Article

citation information:

Konowrocki, R. Modelling of

dynamic aspects of operation in railway vehicle traction drive system including

the electromechanical coupling. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 105, 101-111. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.105.9.

Robert

KONOWROCKI[1]

MODELLING

OF DYNAMIC ASPECTS OF OPERATION IN RAILWAY VEHICLE TRACTION DRIVE SYSTEM

INCLUDING THE ELECTROMECHANICAL COUPLING

Summary. In this paper, the influence of electromechanical

interaction in an electric motor on the railway vehicle driving system dynamics

was investigated. This is the train driven by DC. In particular, there is

considered influence of electromagnetic field between a rotor and stator on

excitation of resonant torsional vibrations of the drive system. Conclusions

drawn from the computational results can be very useful during the design phase

of these devices as well as helpful for their users during regular maintenance.

Keywords: railway drive system,

electromechanical coupling, numerical analysis, electric motor, torsion

vibration, railway vehicle operation

1. INTRODUCTION

Torsional

vibrations occur in every drive train. For a simple drive train, which consists

of an electrical motor, flexible shaft and a load, its system has two basic

torsional vibration modes, the rigid-body mode and the first elastic mode. The

knowledge about the torsional vibrations in drive transmission systems of

railway vehicles is of great importance in the field of dynamics of mechanical

systems [3,4,7,8,10,14,15,19]. Components of driving systems are not fully rigid, it is common

to have fluctuation of torques in different work phases leading to shaft and

wheelset torsional vibration [5,11]. For the

reliability and security of the drive system of railway vehicles driven by

electric motors, the electromagnetic output traction force and torques should

drive stably. Otherwise the shaft train vibration caused by motor torque ripple

will affect the fatigue life of the drive components and the operation security

of the driven railway vehicles [2,9,18]. Generally,

railway drive systems can be divided into electrical and mechanical parts, for

this reason, the influence of the electric motor should also be taken into account

in the dynamic analysis of the drive.

In practice, various

types of motors for traction applications are used. Among which are: DC shunt

motor, compound motors, separately excited motors, AC series motor, 3-phase

induction motor. The selection of motors depends on a variety of factors like

the type of traction, type of supply, mainline/suburban trains, etc. The motor

should provide high starting torque, which is very essential because in trains

there are many compartments full of passengers or goods, so it requires high

torque during initial start-up and traction operation. In our case, we will

deal with the railway traction system driven by a DC motor. In this paper, the

effect of electromechanical coupling in the electric motor on torsion vibration

of the railway drive system was analysed. For this

analysis, the method presented therein [2] was applied. In the considered

model, the magnetic field interaction between the stator and the rotor of the

DC motor was considered. Using the energy balance of the natural modes of

oscillations for the model of the railway traction drive are obtained

expressions for determining the influence of electromagnetic parameters of the

electric motor (stiffness and damping of electromagnetic field) on its

stability in relation to the torsion vibration of the railway drivelines.

2.

THE DRIVETRAIN UNDER INVESTIGATION

For analysis of

torsional vibrations in a dynamic mutual coupling between the wheelset and the

electric motor, a possibly realistic and reliable electromechanical model of

the railway drivetrain was applied. In the study, electric locomotives with the

fully sprung wheelset drive were used. In this drive system, the DC traction

motor is a drive unit. The motor shaft is connected to the pinion wheel of the

gearbox by an elastic coupling. The gearbox provides the transmission of the

torque to the wheel axle thus reducing the angular speed. The gear wheel is

mounted on a hollow shaft which is coupled to the wheel axle by an elastic

coupling. Motor and gearbox housing are connected rigidly to each other and are

suspended in the bogie frame by rubber silent blocs (Fig. 1).

3. MATHEMATICAL MODEL OF THE RAILWAY TRACTION DRIVE

SYSTEM

The kinematic diagram of the considered railway traction drive system

model with a DC motor is depicted in Figure 2. Output shaft of the electric

motor is coupled to the hollow shaft connected with the wheelset. The

electrical drivetrain shown in Figure 1 can be reduced by assuming infinite

gear tooth stiffness and assuming the wheel shaft coupling as a single spring.

A simple model of this drive is shown in Figure 2. The output driving torque

from the electric motor is transmitted via coupling to the hollow shaft, which

surrounds the wheelset axle. On the opposite end of the hollow shaft, the

torque is transmitted by means of a flexible claw coupling to the disc-wheel.

On the basis of the data on the cross-section area as well as the length of the

hollow shaft and geometry of the wheelset, stiffness of these assembled

elements was determined. In the considered model, the toothed gear was omitted,

treating it as an element with several times more stiffness than the hollow

shaft.

Fig.

1. Railway drive system with hollow shaft

transmitted torque [16]

Fig. 2. Scheme of model of railway drive

The equation of motion

of the mechanical model shown in Fig 2 can be described in matrix form

|

|

(1) |

where I denotes the mass matrix containing mass moments of inertia of

rotating elements of the drive system, the matrixes,

Ce-m, Ccoupl, Cwheelset, Kcoupled , Ke-m and Kwheelset represent the torsional damping and stiffness properties of electric

motor magnetic field, rotor shaft, the hollow shaft and the wheelset,

respectively. Vector Tmotor contains the electromagnetic torque generated by the electric motor

described in equation (1) of the paper and vector Mcreep contains the traction torque generated by

longitudinal tangential loads Tcreep_i in the wheel-rail zones

acting on wheel radius ri.

The electromagnetic torque of DC motor Tmotor,

the stiffness and damping generated by the electromagnetic field between stator

and rotor of the motor are defined by equation 2-4, according to Riven [1].

|

|

(2) |

|

|

(3) (4) |

where: ![]() . Parameters kv, R, L, U,

IM, ω0, τe, p and

. Parameters kv, R, L, U,

IM, ω0, τe, p and ![]() are respectively constant (ratio of the voltage generated by the motor

to the speed), electrical resistance and inductance of the motor windings, the

power supply voltage, mass moments of inertia of rotor, no-load speed of the

motor, electromagnetic time constants, slope of torque Tmotor versus

slippage characteristic (Fig. 3), angular speed of rotor. ke-m(ω) and ce-m(ω) are respectively the stiffness and damping

coefficients associated with the electromagnetic field. These parameters in the

considered model are represented as the viscoelastic electromagnetic clamping

of the motor rotor with the immovable stator (Fig. 2). The angular position of the rotor of the DC motor is

represented by j1 and the

angular positions of the wheels of the wheelset are described by j2 and j3, respectively. Ikl, Ikr

are the mass moment of inertia of the left and right wheel of the wheelset.

are respectively constant (ratio of the voltage generated by the motor

to the speed), electrical resistance and inductance of the motor windings, the

power supply voltage, mass moments of inertia of rotor, no-load speed of the

motor, electromagnetic time constants, slope of torque Tmotor versus

slippage characteristic (Fig. 3), angular speed of rotor. ke-m(ω) and ce-m(ω) are respectively the stiffness and damping

coefficients associated with the electromagnetic field. These parameters in the

considered model are represented as the viscoelastic electromagnetic clamping

of the motor rotor with the immovable stator (Fig. 2). The angular position of the rotor of the DC motor is

represented by j1 and the

angular positions of the wheels of the wheelset are described by j2 and j3, respectively. Ikl, Ikr

are the mass moment of inertia of the left and right wheel of the wheelset.

Depending on the adopted various maintenance,

operation and weather conditions, an adhesion in wheel-rail contact zone

characteristic can take into consideration these various forms [17]. The

adhesion curve applied for the carried out investigations was plotted in Fig. 3

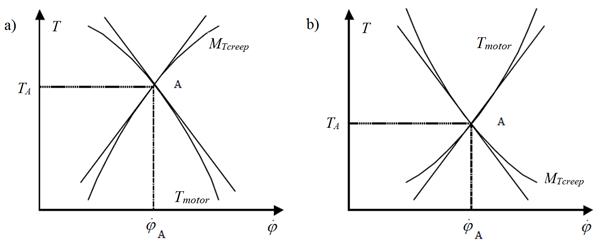

(left). Presented in the figure are an adhesion

and traction characteristic and instantaneous point equilibrium between them. Here, p

and ηi

meaning respectively, the slope coefficients of the traction

characteristics (green curve) and adhesion characteristics (red curve) in the

vicinity of the temporary equilibrium point. Example graphs of the driving/electric

torque moment Tmotor

and the resistance torque MTcreep caused by the coefficient of wheel-rail

adhesion are shown in Fig 4a and b. These diagrams

illustrate the stability of the drive wheel set depending on which of the Tmotor

or MTcreep

torque is larger. Such an appearance has an effect on the torsional vibration

of the wheelset.

The matrix form of traction drive

model represented by a three-mass rotating system (Fig. 2) can be

described by a system of differential equations (5).

|

|

,

(5) |

where k2 and c2 are the stiffness

and damping characteristics of the wheelset structure. ηkp and ηkl

coefficients

of slope of the adhesion characteristics in the wheel-rail contact area of both

wheels. The

electromagnetic time constant of the windings ![]() describes the delay of reduce in

the current in comparison to the initial value when the voltage is switched at

the terminals of DC motor. It is actually the stall current because as soon as

the motor starts to rotate, it generates a back electromotive force (EMF) to oppose the

applied voltage, which reduces the actual current flowing. Therefore, for rapid

acceleration of a motor, a very high voltage and steady feed of the motor with

a constant current circuit is needed.

describes the delay of reduce in

the current in comparison to the initial value when the voltage is switched at

the terminals of DC motor. It is actually the stall current because as soon as

the motor starts to rotate, it generates a back electromotive force (EMF) to oppose the

applied voltage, which reduces the actual current flowing. Therefore, for rapid

acceleration of a motor, a very high voltage and steady feed of the motor with

a constant current circuit is needed.

Fig.

3. Equilibrium mode of adhesion and traction characteristic

Fig.

4. Example of stability, a) and unstability, b) conditions of the adhesion

and traction characteristic [6]

In the considered case,

we assume that the conditions of adhesion in wheel-rail zones of both wheels of

wheelset are the same. Therefore, we can simplify the considered system by introducing a

relationship that ηkp= ηkl= η (Fig. 3). If the system is on the boundary of

stability, the condition of energy balance implies that the average power

supplied to the system in the process of self-excited oscillations with i-th natural frequency is equal to the average power

dissipated in the process of self-oscillations, a similar approach was used in

this paper [12]. Assuming that the generalised coordinates of the model vary

harmonically, we define the average for the period of power supplied into the

system in the process of self-excited oscillations with natural frequency ωi

|

|

(6) |

where Ti describes the period of

oscillation with a natural frequency of this system, expressed relation ![]() . In

the considered case, the power dissipated due to mechanical damping of the

railway drive elements

. In

the considered case, the power dissipated due to mechanical damping of the

railway drive elements![]() can be determined by equation 7

can be determined by equation 7

|

|

(7) |

In order to estimate the

average over power Ee-mech

consumed in the electromechanically interaction in motor, the first equation of

system (5) was analysed. In (5), Tmotor stands for the

dissipative torque that reflects the electromechanical coupling in the electric

motor. Accordingly, to [12] the average power Ee-mech computed for the oscillation

period can be defined as follows:

|

|

(8) |

Introducing the

assumption Tmotor=Tmotor

sin(ωit+ψi), we can estimate the

modulus of torque Tmotor, and solve the first equation of system

(5) by employing the method of complex amplitudes, described in detail in this

paper [12]. This approach takes into account both the amplitude-frequency

characteristic of the inertial link W(ωi)

and phase angle ψi

between the velocity and torque of the motor. Such a link in the first order equation

(5) can

influence the phase angle between the input and output in the range ψ=0-π/2. Note that a small value of the dissipation phase angle ψ does not significantly affect the

frequency of the oscillations. Nevertheless, in calculating the power

dissipation, the phase angle must be taken into account. As a result, equation

(8) can be represented by

|

|

(9) |

where pequili_i is the

dynamic slope coefficient of the traction characteristics of motor that depends

on the electrical machine’s time constant τe and frequency of the vibration of the rotor ωi.

The

total average power Ed

dissipated in the motor during the oscillations can be computed using:

|

|

(10) |

The condition at which

the input energy generated by self-excited vibration and the dissipated energy

are equal Eself =Ed, and the system is on the

stability boundary (Fig. 4a) takes the following

form:

|

|

(11) |

Using the values of the

coefficients of forms of vibration that correspond to the boundary damping ![]() for the oscillations with

the natural frequency ωi, the equation (11) can be written by:

for the oscillations with

the natural frequency ωi, the equation (11) can be written by:

|

|

(12) |

The natural frequencies

of oscillations in the considered drive can be computed by using the equation

|

|

(13) |

where the coefficients of the

natural forms are as follows:

|

|

(14) |

In the case of the

considered traction drive model, the coefficients of natural forms (14) depend

on the inertial parameters of drive IM,

Ikp and stiffness

coefficients k1,

k2,

ke-m.

For the assumption that

the damping in the wheelset is a small number and can be neglected (c2=0),

the equation (12) can be written as follows:

|

|

(15) |

The expression (15) for the

low-frequency mode of vibration becomes:

|

|

(16) |

Furthermore, the expression (15)

for the high-frequency mode of vibration can be written as:

|

|

(17) |

In the numerical study,

we considered a railway drivetrain system with torsionally

flexible hollow shaft. The wheelset of the total weight of 1700 kg and the

loads for the wheels of Q1=Q2=42 kN are assumed. The wheelset is

driven by the DC motor by means of the hollow shaft with the torsional

stiffness and damping coefficient k1=3000 kNm and c1=100 Ns/m, respectively. It is assumed that the radius of

the wheelset axle and the length of the axle is respectively equal to 0.07 m

and 1.6 m. The torsional stiffness of this axis was determined as k2=14e7 Nm/rad. The remaining

parameters used in the simulations are summarised in

Table 1.

Tab. 1

Simulation base parameters

|

η, kNms |

ce-m, Ns/m |

c2, Ns/m |

p, kNms |

IM, kgm2 |

Ikl = Ikr, kgm2 |

τe, s |

|

10 |

4 |

50 |

20 |

2.1 |

78 |

0.01 |

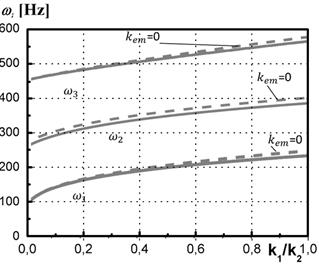

Applying equations 13

and 14 for the considered railway drive, we can demonstrate the natural

frequencies of the system as functions of the stiffness of the wheelset k2

and stiffness of the connection between the electric drive and wheelset k1

(Fig. 5). The influence of skipping of the stiffness coefficient kem

associated with the electromagnetic field of electric motor on the dynamics of

the considered drive system is marked on the charts (Fig. 5) by kem=0.

Using equations 15-17

obtained from the analysis of the railway drivetrain’s model are plotted

the regions of existence of torsional self-vibration by the consideration and

non-consideration of the damping coefficient associated with the

electromagnetic field of electric motor (cem![]() 0 and cem=0) (Fig. 6). The chart

demonstrates four areas I, II, III, IV corresponding to different types of

vibrations.

0 and cem=0) (Fig. 6). The chart

demonstrates four areas I, II, III, IV corresponding to different types of

vibrations.

Fig.

5. The natural frequencies of existence of torsion

vibration in the traction drive

as a

function of the relationship k1/k2

Comparing the obtained

results with those presented in the paper [12], a qualitative match can be

observed. Analysing the waveforms presented in Figure 5, it can be concluded that

if the damping coefficient c2 in the driveline takes value located below the

line ![]() , then the system is sensitive to low frequency torsional vibrations. On

the other hand, if the value of c2 is within the region located below the line

, then the system is sensitive to low frequency torsional vibrations. On

the other hand, if the value of c2 is within the region located below the line ![]() , then the high self-excited torsional vibrations can be observed.

, then the high self-excited torsional vibrations can be observed.

Summarising the results,

it can be concluded that in the region I, only the high-frequency self-excited

vibration may occur. The value of damping c2 in the region II

can induce the low-frequency self-excited torsional vibrations. In region III,

the self-excited torsional vibrations cannot occur. Finally, in region IV, both

types of vibrations mentioned above may be induced.

It is worth mentioning

that if we omit the damping cem generated by the electromagnetic field in the

model of DC motor, then the region IV expands its area. In the same time, the

area of the region I shrinks.

Fig. 6. The regions of

low-, high- and self-

excited torsional vibrations

in the considered driveline

4. SUMMARY AND CONCLUSION

The obtained results

demonstrated that the electromagnetic transient processes generated in the

electric motor should be taken into account when analysing

the stability of the system. The knowledge about the stability of drive

transmission systems of railway vehicles is of great importance in the field of

dynamics and material fatigue of the drive systems component.

In this paper, a dynamic

interaction between the torsionally vibrating railway

wheelset and rotor of driving DC motor was investigated. Based on the method of

the energy balance of the natural modes as described in detail in this paper [12],

the analysis on the oscillations of a railway driveline takes into account the

influence of electromagnetic parameters on its stability in relation to

self-excited torsional vibration generated by adhesion in the wheel-rail zone.

From the viewpoint of

the transient and steady state dynamic responses, particular attention was

focused on the influence of the dynamic properties of the mechanical system as

well as selected electromagnetic parameters of the electric motor. In the analysed case, special attention was focused on the

stiffness and damping coefficients associated with the electromagnetic field of

the DC motor. The less the mechanical damping in the driven system, the greater

the possibility of severe torsional resonances, particularly when in such a

drive train, a semi-elastic connection as hollow shaft with a linear

characteristic is used. The obtained results can serve for the design of the

driven systems and be helpful for their users during regular maintenance.

Reference

1.

Amezquita-Brooks

Luis, Eduardo Liceaga-Castro, Jesus Liceaga-Castro. 2014. “Novel design

model for the stator currents subsystem of induction motors”. Applied Mathematical Modelling 38(23): 5623-5634. ISSN 0307-904X.

2.

Bogacz Roman, Kurt Frischmuth. 2016.

“On dynamic effects of

wheel–rail interaction in the case of Polygonalisation”. Mechanical Systems and Signal Processing 79: 166-173. ISSN: 0888-3270. DOI:

10.1016/j.ymssp.2016.03.001.

3.

Czech Piotr. 2012.

„Determination of the course of pressure in an internal combustion engine

cylinder with the use of vibration effects and radial basis function -

preliminary research”. Communications in Computer and Information

Science 329: 175-182. DOI:

https://doi.org/10.1007/978-3-642-34050-5_21. Springer, Berlin, Heidelberg.

ISBN: 978-3-642-34049-9. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Telematics in the Transport Environment,

12th International Conference on Transport Systems Telematics, Katowice Ustron, Poland, October

10-13, 2012.

4.

Czech Piotr. 2011. „Diagnosing of disturbances in the ignition

system by vibroacoustic signals and radial basis

function - preliminary research”. Communications in Computer and Information Science 239: 110-117. DOI:

https://doi.org/10.1007/978-3-642-24660-9_13. Springer, Berlin, Heidelberg.

ISBN: 978-3-642-24659-3. ISSN: 1865-0929. In: Mikulski Jerzy (eds), Modern

Transport Telematics, 11th International Conference on Transport Systems

Telematics, Katowice Ustron, Poland, October 19-22, 2011.

5.

Duda Sławomir. 2014.

“Numerical simulations of the wheel-rail traction forces using the

electromechanical model of an electric locomotive”. Journal Theoretical and Applied Mechanics 52(2): 395-404.

6.

Eugene

I. Rivin. 1999. Stiffness and

damping in mechanical design, CRC Press, pages 528. DOI:10.1115/1.802939.

7.

Haniszewski Tomasz. 2017. “Modeling the

dynamics of cargo lifting process by overhead crane for dynamic overload factor

estimation”. Journal of Vibroengineering 19(1): 75-86. DOI: 10.21595/jve.2016.17310. ISSN: 1392-8716.

8.

Haniszewski Tomasz, Damian Gaska. 2017.

“Numerical modelling of I-Beam jib crane with local stresses in wheel

supporting flanges - influence of hoisting speed”. Nase More 64(1): 7-13. DOI: 10.17818/NM/2017/1.2. ISSN: 0469-6255.

9.

Henao Humberto, Shahin Hedayati Kia, Gérard-André Capolino. 2011. “Torsional-vibration assessment and

gear-fault diagnosis in railway traction system”. IEEE Trans. Ind. Electron. 58(5): 1707-1717. ISSN: 0278-0046. DOI: 10.1109/TIE.2011.2106094.

10.

Jára Miloslav. 2017. “Introduction to the Influence of Torsional

Oscillation of Driving Wheelsets to Wheel/Axle Press-fitted Joint”. Conference

proceedings of Student's Conference STC. P. 17-26.

11.

Jouch Lieh, Jan Yin. 1998.

“Stability of a Flexible Wheelset for High Speed Rail Vehicles With Constant and Varying Parameters”. Journal of Vibration

and Acoustics 120(4): 997-1002. ASME.

DOI: 10.1115/1.2893933.

12.

Klorkopet Peter. z. 2014. “The Incfinlualencle

of Electromagnetic Processes on Stapbility of Loiclomotives Traction Drive in The

Slipping Mode”. Transalport

Problems 9 (2): 41-48.

13.

Mei T.X.,

I. Hussain. 2010. “Detection of wheel-rail conditions for improved

traction control”. Railway Traction Systems (RTS 2010) IET Conference 1(6): 13-15. DOI:10.1109/Control.2012.6334713.

14.

Pochanke Andrzej. 2008. „Engines induced with permanent magnet

in applying to the drive of traction vehicles”. TTS - Rail

Transport Technique 14(5-6): 22-25.

15.

Shahin Hedayati Kia, Humberto Henao, Gérard-André Capolino.

2009. “Torsional vibration assessment in railway traction system

mechanical transmission”. 2009 IEEE International Symposium on Diagnostics

for Electric Machines, Power Electronics and Drives. P. 1-8. ISBN:

978-1-4244-3441-1. DOI: 10.1109/DEMPED.2009.5292750.

16.

Vectron – the drive system. Siemens.com Global Website.

17.

Voltr Petr, Michael Lata, Ondřej Černý.

2012. “Measuring of wheel-rail adhesion

characteristics at a test stand”. In: Proceedings of

XVIII International Conference on Engineering Mechanics.

Czech Republic.

18.

Winterling M.W., E. Tuinman,

W. Deleroi. 1998. “Simulation of drive line

dynamics of light-rail vehicles”. In: Simulation

’98. International Conference. Conf. Publ. No.

457. IET. P. 79-84. DOI:10.1049/cp:19980619.

19.

Xu Kun, Zeng Jing, Wei

Lai. 2019. “An analysis of the self-excited torsional vibration of

high-speed train drive system”. Journal of Mechanical Science and

Technology 33(3): 1149-1158.

Received 15.09.2019; accepted in revised form 05.11.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License