Article

citation information:

Kubik, A., Hadryś, D., Stanik,

Z., Jasiok, M. Analysis of tribological wear in block – on ring contact

on tribological tester T-05. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 105, 113-123. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.105.10.

Andrzej KUBIK[1],

Damian HADRYŚ[2],

Zbigniew STANIK[3],

Marek JASIOK[4]

ANALYSIS

OF TRIBOLOGICAL WEAR IN BLOCK – ON RING CONTACT ON TRIBOLOGICAL TESTER

T-05

Summary. Friction is one of the most common phenomena in this

technique. The friction process in the tribography systems causes both energy

losses and consumption process losses. The layer of the surface of a solid body

differing from the material to the entire volume of the solid is a close

participant in the tribological process. The effects of external influences

during treatment of the material and in friction processes were established and

modified. The well-shaped layer of the surface provided optimum tribological

properties during operation.

This work provides an analysis of the use of a

tribological pair working in a rotational movement, in different operating

conditions. The tests carried out showed the impact of the selected

exploitation factors, that is, the speed and load, the consumption and the

friction coefficient of the saliva and the graphical interpretation of results

from the results obtained from experimental and metallographical studies. The

tests carried out in the block-on ring position of the T-05 tribology was the nature

of preliminary tests. Preliminary tests enabled the effects of designated

performance parameters to be determined on selected tribological properties.

Low-carbon steel used for heat-chemical treatment and steel with DLC coating

was used for the test. Metallographic studies enabled the dominant use

mechanism to be determined, depending on external factors.

The application of the above-mentioned value for

materials currently used in various types of constructions allows for extending

the life of a given device without major financial and constructional costs. A

wide range of applications can bring many benefits to the current design

solutions, in which the efficiency of the entire device can be easily improved.

Keywords: friction, lubrication,

DLC layer

1. INTRODUCTION

The wear of cooperating

elements with each other has being a focal point of interest for a long time [1-3].

The following articles show the various approaches to engineering solutions for

improvement of wear elements [4-10]. Machinery for using machinery components

is the inseparable effect of the device. One of the main phenomena that happen

during the cooperation of two elements is the friction phenomenon. The friction

process entails both positive (for example, motor vehicle equipment) and

negative effects (for example, aerodynamic resistance). The friction process in

the tribography systems causes both energy losses and consumption process

losses (Figure 1).

The surface layer of the

solid differing in structure and properties from the material in the entire

volume of the solid body is a strict participant entering the tribological

process. It is created and modified under the influence of external influences

during material processing and in the friction process. A properly shaped top layer

ensures optimal tribological properties during operation [11].

Fig. 1. Dependency:

input-output in the tribological test [12]

The sliding friction, classified as the sliding friction, occurs at the

interface between two solid bodies, while the bodies slide against each other

or remain at rest. In the case of external friction (for example, sliding), the

force occurring causes the displacement of one of the bodies relative to the

other. Sliding friction occurs when a pressure force is transferred at the

contact point of the bodies. This is accompanied by many phenomena occurring on

the friction surface and just below it. In the case of dry friction, where

there is no lubricant and foreign matter between the cooperating elements, the

intensity of friction increases with the increase of surface roughness, this is

accompanied by the release of a large amount of heat, which results in loss of

strength and increased wear of selected machine parts [11]. Exploitation under

the conditions of changing tribological and corrosive excitations results in

unfavourable changes in the structure of materials that may cause the loss of

important functional properties or even the complete destruction of structural

elements of machines and devices [14]. The functional properties of machine

parts depend not only on the possibility of transferring mechanical loads but

mainly on the structure and properties of surface layers [15-19]. Factors

determining the tribological properties of the coating are shown in Figure 2.

Fig. 2. Factors

determining tribological properties of coatings [20]

2. TRIBOLOGICAL STUDIES - TEST FACILITY

The Common Rail injection system leads all other types of injection

systems in diesel engines in the passenger and supply sectors. This system

works in a pressure range of 30 to 220 MPa where the fuel pressure is produced

continuously by a high-pressure pump. As a high-pressure pump, piston pumps

driven by one to four piston pumps were used. The accuracy of the performance

of the cooperating pair is up to 0,001 mm. This makes it impossible for any

part of the various components to be included, which would result in a flawed

injection and calibration [13].

The device for assessing the tribological properties of material

combinations is a block-on ring-testing machine. Tribological tests using the

T-05 tester were carried out with the following parameters:

• friction association: roll - made of 17 HNM material and

block made of 17 HNM material with DLC coating, where the chemical composition

of 17 HNM steel is:

Tab.

1

Chemical composition of 17HNM steel, %

|

C |

Si |

P |

S |

Cr |

Ni |

Mo |

W |

V |

Cu |

|

0,14-0,19 |

0,17-1,37 |

max 0,035 |

max 0,035 |

1,5-1,8 |

1,4-1,7 |

0,25-0,35 |

max 0,05 |

<=0,2 |

max 0,3 |

• load

P = 10 N,

• sliding

speed v = 0.18 m/s,

• road of friction s = 1950 m (for 0.18 m/s),

• test

time t = 10800 s.

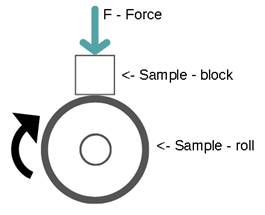

Fig. 3. Tribological

knot block-on ring

Fig. 4. Tester used for

tests - T-05

3. TRIBOLOGICAL STUDIES - TEST RESULTS

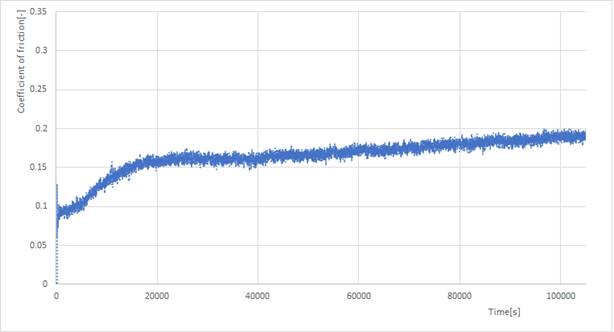

The tests used the T -05 type test equipment working in the cinematic

pairs of the block-on ring. During the tests, the friction force was recorded

for 10800 s. The tests were carried out for five samples from each type of

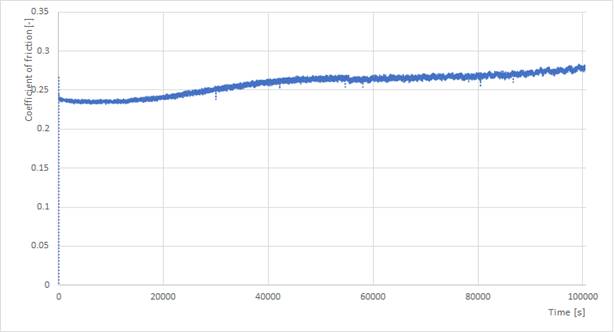

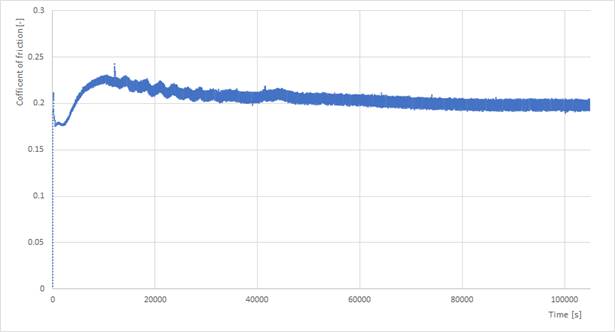

material. Figures 5 and 6 show indicative graphical interpretation of the

friction coefficient where the rotational bar and load were constant and 100 N.

Figure 5 presented the values for the case tested - steel with the DLC layer.

Figure 5 shows the values for steel-steel tested. The drawings indicate that

the values of the different materials differ. The case shown in Figure 5 shows that

for steel with a DLC layer the value of the coefficient is significantly lower.

As the journey of friction grows, it increases. For the case of Figures 5 and

6, the friction coefficient after the test increased by about 0,08 [-]. Figure

7 shows the loss of mass of the samples tested. The primacy between materials

showed that the material without the DLC layer recorded a loss of mass almost

three times larger than material with a layer.

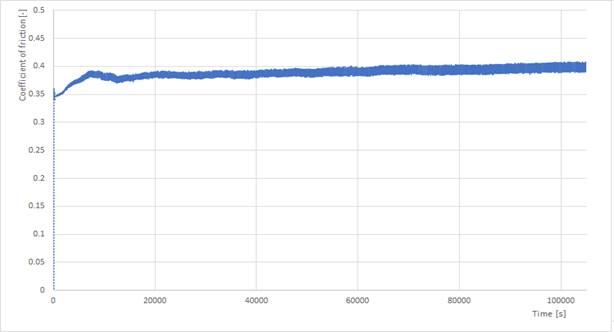

Figures 8 and 9 show

examples of graphical frictional interpretation for parameters as in Figures 5

and 6, except for load. For the following examples, it is increased to 100 N.

Figure 8 presented the values for the case tested - steel with the DLC layer.

Figure 9 shows the values for steel-steel tested. As seen in the charts, the

coefficient of friction in the DLC layer falls over time. The initial value of

the coefficient increased rapidly due to the break of the layer from the

surface of the sample.

Figures 11 and 12 show

one of the samples surface cooperating with the counter sample. The migrating

of the DLC layer between samples can be noticed, thus, the value of the

coefficient of friction decreased during the test.

Fig. 5. Cofficient of

friction steel - steel with DLC layer - load 10 N

Fig. 6. Cofficient of

friction steel - steel - load 10 N

Fig. 7. Mass decrement

of investigated materials (load 10 N)

Fig. 8. Cofficient of

friction steel - steel with DLC layer - load 100 N

Fig. 9. Cofficient of

friction steel - steel - load 100 N

Fig. 10. Mass decrement

of investigated materials (load 100 N)

DLC layer

Fig. 11. Example sample with DLC layer (load 100 N)

DLC layer

![]()

![]()

Fig. 12.

Example sample with DLC layer (load 100 N).

4. SUMMARY

The tribological tests

carried out using the T-05 tribotester were preliminary tests that were

introduction to the main studies. Microscopic examination allowed observation

of the sliding association in a swinging motion whose lubricating medium was

diesel oil. Magnification of the drawings revealed various types of grooves,

and discontinuities caused by the interaction of friction elements.

The following

conclusions were formulated on the basis of the conducted research:

- carrying out research in

a block-on ring system at T-05 in single-sided traffic, a significant impact of

the load on the value and type of wear was found,

- wear in the sliding

combination is of the abrasive and adhesive nature, and its intensity depends

on the operating parameters (for example, load),

- in view of the nature of

the tests leading to comparison of the coefficient of friction of the two

samples, the mass loss was measured, and rightness correctness of the applied

DLC layer,

- the application of the

above-mentioned value for materials currently used in various types of

constructions allows for extending the life of a given device without major

financial and constructional costs.

References

1.

Lawrowski Zbigniew. 1985. Tribologia.

Tarcie, zużycie i smarowanie. [In Polish: Tribology.

Friction, wear and lubrication]. Wroclaw:

Publishing House of the Wroclaw University of Technology. ISBN

978-83-7493-383-4.

2.

Madej Monika. 2014. „The effect of TiN and

CrN interlayers on the tribological behavior of DLC coatings”. Wear

314: 179-187. ISSN 0043-1648. DOI: http://dx.doi.org/10.1016/j.wear.2014.05.008.

3.

Vasilyev A., E. Deynichenko, D. Popov. 2005. „Internal combustion engine valve

gear cam wear and its influence on valve gear and engine efficiency”. Mechanika 4(54): 44-49. ISSN 1392-1207.

4.

Baradeswaran Andreas, Ayyasamy

Elayaperumal. 2014. „Wear and mechanical characteristics of Al

7075/graphite composites”. Composites: Part B 56: 472-476. ISSN:

1359-8368. DOI: https://doi.org/10.1016/j.compositesb.2013.08.013.

5.

Frocisz Łukasz, Janusz Krawczyk, Monika Madej. 2017. „Tribological

properties of high carbon steels in an as-cast state and after plastic

deformation”. Tribologia 6:19-26. ISSN 0208-7774.

6.

Hua Zhang, Yanxin Wu, Qiuju Li, Xin Hong. 2018. „Mechanical

properties and rolling-sliding wear performance of dual phase austempered

ductile iron as potential metro wheel material”. Wear

406: 156-165. ISSN 0043-1648. DOI: https://doi.org/10.1016/j.wear.2018.04.005.

7.

Ilanaganar E., S. Anbuselvan, 2018. „Wear mechanisms of

AZ31B magnesium alloy during dry sliding condition”. Materials Today:

Proceedings 5: 628-635. ISSN: 2214-7853. DOI: https://doi.org/10.1016/j.matpr.2017.11.126.

8.

Kumara Narendra, Gaurav Gautam, Rakesh Kumar

Gautamc, Anita Mohanb, Sunil Mohand. 2016. „Wear, friction and profilometer

studies of insitu AA5052/ZrB2 composites”. Tribology International

97: 313-326. ISSN 0301-679X. DOI: https://doi.org/10.1016/j.triboint.2016.01.036.

9.

Michalczewski Remigiusz, Witold Piekoszewski,

Marian Szczerek, Waldemar Tuszynski. 2009. „The lubricant-coating

interaction in rolling and sliding contacts”. Tribology International

42(4): 554-560. ISSN 0301-679X. DOI: http://doi.org/10.1016/j.triboint.2008.05.001.

10. Paczkowska Marta, Łukasz

Wojciechowski. 2015. „A wear analysis of steel rings workings with

nodular iron after laser heat treatment”. Tribologia

5:99-107. ISSN 0208-7774.

11. Janecki Janusz, Stefan Gołąbek. 1984. Zużycie części i

zespołów pojazdów samochodowych. [In Polish: Wear of parts and assemblies of motor

vehicles]. Warsaw: WKiŁ. ISBN 83-206-0450-8.

12. Szczerek Marian. 1997. Metodologiczne problemy systematyzacji eksperymentalnych badań

tribologicznych. [In Polish: Methodological

problems of systematization of experimental tribological studies]. Radom: ITE. ISBN 838703942X.

13. Hubertus Gunther.

2010. Układy wtryskowe Common Rail w

praktyce warsztatowej. [In Polish: Common Rail injection systems in workshop practice]. Warsaw:

WKiŁ. ISBN 978-83-206-1936-2.

14. Gajewski Mirosław, Justyna Kasińska, Leopold

Barwicki. 2011. „Degradacja struktury

i uszkodzenia rur kotłowych ze stali 13CrMo4-5 (15HM)”. [In Polish:

„Structure degradation and damage to boiler pipes made of 13CrMo4-5

(15HM) steel”]. Energetyka, problemy energetyki i

gospodarki paliwowo – energetycznej 11: 680-683. ISSN 0013-7294.

15. Burakowski Tadeusz. 2013. Aerologia. Podstawy teoretyczne. [In Plish: Aerology. Theoretical basics]. Radom: ITeE–PIB. ISBN: 978-83-7789-195-7.

16. Dadić Z., D. Živković, N. Čatipović. 2016. „Tribological wear mechanisms of

molds for high pressure die casting”. Metalurgija

55(2): 249-252.

17. Kulasa J., W. Malec, B. Juszczyk, S. Malara, B. Cwolek. 2016. „Microstructure and tribological

properties of tin bronze-graphite composites made by stir casting”. Metalurgija 55(1): 19-21.

18. Mazurkiewicz D. 2014.

„Computer-aided maintenance and reliability management systems for

conveyor belts”. Eksploatacja i

Niezawodnosc – Maintenance and Reliability 16(3): 377–382.

19. Mazurkiewicz D. 2010.

„Tests of extendability and strength of adhesive-sealed joints in the

context of developing a computer system for monitoring the condition of belt

joints during conveyor operation”. Eksploatacja

i Niezawodnosc – Maintenance and Reliability 3: 34-39.

20. Holmberg Kenneth, Ronkainen

Helena, Matthews Allan. 2000. „Tribology of thin coatings”. Ceramics

International 26: 787-795. ISSN 0272-8842.

DOI: https://doi.org/10.1016/S0272-8842(00)00015-8.

Received 18.09.2019; accepted in revised form 12.11.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License