Article

citation information:

Shpachuk, V., Chuprynin, A., Daleka,

V., Suprun, T. Simulation of impact interaction of rail transport carriage in a butt

roughness zone. Scientific Journal of

Silesian University of Technology. Series Transport. 2020, 106, 141-152. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.106.12.

Vladimir SHPACHUK[1],

Aleksandr CHUPRYNIN[2], Vasily DALEKA[3], Tatiana SUPRUN[4]

SIMULATION

OF IMPACT INTERACTION OF RAIL TRANSPORT CARRIAGE IN A BUTT ROUGHNESS ZONE

Summary. Mechanical and mathematical models of mechanical

multidimensional discrete-continuous systems “carriage – track”

in terms of static and impact interaction in a butt roughness zone are

proposed. Their interaction is investigated with the example of a four-axle car

and a track for four motion phases in the place of isolated butt roughness.

Parameters of static and impact interaction of the carriage with a track in a

place of butt joint which takes into account operational and constructive

factors are defined.

Keywords: four-axle carriage,

tram, track, butt roughness, carriage motion phase, shock interaction

1. INTRODUCTION

Experience

around the world indicates in multidimensional discrete-continuum

mechanical complex „carriage – track”

reliability and durability indicators to depend on the rolling stock and the

truck common work peculiarities, rolling stock type, rails and sleepers type,

considered mechanical system operating conditions. As well as on the ability to

resist the destructive action of shock and vibration loads emergent, that are

cyclically repetitive.

It is

also known, that the highest level of the ballast deposition arises under the

first sleeper of a receiving rail. This is related to the fact [17,28] that

in these places, the first sleeper under the receiving rail usually experiences

the greatest power interaction between the carriage and the top structure of

the way, due to their impact force [2,16,18,20,30,31]. Thus, the deflection of

the receiving rail under the first personal sleeper tend to be an essential

indicator, which corresponds to the peculiarities of the processes of static,

shock and dynamic interaction of the receiving rail with the upper structure of

the path in places with isolated path butt joints [5,23].

2. ANALASIS OF LITERATURE DATA AND

TASK STATEMENT

Analysis of the data, that is dedicated to the four-axle carriage and

the rail trackway interaction indicates [28] that the weakest link of the tram

carriage - rail track system is the isolated zone of the track joints.

Particular studies consider the phases of the carriage movement due to the butt roughness [17], their results

allow a more thorough analysis of this interaction. The collaboration of the

rolling stock and the rail track is simulated as well, this determines the

features of their mechanical interaction [6,7] while carriage passing of the

butt, including shock interaction. Current studies indicate that the interaction between

rolling stock and railway track components define the parameters of durability

in operation, the strength and rigidity of the track [14,15,21,29]. One of the

essential components of such interaction is shock interaction. In aggregate

with other characteristics of dynamic interaction, it affects the technical

resource and service duration.

Practice shows [1,6,28]

that in the mechanical complex “carriage - rail track” reliability

and durability indicators significantly depend on the processes peculiar

properties of interaction between the track and the rolling stock, especially

the operating conditions of the system. In addition, this interaction affects

the ability of the system to withstand the destructive action of the resulting

shock loads [24,29]. To simulate the interaction between the rolling stock and

the track, there is need a to solve several related problems particularly

static and shock ones. A lot of attention is focused on these issues and there

is a sufficient number of new investigations in this sector.

2.1. Recent research analysis

Modern investigations

were considered for this kind of interaction. Most of the papers are currently

limited to the consideration of individual parameters of operation. A more

generalised approach, which considers the totality and interaction of different

factors, is necessary to ensure an adequate description. Currently, significant

investments are made in the transport infrastructure in many countries,

particularly the rail track [3]. Improving the quality and capacity of existing

services and developing new infrastructure are necessary to meet the growing demand

for qualitative and reliable logistics of goods and people. Here the efficiency

and reliability of the track design are crucial for a successful operation. A

lot of modern rail track studies focus on individual aspects of design and

operation, such as fatigue [21,24], ballast failure [9], driving comfort [31],

noise or vibration [8,12,13,30].

At this rate, some

papers [20] consider processes of mechanical interaction in the system

“carriage - rail track” only taking into account the vehicle motion

on the jointless sectors of the route, that is, without considering the

existing dangerous zones with butt irregularities. While other studies [2] do

not take into account the limiting conditions for the receiving rail, depending

on the elastic characteristics of the giving rail and butt overlays.

Practically, this does not correspond to the conditions of the real mechanical

load of the tram carriage, the sections of the rear and receiving rails, which

are located in the areas of the joints of the track. Therefore, the values of

the constructive velocity of the tram carriage, determined in the

investigations, appears virtual, and can not be accepted as reliable.

Thus, one can state that

developing an adequate and convenient model of shock interaction between the

rolling stock and the track is required, and an appropriate method of analysing

their interaction, which considers the rail carriage in the form of a

multi-dimensional discrete system, and the upper structure of the track –

as a continuum system. In this formulation, the essential characteristics of

the mechanical interaction are the shock impulse that occurs in the zone of

butt roughness, as well as the aftershock velocity of the receiving rails.

2.2. Research

objectives

The purpose of the work is

to study the static and shock interaction of the carriage and the upper

structure of the path to improve the parameters of discrete-continuum system

“carriage – rail track” by rational selection and

optimisation of the parameters of its components. This will provide an

additional positive impact on the reliability and durability of the system in

the area with isolated butt roughness.

Including the

above-mentioned, the following research tasks were formulated: to create a

mechanical model of static and shock interaction of four-axle carriage and rail

track, taking into account the variation of load, velocity and reduced to the

one wheel mass of the car, as well as the motion phase of the carriage through

the rail joint; methods of numerical analysis based on the created mathematical

models to determine and analyse the interaction of the components of the

transport discrete-continuum mechanical complex; to establish new regularities

of mechanical interaction of the four-axle carriage and the track in a zone of

butt roughness.

3. MODEL AND INVESTIGATION

METHODS OF THE CARRIAGE AND RAIL TRACK INTERACTION

The discrete-continuum

model of static and shock interaction of a four-axle carriage with the upper

structure of the track is used. It takes into account the design parameters of

the path, carriage, load and speed of the vehicle. The carriage passage of the butt roughness of the way on all four

phases of movement is considered. Thus, all wheels of the carriage wheel pairs

settle down on the rear rail in the first phase, in the second phase – it

is three of them to remain, in the third one – two and on the fourth only

one wheel pair.

3.1. Mechanical model

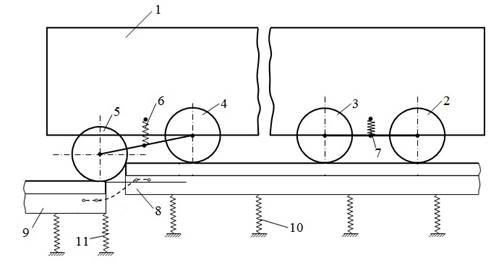

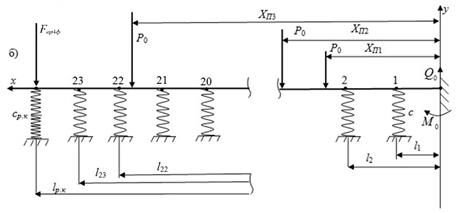

The mechanical scheme is

given in this paper in the example of the fourth phase of motion in Fig. 1.

Here: 1 – vehicle carriage, 2-5 – the corresponding wheel of the

wheel pair; 6-7 – the carriage central suspension; 8 – the

receiving rail; 9 – the rear rail; 10 – the elastic elements of the

ballast layer under the sleepers; 11 – the springing element that models

the rear rails rigidity at the end. This corresponds to the design scheme of a

multispan beam on elastic supports.

Fig. 1. The

scheme of passage of butt roughness

3.2. Static interaction

For the

static calculation of the rail deflections, a model of a multispan beam on 24

elastic supports is used (23 ties and support, which simulates a connection to

the adjacent rail running through the working overlay). To calculate the rail

rigidity value (ср) its deflection at the

end δр under the action of a single force

is determined, then: ср=1/δр. Taking

into account the connection of the working overlay with the rigidity сн of the

giving and receiving rails, we obtain the rigidity of the rail at the end:

![]() . (1)

. (1)

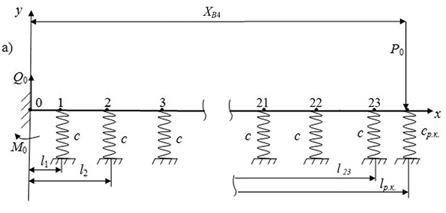

The main force factors

determining the static deflection of the receiving rail under the first elastic

support are constant in magnitude external

forces Р0. They correspond to the

current number of wheel pairs on the rails attached to the giving rail (Fig. 2)

and have the coordinates ХВj, where j = 1, 2, 3, 4 –

the number of the carriage wheel pair.

On Fig. 2: li (і = 1–23); l24=lр.к.=12.5 m – geometric coordinates of elastic supports; Р0 – loads on the side of the

carriage per wheel; ![]() – spring force applied to the

end of the receiving rail by the giving rail at the end;

hВ4ф –

giving rail deflection at the end of the fourth motion phase of the tram

carriage;

– spring force applied to the

end of the receiving rail by the giving rail at the end;

hВ4ф –

giving rail deflection at the end of the fourth motion phase of the tram

carriage; ![]() ;

; ![]() ,

, ![]() ,

, ![]() , c – the ballast

layer rigidity under the sleeper of the upper structure of the path.

, c – the ballast

layer rigidity under the sleeper of the upper structure of the path.

The

equation of the curved axis of the rails at the fourth motion phase will be

written using the method of initial parameters, including the conditions of

fastening. At the origin of the deflection and the angle of rotation of the

sections of both rails are zero, so we get: (у0 = у0' = 0).

For the

other three phases', there will be a difference only in the number of wheels on

the giving and receiving rails.

For the rear rail is

obtained

. (2)

. (2)

For the receiving rail

; (3)

; (3)

Here J – is inertia moment of the rail

cross-section relative to the neutral axis; Е – elastic modulus of rail

material; ![]() – rail length; Q0, M0 are the transverse force and the bending moment in

the coordinate origin.

– rail length; Q0, M0 are the transverse force and the bending moment in

the coordinate origin. ![]() – reaction force of elastic supports. The main force factors

that determine static deflection of the receiving rail under the first elastic

support (2-3) are the external forces Р0=Р/8 (the load at the side of the

car that falls on one wheel; P is the

weight of the car with respect to its load), constant by their magnitude.

– reaction force of elastic supports. The main force factors

that determine static deflection of the receiving rail under the first elastic

support (2-3) are the external forces Р0=Р/8 (the load at the side of the

car that falls on one wheel; P is the

weight of the car with respect to its load), constant by their magnitude.

Fig. 2.

The mechanical pattern of calculation of the junction height in the fourth

motion phase: а) rear rail; b) receiving rail

The

current value of the butt roughness height is calculated from the defined

elastic lines of the rear and receiving rails

![]() ,

,

where ![]() ,

, ![]() – deflections of receiving

and rear rails at the ends. Taking into account that the

expressions (2) and (3) in the right part contain summands, which in turn

depend on deflections, the solutions of these equations are performed

numerically.

– deflections of receiving

and rear rails at the ends. Taking into account that the

expressions (2) and (3) in the right part contain summands, which in turn

depend on deflections, the solutions of these equations are performed

numerically.

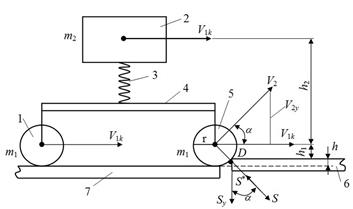

3.3. Shock interaction

Putting into

consideration the parameters dependence of the shock impulse as well as after the impact

speed of the trolley wheel, passing butt roughness path from the following factors: the joint height of the type “gap

– step up”; carriage loading; design and operational parameters of

the vehicle. Hence, the carriage is presented in the form of a sprung summary

mass on the truck, and it is assumed that when the wheel hits the edge of the

receiving rail, its separation does not occur, as well as its sliding relative

to the rail, which does not contradict the results of the papers [6,17,28]. At

this stage, using the system motion angular momentum theorem [28], the

parameters of the shock impulse are determined, the receiving rail will test in

its shock interaction with the truck wheel. Presented according to the scheme

in Fig. 3 is the shock interaction

of the wheel from first wheel pair of the carriage and the receiving track rail

with consideration for the motion angular momentum theorem of the mechanical

system.

Fig. 3. Shock interaction scheme

Here: 1 – wheel of the corresponding wheel pair of the tram carriage; 2 – structural element that models the reduced mass of the; 3 – elastic suspension of the carriage; 4 – truck frame; 5 – wheel from the first wheel pair of the truck; 6, 7 – the rear and receiving rail of the path; h – joint height; h1, h2 – geometrical coordinates of the mass

centres of the wheels 1, 5 and reduced mass 2 of

the carriage; V1k, V2 – to-the-shock and after-the-shock

velocity of the wheel 5; S, Sy – shock impulses, that the receiving rail do

experience while its shock interaction with wheel 5 from the first wheel pair of the

truck; α – angular coordinate of

the wheel centre of mass 5; m1, m2 – reduced masses of the wheel and the

carriage; r – wheel radius. Here, the shock impulse S* equals

by value to the impulse S. In this setting, it corresponds to

the law of conservation of momentum

![]() ,

(4)

,

(4)

where К1, К2

– to-the-shock and after-the-shock system motion angular momentum relative to the axes, passing along the edge D of the receiving rail 6; S* – external shock impulse, applied to the wheel 5 from the receiving rail; ![]() – shock impulse-momentum

relative to the edge D. In equation (4) the moments of the

amount of motion, taking into account the scheme in Fig. 3, which is

– shock impulse-momentum

relative to the edge D. In equation (4) the moments of the

amount of motion, taking into account the scheme in Fig. 3, which is

![]()

![]() .

.

Taking into the account, that shock impulse S* crosses wheel centre of masses 5, while velocities of the wheel 1 and reduced mass 2 of the carriage equals to V1k and do

not change own direction during

the strike, equation 4 allows to indicate the value after-the-shock

speed:

![]() .

.

One defines a shock impulse

of the mechanical scheme interaction in Fig. 3 with the flat end of the receiving rail in projections

on the vertical axis y, in accordance

with the system motion angular momentum theorem, as (considering V1ky = 0)

![]() ,

(5)

,

(5)

where ![]() . Equation 5 establishes

the dependence of the parameters of the vertical component of the shock pulse

on the mass and radius of the wheel, the speed of its centre of mass, as well

as the height of the butt roughness at this phase of the movement. In this

paper, the dependence (5) is further used to determine after-the-shock vertical

cross-section velocity of the receiving rails at the end. The following

approach is used. Experiencing shock impulse Sy, the flat end of the

rail 6 (Fig. 3) will receive at

. Equation 5 establishes

the dependence of the parameters of the vertical component of the shock pulse

on the mass and radius of the wheel, the speed of its centre of mass, as well

as the height of the butt roughness at this phase of the movement. In this

paper, the dependence (5) is further used to determine after-the-shock vertical

cross-section velocity of the receiving rails at the end. The following

approach is used. Experiencing shock impulse Sy, the flat end of the

rail 6 (Fig. 3) will receive at ![]() (Fig. 2), given that on impact, the

receiving rail bends along the same curve as under the action of a static

concentrated load, under elastic deformation conditions according to (3),

vertical displacement

(Fig. 2), given that on impact, the

receiving rail bends along the same curve as under the action of a static

concentrated load, under elastic deformation conditions according to (3),

vertical displacement

,

,

where ![]() – peak value of deflection;

– peak value of deflection; ![]() – deflection of the rail flat end under the action of a single force

– deflection of the rail flat end under the action of a single force ![]() Н when

Н when ![]() ;

; ![]() – joint

height on the i-th carriage

motion phase. It is taken into account that the

joint height of the track is a function of the motion phase. The

velocity of the rail cross-section with the coordinate х will be at time t, in accordance with the Fourier method

of variables separation:

– joint

height on the i-th carriage

motion phase. It is taken into account that the

joint height of the track is a function of the motion phase. The

velocity of the rail cross-section with the coordinate х will be at time t, in accordance with the Fourier method

of variables separation:

,

(6)

,

(6)

where ![]() – the change rate of the amplitude with time

– the change rate of the amplitude with time ![]() , that

is, the vertical cross-section velocity of the receiving rail. The obtained

distribution of speed along the length of the rail (6), allows writing the expression for

its momentum (5). This results in an expression for

the vertical component, for the subsequent calculation of the after-the-shock velocity. Momentum

, that

is, the vertical cross-section velocity of the receiving rail. The obtained

distribution of speed along the length of the rail (6), allows writing the expression for

its momentum (5). This results in an expression for

the vertical component, for the subsequent calculation of the after-the-shock velocity. Momentum ![]() of the receiving rail 6 in the projection on the axis

after-the-shock interaction with the wheel 5 we define as

of the receiving rail 6 in the projection on the axis

after-the-shock interaction with the wheel 5 we define as

,

,

where ![]() . Thus, including (5) and (6) with

. Thus, including (5) and (6) with ![]() after-the-shock vertical velocity of the rail is

determined as

follows:

after-the-shock vertical velocity of the rail is

determined as

follows:

. (7)

. (7)

4. INVESTIGATION RESULTS

According to the model proposed, the numerical analysis of the parameters between the shock interaction

of a four-axle vehicle with a rail track in the place of an isolated butt roughness of the “gap”

type is performed on the example of a tram carriage. The calculations were

conducted based on the variation of carriage loading, velocity and reduced to

one of the wheels mass of the carriage according to the defined phases of

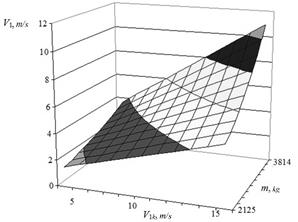

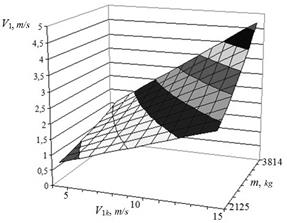

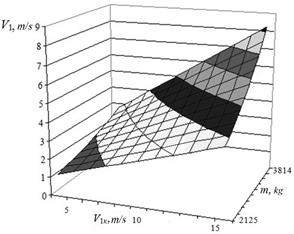

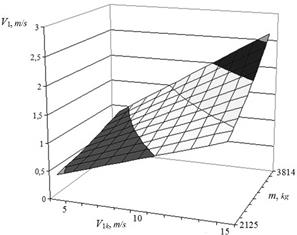

motion. Fig. 4-7 show the dependences after the shock velocity ![]() of the receiving rail. Table

1 shows the data of mechanical interaction at the maximum load of the carriage

and the speed of movement tram (15 m/s)

at all phases.

of the receiving rail. Table

1 shows the data of mechanical interaction at the maximum load of the carriage

and the speed of movement tram (15 m/s)

at all phases.

The analysis was carried out according to the

calculation scheme shown in Fig. 2–3. The following design

characteristics of the rail Р-65 and the tram Т-3 [18]: Е = 2.6·1011 N/m2; J = 3573 сm4; ρ = 7.8 кg/m3; F = 82.65 сm2; с = 4.225·105 N/m were

used.

The reduced to one wheel mass of the empty carriage is m = m1+m2 = 2125 кg, while maximum mass (with 193 passengers) of the

loaded one – m = 3814 кg; m1 = 1100 кg. This

corresponds to real operating conditions and design characteristics of the tram

vehicle and rail track.

Tab. 1

Characteristics of

mechanical interaction of four-axle tram and track

|

Characteristic |

Phase 1 |

Phase 2 |

Phase 3 |

Phase 4 |

|

Height of joints [mm] |

3.89 |

1.01 |

1.95 |

0.67 |

|

After-the-shock velocity [m/s] |

10.93 |

4.708 |

8.234 |

2.623 |

|

Fig. 4. Dependence after-the-shock

velocity on the operational factors at the first phase |

Fig. 5. Dependence after-the-shock

velocity on the operational factors at the second phase |

|

Fig. 6. Dependence after-the-shock

velocity on the operational factors at the third

phase |

Fig. 7. Dependence

after-the-shock velocity on the operational factors at the fourth phase |

5. SUMMARY

The laws analysis shows, for example, that the variation of reduced to the one wheel mass of the tram carriage in the range ![]() кg with design velocity of

кg with design velocity of ![]() m/s leads to a change after the shock

velocity depending on the phases of the tram carriage motion, respectively, in

the ranges V1 = [4.635÷10.93] m/s, V1 = [2.355÷4.708] m/s, V1 = [3.729÷8.234] m/s, V1 = [1.368÷2.623] m/s, that is, to the growth 2.36; 1.99; 2.2; 1.92 times.

m/s leads to a change after the shock

velocity depending on the phases of the tram carriage motion, respectively, in

the ranges V1 = [4.635÷10.93] m/s, V1 = [2.355÷4.708] m/s, V1 = [3.729÷8.234] m/s, V1 = [1.368÷2.623] m/s, that is, to the growth 2.36; 1.99; 2.2; 1.92 times.

One presented the results of numerical calculations of static and shock interaction

parameters on the example of a tram carriage with a rail track at the junction,

which takes into account operational, mechanical and geometric factors using

the proposed models. It defines new regularities of interaction of the

four-axle carriage with a rail track with vehicle passing through the butt

roughness and allows to make improvement of operational parameters and design

characteristics of the carriage and the top structure of a truck by rational

choice and optimisation of parameters.

The results obtained are of significant theoretical importance in

establishing the laws of influence of operational factors, and practically,

they are used in the development of technical solutions to improve the junction

of the track, in determining the modes of operation of tram carriages,

including other four-axis, taking into account the limit values of shock

impulses of interaction. Also, when creating an experimental-theoretical

complex for research, calculations and improvement of the parameters of the

carriage and the upper structure of the track.

References

1.

Aristizabal Mauricio, Jaime L. Barbosa, German R. Betancur, Leonel F.

Castañeda, Bogdan Żółtowski. 2014. “Structural

diagnosis of rail vehicles and method for redesign”. Diagnostyka 15(3): 23-31.

2.

Auersch

L. 2017. „Mitigation of railway induced vibration at

the track, in the transmission path through the soil and at the building”. Procedia Engineering

199: 2312-2317. DOI: 10.1016/j.proeng.2017.09.192Get rights and content.

3.

Cejka Jiri, Martin Telecky. 2019. „Influence of economic and

political factors on the public rail transport”. Komunikacie (Communications - Scientific Letters of the University of

Zilina) 21(2): 13-17. ISSN: 1335-4205.

4.

Czech Piotr. 2011. „Diagnosing of disturbances in the ignition

system by vibroacoustic signals and radial basis function - preliminary

research”. Communications in

Computer and Information Science 239: 110-117. DOI

https://doi.org/10.1007/978-3-642-24660-9_13. Springer, Berlin, Heidelberg.

ISBN: 978-3-642-24659-3. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Modern

transport telematics, 11th International Conference on Transport Systems

Telematics, Katowice Ustron, Poland, October 19-22, 2011.

5.

Czech Piotr. 2012. „Determination of the course of pressure

in an internal combustion engine cylinder with the use of vibration effects and

radial basis function - preliminary research”. Communications in Computer and Information Science 329: 175-182.

DOI https://doi.org/10.1007/978-3-642-34050-5_21. Springer, Berlin, Heidelberg.

ISBN: 978-3-642-34049-9. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Telematics

in the transport environment, 12th International Conference on Transport

Systems Telematics, Katowice Ustron, Poland, October 10-13, 2012.

6.

Даренський

О.М., А.В. Клименко. 2013. „Моделирование взаимодействия пути и подвижного состава при дискретном подрельсовом основании в зоне рельсовых стыков”. Інформаційно-керуючі

системи на

залізничному

транспорті 4: 15-22. [In Ukrainian: Darensky O.M., A.V. Klimenko. ”Modeling of interaction between track and rolling stock at discrete

track base in the zone of rail joints”. Railway information and control systems 4: 15-22].

7.

Darensky

O.M., Klimenko A.V. 2013. „Simulation

of the interaction of the track and rolling stock at a discrete sub-rail base

in the area of rail joints”. Information

and control systems in railway transport 4: 15-22.

8.

Fomin

Oleksij, Juraj Gerlici, Alyona Lovska, Kateryna Kravchenko, Pavlo Prokopenko,

Anna Fomina, Vladimir Hauser. 2019. “Durability determination of the

bearing structure of an open freight wagon body made of round pipes during

its transportation on the railway ferry”. Komunikacie (Communications - Scientific Letters of the University

of Zilina) 21(1): 28-34. ISSN: 1335-4205.

9.

Gu

Sh., X. Yang, Sh. Zhou, S. Liang, Yu Zhou. 2016. „An innovative contact partition model for

wheel/rail normal contact”. Wear 366-367: 38-48. DOI: 10.1016/j.wear.2016.07.001.

10. Homišin J., R. Grega, P.

Kaššay, G. Fedorko, V. Molnár. 2019. “Removal of

systematic failure of belt conveyor drive by reducing vibrations”. Engineering Failure Analysis 99:

192-202. ISSN 1350-6307.

11.

Иванов М.Д., А.А. Пономарев, Б.К. Иеропольский.

1977. Трамвайные

вагоны Т-3. [In Russian: Ivanov M.D., Ponomarev A. A., Ieropolsky B. K. Tram cars T-3]. Moscow:

Transport. 240 p.

12. Jacyna M., J. Merkisz.

“Proecological approach to modelling traffic organization in national

transport system”. Transport

systems of Transport 2(30): 43-56.

13. Jacyna

M., M. Wasiak, K. Lewczuk, G. Karoń. 2017. “Noise and environmental pollution from

transport: decisive problems in developing ecologically efficient transport

systems”. Journal of

Vibroengineering 19: 5639-5655. DOI: doi.org/10.21595/jve.2017.19371.

14. Jin Shi, Defeng Hou.

2017. “Failure analysis for railroad embankment under heavy haul wagon

loads”. Mechanika 23(2):

197-203. ISSN 1392-1207.

15. Khadri Y., S. Tekili, E.

M. Daya, A. Daouadji, B. Merzoug. 2013. “Effects of rail joints and

train's critical speed on the dynamic behaviour of bridges”. Mechanika 19(1): 46-52. ISSN 1392-1207.

16. Krajňák J., J. Homišin,

R. Grega, M. Urbanský, 2016. „The

analysis of the impact of vibrations on noisiness of the mechanical system”. Diagnostyka 17(3): 21-26. ISSN 1641-6414.

17. Лазарян В.А.

1964. Динамика

вагонов.

Устойчивость

движения и

колебания. [In Russian: Lazaryan V.A. 1964. The dynamics of the cars. Stability of movement and fluctuations]. Moscow: Transport. 255 p.

18.

Ling X., H. Xiao, X. Cui. 2018. „Analysis of mechanical properties of

polyurethane-mixed ballast based on energy method”. Construction and

Building Materials 182: 10-19. DOI: 10.1016/j.conbuildmat.2018.06.008.

19. Maláková S. 2017.

„Analysis of gear wheel body influence on gearing stiffness”. Acta Mechanica Slovaca 21(3): 34-39.

ISSN 1335-2393.

20. Meehan P.A., R.D. Batten, P.A. Bellette.

2016.

„The effect of non-uniform train speed

distribution on rail corrugation growth in curves/corners”. Wear 366-367: 27-37. DOI: 10.1016/j.wear.2016.05.009.

21. Michalski R., S. Wierzbicki. 2008.

„An analysis of degradation of vehicles in operation”. Eksploatacja i Niezawodnosc –

Maintenance and Reliability 1: 30-32.

22. Moravec M., G. Ižariková, P.

Liptai, M. Badida, A. Badidová. 2018. „Development of

psychoacoustic model based on the correlation of the subjective and objective

sound quality assessment of automatic washing machines”. Applied Acoustics 140: 178-182.

ISSN 0003-682X. DOI: 10.1016/j.apacoust.2018.05.025.

23.

Prakoso P.D. 2012. „The Basic Concepts of Modelling Railway

Track Systems Using Conventional and Finite Element Methods”. Jurnal Ktilmual dan Aplikasi Teknik

13(1): 18-24. DOI: 10.20527/infotek.v13i1.1816.

24. Pukach P.Ya., I.V. Kuzio, Z.M. Nytrebych,

V.S. Il’kiv. 2018. „Asymptotic

method for investigating resonant regimes of nonlinear bending vibrations of

elastic shaft”. Scientific Bulletin

of National Mining University 1:

68-73.

DOI: 10.29202/nvngu/2018-1/9.

25. Puškár M., M. Kopas. 2018.

„System based on thermal control of the HCCI technology developed for

reduction of the vehicle NOX emissions in order to fulfil the future standard

Euro 7”. Science of the Total

Environment 643: 674-680. ISSN 0048-9697. DOI: 10.1016/j.scitotenv.2018.06.082.

26. Sága M., M. Vaško, P. Kopas,

L. Jakubovičová. 2010 „Identification of the hysteretic material

model parameters and application on energy fatigue curve”. Machine Dynamics Research: 79-87. Warsaw University of Technology.

27. Sturm M., L. Pešík. 2017.

„Determination of a vibrating bowl feeder dynamic model and mechanical

parameters”. Acta Mechanica et

Automatica 11(3): 243-246. ISSN 1898-4088. DOI: 10.1515/ama-2017-0038.

28. Вериго

М.Ф.,

А.Я. Коган. 1986. Взаимодействие

пути и

подвижного

состава. [In Russian: Verigo M.F., A.Ya. Kogan. 1986. Interaction of track and rolling stock]. Moscow: Transport. 559 p.

29. Vinogradov B.V. 2015. „The equivalent number of stress cycles in

view of fatigue calculation of tumbling mill gear”. Scientific Bulletin of National Mining

University 1:

72-76.

30. Wheeler

L.N.,

W.A. Take, N.A. Hoult. 2016. „Measurement of rail deflection on soft

subgrades using DIC”. Proceedings

of the Institution of Civil Engineers. Geotechnical Engineering 169(5): 383-398. DOI: 10.1680/jgeen.15.00171.

31. Zul'ová L., R. Grega, J.

Krajňák. 2017. „Optimization of noisiness of mechanical

system by using a pneumatic tuner during a failure of piston machine”. Engineering

Failure Analysis 79: 845-851. ISSN 1350-6307.

Received 05.11.2019; accepted in revised form 10.01.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License