Article

citation information:

Askerov, H., Vakulenko, I.,

Grischenko, N. Insights into factors of damage of surface rolling of railway

wheels during operation. Scientific Journal of Silesian

University of Technology. Series Transport. 2019, 105, 27-33. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.105.3.

Hangardas ASKEROV[1], Igor

VAKULENKO[2], Nikolaji GRISCHENKO[3]

INSIGHTS

INTO FACTORS OF DAMAGE OF SURFACE ROLLING OF RAILWAY WHEELS DURING OPERATION

Summary. The systematization results of microstructure

studies of carbon steel has made it possible to explain the mechanism of

formation of certain damages to the rolling surface of railway wheels during

operation. The evaluation ability of metal to strain hardening was used to

explain the nature of the influence compactly located non-deformable dispersed

particles on the strength properties steel during cold plastic deformation. In

the process of the interaction of a railway wheel with a rail, successively

occurring heterogeneities in the distribution of the plastic flow metal are one

of the main reasons for the formation of defects on the rolling surface of the

wheel.

Keywords: carbon steel,

microhardness, strain hardening, rolling surface of a railway wheel,

non-metallic particles

1. INTRODUCTION

The process of damage

formation on the rolling surface of railway wheels is determined not only by

the rate accumulation of defects in the crystalline structure but also by the

uniformity of their distribution in the metal [1-4]. A high degree localisation

of the plastic deformation carbon steel on the rolling surface of the wheel

leads to a corresponding increase in the heterogeneity of the strength

properties in adjacent micro volumes of the metal [5]. In addition, the very

nature of loading introduces certain difficulties in the development processes

of strain hardening of carbon steel. Indeed, when compared with simple

deformation schemes, a change in the magnitude and even the sign of the

deformation is accompanied by qualitative structural changes, which greatly

complicates the assessment of the service life of cyclically loaded metal

structures [6]. Additional strengthening of the negative effect of

inhomogeneous metal hardening should be expected from the presence of

non-deformable particles of non-metallic inclusions of various nature of origin

and their location [7]. Based on this, the formation of defects in the rolling

surface of railway wheels is the result of the gradual accumulation of metal

damage with a rather complex interaction with the rail.

2. MATERIALS AND METHODS

The material for the

study was a part of a rim railway wheel, which was withdrawn after completion

of its service life. The carbon steel of wheel with a carbon content of 0.59%,

silicon 0.31%, manganese 0.75% and other chemical elements fully met the

regulatory and technical documentation requirements for railway wheels [8]. The

microstructure was examined under a light microscope. To identify the structure

of the steel under study, the standard reagent “nital” was used.

The size of the structural elements was estimated using quantitative

metallographic techniques [9].

Microhardness (Hμ) was used as a characteristic of

the strength of micro volumes of metal. The ability of the metal to strain

hardening in micro volumes was evaluated by a technique similar to the construction

of a tensile curve [10]. In the Hμ

magnitude, for a certain load on the indenter, the current stress value (σᵢ) was determined (the

maxima load on indenter 0,098 N). The true deformation (εᵢ,) was determined by the ratio: εᵢ = ln(dᵢ/d̥ₐ), where dᵢ - is the current value

diagonal of the imprint, and d̥ₐ

- is the initial value (of minimum). The diagonal d̥ₐ of print was taken with a minimum load on the

indenter. Analysis of the obtained ratio

σᵢ - εᵢ,

allows us to judge the nature of the development strain hardening processes in

micro volumes of metal [11].

3. RESULTS AND DISCUSSION

The cyclic nature of the change in stress on the rolling surface causes

the development of fatigue processes in the metal of wheel rim [5]. These

phenomena in metallic materials are irreversible, and traces of their presence

are detected even at stresses significantly lower than when the first signs of

plastic deformation appear [12]. A detailed analysis [5] indicates that in the absence

of negative influence from nonmetallic particles of various nature origin, one

of the main signs of fatigue damage to be considered are the formation of

extrusions (extruded) and intrusions (absent) of metal volumes on the rolling

surface [13].

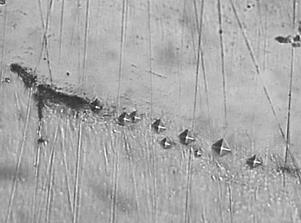

Studies of the rolling surface profile railway wheel after operation

confirms the above positions (Fig. 1a). According to external signs, the

observed anomalies on the surface of rolling should be considered as a certain

alternation of extruded and concave volumes of metal. The study of the

microhardness distribution of the metal matrix near the contour of the rolling

surface (Fig. 1a) showed the existence of a certain pattern in the change of Hμ (Fig. 1b).

From the analysis of the given distribution of microhardness, it follows

that in the vast majority of cases, convex volumes of metal correspond to

higher values, and concave volumes correspond to lower values. Indeed, in the

conduct of a joint analysis location of indenter prints and the corresponding

value of the microhardness of the metal (Fig. 1), we can find that regardless

of the size (depth) of the intrusion, the minimum values of the hardness metal

remain almost unchanged. Furthermore, as it moves along the banks of the

recess, towards the surface of the skating, the absolute values of

microhardness begin to increase gradually, reaching certain extreme values

around the middle of the convex part. Based on the presented character of the

distribution microhardness, it can be assumed that the convex sections should,

in fact, correspond to the extrusion or that part of them that remained on the

surface of the wheel. The fact is that after extrusion is formed, the extruded

part of the metal is partially carried away from the interaction with the rail

and only a certain part of it remains, as evidenced by the absolute values of

microhardness (Fig. 1b).

On the other hand, the sites of formation of future intrusions can be

unambiguously determined by the nature Hμ of the change. This is due to the fact that during the propagation of

plastic flow, the development of processes strain hardening of the metal leads

to an increase in the strength characteristics [12]. Based on this, in places

of current maximum stresses, in the direction of the likely localisation of plastic

deformation, a certain increase in microhardness should be expected. The given

position was confirmed by the data of microhardness measurements on places with

numbers from 19 to 22 and designation “A”

(Fig. 1a). Subsequently, considering that the values of Hμ qualitatively reflect the level of residual stresses in the micro

volumes of metal [12], traces of the increased solubility of metal in the

etchant should indicate the most probable direction of the local propagation

plastic deformation (from N = 19 to N = 22). After the metal has exhausted

the resource of accumulation defects of crystal structure and, in the first

place, dislocations, an intrusion was formed with an inevitable relaxation of

internal stresses. Thus, micro volumes with local plastic flow become places of

origin of future damage rolling surface of railway wheels during operation.

Compared to the mechanism influence

of a non-deformable non-metallic inclusion considered in detail on the

formation system of internal stresses in carbon steel [14], the compact

arrangement dispersed particles can have a qualitatively different effect. This

was confirmed by the results

of a study in which a site with a local arrangement of dispersed carbide

particles in ferrite during plastic deformation was able to behave as a whole

[15].

Figure 2 shows such

volume metal of the wheel rim in which, next to insulated particles

(designation B), a section with

compactly dispersed non-metallic inclusions was observed. In accordance with

the methodology [11], microhardness was measured at various levels of loading

on the indenter and the corresponding curves were constructed to evaluate the

ability of the metal to strain hardening (Fig. 3). Considering that the

accuracy of microhardness determination is inversely proportional to the load

on indenter [16], the section curve with values εᵢ, < 0.4 is most likely due to a large error in the

determination of Hμ.

Subsequently, the indicated section curves (Fig. 3) was excluded from the

analysis of nature strain hardening of the metal. At initial loads on indenter (εᵢ,> 0.4), a metal with dispersed non-metallic

inclusions (Fig. 3a) has almost the same resistance to plastic flow (of the

order 1 GPa) compared to the volume without particles (Fig. 3b). As the load on

indenter increases, the degree of plastic deformation increases in proportion to

its introduction into the metal. A comparative analysis of the constructed

curves under loading volumes of metal with and without particles indicates the

existence of certain differences in the shape of the curves.

a

b

Fig. 1. The profile surface rolling of wheel's (a) and the nature of

change microhardness (load on the indenter is 0,196 N) in accordance with

the numbers (N) of

measurement sites (b). Magnification 350 x 1.2

Visually, the stress growth rate for a place with inclusions (Fig. 3a)

significantly exceeds the similar characteristic for a metal without inclusions

(Fig. 3b), thereby ensuring a higher hardness level at the same values of

εᵢ. The above increase in microhardness does not contradict the

well-known effect of dispersion hardening metal matrix from the presence of

particles second phase [17]. Based on this, it can be

assumed that the indicated differences in curves can be explained to a certain

extent by the nature of accumulation defects crystal structure during the

plastic flow of the metal. Hence, according to [12, 18], the estimation of the

rate accumulation dislocations by the value of angular coefficient of tangent

in the region of uniform strain hardening was fairly well confirmed by the

analysis of density dislocations by the expansion of X-ray interference [15].

Considering that, the strain hardening characteristics quite unambiguously

estimate the growth rate of defects in the crystal structure during plastic

deformation of carbon steels [17, 18], this technique can be used to analyse

the loading curves under study (Fig. 3). As a characteristic of strain

hardening, the angular coefficient of the tangent, constructed at points with

the same value of εᵢ,, was

adopted. Numerically, the coefficient of tangents corresponded to the magnitude

of the increase in microhardness at a unit change of εᵢ, (ΔΗμ/Δεᵢ), when the Δεᵢ → 0. The values of the angular

coefficient were determined in the range of εᵢ,

0.4 - 0.6. The analysis of ΔΗμ/Δεᵢ

values indicates that for a volume of metal with non-metallic inclusions, this

characteristic is approximately an order of magnitude higher than the value for

a metal matrix without inclusions (7.5 versus 0.6 GPa, respectively). The

observed difference in the parameters of strain hardening is in fair agreement

with the estimate of the ductility margin for carbon steels [19]. From the

results of the studies [20], it is obvious that the lower characteristics

strain hardening, the higher the plastic properties of medium- and high-carbon

steels.

В

Fig. 2. The

volume of metal with compactly located disperse non-metallic inclusions after

measuring microhardness. Magnification 350 x 1.6

Thus, one of the reasons

formation damage railway wheels along the rolling surface should be considered

is an increase of density defects of crystalline structure and, firstly,

dislocations, in areas with a local arrangement non-metallic dispersed

particles. Based on this, during the operation of railway wheels, regardless of

the strength level and structural state of the steel, the location of metal

volumes with such non-metallic dispersed inclusions near the rolling surface

will lead to the rapid exhaustion of the resource of accumulation defects of crystal

structure and cause the formation of surface damage.

Based on this,

assessment nature of the accumulation defects of crystalline structure in a

metal near the rolling surface should be considered as a tool for studying the

processes of structure formation and developing measures to increase the

service life of railway wheels.

4. FINDINGS

1. The formation of extrusions on

rolling surface of a railway wheel was accompanied by an increase in

microhardness carbon steel and intrusions by its decrease.

2. Regardless of the intrusion

depth, the microhardness carbon steel remained practically unchanged.

3. The local arrangement of

non-metallic particles contributed to an increase in the strain hardening

characteristics in micro volumes carbon steel.

4. The formation of damage rolling

surface due to accelerated growth density defects of crystalline structure from

the presence of non-metallic dispersed particles.

а

b

Fig. 3. The ratio of σᵢ - εᵢ for volumes of metal

with dispersed particles of non-metallic inclusions (a) and without them (b)

Acknowledgements

The authors are grateful to Dr.

V.G. Anofriev for providing material for research. Thanks to Drs. O.N. Perkov

and O.A. Tchaikovsky for their valuable advice on research results and paper

design.

References

1.

Knott J.F. 1973. Fundamentals of

fracture mechanics. London: Butterworths.

2.

Koymatcik H., T. Tozlu, H. Cug, Y. Sun, H. Ahlatci. 2013.

“Hardening of the head portions of the pearlitic rails by accelerated

cooling”. JESTECH. 16: 53-58.

3.

Sysyn Mykola, Ulf Gerber, Dimitri Gruen, Olga Nabochenko, Vitalii

Kovalchuk. 2019. “Modelling and vehicle based measurements of ballast

settlements under the common crossing”. European Transport \ Trasporti Europei 71(5). ISSN: 1825-3997.

4.

Vasauskas V., Ž. Bazaras, V. Čapas. 2005. “Strength

anisotropy of railway wheels under contact load”. Mechanika 1(51): 31-38. ISSN: 1392-1207.

5.

Jahanmir S., N.P. Suh. 1977. “Surface topography and integrity

effects on sliding wear”. Wear. 44:

87-99.

6.

Walther F., D. Eifler. 2004. “Fatigue behaviour of railway wheels

at different temperatures” Mater.

Test. 46: 158-162.

7.

Gubenko S., Y. Proidak. 2012. “Investigation of wear mechanism of

tread during operation of railway wheels” Transport problems 7: 111- 125.

8.

En N.F. 2009 “European standard for Wheels – EN 12262

Product requirements”.

9.

Boljshakov V.I., G.D. Sukhomlin, N.Eh. Pogrebnaya. 2001. “Atlas

struktur metallov I splavov” [In Russian: „Atlas of metal and alloy structures”]. Dnepropetrovs, Ukraine: Gaudeamus.

10. Hollomon J.H. 1945.

“Tensile deformation”. Trans.

A.I.M.E 162: 268-290.

11. Patent UA 418818 G01N

3/40. Спосіб

оцінки

деформаційного

зміцнення

мікрооб’ємів

зерен

полікристалів.

Київ, UA. Бюл. №11, Публ.

10.06.2009, 4с. [In Ukrainian: A method of

estimating the strain hardening of the micro-volumes of polycrystalline grains.

Kiev, UA. Bul. No 11, Publ. 10.06.2009, 4s].

12. Trefilov V.I.,

V.F.Moiseev. 1978. “Dispersnihe

chasticih v tugoplavkikh metallakh” [In Russian: “Dispersed particles in refractory metals”]

Kiev, Ukraine: Naukova dumka.

13. Cahn R.W. (Ed.). 1965.

“Physical Metallurgy”.

Amsterdam: North-Holland publishing company.

14. Gubenko S., Y. Proidak, A.

Kozlovsky, et. al. 2008. “Influence of nonmetallic inclusions on micro breaks formation in

wheel steel and railway wheels”. Transport

Problems 3: 77-81.

15. Babich V.K., Yu.P. Gulj, I.E. Dolzhenkov. 1972. “Deformacionnoe starenie stali”. [In Russian: „Deformation

aging of steel”]. Moscow: Metallurgiya.

16. Grigorovich V.K. 1976. “Tverdostj i mikrotverdostj metallov” [In Russian: „Hardness

and microhardness of metals ”]. Moscow: Metallurgiya. Moskva: Nauka.

17. Pickering F.B. 1978.

“Physical metallurgy and the design

of steels”. Applied science publishers LTD.

18. Bergstrom J., B.

Aronson. 1971. “The application of a dislocation model to the strain and

temperature dependence of the strain hardening exponent n in Ludwik’s

relation between stress and strain in mild steels”. Inst. Metallforsk 753: 27-39.

19. Morrison W.B. 1966.

“The effect of grain size on the stress-strain relationship in low carbon

steel”. Trans. Am. Soc. Metals.

59: 824-846.

20. Fetisov V.P., V.K.

Babich, V.A. Pirogov. 1983. “Opredelenie

deformiruemosti katanki iz nizkouglerodistoyj stali pri volochenii”. [In Russian: „Determination deformability of a low

carbon steel wire rod during drawing”]. Chernaya metallurgiya. Byul. NTI 17: 58-59.

Received 03.10.2019; accepted in revised form 21.11.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License