Article

citation information:

Szczucka-Lasota, B., Węgrzyn,

T., Łazarz, B., Jurek, A. Welding of mobile platform elements made of AHSS steel

and a non-alloy steel. Scientific Journal

of Silesian University of Technology. Series Transport. 2020, 106, 165-171. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.106.14.

Bożena SZCZUCKA-LASOTA[1], Tomasz WĘGRZYN[2], Bogusław

ŁAZARZ[3], Adam JUREK[4]

WELDING

OF MOBILE PLATFORM ELEMENTS MADE OF AHSS STEEL AND A NON-ALLOY STEEL

Summary. In the construction of mobile platforms, there is an

increasing necessity to weld steels from the AHSS group (AHSS - Advanced

High-Strength Steel) with low-alloy steels. This article verifies the

possibility of obtaining accurate mixed welded joints from different grades of

AHSS steel with S355J2 steel. The structure, as well as mechanical properties

of the obtained welded joints, were thoroughly analysed.

Keywords: civil engineering,

transport, mobile platforms, welding

1. INTRODUCTION

In civil engineering and transport,

mixed joints made of AHSS steel and non-alloy steel play an important role [1].

High-strength AHSS steels find increasing use in civil engineering and

transport due to their high tensile strength at the level of around 700-1200

MPa [2-6]. This article aims to present the results of tests designed for

proper selection of welding parameters of mobile platforms thin-walled

construction elements made of tested steel grades. It was decided to create

mixed AHSS/non-alloy steel joints using the MAG process and two different

welding parameters. Welding of AHSS steels used for the construction of mobile

platforms has been previously analysed, however, welding of AHSS steels with

non-alloy steels is novel and not widely presented in technical literature. The

possibility of welding AHSS/non-alloy steel joints correctly and repeatably

could affect new design constructions and usage of mobile platforms with

increasing lifting capacity and working range.

2. RESEARCH MATERIALS

AND WELDING PARAMETERS

From the available AHSS

materials, two grades were selected (Tab. 1) and combined with a non-alloy

steel S355J2. The welded steel grades differ significantly due to their

chemical composition (Tab. 1). Steels from the AHSS group are typically

considered as difficult to weld because of cracks that appear in the weld and

in the heat-affected zone after the welding [7]. Non-alloyed steels are

considered as rather well-weldable.

Tab. 1

Chemical

composition of selected steel grades [7]

|

Steel grade |

C% |

Si% |

Mn% |

P% |

S% |

Al% |

Ni% |

Ti% |

|

Docol 1200M |

0.11 |

0.20 |

1.70 |

0.01 |

0.002 |

0.04 |

- |

0.025 |

|

S700MC |

0.12 |

0.1 |

2.1 |

0.025 |

0.01 |

0.015 |

0,09 |

0.15 |

|

S355J2 |

0.2 |

0.4 |

1.50 |

0.03 |

0.03 |

0.02 |

0.3 |

- |

When welding AHSS steel

it is recommended to limit the linear energy during welding to 5 kJ/cm level [1,4,8],

whereas S355J2 steel does not pose any major welding problems. The weldability

of mixed joints has not been yet sufficiently investigated and there is

deficient literature information on it, especially regarding its use in the

construction of transport means. Non-alloy steels might be welded applying

various processes, with the best results obtained using the low oxygen methods

[9,10]. During the welding of non-alloy steels, micro-jet cooling is employed

with an increasing frequency in order to control the structure and to enhance

the plastic properties of the joint [7].

3. PREPARATION OF

SAMPLES FOR TESTING

MAG welded joints were

made using the following steel grades: S355J2 with S700MC and Docol 1200.

Significant differences in the chemical composition of the selected steel

grades affect the structure, weldability and mechanical properties of the

joint. Selected mechanical properties of the steels used to create a connection

in the mobile platform are presented in Tab. 2.

It is worth pointing out

the vast difference in strength and yield strength for both material groups.

It was decided to make

mixed joints using two different types of electrode wires: Union X90 and Union

X96. The chemical composition of both wires is presented in Tab. 3.

Tab. 2

AHSS

steels used to build mobile platforms - mechanical properties [7]

|

Steel grade |

The

yield point YS [MPa] |

Tensile strength UTS [MPa] |

Elongation A5 [%] |

|

Docol 1200M |

950 |

1150 |

5 |

|

S700MC |

700 |

900 |

9 |

|

S355J2 |

355 |

600 |

11 |

Tab. 3

Electrode wire UNION X90 - chemical composition [7]

|

Electrode

wire |

C% |

Si% |

Mn% |

P% |

Cr% |

Mo% |

Ni% |

Ti% |

|

Union

X90 |

0,1 |

0,81 |

1,8 |

0,01 |

0,35 |

0.6 |

2.3 |

0,005 |

|

Union

X96 |

0,12 |

0,87 |

1,89 |

0,010 |

0,29 |

0.46 |

3.3 |

0,005 |

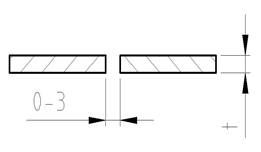

The steel welding

parameters were as follows: the diameter of the electrode wire was 1 mm,

the arc voltage was 19 V and the welding current was 115 A. The welded sheets

had dimensions of 1000 × 150 × 3 mm and the weld was of single

stitch type. In the MAG process, 80% Ar,18% CO2,2% O2 and

a mixture of 82% Ar and18% CO2 were selected to act as shielding gases.

The shielding gases flow rate was at a level of 15 l/min. The joints were made

at a speed of 400 mm/min. The linear energy was at 4.34 kJ/cm. A 3 mm thick

welded butt joint (BW) was made (KT sample). The MAG (135) welding method was

applied in the down position (PA) and according to the requirements of EN

15614-1 norm. The preparation of the material for single stitch welding as well

as created weld made from AHSS/non-alloy steel with thickness of 3 mm are

presented in Fig. 1.

Fig. 1. Groove shape of P3 (a), welding

order of P3 (b)

4. RESULTS AND

DISCUSSION

Once the joints welded with various

parameters were completed, tests of immediate tensile strength were performed.

Joint strength tests were carried out on the ZWICK 100N5A strength testing machine.

The results of the mechanical tests of the welds: S355J2/Docol1200M and

S355J2/S700MC (average of three measurements) are presented in Tabs. 4-5.

Tab.

4

Mechanical

properties of the mobile platform joint

(mixed joint S355J2/Docol1200M).

|

Welding types |

Electrode wire |

Shielding gases |

Rm, MPa |

Re, MPa |

A5, % |

|

S355J2/ Docol 1200M |

Union

X90 |

80% Ar-18% CO2-2%

O2 |

517 |

422 |

7.4 |

|

S355J2/ Docol 1200M |

Union

X96 |

80% Ar-18% CO2-2%

O2 |

524 |

434 |

7.1 |

|

S355J2/ Docol 1200M |

Union

X96 |

82% Ar-18% |

533 |

439 |

6.4 |

|

S355J2/ Docol 1200M |

Union

X90 |

82% Ar-18% |

538 |

447 |

6.3 |

The analysis of the array data shows that

the connectors were made correctly. The best plastic properties had a joint

created of Union X90 electrode wire and made in the shielding gas mixture

containing 80% Ar, 18% CO2 and 2% O2. Union X96 wire

supports greater joint strength, but at the cost of plastic properties

deterioration. The highest relative elongation value of the mixed joint was

obtained when welding with the use of MAG method, Union X90 electrode wire and

a gas mixture containing 2% O2. Again, the weldability of

S355J2/S700MC steel was verified. The test results are presented in Tab. 5.

Tab. 5

Mechanical

properties of the mobile platform joint (mixed joint S355J2/S700MC)

|

Welding types |

Electrode wire |

Shielding gases |

Rm, MPa |

Re, MPa |

A5, % |

|

S355J2/ S700MC |

Union

X90 |

80% Ar-18% CO2-2%

O2 |

502 |

401 |

7.7 |

|

S355J2/ S700MC |

Union

X96 |

80% Ar-18% CO2-2%

O2 |

487 |

386 |

7.4 |

|

S355J2/ Docol 1200M |

Union

X96 |

82% Ar-18% |

507 |

397 |

7.2 |

|

S355J2/ Docol 1200M |

Union

X90 |

82% Ar-18% |

513 |

401 |

7.1 |

Also, in this case, the analysis of the

array data shows that the joints were made correctly. The strength of the

joints after the welding with two different electrode wires was at the level of

500 MPa, and the relative elongation was always above 7%. Similarly in this

situation, the best effects were obtained using 80% Ar,18% CO2, 2% O2

shielding gas and UNION X90 wire.

Next, the bending test of the created

joints was performed. For the test, a sample with thickness of a = 3 mm, width

of b = 20 mm, mandrel of d = 22 mm and support spacing of d + 3a = 31 mm was

used, the required bending angle was at the level of 180°. Five bending

tests measurements were carried out both on the face side and on the root side

of the weld.

Those joints that obtained the best

plastic properties (using UNION X90 electrode wire together with 80% Ar, 18% CO2

and 2% O2 gas mixture) were subjected to the bending test. The

tests results are summarised in Tab. 6.

Tab. 6

Mixed

joints bending test results

|

Welding types |

Side deformation |

Size [mm] |

Bending angle [o] |

Comments |

|

S355J2/ S700MC |

root of the weld |

3 x 20 |

180 |

no cracks, no incompatibilities |

|

S355J2/ S700MC |

face of the weld |

3 x 20 |

180 |

no cracks, no incompatibilities |

|

S355J2/ Docol 1200M |

root of the weld |

3 x 20 |

180 |

no cracks, no incompatibilities |

|

S355J2/ Docol 1200M |

face of the weld |

3 x 20 |

180 |

no cracks, no incompatibilities |

|

Exterior diameter [m] |

below 24 |

from 24 to 30 |

above 30 to 36 |

above 36 |

|

Critical gap [s] |

5.0 |

4.8 |

4.6 |

4.5 |

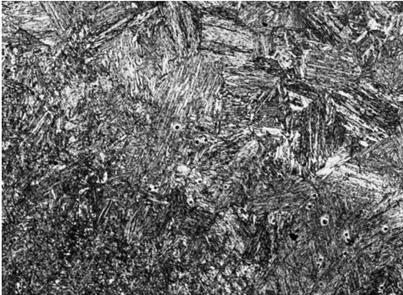

The analysis of Tab. 6 shows that the

joints were made correctly. No cracks or other incompatibilities were found in

the tested samples. Next, the microstructure analysis was performed. Similarly,

the structure of those mixed joints that ensured the best relative elongation

was analysed. The microstructure of the cross-section of the S355J2/Docol 1200M

joint is presented in Fig. 2.

![]()

![]()

Fig. 2. Structure of the

S355J2/Docol 1200M joint

Fig. 2 shows the dominant area with

martensitic structure and ground ferrite grains. Furthermore, after the welding,

a non-destructive testing (NDT) was carried out. It was decided to perform

visual test (VT) of the created joints. The test was performed with an eye

equipped with a magnifying glass at 3x magnification and was carried out

according to the requirements of PN-EN ISO 17638 standard with assessment

performed according to EN ISO 5817 norm.

In addition, a magnetic particle testing

(MT) was performed. The test was carried out according to the PN-EN ISO 17638

standard, the assessment was performed according to EN ISO 5817 norm using a

REM-230 magnetic flaw detector. All analysed welds were made correctly, the

test result was positive.

5. CONCLUSION

1. It

is possible to create correct and repeatable joints made of two different

grades of AHSS steel and non-alloy steel.

2. The

strength of mobile platforms elements joints made of AHSS and non-alloy steel

grades is at the required level of 500 MPa.

3. The

electrode wire UNION X90 and a shielding gas mixture of 80% Ar, 18% CO2 and

2% O2 provide the most preferred plastic properties of a joint

during the MAG welding.

4. Bending

tests, structure testing, as well as non-destructive tests, confirmed the

possibility of correct welding of the mobile platform elements.

References

1.

Benato

R., F. Dughiero, M. Forzan, A. Paolucci. 2002. “Proximity effect and

magnetic field calculation in GIL and in isolated phase bus ducts”. IEEE Transactions on Magnetics 38(2):

781-784. DOI: https://doi.org/10.1109/20.996202.

2.

Izairi

N., F. Ajredini, A. Vevecka-Pfiftaj, P. Makreski, M.M. Ristova. 2018.

“Microhardness evolution in relation to the cFigtalline microstructure of

aluminum alloy AA3004”. Archives of

Metallurgy Materials 63(3): 1101-1108. DOI: https://doi.org/10.24425/123782

3.

Giles

T.L., K. Oh-Ishi, A.P. Zhilyaev, S. Swami, M.W. Mahoney, T.R. McNelley. 2009.

“The Effect of Friction Stir Processing on the Microstructure and

Mechanical Properties of an Aluminum Lithium Alloy”. Metallurgical and Materials Transactions 40(1): 104-115. DOI: https://doi.org/10.1007/s11661-008-9698-8.

4.

Hamilton C., S. Dymek, A. Węglowska, A. Pietras. “Numerical simulations for bobbin

tool friction stir welding of aluminum 6082-T”. 2018. Archives of Metallurgy Materials 63(3):

1115-1123. DOI: https://doi.org/10.24425/123784.

5.

Jambor M., F. Novy, M. Mician, L. Trsko, O. Bokuvka, F. Pastorek,

D. Harmaniak. 2018. „Gas metal arc welding of thermo-mechanically

controlled processed S960MC steel thin sheets with different welding

parameters”. Komunikacie

(Communications - Scientific Letters of the University of Zilina) 20(4):

29-35. ISSN: 1335-4205.

6.

Spišák

E., J. Majerníková, J. Slota. 2014. “Change of ears

creation of AHSS steels after heat treatment of zinc coating”. Metalurgija 53(4): 473-476.

7.

Hadryś

D. 2015. “Impact load of welds after micro-jet cooling”. Archives of Metallurgy and Materials

60(4): 2525-2528. DOI: https://doi.org/10.1515/amm-2015-0409.

8.

Jaewson

L., A. Kamran, P. Jwo. 2011. “Modeling of failure mode of laser welds in

lap-shear speciments of HSLA steel sheets”. Engineering Fracture Mechanics 78(2): 347-396.

9.

Celin

R., J. Burja. 2018. “Effect of cooling rates on the weld heat affected

zone coarse grain microstructure”. Metallurgical

and Materials Engineering 24(1): 37-44. DOI: https://doi.org/10.30544/342.

10. Darabi J., K. Ekula. 2003.

“Development of a chip-integrated micro cooling device”. Microelectronics Journal 34(11):

1067-1074. DOI: https://doi.org/10.1016/j.mejo.2003.09.010.

Received 20.10.2019; accepted in revised form 19.12.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License