Article

citation information:

Jírová, R., Pešík, L. Identification and verification of

dynamic parameters for the welding manipulator. Scientific Journal of Silesian University of Technology. Series

Transport. 2020, 106, 51-61.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.106.4.

Radka JÍROVÁ[1],

Lubomír PEŠÍK[2]

IDENTIFICATION

AND VERIFICATION OF DYNAMIC PARAMETERS FOR THE WELDING MANIPULATOR

Summary. Welding production lines are indispensable parts of

the production processes in the automotive industry. In many cases, the

production line operation is ensured by equipment with linear conveyors or

robots, wherein linear guiding systems are basic elements of these

manipulators. The failure of some linear guiding system may lead to significant

production losses. Hence, the knowledge of their operating loads is necessary

to determine very exactly. The objective of this article is to identify and

verify the basic dynamic parameters of the welding manipulator, as a starting

point for the operating loads calculation of linear guiding systems. This issue

was solved by combining the measurement of kinematic values and MBS (Multi-body

System) analysis in case of the concrete linear welding manipulator, which was

the main part of the observed welding line. We have measured time values of

acceleration in defined points of the manipulator and evaluated them by FIR

(Finite Impulse Response) filter, FFT (Fast Fourier

Transformation) analysis and ODS (Operating Deflection Shapes) analysis. The

obtained frequency spectrum showed oscillation frequencies, which could be

compared with frequencies of the manipulator dynamical model by different mass

and stiffness parameters. In this way, the dynamic parameters of the welding

manipulator can be identified and used for the next calculations and

simulations, where loads of linear guiding systems will produce very important

results.

Keywords: dynamic parameters,

dynamic system, welding production line, welding manipulator, linear guiding

system

1. INTRODUCTION

Nowadays, during the Industry 4.0,

great emphasis is placed on production machines reliability. Operating

conditions of all important machines should be thoroughly analysed and

evaluated. These precautions should increase their reliability, predict

possible failures and prevent possible production losses [4-8,10,11,13-15,17].

In case of welding production

lines, a prediction of linear guiding system failures in one of the first

places is needed, because these parts enable in these lines the transport of

car bodies for the welding process. Should they fail, the production must be

stopped for a few days. This situation can lead to significant production

losses. Therefore, the prediction of the failures is very necessary and the

determination of the linear guiding systems loads is the main task for

calculations and simulations on the welding manipulator mechanical model [2,3,16].

To identify these operating loads,

it is necessary to have sufficient notions about the dynamical behaviour of the

welding manipulator. In this article, the issue is solved as the planar motion

of the manipulator.

2. MEASUREMENT

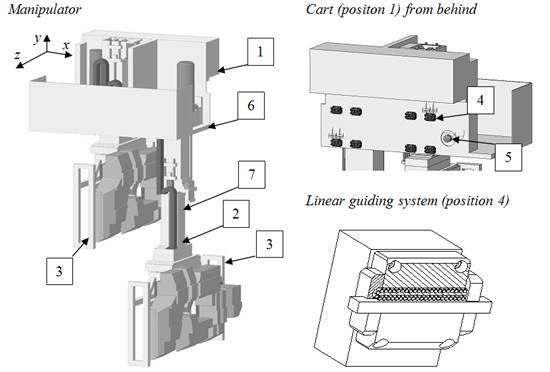

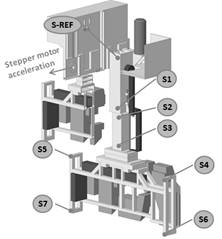

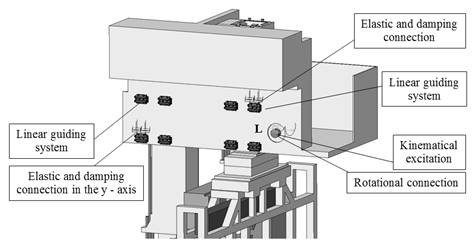

In Fig. 1 is displayed

the 3D model of the welding manipulator with positions of two acceleration

sensors (S-V and S-Z). The major parts of the manipulator are the cart, two

so-called Z-axes and two clamping frames with car bodies.

The welding manipulator

exercises a translation motion, which is provided by the stepper motor through

a rack gear and linear guiding systems. The linear guiding systems connect the

cart with the frame by means of guide profiles. However, the elastic

construction parts and clearances of linear guiding systems cause oscillations

of the manipulator against the mashing point of the rack gear. The rack gear,

the stepper motor and linear guiding systems are placed on the cart of the

manipulator. The clamping frames with the car bodies are connected to the cart

through the Z‑axis that enables their vertical translation motion.

Kinematics of the

welding manipulator was measured by two three-axis acceleration sensors [12]. The first sensor S-V

was situated close to the stepper motor that powers the manipulator. The second

one S-Z was situated close to the car bodies clamping frame (Fig. 1). The

knowledge of the kinematic parameters in two positions gives sufficient notions

about the dynamic system behaviour of the welding manipulator [1].

Fig. 1.

Model of the welding manipulator with positions of two acceleration sensors:

1 - cart,

2 - Z-axis, 3 - clamping frame, 4 - linear guiding system,

5 - rack gear, 6 - acceleration sensor S-V, 7 - acceleration sensor S-Z

2.1. Finite Impulse

Response (FIR) filter

Measured data were

evaluated by the FIR filter that enabled the identification of the system basic

motion in each coordinate axis. Considering the Fast Fourier Transformation (FFT) analysis result, the FIR filter was used as a low pass

filter with the cut-off frequency 3 Hz. The higher order of the filter was used

for reaching the sufficient slope of the transition band.

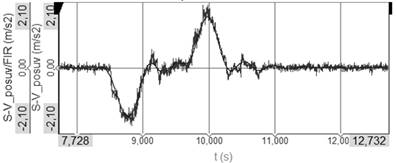

Measured and filtered

values are shown in Fig. 2 – Fig. 7. Wherein Fig. 2 shows acceleration

measured by the first sensor S-V in the translational direction and its result

by FIR filtration. The maximum value of the filtered acceleration was 1,63 m/s2.

Fig. 2.

Acceleration on the place of the sensor S-V in the translational direction

– FIR filter

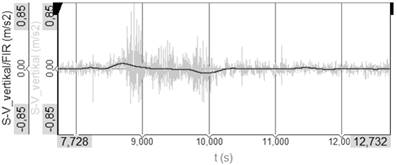

Fig. 3 shows the

acceleration measured by the sensor S-V in the vertical direction and its

result by FIR filtration. The maximum value of the filtered acceleration was 0,07 m/s2.

Fig. 3.

Acceleration on the place of the sensor S-V in vertical direction – FIR

filter

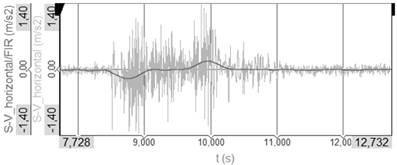

Fig. 4 shows the

acceleration measured by the first sensor S-V in the transversal direction and

its result by FIR filtration. The maximum value of the filtered acceleration is

0,18 m/s2.

Fig. 4.

Acceleration on the place of the sensor S-V in transversal direction –

FIR filter

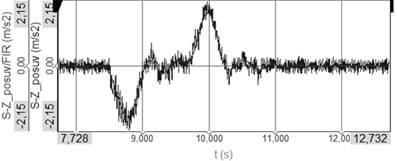

Fig. 5 shows the

acceleration measured by the second sensor S-Z in the translational direction

and its result by FIR filtration. The maximum value of the filtered

acceleration is 1,74 m/s2.

Fig. 5.

Acceleration on the place of the sensor S-Z in translational direction –

FIR filter

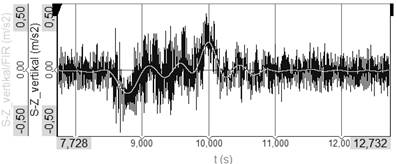

Fig. 6 shows the

acceleration measured by the second sensor S-Z in the vertical direction and

its result by FIR filtration. The maximum value of the filtered acceleration is

0,21 m/s2.

Fig. 6.

Acceleration on the place of the sensor S-Z in vertical direction – FIR

filter

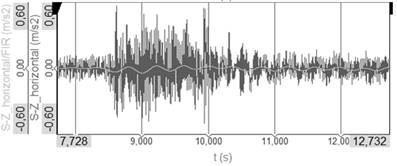

Fig. 7 shows the

acceleration measured by the second sensor S-Z in the transversal direction and

its result by FIR filtration. The maximum value of the filtered acceleration is

0,04 m/s2.

Fig. 7.

Acceleration on the place of the sensor S-Z in transversal direction –

FIR filter

2.2. FFT

analysis

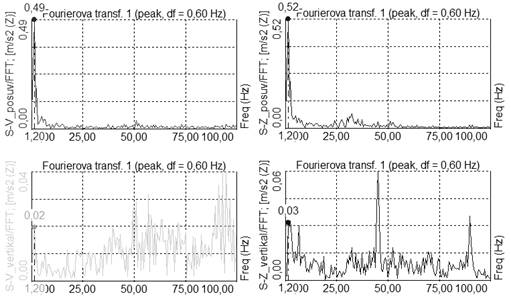

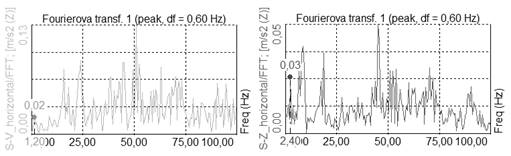

The results of the FFT analysis are shown in Fig. 8.

Fig. 8 shows the results

of the FFT analysis by previously introduced filtered

signals. The basic oscillation

frequency of the manipulator is around 1,2 Hz.

2.3. Operating

Deflection Shapes (ODS) analysis

The ODS analysis was

made for the operating frequency 1,2 Hz of the

manipulator. Eight one-axis acceleration sensors were placed in the

translational direction on the longer Z‑axis and on the clamping frame.

The result of this analysis is shown in Fig. 9.

3. MULTI-BODY SYSTEM

(MBS) ANALYSIS

The basis for creating

the dynamic model of the manipulator is its 3D model that provides its mass

parameters. Kinematic, elastic and damping connections are assigned to the 3D

model. The dynamic system of the manipulator has the kinematic excitation,

where the acceleration values are given by the data of the stepper motor. The

dynamic model with corresponding connections is shown in Fig. 10.

Fig. 8.

Frequency spectrum

3.1. Elastic and damping

parameters of the system

The vertical stiffness

of the elastic connection may be calculated:

, (1)

, (1)

wherein ![]() is the

torsion stiffness,

is the

torsion stiffness, ![]() moment of

inertia about the

moment of

inertia about the ![]() axis,

axis, ![]() basic

oscillation frequency (1,2 Hz) of the manipulator about the

basic

oscillation frequency (1,2 Hz) of the manipulator about the ![]() axis (Fig.

10),

axis (Fig.

10), ![]() distance

between elastic and damping connections and the rotational point

distance

between elastic and damping connections and the rotational point ![]() and

and ![]() number of

elastic and damping connections [4].

number of

elastic and damping connections [4].

The vertical damping

coefficient is:

, (2)

, (2)

wherein ![]() is

relative damping coefficient.

is

relative damping coefficient.

Fig. 9.

Operating deflection shapes of the manipulator

Fig. 10.

Connections in the dynamic model of the manipulator

3.2. Kinematical

excitation

For the kinematical

excitation, the time function of the stepper motor velocity and its derivation

may be used. This was reached by “the five point method” with

equation:

![]() , (3)

, (3)

wherein ![]() is new

value of acceleration (velocity) and

is new

value of acceleration (velocity) and ![]() is last

value of acceleration (or velocity).

is last

value of acceleration (or velocity).

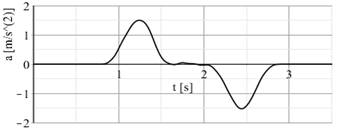

The final acceleration

function used for the kinematical excitation of the system is shown in Fig. 11.

Fig. 11.

Kinematical excitation of the manipulator dynamic system

The maximum value analysed of the

stepper motor acceleration was 1,5 m/s2.

4. Comparison of measured and simulated

acceleration values

Results show the relatively sufficient matching

between measured and simulated acceleration values. However, it should be noted

that for the achievement of better results, it would be appropriate to solve

the system as nonlinear. But in this case, it is necessary to know more input

parameters.

The comparison of

measured and calculated acceleration values is shown in the following figures.

In Fig. 12 is shown the comparison between filtered acceleration values of

the first sensor S-V in the translational direction and the acceleration as the

simulated result of the MBS analysis in the same direction.

Fig. 12. Acceleration in

the place of the sensor S-V in translational direction

Fig. 13 shows comparison

between filtered acceleration values of the first sensor S-V in the vertical

direction and the acceleration as the simulated result of the MBS analysis in

the same direction.

Fig. 13. Acceleration in

the place of the sensor S-V in vertical direction

Fig. 14 shows comparison

between filtered acceleration values of the second sensor S‑V in the

translational direction and the acceleration as the simulated result of the MBS

analysis in the same direction.

Fig. 14.

Acceleration in the place of the sensor S-Z in translational direction

Fig. 15 shows comparison

between filtered acceleration values of the second sensor S‑V in the

vertical direction and the acceleration as the simulated result of the MBS

analysis in the same direction.

Fig. 15. Acceleration in

the place of the sensor S-Z in vertical direction

5. CONCLUSIONS

Nowadays, linear guiding

systems are used in a wide range of applications, especially for enabling the

linear motion of manipulators, robots, transporting parts etc. Usually, the

linear guiding systems are present in the very important part of these

machines. However, their operating load by the relative complicated dynamic

behaviour is not well known, hence, the linear guiding systems might be

overloaded, which can lead to their premature failure. Therefore, the knowledge

of their operating load is strictly demanded. For the operating load

calculation, it is first necessary to identify and verify the dynamical

parameters of these machines with the help of the corresponding dynamic model

to determine the values of the operating load.

This article illustrates

the process of identifying dynamical parameters and their verifications. This

process is based on the combination of the measurement and mathematical

methods, which can be described in a few steps. First, the process uses

measured acceleration values in two points of the moving part. They are

evaluated by FIR and FFT. The evaluation of operating

deflection shapes can be added for the visualisation of the part oscillation.

In the second step, it is necessary to identify mass parameters and elastic and

damping parameters of parts connection in the system. 3D modelling and its

integrated functions can be used. The system movement can be calculated using

the MBS analysis. Finally, the measured kinematical values are compared with

the calculated ones. The dynamic parameters are correctly determined in the

case of good accordance between the measured and simulated results.

Acknowledgements

This publication was written at the Technical

University of Liberec as part of the project "Vibration damage

identification of linear guiding system" with the support of the Specific

University Research Grant provided by the Ministry of Education, Youth and

Sports of the Czech Republic in 2019.

References

1.

Dresig H., Holzweißig F. 2008. Maschinendynamik. [In German: Machine dynamics]. Berlin: Springer-Verlag. ISBN

978-3-540-87693-9.

2.

Gąska

Damian, Tomasz Haniszewski. 2016. “Modelling

studies on the use of aluminium alloys in lightweight load-carrying crane

structures”. Transport Problems 11(3):

13-20. DOI: 10.20858/tp.2016.11.3.2.

ISSN: 1896-0596.

3.

Haniszewski

Tomasz, Damian Gaska. 2017. “Numerical

modelling of I-Beam jib crane with local stresses in wheel supporting flanges -

influence of hoisting speed”. Nase More 64(1):

7-13. DOI: 10.17818/NM/2017/1.2. ISSN: 0469-6255.

4.

Homišin

J., R. Grega, P. Kaššay, G. Fedorko, V. Molnár. 2019 „Removal

of systematic failure of belt conveyor drive by reducing vibrations”.

Engineering Failure Analysis 99: 192-202. ISSN

1350-6307.

5.

Jacyna Marianna, Mariusz

Izdebski, Emilian Szczepański, Paweł Gołda. 2018. „The task assignment of

vehicles for a production company”. Symmetry-Basel

10(11). Article number: 551.

6.

Jacyna-Gołda Ilona,

Mariusz Izdebski, Emilian Szczepanski. 2016. „Assessment of the method

effectiveness for choosing the location of warehouses in the supply

network”. Challenge of Transport

Telematics, TST 2016. Communications in Computer and

Information Science 640: 84-97.

7.

Jacyna-Gołda Ilona,

Mariusz Wasiak, Mariusz Izdebski, Konrad Lewczuk, Roland Jachimowski, Dariusz

Pyza. 2016. „The

evaluation of the efficiency of supply chain configuration”. Proceedings of the 20th International

Scientific Conference Transport Means 2016. Transport Means - Proceedings of

the International Conference: 953-957.

8.

Liptai Pavol, Marek Moravec, Ervin Lumnitzer, Marcela

Gergeľová. 2017. „Proposal of the

sound insulating measures for a vibrational sorter and verification of the

measured effectiveness”. Advances

in Science and Technology-Research Journal 11(3): 196-203. ISSN 2299-8624.

DOI: 10.12913/22998624/76068.

9.

Maláková

Silvia. 2017. „Analysis of gear wheel body influence on gearing

stiffness”. Acta Mechanica Slovaca 21(3): 34-39. ISSN 1335-2393.

10.

Mazurkiewicz D.

2014. „Computer-aided maintenance and reliability management systems for

conveyor belts”. Eksploatacja i Niezawodnosc – Maintenance and Reliability 16(3):

377–382.

11.

Mazurkiewicz D.

2010. „Tests of extendability and strength of

adhesive-sealed joints in the context of developing a computer system for

monitoring the condition of belt joints during conveyor operation”. Eksploatacja i Niezawodnosc – Maintenance and Reliability 3:

34-39.

12. Navrátil M. 1981.

Měření mechanického

kmitání. Úvod do teorie snímačů. [In

Czech: Measurement of mechanical

vibration. Introduction to sensor theory]. Praha: SNTL.

13.

Puškár

Michal, Melichar Kopas.

2018. „System based on thermal control of the HCCI

technology developed for reduction of the vehicle NOX emissions in order to

fulfil the future standard Euro 7”. Science

of the Total Environment 643: 674-680. ISSN 0048-9697. DOI: 10.1016/j.scitotenv.2018.06.082.

14. Sága Milan, Peter Kopas, Milan Uhríčik. 2012. „Modeling and experimental

analysis of the aluminium alloy fatigue damage in the

case of bending - torsion loading”. Procedia

Engineering. 48: 599-606. ISSN 1877-7058.

15. Sága

Milan, Milan Vaško, Nadežda Čuboňová, Wiesława

Piekarska. 2016. Optimisation

algorithms in mechanical engineering applications. Harlow:

Pearson. ISBN 978-1-78449-135-2.

16. Tomeh E. 2015. Technická diagnostika. Vibrační diagnostika strojů a zařízení.

[In Czech: Technical diagnostics. Vibration diagnostics of machines and equipment].

Liberec: Technical university

in Liberec. ISBN 978-80-7494-174-0.

17. Zul'ová L., Grega R., Krajňák J. 2017. „Optimization of

noisiness of mechanical system by using a pneumatic tuner during a failure of

piston machine”. Engineering

Failure Analysis 79: 845-851. ISSN 1350-6307.

Received 18.11.2019; accepted in revised form 12.01.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License