Article

citation information:

Šteininger, J., Hrček,

S., Smetanka, L., Skyba, R. Optimisation procedure of inner geometry in spherical

roller bearings with regard to their durability. Scientific Journal of Silesian University of Technology. Series

Transport. 2020, 106, 173-181.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.106.15.

Ján ŠTEININGER[1],

Slavomír HRČEK[2],

Lukáš SMETANKA[3],

Rudolf SKYBA[4]

OPTIMISATION

PROCEDURE OF INNER GEOMETRY IN SPHERICAL ROLLER BEARINGS WITH REGARD TO

THEIR DURABILITY

Summary. This article deals with an optimisation procedure of

inner geometry of rolling elements designed for spherical roller bearings. A

process of selection of the most appropriate solution to increase spherical

roller bearing durability is understood under the term optimisation in this

case. The aim of this article is to examine the impact of a change of inner

geometry on the durability and reliability of spherical roller bearings

regarding production technology and competitiveness. Contact strain along with

a spherical roller by means of Finite Element Method (FEM) in contact points of

components of a spherical roller bearing by means of designed 3D parametric

models. The most appropriate shape of inner geometry of a bearing from the

standpoint of calculated durability will be determined based on the results of

analyses.

Keywords: spherical roller

bearing, rolling element, optimisation, contact strain

1. INTRODUCTION

Rolling bearings are an inseparable

part of most machines and devices, in which takes place rotational movement or

linear motion. There are different requirements on rolling bearings. Production

machines need bearings, which are able to work in high revolution, in power

engineering, bearings have to carry heavy loads, trains require bearings with

high-speed performance, etc.

Development or rather rolling

bearing optimisation is conditioned by an increase of technical parameters in

machines and devices. This fact refers especially to an increase of input

parameters such as power and revolution, weight and volume reduction, noise

level reduction, etc. However, the most important parameters requiring

optimisation are bearing lifetime and reliability.

The development of new technologies

introduces also new construction materials, new production techniques of

semi-finished products and bearing components or new installation methods. It

is important not to overlook the bearing construction. Here, it is possible to

perform geometry adjustment optimisation. This adjustment applies especially to

geometry adjustment of runways and rolling elements in the spherical roller

bearings.

2. SPHERICAL ROLLER BEARINGS

DURABILITY

The double-row angular

spherical roller bearing has a runway spherically ground on the outer ring. The

bearing is able to accommodate very high radial loads, as well as heavy axial

loads in both directions. High radial load capacity is caused by the great

number of rolling elements, so-called spherical rollers and their close contact

on the inner ring runways [2].

Rolling bearings

durability depends on a revolution number which the bearing can perform until

fatigue of any of their components takes place. A peeled material is a sign of

component fatigue. Fatigue is a basic and natural way of bearing damage. It is

demonstrated by the presence of small cracks under the bearing runway surface.

The depth of these cracks is usually about 0.05 - 0.3 mm depending on the

surface curve radiuses of rolling elements and the bearing rings runways. The

crack depth allows the material changes which are caused by slide pulsing

strain. This process leads to a gradual crack formation under the surface. It

can take quite a long time before it is visible on the surface in the form of a

peeled-off material, so-called pitting [1,6,7].

3. CONTACT STRAIN ALONG SPHERICAL

ROLLER IN SPHERICAL ROLLER BEARING

It is possible to

calculate the intensity of the contact pressure and the size of the contact

surface - effective length lef and width 2b from the contact

pressure distribution on the most strained point in the bearing inner ring. The

picture (Fig. 1) shows the course projection (the curve) of the contact

pressure along the contact surface lef of the contact ellipse on the

bearing inner ring. The contact strain curve was calculated using the finite

element method [5].

Fig. 1. The contact pressure course on the

inner bearing ring runway

4. PREPARATION OF PARAMETRIC 3D

MODEL AND CONTACT ANALYSIS

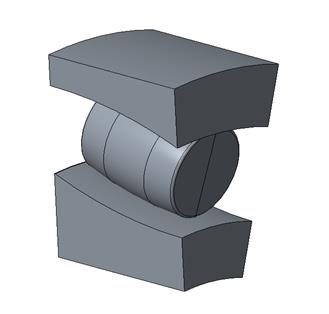

The double-row spherical

roller bearing model (Fig. 2) has been simplified to the maximum extent due to

the even load distribution on both rows and individual rolling elements. The

model consists of the rolling element, the outer ring, the inner ring, and the

contact surfaces. These surfaces are important for more precise model meshing

in FEM system ANSYS. The contact pressure was measured in the above-mentioned

parts [12].

Fig. 2. The simplified model of

the double row spherical roller bearing

5. OPTIMISATION OF

GEOMETRY OF SPHERICAL ROLLER BEARING

The aim of optimisation

is a decrease of contact pressure that acts in the point of contact of the

rolling element with the outer and inner ring. The profile of a rolling

element will be optimised, and we also calculated the contact strain between

rolling elements and bearing rings [10].

We designed three new geometries

of the rolling element for spherical roller bearings that were consequently

compared with the reference profile. A selection of the most appropriate

design of the new geometry of the rolling element was based on

a comparison of volumes of contact pressures of bearing runways of the

inner and outer bearing rings.

The comparison of curves

of contact pressures of rolling elements depends on the length of the contact

surface lef. The pictures Fig. 3 (inner ring) and Fig. 4 (outer

ring) show the curve shape. We reached a decrease of contact pressure on

bearing runways of bearing rings in all designs of a new geometry of the

rolling element [11].

As shown in Figs. 3 and

4, the lowest contact pressure acts between two bearing rings and the rolling

element with new geometry 4. At the same time, contact pressure that acts

between bearing rings and the rolling element does not produce maximum strain

values that negatively affect bearing durability. The new geometry of the

spherical roller bearing formed by the logarithmic curve is the most

appropriate for optimisation of the spherical roller bearing regarding its

durability and lifespan [9].

The evaluation and selection of the

most appropriate design of the new geometry are shown in Tables 1 and 2.

Fig. 3. The comparison of

contact pressure courses in the bearing runway of the inner ring of the

spherical roller bearing of analysed geometries of the rolling element

Tab. 1

The evaluation of results of analyses in the inner

ring of the spherical roller bearing

|

Design nr. |

Title |

lef [mm] |

bef [mm] |

po [MPa] |

σmax [MPa] |

|

Reference bearing |

Profile |

21 |

0.96 |

2106.1 |

1426 |

|

1 |

The change of the main radius |

22.13 |

0.96 |

1921.5 |

1319.9 |

|

3 |

The combination of 2 radiuses |

22.14 |

0.64 |

2106.1 |

1315.3 |

|

4 |

Logarithmic

curve |

21.9 |

0.63 |

1948.3 |

1302.6 |

Fig. 4. The comparison of contact pressure

courses in the bearing runway of the outer ring of the spherical roller bearing

of analysed geometries of the rolling element

Tab. 2

The evaluation of results of

analyses in the outer ring of the spherical roller bearing

|

Design nr. |

Title |

lef [mm] |

bef [mm] |

po [MPa] |

σmax [MPa] |

|

Reference bearing |

Profile |

21.8 |

0.8 |

1758.4 |

1426 |

|

2 |

The change of the main radius |

22.14 |

1.21 |

2048.7 |

1319.9 |

|

3 |

The combination of 2 radiuses |

22.14 |

1.18 |

1719.7 |

1315.3 |

|

4 |

Logarithmic

curve |

22 |

0.64 |

1576.9 |

1302.6 |

For a better

evaluation of analysed geometries, we calculated the durability of individually

analysed geometries according to the Lundberg-Palmgren theory:

![]() (1)

(1)

![]() (2)

(2)

![]() (3)

(3)

where S is the probability of survival,

N- the number of load cycles, V- stressed

volume, e, c, h, A- material

constants defined by experiments, ![]() - pressure present in the contact point, 2b- the minor axis of the ellipse [12].

- pressure present in the contact point, 2b- the minor axis of the ellipse [12].

A calculation of

a total lifetime of the bearing was based on partial lifetimes of bearing rings.

As far as a logical comparison is concerned, 100 per cent lifetime is

assigned to the reference geometry. A comparison of the calculated

lifetimes of analysed geometries is shown in Fig. 5 [8].

5. CONCLUSIONS

Spherical roller

bearings can be optimised by a modification of the geometry of the rolling

element, that is, the spherical roller. The most appropriate geometry seems to

be the one formed by the logarithmic curve after a comparison of lifetimes

of the bearing with the new geometry of the rolling element (Fig. 5). The

logarithmic curve is described by equations while in this case,

a parameter of a loss of the logarithmic curve profile, that is,

a modified surface of the spherical roller. The optimal value of the

parameter is 0.00035 mm which is similar to the case of the rolling bearing

with the logarithmic profile [5,12,14].

The new geometry of the

rolling bearing composed by the logarithmic curve increases total carrying

capacity, and thus, bearing durability by more than 25 per cent. This new

geometry does not form strain peaks that negatively affect total bearing

durability.

Fig. 5. The comparison of calculated

lifetimes of analysed geometries

Acknowledgement

This

work was supported by Grant system of the University of Zilina and the Ministry

of Education, Science, Research and Sport under the contract No. 1/0595/18

– “Optimising the internal geometry of roller bearings with line

contact in order to increase their durability and reduce their structural

weight”.

References

1.

Bartnik Grzegorz,

Zbigniew Krzysiak, Waldemar Samociuk, Grzegorz Lysiak, Krzysztof Plizga, Marek

Szmigielski, Aleksander Nieoczym, Zdzislaw Kaliniewicz, Frantisek Brumercik. 2017.

“Documentation of meeting the requirements in the area of technical

safety on the example of distribution of liquid fuels”. Przemysl Chemiczny 96(5): 1039-1041. ISSN 0033-2496.

2.

Caban J., A. Marczuk, B. Sarkan, J. Vrabel. 2015. “Studies on

operational wear of glycol-based brake fluid”. Przemysł Chemiczny 94(10):

1802-1806. ISSN 0033-2496.

3.

Czech

Piotr. 2012. „Determination of the course of pressure in an internal

combustion engine cylinder with the use of vibration effects and radial basis

function - preliminary research”. Communications in Computer and

Information Science 329: 175-182. DOI

https://doi.org/10.1007/978-3-642-34050-5_21. Springer, Berlin, Heidelberg.

ISBN:978-3-642-34049-9. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Telematics

in the transport environment, 12th International Conference on Transport

Systems Telematics, Katowice Ustron, Poland, October 10-13, 2012.

4.

Czech Piotr. 2011.

„Diagnosing of disturbances in the ignition system by vibroacoustic

signals and radial basis function - preliminary research”. Communications

in Computer and Information Science 239: 110-117. DOI

https://doi.org/10.1007/978-3-642-24660-9_13. Springer, Berlin, Heidelberg.

ISBN:978-3-642-24659-3. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Modern

transport telematics, 11th International Conference on Transport Systems

Telematics, Katowice Ustron, Poland, October 19-22, 2011.

5. Drozdziel P., L. Krzywonos. 2009.

“The Estimation of the Reliability of the First Daily Diesel Engine

Start-up During its Operation in the Vehicle”. Eksploatacja i Niezawodnosc – Maintenance

and Reliability 1(41): 4-10. ISSN 1507-2711.

6.

Figlus Tomasz. 2019. “A method for

diagnosing gearboxes of means of transport using multi-stage filtering and

entropy”. Entropy 21(5): 1-13.

ISSN 1099-4300, DOI: 10.3390/e21050441.

7.

Figlus Tomasz, Mateusz Koziol. 2016. “Diagnosis of

early-stage damage to polymer - glass fibre composites using non-contact

measurement of vibration signals”. Journal

of Mechanical Science and Technology 30(8): 3567-3576. ISSN: 1738-494X.

DOI: 10.1007/s12206-016-0717-1.

8. Jedlinski

L., J. Caban, L. Krzywonos, S. Wierzbicki, F. Brumercik. 2015. “Application of vibration

signal in the diagnosis of IC engine valve clearance”. Journal of vibroengineering

17(1): 175-187. ISSN 1392-8716.

9. Kohár

R., F. Brumerčík, M. Lukáč, A. Nieoczym. 2016. „Numerical analysis of roller

bearing“.Applied computer science 12(1): 5-16. ISSN 1895-3735.

10. Krzysiak

Zbigniew, Grzegorz Bartnik, Waldemar Samociuk, Janusz Zarajczyk, Krzysztof

Plizga, Bartlomiej Rachwal, Slawomir Wierzbicki, Leszek Krzywonos, Frantisek

Brumercik. 2017. “Analysis of explosion hazard

at the liquid fuel station”. Przemysl

Chemiczny 96(2): 279-282. ISSN 0033-2496.

11. Mitka

M., R. Bastovansky, F. Brumercik, P. Ignaciuk. 2017. “Local resistance of heating molybdenum

sheet in a test device”. Advances

in science and technology-research journal 11(3): 87-93. ISSN

2299-8624.

12. Mruzek

Martin, Igor Gajdáč, Ľuboš Kučera, Dalibor Barta. 2016. „Analysis of parameters

influencing electric vehicle range“. Procedia Engineering 134: 165-174. ISSN 1877-7058.

13. Mruzek

Martin, Igor Gajdáč, Ľuboš Kučera, Tomáš

Gajdošík. 2017.

„The possibilities of increasing the electric vehicle range“. Procedia Engineering 192: 621-625. ISSN

1877-7058.

14. Tomasikova

M., M. Tropp, T. Gajdosik, L. Krzywonos, F. Brumercik. 2017. „Analysis

of transport mechatronic system properties”. 12th International Scientific Conference of Young Scientists on

Sustainable, Modern and Safe Transport. Procedia Engineering 192: 881-886. High Tatras, Slovakia, May

31-Jun 02, 2017. ISSN 1877-7058.

Received 18.10.2019; accepted in revised form 22.12.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License