Article

citation information:

Mańka, A., Hełka, A.,

Ćwiek, J. Influence of copper content on pantograph contact strip material on

maximum temperature of railroad wire. Scientific

Journal of Silesian University of Technology. Series Transport. 2020, 106, 97-105. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.106.8.

Adam MAŃKA[1], Andrzej HEŁKA[2], Janusz ĆWIEK[3]

INFLUENCE

OF COPPER CONTENT ON PANTOGRAPH CONTACT STRIP MATERIAL ON MAXIMUM TEMPERATURE

OF RAILROAD WIRE

Summary. This article presents the results of studies on the

impact of the percentage of copper in the carbon composite of the railway

pantograph contact strips on the maximum temperatures of the contact wire of

the overhead contact line. The tests were carried out in accordance with the

requirements of standards [7, 9] and TSI [4]. The obtained relationship allows

for an initial assessment of the introduced materials due to the contact wire

heating criterion based on the copper content of the carbon composite, which

greatly facilitates the design process and the initial assessment of the

pantograph slides performance. This publication also indicates the minimum

value of the percentage of copper at which the standard requirements [7] for

railroad wire heating are still met.

Keywords: pantograph contact

strip material, carbon strips, composite material, railway pantograph, railroad

wire, maximum temperature of railroad wire

1. INTRODUCTION

The railway pantograph contact strip is an element of traction vehicles

that cooperates with railroad wire during operation. The durability,

reliability and safety of the pantograph and, consequently, the entire railway

vehicle depend on its performance. The contact strip and contact wire used for

decades were technically made of pure copper. Graphite grease was used for

proper cooperation and reduction of wear of this friction pair. As technology

progressed, new materials were developed that enabled the withdrawal of

copper-based contact strips in favour of copper-based carbon composites. This

allows:

- longer service life of

carbon strips at a comparable cost,

- longer life of contact

wires, which reduces the overall cost of network maintenance,

- no need to sinter strips

with contact wires (carbon does not react with copper),

- no need to lubricate the

contact surface of the strip-contact wire.

The listed advantages of the introduced contact strips, including the

reduced adverse impact on the environment (reduction of copper consumption

products and the lack of the use of lubricants) have contributed to the introduction

of the obligatory use of composite contact strips in rail transport throughout

the European Union.

In 2011, the Polish

railway lines introduced the obligation to apply pantographs fitted with

contact strips made of carbon composite. These strips have replaced the copper

ones that were used for many years. This change resulted from the need for the

Polish railways to match the requirements of the Technical Specifications for

Interoperability [4]. This provision forced the carriers to install in their

pantographs composite materials that previously had to undergo specific test

procedures [7, 9], material and thermal testing among others.

In professional literature, many researchers take up the topic related

to the analysis of pantograph dynamic cooperation with the overhead contact

line [1, 8, 13]. The authors define mathematical models describing the

interaction between the pantograph and the overhead contact line, including for

the purposes of pantograph diagnostics [1, 8]. They also examine the impact of

a number of parameters on the intensity of the contact wire wear [12]. There

are also works related to thermal phenomena [10], however, they are focused

mainly on testing the contact wire temperature during operation.

It is important, however, that due to the use of overhead contact lines

in the EU with different rated voltages, that is, from 3 kV to 25 kV, and there

are significantly different requirements for its electrical conductivity. For

instance, assuming a constant power demand value for a traction vehicle, for

example, 5 kW as for a Dragon locomotive, it is simplified that this power can

be obtained at 3 KV supply voltage at 1667 A or 200 A at 25 kV. The presented

extreme current values of 200 A and 1667 A also have their effects in the heating

of the elements through which the electric current flows.

According to Joule–Lenz law, which states that the power of

heating generated by an electrical conductor is proportional to the product of

its resistance and the square of the current:

![]() (1)

(1)

where:

Q [W] – power of

heating generated by an electrical conductor,

R [Ω] –

resistance,

I [A] – current,

t [s] – current

flow time.

Therefore, it can be seen that the obvious disadvantage of using a

relatively low voltage overhead contact line generates very high values of the

flowing current I, which in consequence forces the use of conductors with a

very low resistance R. This applies in particular to the contact strip. The

limitation associated with heat release is important both from the viewpoint of

minimising energy losses and the impact of heat on mating elements. In the case

of copper, an increase in temperature above approx. 200°C causes its

recrystallization and a significant deterioration in its performance, which is

unacceptable for railroad wire. Therefore, the criterion of the amount of heat

generated in the interface between the contact strip and the overhead contact

line is particularly important for rail transport, and the need to verify it is

also found in normative requirements [7, 9].

From the above considerations, it is clear that not all contact strips

that work properly in pantographs operated on 25 kV networks can be used on 3

kV networks. In practice, based on many years of research experience of the

authors, it is found that hardly any material used for contact strips meets all

normative requirements related to current carrying capacity. The basic feature

that affects the applicability of a given contact strip is its specific

conductivity, which results directly from the copper content of the carbon

composite. Based on previous experience in testing the compliance of materials

for contact strips, the authors first took into account the results of testing

the percentage of metals and then performed tests on the thermal resistance of

the contact wire, as these tests were the most demanding and indicated the

desirability of performing further tests provided for in the standard [7].

It can therefore be assumed that it is possible to determine the value

of the percentage of copper that will ensure that the maximum temperature

requirement is met when trying to heat with electricity.

2. RESEARCH METHODOLOGY

PN-K-91001: 1997 on page 12 defines the requirements of 2.15.3. “Contact

wire temperature increase”, which posits that the maximum contact wire

temperature increase over the design ambient temperature, that is, 40°C,

cannot be greater than 80°C. This gives a maximum contact wire temperature

of 120 °C. Tested system: contact strip – contact wire, should be

loaded with the maximum current received from the contact system during the

current, that is, 200 A within 30 min.

The test stand was made in accordance with the normative requirements

presented above, with the provision that the wire was used without significant

wear and tear. Stand 1 Fig. 1 is equipped with a current circuit with one

conductive type Djp100 made of copper in CuETP grade with the required current

value of 200 A. The current value was measured with an indicator ammeter with

an accuracy of ± 5 A and a clamp meter ammeter type CM-9930 from Lutron

with serial number 04011 and measurement uncertainty ± 2% A.

During

the tests, pressure 102 N within the normative range of ![]() N was

applied. The contact wire temperature was measured by placing thermocouples in

the contact wire slots located above the contact strips according to the

diagram in Figure 2.

N was

applied. The contact wire temperature was measured by placing thermocouples in

the contact wire slots located above the contact strips according to the

diagram in Figure 2.

Materials for contact strips being

the subject of tests for placing in service in Poland that is operated at the

rated voltage of the traction network 3 kV were used for the tests. These

materials were given letter markings in the order of the smallest percentage of

copper in the carbon composite. Due to similar results obtained for a group of

materials with a copper content in the range of 30%, the mean values from 3

materials with a share of 29.3; 31.2 and 31.7% Cu were used for further

development.

Fig. 1. Laboratory stand

for pantograph and contact strip material testing

![]()

Fig. 2. Diagram of the measuring system

Tab. 1

The percentage of copper in the carbon-copper

composite

|

Material designation |

Copper percentage in composite [%] |

Carbon percentage in composite [%] |

Binder percentage

in composite [%] |

|

A |

0,2 |

94,5 |

5,3 |

|

B |

20,1 |

76,4 |

3,5 |

|

C |

30,7 |

63,5 |

4,8 |

|

D |

40,4 |

48,6 |

11,0 |

It should be noted that, according to the standard [2], the weight of

metals may not exceed 40% of the weight of the overlay material.

A material with a copper percentage of 40.4% was not taken for further

analysis due to a much larger proportion of binders, that is, 11.0%, which

significantly affected the deterioration of the thermal and electrical

properties of the contact strip material. At the same time, exceeding the

threshold of 40% discriminates against this material from further normative

studies.

Importantly, according to the authors, the mandatory examination of the

content of the inclusions of metals required by the standard [7] can also be an

indication for the initial determination of the thermal resistance of the

material to the pantograph contact strips.

3. RESULTS AND

DISCUSSION

As a result of the set current load

in the contact strip – contact wire system, and due to the contact wire

temperature measurement, it was possible to determine in the first minutes of

the test whether the material meets the required condition of not exceeding the

temperature of 120°C. However, the tests were conducted for a period of 30

min set in the standard. The obtained results are presented in Table 2.

Tab. 2

Summary of final temperatures (30 min) of contact wire

for various copper percentages

in the carbon composite of contact strips

|

Material designation |

Copper percentage in composite [%] |

Average contact wire temperature [oC] |

|

A |

0,2 |

230,7 |

|

B |

20,1 |

138,4 |

|

C |

30,7 |

111,7 |

It should be noted that material A

(material used in the 15 kV network) was tested last and as expected, material

with such low copper content does not meet the requirements of the standard [7].

It should also be noted that for material A, already in the 2nd minute of the

test, the contact wire temperature exceeded the permissible value, that is

120°C. In addition, as bench tests showed, the use of such an overlay in

operating conditions would recrystallize the contact wire copper after approx.

9 min of co-operation at standstill, that is, damage to its physical properties

after exceeding 200°C – Fig. 3.

Fig. 3. Summary of test results of the influence of the

percentage of copper strip on the contact

wire temperature (heating 200 A for 30 min)

From the waveforms of temperature

changes presented in Figs. 3 and 4 during the current flow 200 A corresponding

to the values taken by the traction vehicle with the heating switched on, it

can be seen that the material A and B does not meet the heating temperature

criterion, that is 120°C (assuming the initial design temperature of

40°C).

To enable determination of the

minimum value of the percentage of copper above which it is possible to meet

the normative requirements for contact wire heating, the obtained results are

shown in Fig. 4.

Fig. 4. Summary of contact wire temperature increase values for

various materials of the contact strip relative to the ambient temperature

of 20°C (heating 200 A for 30 min)

From the approximation equation for

the exponential function of the relationship between the percentage of copper

in the contact strip and the contact wire temperature, it follows that the

maximum wire temperature will be 120°C, that is, the increase will be

100°C for a percentage of copper of 26%. Below this value, the maximum

contact wire criterion is most likely not met.

The obtained relationship between

the percentage of copper and the increase in contact wire temperature (at an

ambient temperature of 20°C can be described by the relationship (2).

![]() (2)

(2)

where:

ΔTc [oC]

– contact wire temperature increment,

C [%] – the

percentage of copper in the composite.

The above relationships were

obtained for composites in which, apart from carbon and copper, no more than

about 5% of the binder was used as the binder. It should be noted that making a

composite with a binder of 11% significantly worsens its electrical and thermal

properties even if the percentage of copper is within the limit value. The

final temperature of 103°C was obtained for this material (D).

The graph also shows that the

carbon composite alone without copper with the addition of binder up to approx.

5% will achieve a temperature increase of 206°C or 226°C, which causes

damage to the contact wire (its recrystallization) in less than 9 min after

starting the traction vehicle parking.

At the same time, based on this

relationship, it can also be pointed out that when making a 100% copper contact

strip, the contact wire temperature increase will be about 12°C. Indicated

in standard [7], the maximum value of the 40% copper percentage should cause a

temperature increase of 67.5°C, which is to 87.5°C.

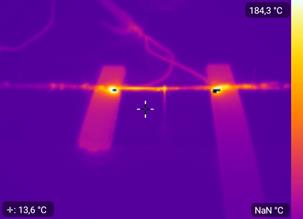

The thermogram (Fig. 5) shows the

temperature distribution in the contact zone of the contact wire with contact

strips.

Fig. 5. Thermogram of an example contact point of contact wire

and contact strip

Regardless of the demonstrated

impact of the percentage of copper in the carbon overlay, it should be noted

that while for networks with a supply voltage of 3 kV, it is particularly

important to note the significance of such testing for the use of sliding

overlays on networks with higher voltages, where current values are much lower.

It is expedient to determine the normative values of current loads for vehicles

used on networks with higher nominal voltages.

4. CONCLUSIONS

The research carried out on the impact of the percentage of copper in

the carbon composite of the rail pantograph contact strips on the maximum

contact wire temperatures of the railroad contact line showed that the increase

in copper content in the contact strip material causes a reduction in the

contact wire temperature. The study of the effect of current-carrying capacity

on the contact wire temperature was the most common reason discriminating a

given material for use in the Polish railroad contact line, therefore, the

authors attempted to determine the relationship between copper content and

contact wire temperature to facilitate the preliminary assessment of the

operational suitability of the tested contact strip materials.

Based on the conducted research, the following conclusions can be drawn:

- it is possible to estimate the contact wire

temperature based on the knowledge of the percentage of copper in the carbon

composite as observed in the presented relationship (2), assuming that the percentage

of binder does not exceed approx. 5.3%,

- a high percentage of binder material (adhesive) in the

composite negatively affects its electrical and thermal properties. In

particular, for material with 11% binder and 40% Cu, the permissible contact

wire temperature was exceeded and amounted to 128°C,

- material A operated on 15 kV network did not meet the

requirements for 3 kV network. At the same time, it should be noted that using

such material, it is possible to “overheat” the contact wire,

that is, exceeding the recrystallization temperature of 200°C after approx.

9 out of 30 min of receiving power when the vehicle is stationary.

The authors of the publication see the need to continue the presented

research and extend it to include the impact of the percentage of carbon

composite binders (adhesives) and to determine the impact of contact wire heat

load on its strength, electrical and thermal properties.

References

1.

Alberto A., J. Benet, E. Arias, D. Cebrian, T. Rojo, F. Cuartero. 2008. „A high performance tool for

the simulation of the dynamic pantograph – catenary interaction”. Mathematics and Computers in Simulation 3(79): 652-667.

2.

Benet J., N. Cuartero, F. Cuartero, T. Rojo, P. Tendero,

E. Arias. 2013. „An advanced 3D-model for the

study and simulation of the pantograph catenary system”. Transportation Research Part C 36: 138-156.

3.

Bucca G., A. Collina. 2009. „A procedure for the wear

prediction of collector strip and contact wire in pantograph – catenary system”. Wear 266: 46-59.

4.

Commission Regulation (EU) No 1301/2014 of 18

November 2014 on the technical specifications for interoperability relating to

the ‘energy’ subsystem of the rail system in the Union Text with

EEA relevance.

5.

Ding T., G.X. Chen, J. Bu, W.H. Zhang. 2011. „Effect of temperature and arc

discharge on friction and wear behaviours of carbon strip/copper contact wire

in pantograph – catenary systems”. Wear 271: 1629-1636.

6.

Ding T., G.X. Chen, Y.M. Li, H.J. Yang, Q.D. He. 2014. „Arc erosive characteristics of a carbon strip

sliding against a copper contact wire in a high-speed electrified railway”. Tribology International 79: 8-15.

7.

EN 50405: 2016 Railway applications -

Current collection systems – Pantographs, testing methods for carbon

contact strips.

8.

Judek S., M. Michna, M. Mizan, K. Karwowski, A.

Wilk, P. Kaczmarek. 2016. „Mathematical modeling of the

overhead contact line for the purpose of diagnostics of pantographs”. Elektrotechnika 113(1-E): 79-89.

9.

PN-K-91001:1997 Electric traction vehicles, Current

collectors, Requirements and test methods, PKN December 1997.

10. Theune N., T. Bosselmann, J. Kaiser,

M. Willsch, H. Hertsch, R. Puschmann. 2010. „Online temperature monitoring of overhead contact

line at the new German high-speed rail line Cologne-Rhine/Main”. WIT Transactions on State of the Art in Science and Engineering 39. WIT Press. ISSN 1755-8336. DOI: 10.2495/978-1-84564-498-7/09.

11. Trans-European-Conventional

Rail System Subsystem Rolling Stock Tsi “Lokomotives And Passenger

Rst” IU-RST-03-08-2009-TSI draft Version 3.0 Date: 3/08/2009.

12. Shing A.W.C., P. Wong. 2008. „Wear of pantograph collector

strips”. Proceedings of the Institution of Mechanical Engineers Part F Journal

of Rail and Rapid Transit 222(2): 169-176. DOI: 10.1243/09544097JRRT156.

13. Sitarz M., A. Hełka, A. Mańka, A. Adamiec.

2013. „Testing of railway pantograph”. Archives

of Transport 25-26(1-2): 85-95. ISSN 0866-9546.

Received 26.10.2019; accepted in revised form 04.01.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License