Article

citation information:

Škrabala,

J., Hajdučík, A., Medvecký, Š., Brumerčík,

F. Optimalisation of the blade movement of the mower. Scientific Journal of Silesian University of

Technology. Series Transport. 2019, 105,

213-222. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.105.17.

Jozef ŠKRABALA[1],

Adrián HAJDUČÍK[2],

Štefan MEDVECKÝ[3],

František BRUMERČÍK[4]

OPTIMALISATION

OF THE BLADE MOVEMENT OF THE MOWER

Summary. This article presents the correct adjustment of the

mower’s blade movement relative to the forward movement of the mower.

Everywhere around us are gardens, parks and meadow, which gives us reason to

solve issues with mowing. The first part of this article shows agricultural

machines, which are used today and the principle of correct cut of grass

stalks. The next part shows the method of adjusting the mower’s blade

speed. Design of a simple model was done with the use of Solid Edge Premium

CAD. For computation, MSC Adams was used and post-processing was done with the

use of Matlab. The connection between MSC Adams and Matlab was created by

co-simulation.

Keywords: mower’s blade,

mowing, movement, kinematics

1. INTRODUCTION

Everywhere around us are grassy

places, which give us the idea to design special mountain mower with respect to

the quality of cut. This mower is intended to mow private gardens, city parks,

grass fields and hardly accessible areas. Nowadays, there are so many types of

mowers, which are intended for various areas of mowing. Nevertheless, users

will not avoid using their combination. Furthermore, the right type of mowing

machine has to be chosen for a given area. The main reason mountain mower can

replace multiple machines is that the construction is adapted for unfavourable

conditions, and uses autonomous control, which increases access for limited

terrain. Also, this mower is designed for the highest possible quality of cut,

with which the blade’s design is directly related. To achieve these

assumptions, it is necessary to determine the correct blade’s teeth

geometry [12, 13, 16]. Thereafter, it is necessary to determine the speed of

the blade relative to the mower’s movement for proper and healthy cutting

[3-6].

2. MOWER MACHINES

Generally, mower

machines are special agricultural machines for mowing plants. Mowers developed

with the evolution of humanity. Gradually, mowers evolved from hand scythes,

through a horse-drawn mower to today's types. Today, there are many types of

mower designed to mow different lands. The most common types are:

·

hand

mower:

§

scythe,

§

sickle,

§

manual

mower,

·

petrol

and electric mower:

§

rotary

mower,

§

drum

mower,

§

string

trimmer,

§

brush

cutter,

·

tractor

mower.

To better understand the

problem, two groups of mowers have been created with respect to the type of

mowing:

·

rotary

mower:

§

horizontal,

§

vertical,

·

reciprocating

bar mower:

§

cutting

without support,

§

cutting

with support.

2.1. Rotary mower

Typical mower of this

group is the gasoline rotary mower, which is shown in Fig. 1. Their great

advantage is the possibility to attach a basket that could also harvest the

leaves. The cutting height is usually adjustable from 3.5 to 5 cm. The right

choice of rotary mower depends on the frequency of mowing, size of the area and

demands of the operator. For example, depending on the size of the mowed area,

the right blade size has to be chosen (blade size 32 cm –up to 200 m2,

40 cm – up to 350 m2, 45cm – up to 500 m2,

53cm – up to 1000 m2 and longer – over 1000 m2).

There are many types of blades, but the quality of the cut is mainly influenced

by their sharpening. The cut of the stalk by a rotary mower is characterised as

a cut without support [11, 17].

Fig. 1. Rotary mower [15]

2.2. Reciprocating bar mower

The reciprocating bar mower is marked with sickle bars. This type of

mower is a very special type of agricultural machine, which is shown in Fig. 2.

Sickle bar mowers are divided into two groups:

·

sickle

bar with support (Fig. 3a),

·

sickle

bar without support (Fig. 3b).

Fig. 2. Sickle bar mower [15]

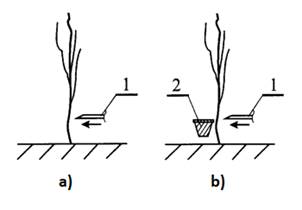

The cut without support

is characterised by a very high blade speed, which often exceeds 30 m.s-1.

This type of cut is executed by stalk tearing, which adversely affects the

health of the plant. Schematic illustration of the blade without support is

shown in Fig. 3a), where position 1 stands for the blade.

On the contrary, the cut

with support has little demands on the speed of the blades. The cut occurs

already at the velocity of 2 m.s-1 and it could be compared to stalk

shearing. Fig. 3b shows the blade (position 1) and the support (position 2) [1,

2].

Fig. 3. Types of cutting: a) without support b) with support

3. SOLUTION OF

KINEMATICS OF MOWER BLADES

The solution of the kinematics of mower blades is done via the kinematic

analysis of blades movement relative to the forward movement of sickle bar

mower [18]. In this case, there is a double stroke bar considered – a

reciprocating movement of both bars [12].

3.1. Modelling mower and

its parts

A simple model was

created in CAD software [7, 10], which is shown in Fig. 4. The simplifications

will not affect the results, because they are not related to machine

kinematics. They also have a positive impact on the complexity of the

mathematical model and thus accelerate the computational time.

Fig. 4. Simplified model of the mower

The next step was to

import the CAD model into the MSC.Adams software, where all parts have been

modelled (Fig. 5).

By defining the

relations between the parts, we used the fixed joint, translational joint and

revolute joint connections. Additionally, we used two types of motions:

rotational and translational motion and a driving motor [8, 9].

Fixed joint is used on

the ground because it has zero degrees of freedom (DOF). Revolute joint is

created between two parts and it is related to one axis. This connection is

used to define the wheels and rotational parts of the crank mechanism.

Translational joint is created between two parts with defined direction. This

joint is used between the ground and the vehicle body and also between the body

and the bars [19].

The contact is defined

between the wheels and the ground. Also used is the Coulomb friction model

to prevent the wheels from slipping.

Fig. 5. Parts of the mower:

1 – ground; 2 - body of the vehicle; 3 - right

front wheel; 4 - left front wheel;

5 - rear right wheel; 6

- rear left wheel; 7 - drive rail; 8 - upper bar; 9 - bottom bar;

10 - top handlebar; 11 -

lower handlebar

3.2. The principle of

mower tracking

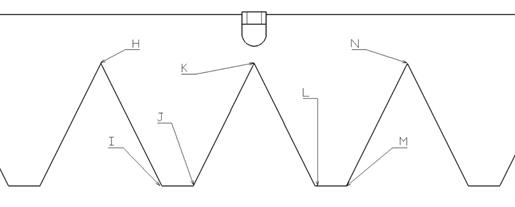

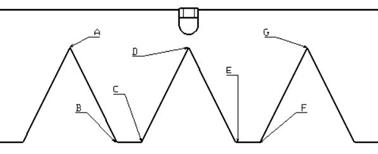

To illustrate the paths

of each blade (the top and bottom bars), it is necessary to create the points

(markers), which will be monitored. These points will be used for kinematic

analysis in MATLAB [14, 15]. Fig. 6 illustrates individual markers on the top

sickle bar (points A to G). The markers were created also on the second bar –

Fig. 7.

To illustrate the paths

of each blade (the top and bottom bars), it is necessary to create the points

(markers), which will be monitored. These points will be used for kinematic

analysis in MATLAB [14, 15]. Fig. 6 illustrates individual markers on the top

sickle bar (points A to G). The markers were created also on the second bar –

Fig. 7.

Fig. 6. Markers of the top sickle bar (A – G)

3.3. Mathematical model

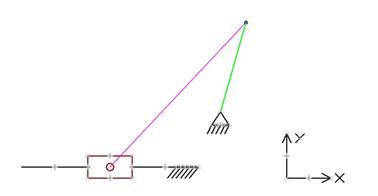

First step of the

solution was to make a simple mathematical model of the solved problem. The

reciprocating movement of the blades is solved as a simple crank mechanism

(Fig. 8).

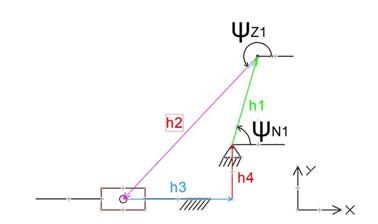

For

the solution of this mechanism, the vector method is used. It is one loop

multi-element case, where the rotational movement is transformed into the

translational movement. The computation of basic parameters of the crank

mechanism follows according to Fig. 9.

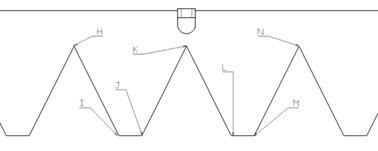

Fig. 7. Markers of the lower sickle bar (H – N)

Fig. 8. Schematic drawing of a crank mechanism

Fig. 9. Block scheme for computation of the crank mechanism

The number of kinematic loops can

be calculated as:

![]() . (1)

. (1)

The kinematic loops equations are

defined as:

![]() . (2)

. (2)

x

axis: ![]() , (3)

, (3)

y

axis:. ![]() (4)

(4)

3.4. Co-simulation and

data processing

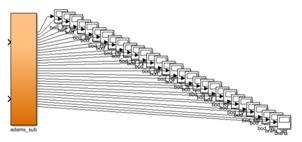

MATLAB Simulink is used

for co-simulation with MSC Adams, because there are more opportunities to

analyse the received data. First step was to choose input and output signals,

which will be exported to MATLAB. As the input signals, the velocity of the

mower and the angular velocity of the crank mechanism were determined. The

paths of all markers were the output signals. After exporting procedure, a

Simulink program was generated. This program was represented by a simple

block diagram, which is shown in Fig. 10.

Fig. 10. Simulink generated scheme

Subsequently, the scheme

was copied into the new program, where the inputs (velocity of the mower and

angular velocity of crank mechanism) are set. The outputs were the observed

point’s positions and the control speed of the crank mechanism. After the

calculation procedure, all data were exported to the Simulink workspace, where

they were stored as vectors.

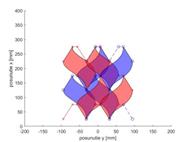

After running the

simulation, all data were started to process and analyse the issue of the lawn

mowing quality. The starting point’s vectors are created to display the

geometry of the bars on the graph – top bar with red colour and the lower

bar with blue colour (Fig. 11). According to the definition of the slider

vectors of the individual points, the paths of the knife blades acting on the

given movements are plotted on the graph. After the paths of the individual

points rendering, the passed areas were coloured. There could be seen in places

of the bends of the stalk, the places of the cutting of the stalk and the

places with the uncut grass blades remained.

4. RESULTS AND

DISCUSSION

Depending on the setting

of the crank mechanism, speeds relative to the forward motion of the mower can

occur in these three situations after analysis [18]:

·

right

cut of the plants (Fig. 11a),

·

bending

of the plants (Fig. 11b),

·

skipping

of the uncut plants (Fig. 11c).

The last type of mowing

is the worst. There are usually unmowed places because the trajectory of

blade’s shapes does not cover the entire mowed area. This case occurs

when the angular velocity of the crank mechanism is low relative to the mower

motion.

When the stalks are

bent, that is a case of high crank speed. This state is energetically

unfavourable. This requires passing the same trajectory more times by mowing.

|

|

|

|

|

a) |

b) |

c) |

Fig. 11. Blade movement:a) Right mowing; b) Bending of stalks; c)

Unmowed places

When the right cut

occurs, the energetic demands are optimal and the stalks damages are minimal. Optimal

speeds based on the performed analysis are shown in Tab. 1.

Tab. 1

Optimal angular velocity of

crank mechanism relative to mower movement

|

Mower speed (m.s-1) |

Crank speed (min-1) |

|

1 |

850 |

|

1,5 |

1100 |

|

2 |

1350 |

The kinematic analysis

in MSC Adams demonstrates the possibilities of solving complex tasks of mutual

motion. The results of the solution were verified on the second prototype of

mountain mower (MM2). All performed tests were successful.

Acknowledgement

The research is supported by the Cultural and Educational Grant Agency of

the Ministry of Education, Science, Research and Sport of the Slovak Republic

under project No. 046ŽU-4/2018.

References

1.

Caban J., P. Drozdziel, J. Vrábel, B. Šarkan, A.

Marczuk, L. Krzywonos, I. Rybicka. 2016.

„The research on ageing of glycol-based brake fluids of vehicles in

operation”. Advances in Science and

Technology 10(32): 9-16.

2.

Caban

J., A. Marczuk, B. Šarkan, J. Vrábel. 2015. „Studies on

operational wear of glycol-based brake fluid”. Przemysł Chemiczny 94(10): 1802-1806.

3.

Czech Piotr. 2012. „Determination of the course

of pressure in an internal combustion engine cylinder with the use of vibration

effects and radial basis function - preliminary research”. Communications

in Computer and Information Science 329: 175-182. DOI https://doi.org/10.1007/978-3-642-34050-5_21.

Springer, Berlin, Heidelberg. ISBN:978-3-642-34049-9. ISSN: 1865-0929. In:

Mikulski Jerzy (eds), Telematics in the transport environment, 12th

International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, October 10-13, 2012.

4.

Czech Piotr. 2011. „Diagnosing of disturbances

in the ignition system by vibroacoustic signals and radial basis function -

preliminary research”. Communications in Computer and Information Science

239: 110-117. DOI https://doi.org/10.1007/978-3-642-24660-9_13. Springer,

Berlin, Heidelberg. ISBN:978-3-642-24659-3. ISSN: 1865-0929. In: Mikulski

Jerzy (eds), Modern transport telematics, 11th International Conference on

Transport Systems Telematics, Katowice Ustron, Poland, October 19-22, 2011.

5.

Faturík

Lukáš, Libor Trško, Slavomír Hrček, Otakar

Bokuvka. 2014. „Comparison of structural design in high and ultra-high cycle

fatigue regions”. Transactions of

FAMENA 38(4): 1-12. ISSN 1333-1124.

6.

Figlus

Tomasz, Mateusz Koziol. 2016. „Diagnosis of

early-stage damage to polymer - glass fibre composites using non-contact

measurement of vibration signals”. Journal of Mechanical Science and Technology 30(8): 3567-3576. ISSN 1738-494X. DOI: 10.1007/s12206-016-0717-1.

7.

Gąska Damian, Tomasz Haniszewski. 2016.

“Modelling studies on the use of aluminium alloys in lightweight

load-carrying crane structures”. Transport

Problems 11(3): 13-20. DOI: 10.20858/tp.2016.11.3.2. ISSN: 1896-0596.

8.

Glowacz Adam, Zygfryd Glowacz. 2017. „Diagnosis

of the three-phase induction motor using thermal imaging”. Infrared physics & technology 81:

7-16. ISSN 1350-4495. DOI: 10.1016/j.infrared.2016.12.003.

9.

Glowacz Adam, Zygfryd Glowacz. 2017.

„Diagnosis of stator faults of the single-phase induction motor using

acoustic signals”. Applied acoustic

117A: 20-27. ISSN 0003-682X. DOI: DOI: 10.1016/j.apacoust.2016.10.012.

10. Haniszewski Tomasz,

Damian Gaska. 2017. “Numerical modelling of I-Beam jib crane with local

stresses in wheel supporting flanges - influence of hoisting speed”. Nase More 64(1): 7-13. DOI:

10.17818/NM/2017/1.2. ISSN: 0469-6255.

11. Kai-Sheng Wang, Chen-Kang

Huang. 2018. “Intelligent Robotic Lawn Mower

Design”. International Conference

on System Science and Engineering (ICSSE). DOI: 10.1109/ICSSE.2018.8520053.

12. Kohár Róbert, Slavomír

Hrček. 2014. „Dynamic Analysis of a Rolling Bearing Cage with

Respect to the Elastic Properties of the Cage for the Axial and Radial Load

Cases”. Communications –

Scientific Letters of the University of Zilina 16(3A): 74-81. ISSN

1335-4205.

13. Koziol Mateusz, Tomasz Figlus. 2017.

„Evaluation of the Failure Progress in the Static Bending of GFRP

Laminates Reinforced With a Classic Plain-Woven Fabric and a 3D Fabric, by

Means of the Vibrations Analysis”. Polymer

composites 38(6): 1070-1085.

14. Rudecki M., O. Kildisheva.

2013. „A modified sickle bar mower: increased flexibility for harvesting

native plant seeds”. Native Plants

Journal 14(3): 257-260. DOI: 10.3368/npj.14.3.257.

15. Siregar Ikhsan, Anggi Ridho, Dinda Gustia, Agung

Triono, Yulia Shafira. 2018. “Product design of a lawn mower tool for

agriculture”. Conference Series

Materials Science and Engineering 420(1): 1-11. DOI:

10.1088/1757-899X/420/1/012140.

16. Skrúcaný

Tomáš, Branislav Šarkan, Tomasz Figlus, et al. 2017. „Measuring of noise

emitted by moving vehicles”.

MATEC Web of Conferences 107: 00072. ISBN: 978-1-5108-4114-7. DOI: https://doi.org/10.1051/matecconf/201710700072.

17. Škrabala Jozef. 2018. „Design

of the remote controlled mower“. Diploma thesis, Bratislava: Slovak

University of Technology in Bratislava.

18. Škrabala Jozef,

Adrián Hajdučík, Štefan Medvecký. 2019.

“Optimization of mower blades movement considering to mower ́s

motion”. Novus Scientia. Proceedings

of XVI. International Scientific Conference of PhD students of engineering

faculties of technical universities and universities. Košice: Technical

University of Košice. ISBN 978-80-553-3249-9.

19.

Thomas

D.G. 1992. Fundamentals of Vehicle

Dynamics. Society of Automotive Engineers. 495 p. ISBN 1560911999.

Received 07.09.2019; accepted in revised form 26.11.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License