig. 4). Vibrations associated with the operation of the

bearings (0.5X) occurred as soon as the rotational speed exceeded 70,000 rpm

and they became dominant in the vibration spectrum at higher speeds. When a

higher vibration amplitude developed (resulting from the unbalance), the 5X

component was visible (a component that was associated with the flow of

compressed air through the compressor blades,

five split blades and five non-split blades). The eigenfrequency of the test

stand, which was around 3,000 Hz, was characterised by a low vibration level

visible in the colourmap. Its harmonics and subharmonics can be noticed.

As with

the polymer disc, an increase in vibration level (1X) was observed at speeds

ranging from 35,000 to 75,000 rpm (Fig. 5). The highest vibration amplitude

occurred at a speed of 50,000 rpm (resonance zone) and was 0.5 g higher than

that in the experiment of the aluminium disc. In comparison with the aluminium

disc, component 0.5X attained a higher level of vibrations and its maximum

value was 0.8 g. The eigenfrequencies of the test stand can be seen in the

colourmap. Unlike in the previous test with the aluminium disc, the 5X

component did not appear, which could be associated with the less efficient

operation of the compressor.

To

thoroughly evaluate the dynamic performance of the tested machine, it was

necessary to perform the FFT analysis of the signals recorded at selected

rotational speeds. The results, which were obtained in the X-direction, are

shown in Figs. 6-9. They are analysed in the following part of the article.

Fig. 5. Colourmap from run-up test conducted with polymeric compressor

wheel

(speed range: from 10,000 rpm to 105,000 rpm)

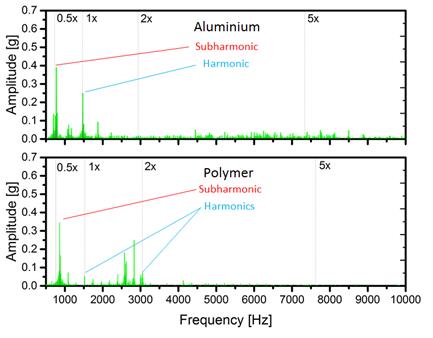

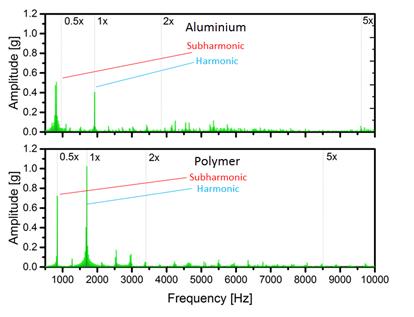

Fig. 6. Vibration amplitude spectra (in the X-direction) of the

turbocharger,

obtained at a rotational speed of 90,000 rpm for two different compressor

wheels

without throttling the flow at the compressor outlet

Fig. 6

shows frequency-amplitude graphs, for the experiments carried out with the

aluminium and polymer disc without throttling the flow at the outlet of the

compressor. In both experiments, the 0.5X component (associated with the

vibrations of slide bearings) is dominant. In the bottom graph (polymer disc),

the 1X component is about five times higher than in the top graph, however, it

can be seen that the spectral components are present within the frequency range

from 2,500 to 3,000 Hz.

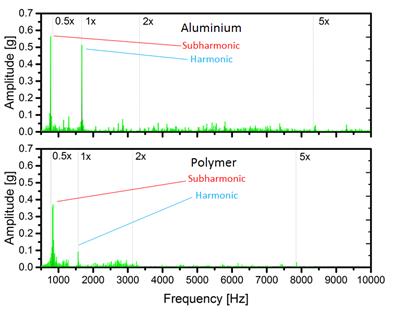

Fig. 7. Vibration amplitude spectra (in the X-direction) of the

turbocharger,

obtained at a rotational speed of 90,000 rpm for two different compressor

wheels at

a throttle level of 60%

After the flow was

throttled at the compressor outlet (Fig. 7), the vibration amplitudes of the

0.5X and 1X components approximately doubled at a speed of 90,000 rpm in the

case of the aluminium disc, while for the polymer disc, they were at the same

level. Regarding the aluminium disc, it can be similarly observed that the

component associated with the functioning of the bearings (0.48X) shifted towards

lower frequencies, indicating that an oil whirl had occurred.

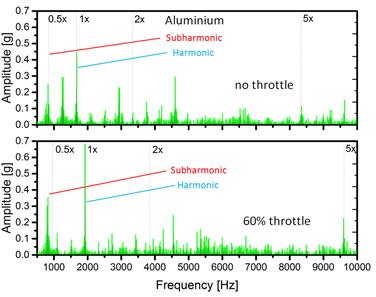

Similar

vibration spectra were obtained at a speed of 100,000 rpm. Fig. 8 shows the

results of the experiment carried out without throttling the flow. As with the

aluminium disc, the vibration amplitudes increased as expected. The 0.5X and 1X

components are dominant, as it was the case at a speed of 90,000 rpm. With

regard to the polymer disc, a considerable increase in the vibration amplitude

resulting from the unbalance (1X) was observed, however, the 0.5X component

increased with an increase in the rotational speed.

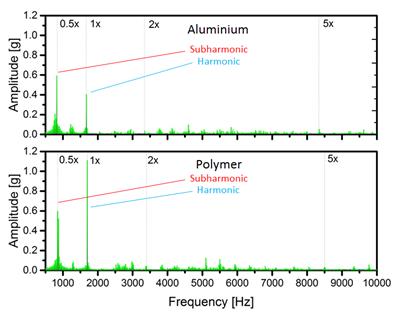

During

throttling the flow at the compressor outlet, the values of amplitudes were at

a similar level at a speed of 100,000 rpm (Fig. 9) for both discs. As for the

aluminium disc, the component associated with the functioning of the bearings moved

towards the lower frequencies (to 0.4X),

indicating that the oil whip instability had occurred.

Fig. 8. Vibration amplitude spectra (in the X-direction) of the

turbocharger,

obtained at a rotational speed of 100,000 rpm for two different compressor

wheels

without throttling the flow at the compressor outlet

Fig. 9. Vibration amplitude spectra (in the X-direction) of the

turbocharger,

obtained at a rotational speed of 100,000 rpm for two different compressor

wheels at

a throttle level of 60%

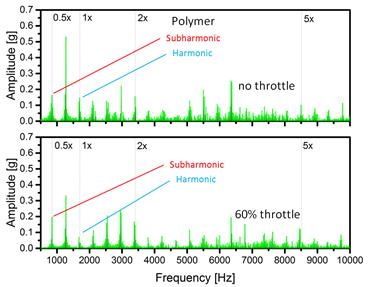

Due to

the oil whip instability and a suspected local disruption of the airflow in the

compressor of the turbocharger (that is, the compressor stall), a decision was

made to analyse the vibration acceleration signals measured in the Z-direction.

These phenomena are often accompanied by a rise in the vibration level in this

direction. Figs. 10 and 11, respectively, show the vibration spectra which were

measured in the Z-direction during the tests of the two discs conducted under

different operating conditions.

In the

case of the aluminium disc, component 1X is dominant in the FFT

amplitude-frequency spectrum (Fig. 10) having the following values: 0.45 g

(without throttling) and 0.69 g (with throttling). The 0.5X component is

visible but its value is about half that of the 1X component. As for the

experiment conducted without throttling the flow, the 0.75X component can be

observed, which is not associated with the compressor stall. The increased

vibration amplitudes that occur at frequencies of 3,000 and 4,900 Hz are

related to the eigenfrequencies of the test stand. After the flow was throttled at the

compressor outlet, an increase in the amplitude of vibrations associated with

the 5X component was observed (blades) and, as in the case of vibrations

registered in the X-direction, the subharmonic linked to the functioning of the

bearings moved towards lower frequencies (to 0.4X), indicating that the oil

whip instability had occurred. Other components

likewise appeared (at different frequencies), which may indicate that the

compressor stall phenomenon occurred.

Fig. 10. Vibration amplitude spectra (in the Z-direction) of the

turbocharger, obtained at a rotational speed of 100,000 rpm for an aluminium

compressor wheel

under different operating conditions

As for

the polymer disc, after analysing the spectrum shown in Fig. 11, it was

discovered that there was no oil whip instability. However, the 0.75X component

was dominant and its value exceeded 0.5 g. During throttling, there was no

increase in the rotational speed as in the case of the aluminium disc, which

may be a sign of inefficient operation of the blades. When the flow was

throttled, an increase in the amplitudes of vibrations was visible at the

following frequencies: 2,500, 3,000 and 3,500 Hz. In both cases, an increase in

vibration level was observed at a frequency of 6,400 Hz (which is one of the

eigenfrequencies of the test stand).

Fig. 11. Vibration amplitude spectra (in the Z-direction) of the

turbocharger, obtained at a rotational speed of 100,000 rpm for a polymer

compressor wheel

under different operating conditions

5. CONCLUSIONS

The

aim of this work was to carry out an experimental study to assess the dynamic

performance of the machine using rotating elements manufactured in a

conventional manner or by precise 3D printing technology. The disc used in the

tests was manufactured using MJP technology.

The

experimental research was conducted under conditions of reduced temperatures

using compressed air as the supply air. Accelerometers were used to measure

vibration amplitudes in two directions (X and Z). The research was carried out

at speeds between 10,000 and 105,000 rpm. The results of run-up tests as

well as a detailed vibration analysis of the turbocharger at elevated levels of

vibration and selected rotational speeds are presented. About the rotational

speeds that did not exceed 90,000 rpm, the use of the polymer disc had a

positive impact on the dynamic performance of the machine. At higher speeds,

the stall condition was observed regardless of the type of disc used. As for

the polymer disc, a decrease in the operating efficiency of the compressor was

observed at speeds greater than 100,000 rpm, which may have been caused by

deformation of the blades. In addition, the results obtained in the axial

direction of the turbocharger show that in the case of the aluminium disc,

during throttling of the flow, the oil whip instability phenomenon was

observed, and its occurrence confirmed. This phenomenon did not occur when the

polymer disc was being used.

Future

research will focus on flow optimisation using the manufacturing technology

described herein. A destructive test will also be performed.

References

1.

Javaid

Mohd, Abid Haleem. 2018. “Additive manufacturing applications in medical

cases: A literature based review”. Alexandria

Journal of Medicine 54(4): 411-422. DOI: 10.1016/j.ajme.2017.09.

2.

Yakout

Mostafa, Andrea Cadamuro, M.A. Elbestawi, Stephen C. Veldhuis. 2017. ,,The selection of process parameters in additive

manufacturing for aerospace alloys”. The

International Journal of Advanced Manufacturing Technology 92(5-8):

2081-2098. DOI: 10.1007/s00170-017-0280-7.

3.

Nejadpak

Ashkan, Yang Cai Xia. 2016. ,,A

vibration-based diagnostic tool for analysis of superimposed failures in

electric machines”. IEEE

International Conference on Electro Information Technology (EIT): 324-329. IEEE Region 4 (R4).

19-21 May 2016, USA. DOI: 10.1109/EIT.2016.7535260.

4.

Zieja

Mariusz, Paweł Gołda, Mariusz Żokowski, Paweł Majewski.

2017. „Vibroacoustic technique for the fault diagnosis in a gear

transmission of a military helicopter”. Journal of Vibroengineering 19(2): 1039-1049.

5.

Landry Michel, François

Léonard, Champlain Landry, Réal Beauchemin, Olivier Turcotte,

Fouad Brikci. 2008. ,,An improved vibration analysis

algorithm as a diagnostic tool for detecting mechanical anomalies on power

circuit breakers” IEEE Transactions

on Power Delivery 23(4): 1986-1994. DOI: 10.1109/TPWRD.2008.2002846.

6.

Xue Song, Ian Howard. 2018.

,,Torsional vibration signal analysis as a diagnostic tool for planetary

gear fault detection”. Mechanical

Systems and Signal Processing 100: 706-728. DOI:

10.1016/j.ymssp.2017.07.038.

7.

Graževičiūtė

J., I. Skiedraitė, V. Jūrėnas, A. Bubulis, V.

Ostaševičius. 2008. „Applications of high frequency vibrations

for surface milling”. Mechanika

1: 46-49.

8.

Ubartas

M., V. Ostaševičius, S. Samper, V. Jūrėnas, R.

Daukševičius. 2011. „Experimental investigation of vibrational

drilling”. Mechanika 4:

368-373.

9.

Vaičekauskis

M., R. Gaidys, V. Ostaševičius. 2013. „Influence of boundary

conditions on the vibration modes of the smart turning tool”. Mechanika 3: 296-300.

10.

Nguyen-Schäfer

Hung. 2015. “Vibrations of Turbocharger”. Rotordynamics of automotive turbochargers: 37-62. Germany: Springer

International Publishing. ISBN: 978-3-319-17644-4. DOI:

10.1007/978-3-319-17644-4.

11.

Chiavola

Ornella, Palmieri Fulvio, Recco Erasmo. 2018. “Vibration analysis to

estimate turbocharger speed fluctuation in diesel engines”. Energy Procedia 148: 876-883. DOI:

10.1016/j.egypro.2018.08.107

12.

Palúch

Stanislav, Peško Štefan, Majer Tomáš, Černý

Jan. 2015. „Transportation network reduction”. Transport Problems 10(2): 69-74. ISSN

1896-0596. DOI: https://doi.org/10.20858/tp.2015.10.2.7.

13.

Ascanio

G., W. Wang. 2007. “Diesel engine turbocharger performance monitoring

using vibration analysis”. 8th

International Conference on Engines for Automobiles. SAE Technical Paper

2007-24-0082. 16-20 September 2007, Italy. DOI: 10.4271/2007-24-0082.

14.

Crescenzo

Domenico, Viktor Olsson, Javier Arco Sola, Hongwen Wu, Andreas Cronhjort, Eric

Lycke, Oskar Leufven, Ola Stenlaas. 2016. ,,Turbocharger

speed estimation via vibration analysis”. SAE 2016 World Congress and Exhibition. SAE Technical Paper

2007-24-0082. 12-14 April 2016, USA. DOI: 10.4271/2016-01-0632.2016.

15.

Chaitanya

S Krishna, K. Madhava Reddy, Sai Naga Sri Harsha Ch. 2015. “Vibration

properties of 3D printed/rapid prototype parts”. Int. J. Innov. Res. Sci. Eng. Technol 4(6): 4602-4608.

DOI:10.15680/IJIRSET.2015.0406087.

16.

Andrearczyk

Artur. 2015. ,,The application of a photopolymer

material for the manufacture of machine elements using rapid prototyping

techniques”. Logistyka 4:

8628-8635.

17.

Kirk

R. Gordon, Alan A. Kornhauser, John, Alsaeed Ali Sterling. 2010.

“Turbocharger on-engine experimental vibration testing”. Journal of Vibration and Control 16(3):

343-355. DOI: 10.1177/1077546309103564.

18.

Andrearczyk

Artur, Paweł Baginski, Pawel Zywica. 2018. ,,Test

stand for the experimental investigation of turbochargers with 3D printed

components”. Mechanics and

Mechanical Engineering 22: 397-404.

Received 17.03.2020; accepted in revised form 19.05.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License