Article

citation information:

Skrzypczak, I., Kokoszka, W., Pytlowany, T., Radwański, W. Control charts monitoring for

quality concrete pavements. Scientific

Journal of Silesian University of Technology. Series Transport. 2020, 106, 153-163. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.106.13.

Izabela

SKRZYPCZAK[1], Wanda KOKOSZKA[2],

Tomasz PYTLOWANY[3], Wojciech RADWAŃSKI[4]

CONTROL

CHARTS MONITORING FOR QUALITY CONCRETE PAVEMENTS

Summary. In this article, Control charts are employed to

analyse the strength quality control of ready-mixed concrete for rigid

pavement. The results of the study support that CUSUM

statistical analysis is more sensitive than the Shewhart

control chart. The CUSUM chart can detect the

continual changes in the concrete quality in a more accurate way. By combining

the CUSUM control chart and the Shewhart

control chart, higher accuracy of quality control analysis could be achieved,

in order words, for quality control performance when in built/pouring the

ready-mix concrete as rigid pavement.

Keywords: pavements, quality,

monitoring, CUSUM charts, Shewhart

charts

1. INTRODUCTION

The intent of a statistical control

chart of the quality of concrete pavements is to provide practitioners in the

field with clear and concise information that will

give them guidance on steps that they can take to construct a durable concrete

pavement. Moreover, this also motivates the exploration of various reliability

and durability related studies [1-7,16-21,26,28-30].

In keeping with this objective, the recommendations provided in code EN 206 [9] and the use of control charts in concrete

production are key references. Publicly funded construction of transportation

facilities in Poland is a multi-billion zlotys industry, which entrusts

taxpayer funds to state transportation agencies (GDDKiA)

and private contractors to provide durability and reliability of public roads.

Currently, the roads are expected to have assured quality.

Early

implementation of quality control charts in the transportation arena is a more

comprehensive approach to consider quality control as an element of quality

assurance. As taxpayers, we expect our investment to yield a long-lasting

transportation system. Improved quality reduces the costs associated with

re-work. These cost savings from improved quality have benefits for contractors

and agencies. Although quality control functions are commonly contractually

delegated to subcontractors, producers, fabricators and manufacturers, the

prime contractor must take the lead role in monitoring the effectiveness of

quality control at all levels during the construction process. Good quality can

only be achieved by a trained labour force utilising materials that conform to specifications, and

which are supported by a QC staff and program that provide timely feedback.

Continuous process improvement and prevention of defects should be the aim of

the contractor and material supply chain. It is far better to prevent defects

rather than become proficient at finding the cause of defects after the fact.

Open and timely communication between all parties is vital to an effective

quality control program based on, for example, quality control chart Acceptance

testing should be based upon samples, which have been obtained in a random

manner to remove any potential bias. Random sampling is also applicable to

contractor testing which will be evaluated using statistical process control (SPC) techniques. Random samples should be obtained in

accordance with EN 206 [9] or other code procedures.

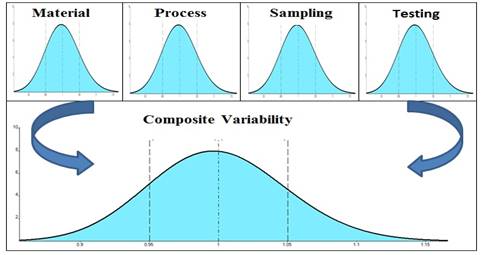

The variability observed in concrete paving projects is attributable to four

sources: material, process, sampling, and testing (Figure 1). It is

important to note that every test result we examined includes these sources of

variability [10-12,14,22-25].

Fig. 1. Sources of

construction variability

Understanding the materials,

precision and bias of each test procedure is critical to proper interpretation

of quality control testing and acceptance testing. The term process control is

often used synonymously with quality control. Reducing variability in materials

and in processes is a focus of quality control efforts. Reduced variability

indicates a higher level of control. The same is true in sampling and testing

activities. We should strive to reduce the variability of our QC testing

activities:

- utilising the same technician,

especially within payment lots,

- all technicians should

be properly trained and certified,

- follow strict adherence

to testing procedures,

- testing equipment should be

calibrated and certified as necessary [10-12,14,22-25].

2. STATISTICAL PROCESS CONTROL

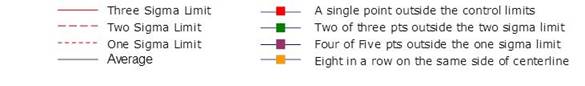

Control charts are

useful tools which when combined with some well-proven rules can assist

contractors in identifying changes in their materials and processes. The

primary purpose of using Statistical Process Control (SPC),

specifically control charts, is to identify change. Their function is not to

indicate whether a test result passes or fails the acceptance criteria, but

rather to indicate if the test result was unusual. Control charts are an effective

means for identifying the impact of assignable causes on the materials and/or

construction processes. Some agencies/contractors use moving average instead of

individual test results as a tool for trend evaluation. Once identified, the

materials and/or processes can be adjusted to account for the influence of the

assignable cause [10-12,14,22-25]. For example, a sharp reduction in air

content may indicate that the carbon content of the fly ash has changed,

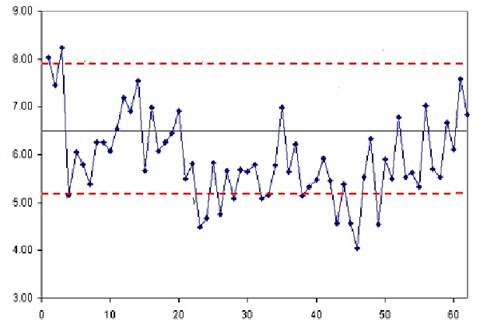

requiring an increased dosage of air-entraining admixture [8,13]. Simply put, a

control chart provides a visual indication of whether a process is in control

(Figure 2).

Fig. 2. Control chart for the average air void content according to [24]

3. THE CUSUM

CONTROL CHART

Cumulative Sum (CUSUM) charts

are proven techniques for improving productivity, effective in defect

prevention, prevent unnecessary process adjustments, provide diagnostic

information and provide information about process capability. CUSUM control charts are amongst some of the most important

management control tools. CUSUM control charts

directly incorporate all the information in the sequence of sample values by

plotting the cumulative sums of the deviations of the sample values from a

target value. The CUSUM chart presents the cumulative

sum and they combine information from several samples, thus, CUSUM charts are more effective than Shewhart

charts for detecting small process shifts. If the process remains in control at

the target mean value - μ0, the CUSUM defined in the above equation should vary randomly

about zero. However, if the mean shifts upward to some value μ1 > μ0,

then an upward or positive drift will develop in the cumulative sum (CUSUM). Conversely, if the mean shifts downward to some

value μ2 < μ0, then a downward or negative drift in CUSUM will develop [8,11-14,25,28].

Therefore, if a trend develops in the plotted points

– either upward or downward, we should consider this as evidence that the

process mean has shifted, and a search for some assignable cause should be

initiated. For determining whether the process is out of control, a formal

decision procedure can be laid down in the form of a truncated V-shaped mask

popularly known as V-mask [10,22,23].

CUSUM charts are more effective than Shewhart charts in detecting small and moderate-sized

sustained shifts in the parameters of the probability distribution of a quality

characteristic. Though in some cases, CUSUM charts

are very useful, they are not meant to replace the Shewhart

chart, which can be used to detect a wider assortment of effects due to

assignable causes. It is, therefore, frequently recommended that Shewhart control lines be used in conjunction with CUSUM charts. In Statistical Process Control (SPC) methods, the control charts are major tools used for

monitoring and improving manufacturing processes [10-12,14,22-25].

4. THE APPLICATION OF CUSUM CONTROL CHART

This study shows the Shewhart

control chart and the CUSUM chart applied to analyse contrete compressive

strength for monitoring the changes and variation factors of the trend of

quality concrete intended for building a road. In practical application, the

concrete strength quality will be accepted on the basis of each individual lot

and is established according to the requirements specified in the EN 206 [9] as well, in which, the Shewhart

control chart and CUSUM control chart is recommended

as the basis of quality statistical acceptance.

The Shewhart

control chart and the Tabular CUSUM chart can be

independently applied in the Acceptance control chart. However, distinctive

characteristics exist between the CUSUM and Shewhart control chart. In this respect, the Shewhart control chart does not take into account the

changes in the average value of continuous compressive strength under the same

construction project and the same mixing ration parameter required for

designing the concrete strength, instead, quality control and analysis are

executed for the total lot count of the current concrete displacement.

Unlike the Shewhart

control chart, the CUSUM statistic

analysis method has its own serial and cyclic features, meaning that CUSUM will make reference to the cumulative variation

amount of the average deviation target value obtained from previous samples. In

this way, it will be accumulated to current-term average sample count for

overall consideration in order to effectively evaluate the supplier’s

concrete quality control and stability in the material used in the same

construction site, the same strength mixing ratio, and the same design

strength.

Fig. 3. Shewhart

control chart: X-bar chart and range chart

The CUSUM

quality control chart comprises all the information provided for the average

compressive strength value of the concrete subject selected from the test batch

in appropriate time, for which the previous mean compressive strength value is

set asp,0 for use

as a referential or target value, and the mean compressive strength value of

the respective batch subsequently poured is set as ^1 in order to

continuously detect the minor deviations between each batch. The result of

relevant studies support that, with the quality subjected to normal

distribution (p,o2) and using 3o as the control scope, the trend and deviation pre-alert

of the cumulative and control charts are more sensitive than the Shewhart control chart. The development of the CUSUM method is to detect small shifts and fluctuations of

variables for the mean value in order to provide judgment that is more

sensitive when the mean compressive strength is beyond control.

In practice, the construction industry

usually uses the X-bar-R chart as the concrete strength evaluation method for

executing statistical quality control with the metering value of the pre-mixed

concrete. The purpose of the X bar chart is to measure the stability of the

mean concrete value, and the R-chart is to monitor the accuracy of the

measuring equipment (Fig. 3). In comparison, the CUSUM

chart is used to accumulate the deviation values between the average count of

each sample group and the overall groups to present the development of the

variation trend between the concrete lots. The change of the trend transition

variation can be used to immediately detect minor changes in strength.

The Shewhart

control chart does not take into account the changes in the average value of

continuous compressive strength under the same construction project and the

same mixing ration parameter required for designing the concrete strength;

instead, quality control and analysis are executed for the total lot count of

the current concrete displacement.

The CUSUM

Control Chart makes reference to the cumulative variation amount of the average

deviation target value obtained from previous samples. It will be cumulated to

current-term average sample count for overall consideration in order to

effectively evaluate the supplier’s concrete quality control and

stability in the material used in the same construction site, the same strength

mixing ratio and the same design strength.

The CUSUM

quality control chart comprises of all the information provided for the average

compressive strength value of the concrete subject selected from the test batch

in appropriate time, for which the previous mean compressive strength value is

set 35,04 MPa for use as a referential or target

value, and the mean compressive strength value of the respective batch

subsequently poured is set in order to continuously detect the minor deviations

between each batch.

All data for reference class C30/37 was presented in Table 1. The basic analysis for

formulating a CUSUM chart is as follows:

- Mean

Sample (MS): 45,0 MPa,

- Standard

Deviation (σ) : 5,02 MPa (Standard Deviation of compressive strength from

the initial production),

- Target

Mean Strength (TMS) = fck+2σ, according to [6],

so: TMS = 37 + 2(5,02)= 47,04 MPa.

Data for the CUSUM

plot are presented in Table 1. The column 1 of Table 1 represents concrete

class, column 2 represents the 28-day cube compressive strength (xt) and in column 3 the deviations (both positive and

negative) of TMS (47,04 MPa.) from xt

are calculated.

In general, upward slopes indicate an

increase in mean strength and standard deviation, and downward slopes reflect a

reduction. Minimum fluctuation of test strength of the target mean strength is

desirable. As per Fig. 3, the trend of the graph for the Conventional CUSUM plot shows an increase in the strength trend up to

sample no. 14, after which at sample no. 15 the strength falls below the

specified strength of 35 MPa.

Tab. 1

Calculation of CUSUM

charts

|

No. of samples |

28-Day Compressive Strength [MPa] |

xi-MS [MPa] |

CUSUM Plot [MPa] |

Cumulative sum [MPa] |

|

1 |

40,9 |

0,9 |

0,9 |

6,4 |

|

2 |

37,2 |

-2,8 |

-1,9 |

9,1 |

|

3 |

36,6 |

-3,4 |

-5,3 |

11,2 |

|

4 |

48,6 |

8,6 |

3,3 |

25,3 |

|

5 |

47,2 |

7,2 |

10,5 |

38 |

|

6 |

45 |

5 |

15,5 |

48,5 |

|

7 |

45,5 |

5,5 |

21 |

59,5 |

|

8 |

46,4 |

6,4 |

27,4 |

71,4 |

|

9 |

46,6 |

6,6 |

34 |

83,5 |

|

10 |

44,8 |

4,8 |

38,8 |

93,8 |

|

11 |

44,1 |

4,1 |

42,9 |

103,4 |

|

12 |

37,1 |

-2,9 |

40 |

106 |

|

13 |

43,1 |

3,1 |

43,1 |

114,6 |

|

14 |

40,2 |

0,2 |

43,3 |

120,3 |

|

15 |

34,4 |

-5,6 |

37,7 |

120,2 |

|

16 |

35,1 |

-4,9 |

32,8 |

120,8 |

|

17 |

40,8 |

0,8 |

33,6 |

127,1 |

|

18 |

47,9 |

7,9 |

41,5 |

140,5 |

|

19 |

32,8 |

-7,2 |

34,3 |

138,8 |

|

20 |

38,8 |

-1,2 |

33,1 |

143,1 |

|

21 |

42,5 |

2,5 |

35,6 |

151,1 |

|

22 |

42,9 |

2,9 |

38,5 |

159,5 |

|

23 |

41,4 |

1,4 |

39,9 |

166,4 |

|

24 |

41,1 |

1,1 |

41 |

173 |

|

25 |

32,1 |

-7,9 |

33,1 |

170,6 |

|

26 |

29 |

-11 |

22,1 |

165,1 |

|

27 |

32,9 |

-7,1 |

15 |

163,5 |

|

28 |

40,8 |

0,8 |

15,8 |

169,8 |

|

29 |

39 |

-1 |

14,8 |

174,3 |

|

30 |

41,2 |

1,2 |

16 |

181 |

|

31 |

40,9 |

0,9 |

16,9 |

187,4 |

Though there is again a recovery of

strength up to sample no. 17, the strength again falls below the specified

strength at sample no. 18. Thereafter, the CUSUM plot

shows a negative trend up to sample no. 30. This high degree of fluctuation of

mean strength and standard deviation reveals the fact that the system of

quality monitoring adopted by the RMC plant under study is inadequate. This

also increases the probability of rejection of the concrete by the client.

Fig.3.

Conventional CUSUM chart for compressive strength

To confirm whether a significant change

has occurred, a transparent mask, in the shape of a truncated “V”

is placed over the last CUSUM plotted with the

designated lead point shown in Fig. 2 superimposed over it. If the plot remains

inside the boundaries of the mask, no significant change has occurred, that is,

the concrete quality has not deviated from the desirable level significantly.

The deviations that have occurred are acceptable and these are due to

uncontrollable random factors. However, if the plot crosses a boundary, a

significant trend can be detected and action is required. This mask is applied

to the plot each time a new result is added and further check is made. The V

mask is drawn joining three straight lines, namely, the base of the truncated V

and the two inclined lines joining the base. The base is called the decision

interval (DI) and its length is 8.1 σ. The gradient of the two

symmetrically placed inclined lines is σ / 6 in the case of the mask meant

for detecting a significant change in mean, a being the plant standard

deviation. Application of V-Mask to CUSUM plot as a

daily monitoring tool [9,13].

In Fig. 4, it is observed that by putting

the lead point of the mask on sample no. 16, the CUSUM

plot sample numbers 1 to 4 go beyond the boundary of the mask, which is a

signal that a significant change has taken place in the compressive strength of

concrete or a significant change of concrete class, sample no. 3 (36,6 MPa).

The result of relevant studies support

that, with the quality subjected to normal distribution and using 3o as the control scope, the trend and deviation pre-alert

of the cumulative and control charts are sensitive control chart. The

development of the CUSUM method is to detect small

shifts and fluctuations of variables for the mean value in order to provide

more sensitive judgment when the mean compressive strength is beyond control.

In practice, the CUSUM

chart is used to accumulate the deviation values between the average count of

each sample group and the overall groups to present the development of

variation trend between the concrete lots. The change of the trend transition

variation can be used to immediately detect minor changes in strength.

Fig. 4. CUSUM chart for compressive strength without and with

V-Mask

5. CONCLUSIONS

Offering

products and services of the highest quality is essential for durability,

reliability and security of rehabilitated infrastructure investments, including

roads. Ensuring the proper quality of production and services requires constant

application of properly selected methods and tools enabling the analysis and

evaluation of the processes carried out. Quality control should be active and

not passive, therefore, it is extremely important to constantly monitor

processes, analyse their variability and test their

qualitative ability through the use of control charts.

The CUSUM chart

uses a cumulative variation value, therefore, it should be suitable for

application in the quality control of the concrete compressive strength.

According to practical test application results, this study proposes that the CUSUM control chart should be used in order to objectively

set the overall mean value as the average compressive strength of the concrete

for accumulating to the current compressive strength deviation value. When a continuous

deviation appears in the cumulative quantity of each group, it means that

change has happened to the quality of the concrete compressive strength during

the process and the acceptance and that the reasons must be sourced.

The CUSUM

control chart is used to detect the existence of minor deviation in the target

mean value, whereas, the conventional Shewhart

control chart exhibits more significant changes when a greater deviation exists

in the target mean value. Both have their advantages and weaknesses, and we

suggest that they should be used together. To achieve the stabilised

overall quality, the CUSUM allows for the use of the

V-Mask for compliance control so that the causative reasons may be identified

in advance in order to make appropriate process modification or adjustment.

References

1.

Ahmet Beycioğlu, Adil Gültekin, Hüseyin Yılmaz Aruntas,

Osman Gencel, Magdalena Dobiszewska,

Witold Brostow. 2017.

“Mechanical properties of blended cements at elevated temperatures

predicted using a fuzzy logic model”. Computers

and concrete 20(2): 247-255.

2.

Cihlarova D., P.

Mondschein, S. Capayova.

2018. “Compaction density determination of the road asphalt

layers”. Komunikacie (Communications - Scientific Letters of the

University of Zilina) 20(3): 61-66. ISSN:

1335-4205.

3.

Chakraborty Joyraj,

Andrzej Katunin. 2019. “Structural diagnosis of

rail vehicles and method for redesign”. Diagnostyka 20(1): 103-110. DOI: https://doi.org/10.29354/diag/100448.

4.

Czarnecki Lech, Piotr Wojciechowski. 2012. Modelling of

concrete carbonation; is it a process unlimited in time and restricted in

space?” ACI Materials Journal 109(3):

275-282.

5.

Czarnecki Lech, Piotr

Wojciechowski, Grzegorz Adamczewski. 2018. “Risk of concrete carbonation with mineral

industrial by-products”. KSCE Journal of Civil Engineering 22(2): 755-764

6. Deja

Jan. 2003. “Polish roads”. Review

of Road and Bridge Technique.

7.

Dobiszewska Magdalenia. 2017. “Waste materials used in making mortar and concret”. Journal

of Materials Education 39(5-6): 133-156.

8. Dutta Goutam,

Debasis Sarkar. 2008. Design and Application of

Risk Adjusted Cumulative Sum (RACUSUM) for Online

Strength Monitoring of Ready Mixed Concrete. Indian Institute of Management

Ahmedabad, India.

9.

EN

206: 2013 Concrete: Specification, Performance, Production and Conformity.

10.

Eugene

L. Grant, Richard

S. Leavenworth. 1988. Statistical

Quality Control. McGraw-Hill, USA. ISBN-10:

0070241171.

11.

Dong

Han, Fugee Tsung, Xijian Hu and Kaibo Wang. 2007.

“CUSUM and EWMA

Multi-Charts for detecting a range of mean shifts”. Statistica Sinica 17: 1139-1164.

12.

Fah Fatt Gan. 1991. “An optimal design of CUSUM quality control charts”. Journal of Quality

Technology 23: 279-286.

13. Gibb Ian, Tom A Harrison. 2010. Use of control charts in the production of concrete. DOI:10.13140/RG.2.1.3233.7045.

14.

Goel

Amrit L., S.M. Wu. 1973.

“Economically Optimum Design of CUSUM

Charts”. Management Science 19: 1271-1282.

15. Jasiczak

Józef. 1992. Kryteria kontroli

stabilizacji wytrzymałości betonu na ściskanie określane

metodami probabilistycznymi. [In

Polish: Criteria for controlling the

stabilization of concrete compressive strength determined by probabilistic

methods]. Poznan: WPP.

16.

Macioszek Elżbieta.

2017. “Analysis of Significance of Differences Between

Psychotechnical Parameters for Drivers at the Entries

to One-lane and Turbo Roundabouts in Poland”. In: G. Sierpiński

(Ed.). „Intelligent Transport

Systems and Travel Behaviour”. Advances

in Intelligent Systems and Computing 505: 149-161. Springer International Publishing Switzerland.

17.

Mackiewicz Piotr.

2015. “Analysis of stresses in concrete pavement under a dowel according

to its diameter and load transfer efficiency”. Canadian Journal of Civil Engineering 42(11): 845-853.

18.

Mackiewicz Piotr.

2015. “Finite-Element Analysis of Stress Concentration around Dowel Bars

in Jointed Plain Concrete Pavement”. Journal

of Transportation Engineering 141(6).

19.

Mackiewicz Piotr. 2014.

“Thermal stress analysis of jointed plane in concrete pavements”. App. Therm. Eng. 73: 1167-1174.

20. Matić B., D. Matić,

D. Ćosić, S. Sremac,

G. Tepić, P. Ranitović.

2013. „A model for the pavement temperature prediction at specified depth”.

Metalurgija

52(4): 505-508.

21. Matić B., D. Matić,

S. Sremac, N. Radović,

P. Vidikant. 2014. „A model for the pavement temperature prediction at specified

depth using neural networks”. Metalurgija 53(4): 665-667.

22. Montgomery Douglas C. 2008. Introduction to statistical quality

control. Wiley, New York. NIST/SEMATECH e-handbook of statistical methods.

23.

Montgomery Douglas C. 1980. “The Economic Design of

Control Charts: A Review and Literature Survey”. Journal of Quality

Technology 12: 75-87.

24.

Pavement interactive. Available at:

https://www.pavementinteractive.org/reference-desk/qc-qa/statistical-acceptance/control-charts/.

25.

Sarkar

D., B. Bhattacharjee. 2003. “Quality Monitoring

of Ready Mixed Concrete Using Cusum System”. Indian

Concrete Journal 7: 1060-1065. DOI: 10.1002/best.200810114.

26. Sheng Li, Zhaohui Liu.

2012. „Study on crack extension

of the AC layer of CRC+AC composite pavement”. Mechanika 18(2): 141-147. ISSN

1392-1207.

27.

Shih-Hui

Hsu. 2007. Quality Management, Future

Career Management Corporation. FCMC, Taipei.

28.

Shin-Yi

Chen. 2009. “The concrete is in charge of application and improvement of

drafting”. Concrete Technology

3. Taiwan Concrete Institute. Taipei.

29.

Sztubecka Małgorzta, Adam Bujarkiewicz, Jacek Sztubecki. 2016. “Optimization of Measurement Points Choice in Preparation of

Green Areas Acoustic Map”. Civil

and Environmental Engineering Reports 23(4): 137-144.

30.

Szydło

Antoni. 2004. Road pavements made of

cement concrete. Theory of dimensioning. Cracow: Polski

Cement.

Received 07.11.2019; accepted in revised form 15.01.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License