Article

citation information:

Zarenbin, V., Kolesnikova, T.,

Sakno, O., Ollo, V., Klimenko, V. Impact evaluation of piston rings mobility on a gas

passage in an internal combustion engine (ICE). Scientific Journal of Silesian University of Technology. Series

Transport. 2019, 104, 187-201.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.104.17.

Volodymyr ZARENBIN[1],

Tatiana KOLESNIKOVA[2], Olha SAKNO[3],

Vasyl OLLO[4], Victor KLIMENKO[5]

IMPACT EVALUATION OF PISTON RINGS MOBILITY ON A

GAS PASSAGE IN AN INTERNAL COMBUSTION ENGINE (ICE)

Summary. To estimate the effect of the axial movement of piston rings in the piston

grooves on the blow-by in the internal combustion engine (ICE) by an

experiment- calculated method. This contributes to the development of practical

recommendations for the further improvement of the engine ring seal designs. Abstract theorems were used when modelling the effect of the axial movement

of piston rings in the piston grooves on the blow-by in an ICE. They are based

on the fundamental theory of heat engines, thermodynamics and hydraulics. The

ICE running was analysed using design-theoretical research

methods. The effect of the axial

movement of piston rings in the piston grooves on the blow-by in the ICE was established. This creates

prerequisites for a more accurate assessment of their sealing capacity and for ways to further improve them.

Calculated dependences for computing the blow-by depending on the positional relationship of

the rings in the piston grooves were obtained. The dependences of gas escapes on the engine crankshaft

speed were obtained, which is especially

important for idling modes by which one can judge the dynamic stability of the

ring seal and solve the problems of improving its service properties. The calculated dependences for

evaluation of the blow-by depending on the positional relationship of the rings

in the piston grooves and their respective possible gas flows in the ring seal were obtained for the first time. The practical method for estimating

the dynamic stability of the ring seal by decencies of gas escape on the

crankshaft rotation speed in ICE was proposed.

Keywords: ICE ring seal, piston ring

mobility, calculation of gas escape.

1. INTRODUCTION

The internal combustion engines (ICE) of trucks

used in the mining industry are one of the critical units with expensive

repairs. The ICE requires a preliminary diagnosis, which assesses the technical

condition of both the engine and the truck as a whole.

The ICE generate vibrations and noise during operation. They

can also be successfully used for diagnostic purposes. Such methods have been

increasingly used in recent years [3-8,10,16,18,23,24].

The technical condition of the parts of the

cylinder-piston group (CPG) can be determined by gas escape in the ICE.

The modern development of the high-speed

ICE is the way to improve their technical, economic and environmental

performance. This predetermines [1,2,9,15,20]:

a) the expansion of research and

development projects on the further design and technological improvement of

parts of the CPG of the ICE

b) the choice of optimal

conditions for interfacing their contacting surfaces

c) improving the quality of used materials

Piston rings (PR) are the most

high-wear parts of the CPG, thus, the issues of improving their performance and

reliability are of current importance when creating prospective engines used in

the mining industry.

The main factors that

determine the normal running of the ICE are the condition of coupling of

surfaces of the compression rings with the cylinder wall and their ends with

the top and bottom planes of the piston grooves. This is connected with the

sealing of the combustion chamber and prevention of a considerable blow-by in the engine

case.

Gas escapes through the gaps

in the parts mating of the CPG, break the oil film and increase wear which, in turn, increases gas escape.

This furthers the seizing of the piston rings, increase in oil consumption and fuel, and

smoking. The final result is jamming and engine trouble.

A wide variety of factors

influencing the operation of the PR complicates analysis and generalisation of the experimental data and

development of general principles of the theoretically substantiated choice of

designs of the ICE ring seal. The solution of this issue could be based on the account of

the totality of the main phenomena that determine the operability of CPG and PR

parts.

Numerous papers cover the experimental and theoretical

study of the PR operation. In [12] it was found that the

hydrodynamic friction increased with the initial wear of the PR in conditions

of increasing minimum thickness of the oil film. This contributes to the fact

that the PR can remain operational during the entire service life. Hydrodynamic

friction for high rings can be reduced using a narrow parabolic profile, which is impossible for narrow rings.

A laser fluorescence system

was developed to visualise

the thickness of the oil film between the PR and the cylinder wall of the

running gasoline engine through a small optical window installed in the

cylinder wall. The results show significant differences in the profiles of the

thickness of the lubricant film for the ring seal if the lubricant

deteriorates, which affects the ring friction and, ultimately, fuel economy [14].

The diagnostic methodology can

effectively determine the control of the condition of the PR in accordance with

the characteristics of combustion [13].

The calculation of the gas

flow through the ICE ring seals with regard to the piston rings dynamics allows

diagnosing the engine technical condition.

2D CFD model is used to study

the effect of the ring seal design on the friction process, oil consumption and

oil flow. Calculations of the piston rings dynamics were carried out on the assumption of

forces balance [11].

Methods and devices to study

mechanical friction losses were developed [19]. A simplified floating liner

method was used and the test equipment was developed to fill the gap in between

the full floating liner engine and the typical component bench test equipment.

The purpose of this research [17] was to study the potential of the

laser oil pockets new design so as to improve the piston rings lubrication. These pockets

make it possible to achieve significant friction reduction by using appropriate

geometric parameters [7,8,10,24].

Presently, there is a wide range of

solution of the PR reliability and operating life problems. However, the

dynamics of the parts of the CPG are not sufficiently considered. In

particular, this is the PR movement in the piston grooves. This is connected

with the engine running, where

all piston rings moving are

difficult to measure; there are no theoretical dependencies that link the PR

mobility in the piston grooves with gas escapes through the ring seal.

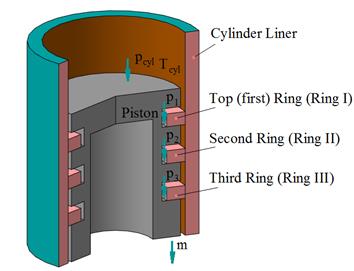

2. DYNAMIC ANALYSIS OF GAS FLOW

THROUGH THE ICE RING SEAL

In general, the problem of the

gases flow through the volumes on lands and piston ring grooves is quite

complicated. However, it can be simplified if the following experimental and

theoretical justifications of assumption are introduced:

a) the gas flow process is taken

to be quasi-stationary

b) the areas of the flow passage

between the PR, the piston and the cylinder liner should be replaced by the

equivalent area of the flow passage of the piston-ring lock

c) geometric relationships in the ring seal can only be

changed due to axial unloading of the rings and their subsequent separation

from the bearing area of the groove

In this paper, the problem is considered on the

example of the ring seal consisting of three rings in various cases of their

relative position in the grooves, which received experimental confirmation in

the paper.

The principal features of the

adopted model were that

it takes into account the throttling effect of the upper fascia of the piston

and the change in the areas of the flow sections and the volume of the annular

spaces due to the movement of the rings in the grooves.

It is accepted that the

separation of the rings from the support surfaces of the groove in the

direction of the piston axis occurs at the moments when the sum of the forces

from the gas pressure ![]() , the inertia of the ring

, the inertia of the ring ![]() and the friction

and the friction ![]() are zero, which means

are zero, which means

![]() (1)

(1)

The theoretical studies were

based on the differential equations of mass and energy balances, as well as the

criterion equation of heat exchange for the gases flow in micro-gap channels.

For the second and third piston grooves, the gases flow was accepted to be

isothermal with a gas temperature equal to the arithmetic average of the

temperatures of the piston grooves and the cylinder liner.

As a result of the dynamic

calculation the total forces that act on the piston rings, as well as various

cases of their positional relationship in the grooves and their corresponding

possible gas flows in the ring seal were identified.

Blow-by m through the PR leakiness was calculated by the formula:

(2)

(2)

where ![]() – discharge coefficient

and flow section between volumes on lands and the piston ring grooves [m2];

– discharge coefficient

and flow section between volumes on lands and the piston ring grooves [m2];

![]() – speed

function, which depends on the pressure ratio;

– speed

function, which depends on the pressure ratio; ![]() ,

, ![]() – pressure [Pa] and gas

temperature in the grooves [K];

– pressure [Pa] and gas

temperature in the grooves [K]; ![]() – gas constant, R=287 [J/(kg.K)];

– gas constant, R=287 [J/(kg.K)];![]()

![]() – time [s].

– time [s].

The following formulas to

calculate the pressures and the blow-by in various cases of the positional

relationship of the rings in the piston grooves were obtained.

2.1. Case 1 of the positional

relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]()

The initial equations

for the calculation are the mass and energy balance Equations. Cylinder

pressure (![]() ) is calculated

) is calculated

![]() (3)

(3)

![]() (4)

(4)

where ![]() and

and ![]() – change of

elementary mass and internal energy of gases in the top groove during

– change of

elementary mass and internal energy of gases in the top groove during ![]() ;

; ![]() and

and ![]() – the

elementary mass and enthalpy of gases which flow into the top groove out of the

cylinder during

– the

elementary mass and enthalpy of gases which flow into the top groove out of the

cylinder during ![]() ;

; ![]() and

and ![]() – the

elementary mass and enthalpy of gases which flow from the top groove to the

second groove during

– the

elementary mass and enthalpy of gases which flow from the top groove to the

second groove during ![]() ;

; ![]() – the

elementary quantity of heat that is transferred (or perceived) gases

surrounding surfaces of CPG parts during

– the

elementary quantity of heat that is transferred (or perceived) gases

surrounding surfaces of CPG parts during ![]() .

.

The Equation (4) is

differentiated. The Equation (3) is substituted into this equation. As a

result, the following equation has the form:

![]() (5)

(5)

Internal energy of gases

is determined ![]() (

(![]() – mass isochoric heat capacity of gases at constant

volume V in the ring groove); the

enthalpy of gases is determined

– mass isochoric heat capacity of gases at constant

volume V in the ring groove); the

enthalpy of gases is determined ![]() (

(![]() – mass isobaric heat capacity of gases at constant

volume V in the ring groove); gas

state is determined

– mass isobaric heat capacity of gases at constant

volume V in the ring groove); gas

state is determined ![]() . The following equations are used

. The following equations are used

![]() and

and ![]() (6)

(6)

where ![]() – heat

exchange coefficient from gases to surfaces of the cylinder and the piston

– heat

exchange coefficient from gases to surfaces of the cylinder and the piston

[![]() ];

]; ![]() – cooling

surface temperature [K].

– cooling

surface temperature [K].

The equation is

transformed and as a result has the following form

(7)

(7)

where ![]() ;

; ![]() ;

; ![]() ;

; ![]() ;

; ![]() ;

; ![]() ;

; ![]() ;

; ![]() – volume of

ring groove I [m3];

– volume of

ring groove I [m3]; ![]() ,

, ![]() – average

temperature of the piston head [K];

– average

temperature of the piston head [K]; ![]() – the

determining gas temperature [K];

– the

determining gas temperature [K]; ![]() – gas

pressure in the minimum section of the jet [Pa];

– gas

pressure in the minimum section of the jet [Pa]; ![]() – gas

pressure in the cylinder [Pa];

– gas

pressure in the cylinder [Pa]; ![]() – average

temperature of the piston head and cylinder liner [K].

– average

temperature of the piston head and cylinder liner [K].

The calculation of the

blow-by when the sum of the forces acting on the rings ![]() is positive and the gases

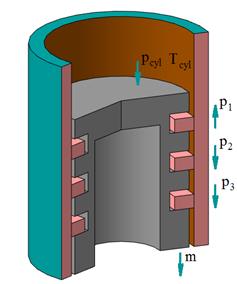

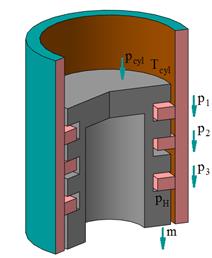

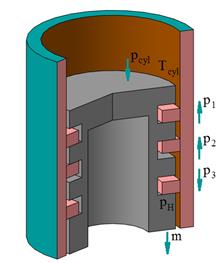

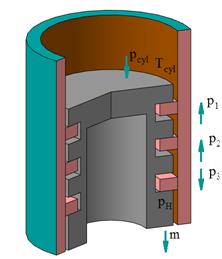

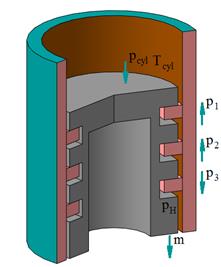

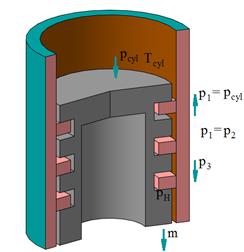

pressure decreases from the top PR to the bottom (Fig. 1) is the following:

is positive and the gases

pressure decreases from the top PR to the bottom (Fig. 1) is the following: ![]() ,

, ![]() and

and ![]() with

with ![]() .

.

![]() – mass gas

escape;

– mass gas

escape; ![]() ,

, ![]() ,

, ![]() – gas

pressure in annular piston cavities I, II and III

– gas

pressure in annular piston cavities I, II and III

Fig. 1. Case 1 of the

positional relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]()

Then

(8)

(8)

where рН – gas pressure in the crankcase

[Pa]; ![]() – the

adiabatic coefficient of gas per ring I;

– the

adiabatic coefficient of gas per ring I; ![]() – the

adiabatic coefficient of gas in the cylinder;

– the

adiabatic coefficient of gas in the cylinder; ![]() – gas

temperature in the cylinder [K];

– gas

temperature in the cylinder [K]; ![]() – heat

receiving surface area [m2];

– heat

receiving surface area [m2]; ![]() – mass heat

capacity of gases at constant volume in the ring groove I [

– mass heat

capacity of gases at constant volume in the ring groove I [![]() ];

]; ![]() – mass heat

capacity of gases at constant volume in the cylinder [

– mass heat

capacity of gases at constant volume in the cylinder [![]() ]

]

and

![]()

![]()

![]()

![]() (9)

(9)

Pressure difference in

the heat zone of the piston, subject to maintaining the constancy of the gases

velocity is determined

![]() (10)

(10)

where р – gas pressure in the annular gap between

the heat zone of a piston and cylinder; W

– average consumed gases velocity; ![]() – gas

density;

– gas

density; ![]() – the

equivalent diameter of the channel in the form of gap;

– the

equivalent diameter of the channel in the form of gap; ![]() – width of

a gap;

– width of

a gap; ![]() – movement gas

resistance coefficient.

– movement gas

resistance coefficient.

The Equation (10) is

integrated on condition that ![]() (

(![]() is Reynolds number).

is Reynolds number).

Then

![]() (11)

(11)

where ![]() is gas density in the minimum

section of the jet and

is gas density in the minimum

section of the jet and  .

.

Then

![]() (12)

(12)

Equations (11) and (12)

are taken into consideration. As a result, the following equation is obtained

(13)

(13)

where ![]() – speed loss coefficient.

– speed loss coefficient.

The equation for the second and third grooves (m = 2, 3, ![]() =

=![]() ) is the following:

) is the following:

(14)

(14)

where ![]() is the adiabatic

coefficient in m-th groove;

is the adiabatic

coefficient in m-th groove; ![]() is gas

temperature in m-th groove [K].

is gas

temperature in m-th groove [K].

Then Formula (2) is the

following:

![]() (15)

(15)

where ![]() – Discharge

coefficient and flow section over PR III [m2];

– Discharge

coefficient and flow section over PR III [m2]; ![]() and

and ![]() – Pressure [Pa] and gas

temperature in ring groove III [K].

– Pressure [Pa] and gas

temperature in ring groove III [K].

Pressure in

ring groove II has the following by Formula (16) if ![]() <

<![]() <

<![]() and

and ![]() >

>![]() (Fig. 2). The

Formula (16) is following:

(Fig. 2). The

Formula (16) is following:

(16)

(16)

where ![]() is a volume of

ring groove II [m3];

is a volume of

ring groove II [m3]; ![]() is determined by the Formula (4)

is determined by the Formula (4)

with m = 3; ![]() – Volume of

the ring groove III [m3]

– Volume of

the ring groove III [m3]

and

![]() =

=![]()

![]()

![]()

![]()

![]()

![]()

Fig. 2. Case of the

positional relationship of the rings in the grooves of the piston, when ![]() <

<![]() <

<![]() and

and ![]() >

>![]()

2.2. Case 2 of the

positional relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]()

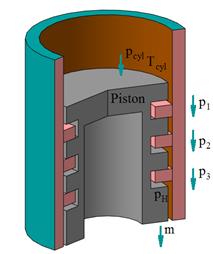

The calculation of the

blow-by if the sum of the forces acting on the ring I is positive and on the

rings II and III is negative (Fig. 3, a) is the following:

![]() ,

, ![]() ,

, ![]() with

with ![]() .

.

Then

![]() is determined by the Formula (8);

is determined by the Formula (8);

![]() is determined by the Formula (14) with m = 2;

is determined by the Formula (14) with m = 2;

![]() =

=![]() .

.

When ![]() <

<![]() >

>![]() (Fig. 3, b):

(Fig. 3, b):

![]() (17)

(17)

where ![]() is gas pressure

in the in the ring groove II [Pa]

is gas pressure

in the in the ring groove II [Pa]

![]()

![]()

a) b)

Fig. 3. Case 2 of the

positional relationship of the rings in the grooves of the piston, when:

a) ![]() ,

, ![]() and

and ![]() ; b)

; b) ![]() <

<![]() >

>![]()

Then Formula (2) is the

following:

(18)

(18)

where ![]() is gas

temperature in the ring groove II [K].

is gas

temperature in the ring groove II [K].

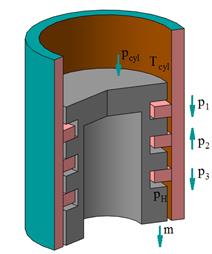

2.3. Case 3 of the

positional relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]()

The calculation of the

blow-by if the sum of the forces acting on the ring I and III is positive and on the

ring II is negative (Fig. 4, a) is the following:

![]() ,

, ![]() and

and ![]() with

with ![]() .

.

a)

b)

Fig. 4. Case 3 of the

positional relationship of the rings in the grooves of the piston, when:

a) ![]() ,

, ![]() and

and ![]() ; b)

; b) ![]() =

=![]() >

>![]()

Then ![]() is determined by the Formula (8)

is determined by the Formula (8)

(19)

(19)

where ![]()

When ![]() =

=![]() >

>![]() and

and ![]() =

=![]() (see Fig. 4, b):

(see Fig. 4, b):

(20)

(20)

Then Formula (2) is the

following:

(21)

(21)

2.4. Case

4 of the positional relationship of the rings in the grooves of the piston,

when ![]() ,

, ![]() and

and ![]()

The calculation of the

blow-by if the sum of the forces acting on the ring I and II is negative

and on the ring III is positive is the following (Fig. 5):

![]() ,

, ![]() and

and ![]() with

with ![]() .

.

Fig. 5. Case 4 of the

positional relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]()

Then

(22)

(22)

2.5. Case 5 of the

positional relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]() with

with ![]() and

and ![]() =

=![]()

The calculation of the

blow-by if ![]() ,

, ![]() and

and ![]() with

with ![]() and

and ![]() =

=![]() (Fig. 6) is the

following.

(Fig. 6) is the

following.

Fig. 6. Case 5 of the

positional relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]() with

with ![]() and

and ![]() =

=![]()

Then ![]() is determined by the Formula (15) with

is determined by the Formula (15) with ![]() =

=![]() ;

; ![]() =

=![]() and

and ![]() =

=![]() .

.

2.6. Case 6 of the

positional relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]() with

with ![]() ,

, ![]() =

=![]() and

and ![]() =

=![]()

The calculation of the

blow-by if ![]() ,

, ![]() and

and ![]() with

with ![]() ,

, ![]() =

=![]() and

and ![]() =

=![]() (Fig. 7) is the

following.

(Fig. 7) is the

following.

Fig. 7. Case 6 of the

positional relationship of the rings in the grooves of the piston, when ![]() ,

, ![]() and

and ![]() with

with ![]() ,

, ![]() =

=![]() and

and ![]() =

=![]()

Then ![]() is determined by the Formula (14) with m = 3,

is determined by the Formula (14) with m = 3, ![]() =

=![]() .

.

For further analysis, it

is convenient to consider the relative magnitude of gas escapes:

![]() (23)

(23)

where m is current gas escape in the crank angle [kg]; ![]() is total gas

escape per cycle [kg].

is total gas

escape per cycle [kg].

3. THE RESULTS OF THE

CALCULATIONS

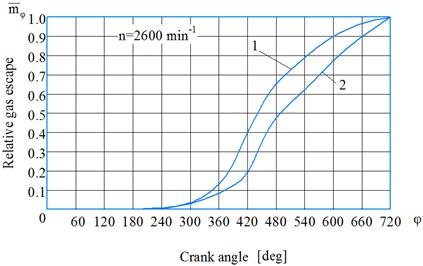

The dependencies ![]() and

and ![]() for the diesel

with the main initial data are shown in Fig. 8 and 9:

for the diesel

with the main initial data are shown in Fig. 8 and 9:

-

engine power Nе = 155 kW

-

engine speed n = 2600 min-1

-

value of flow section ![]() = 0.3ˑ10-6 m2

= 0.3ˑ10-6 m2

-

volume on lands and the piston ring grooves: ![]() = 1.73ˑ10-6

m3

= 1.73ˑ10-6

m3

The initial and boundary

conditions were set according to the results of indexing and thermometry of the

diesel engine at the rated duty; discharge coefficient ![]() =0.85.

=0.85.

Fig. 8. Changes of the

relative gas escape ![]() depending on

the crank angle (n = 2600 min-1) subject to: 1 – the movement

of the rings in the grooves; 2 – the fixed rings

depending on

the crank angle (n = 2600 min-1) subject to: 1 – the movement

of the rings in the grooves; 2 – the fixed rings

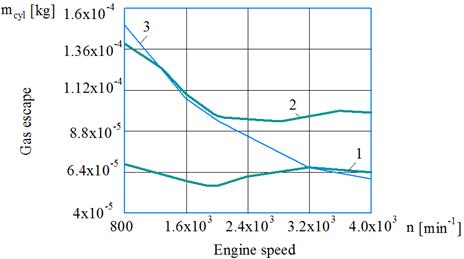

Fig. 9. Changes of the gas

escape ![]() depending on the

engine speed: 1 – idling conditions;

depending on the

engine speed: 1 – idling conditions;

2 – load conditions; 3

– the fixed rings

Movements of the rings in the

grooves noticeably affect the gas escape into the crankcase, especially when

the pressure in the cylinders is the biggest, that is, at 360-660o

crank angle (Fig. 8). After 660o crank angle, the difference in gas

escape values can be neglected.

The analysis of dependences ![]() confirms the

significant influence of the dynamics of rings on the course of cyclic gas

escape curves (Fig. 9). The deterioration of the sealing properties of the

piston rings with increasing the engine speed was noted earlier in other

studies [21,22].

confirms the

significant influence of the dynamics of rings on the course of cyclic gas

escape curves (Fig. 9). The deterioration of the sealing properties of the

piston rings with increasing the engine speed was noted earlier in other

studies [21,22].

This fact especially manifests

itself in idling modes due to the reduced pressure in the combustion chamber.

Thus, according to the gas

escape flow nature dependence on the engine speed, it is possible to assess the

compression ability of the diesel ring seal, the quality operation of the piston

rings. This enables

the determining of the technical condition of the CPG

parts which is especially important for mining industry trucks.

4. CONCLUSIONS

1. The effect of

the axial movement of the piston rings in the piston grooves on the blow-by in

the ICE was established. This creates

prerequisites for a more accurate assessment of their sealing ability and the

search for ways to further improve them.

2. The calculated

dependences to compute

the blow-by depending on the positional relationship of the rings in the piston

grooves was obtained

3. The dependencies of the gas escapes on the engine

speed allow judging upon the dynamic stability of the ring seal and solving the

issues of evaluating the technical condition of the CPG parts and improving

their operational properties, especially for idling modes.

Acknowledgements

The authors would like to express their gratitude to the referees for their

constructive and valuable suggestions.

References

1.

Abramchuk F., O. Grytsyuk, A. Prokhorenko, I.

Reveliuk. 2018. “Specifying the procedure for designing the elements of the

crankshaft system for a small high-speed diesel engine”. Eastern-European Journal of Enterprise

Technologies 3/1(93): 60-66. DOI: 10.15587/1729-4061.2018.133353.

2.

Akimov

O.G., V.I. Gusau, A.P. Marchenko. 2015.

“Обзор

компьютерно-интегрированных

систем и

технологий

изготовления

поршней двигателей

внутреннего

сгорания”. Восточно-Европейский

журнал

передовых

технологий. [In Russia: “Overview of computer-integrated systems and technologies

for manufacturing pistons of internal combustion engines”. East European Journal of Advanced

Technologies 6/1(78): 35-42. DOI: 10.15587/1729-4061.2015.56318. ISSN 1729-3774].

3.

Czech P.

2012. “Determination of the course of

pressure in an internal combustion engine cylinder with the use of vibration

effects and radial basis function - preliminary research”. TELEMATICS IN

THE TRANSPORT ENVIRONMENT. Edited by: Mikulski J. Book Series: Communications

in Computer and Information Science. Vol.: 329. P. 175-182. Conference: 12th

International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, Oct 10-13, 2012.

4.

Czech P.

2011. “Diagnosing of disturbances in the

ignition system by vibroacoustic signals and radial basis function -

preliminary research”. MODERN TRANSPORT TELEMATICS. Edited by: Mikulski

J. Book Series: Communications in Computer and Information Science. Vol.: 239.

P. 110-117. Conference: 11th International Conference on Transport Systems

Telematics, Katowice Ustron, Poland, Oct 19-22, 2011.

5.

Figlus T., M. Stanczyk. 2016. “A method for detecting damage

to rolling bearings in toothed gears of processing lines”. Metalurgija 55(1): 75-78. ISSN: 0543-5846.

6.

Figlus T., M. Stanczyk. 2014. “Diagnosis of the wear of

gears in the gearbox using the wavelet packet transform”. Metalurgija 53(4):

673-676. ISSN: 0543-5846.

7.

Homišin

J. 2016. “Characteristics of

pneumatic tuners of torsional oscillation as a result of patent activity”. Acta

Mechanica et Automatika 10(4): 316-323. ISSN 1898-4088.

8.

Homišin

J., R. Grega, P. Kaššay, G. Fedorko, V. Molnár. 2019.

“Removal of systematic failure of belt

conveyor drive by reducing vibrations”.

Engineering

Failure Analysis 99: 192-202. ISSN 1350-6307.

9.

Iwnicki S. (editor). 2006. Handbook of Vehicle Dynamics. (Powertrain

and Transport). London, New York: Taylor & Francis Group. LLC.

10.

Kuľka J., M. Mantič, M. Kopas, E. Faltinová. 2017. ”Necessity

of wire rope replacement in crane lifting equipment after change of crane

operational parameters”.

Advances in Science

and Technology Research Journal 11: 226-230. DOI: 10.12913/22998624/71180. ISSN 2299-8624.

11.

Lyubarskyy P., D. Bartel.

2016. “2D CFD-model of the piston assembly in a diesel engine for the

analysis of piston ring dynamics, mass transport and friction”. Tribology International 104:

352-368. DOI: https://doi.org/10.1016/j.triboint.2016.09.017.

12.

Ma W., N. Biboulet, A.A. Lubrecht. 2018. “Performance evolution of a

worn piston ring”. Tribology International 126:

317-323. https://doi.org/10.1016/j.triboint.2018.05.028.

13.

Mohamed E.S. 2018. “Performance

analysis and condition monitoring of ICE piston-ring based on combustion and

thermal characteristics”. Applied Thermal

Engineering 132: 824-840. DOI: https://doi.org/10.1016/j.applthermaleng.2017.12.111.

14.

Notay R.S., M. Priest,

M.F. Fox.

2019. “The influence of lubricant

degradation on measured piston ring film thickness in a fired gasoline

reciprocating engine”. Tribology International 129:

112-123. DOI: https://doi.org/10.1016/j.triboint.2018.07.002.

15.

Postrzednik S., Z. Żmudka,

G. Przybyła. 2013. “Influence of the exhaust gas recirculation on

the oxygen contents and its excess ratio in the engine combustion

chamber”. Journal of KONES.

Powertrain and Transport 20 (3): 315-321.

16.

Sapietova

A., V. Dekys. 2016. „Use od Msc. Adams software product in modeling

vibration sources”. Komunikacie

1a(101): 101-107. ISSN: 2585-7878.

17.

Shen C., M.M. Khonsari.

2016. “The effect of laser machined

pockets on the lubrication of piston ring prototypes”. Tribology International 101:

273-283. DOI: https://doi.org/10.1016/j.triboint.2016.04.009.

18. Smutny J., V. Nohal, D. Vukusicova, H.

Seelmann. 2018. “Vibration analysis by the Wigner-Ville transformation

method”. Komunikacie 4. ISSN:

1335-4205.

19.

Söderfjäll M., A. Almqvist,

R. Larsson.

2016. “Component test for simulation of

piston ring – cylinder liner friction at realistic

speeds”. Tribology International 104: 57-63. DOI: https://doi.org/10.1016/j.triboint.2016.08.021.

20.

Tomazic D. 2005. Emissions

control. Engine Technology International (ETI) 01.

21.

Usman A., C.W. Park.

2016. “Optimizing the tribological

performance of textured piston ring–liner contact for reduced frictional

losses in SI engine: warm operating conditions”. Tribology International 99: 224-236. DOI: https://doi.org/10.1016/j.triboint.2016.03.030.

22.

Wong V.W., Simon C. Tung.

2016. “Overview of automotive engine friction and reduction

trends–effects of surface, material, and lubricant-additive

technologies”. Friction 4 (1): 1-28.

23.

Zapoměl

J., V. Dekýš, P. Ferfecki, A. Sapietová, M. Sága, M.

Žmindák. 2015. „Identification of material damping of a carbon composite

bar and study of its effect on attenuation of its transient lateral vibrations”. Journal of

Applied Mechanics 7(6). DOI:

https://doi.org/10.1142/S1758825115500817.

24.

Žuľová L., R.

Grega, J. Krajňák, G. Fedorko, V. Molnár. 2017. “Optimization of noisiness of mechanical system by using a

pneumatic tuner during a failure of piston machine”. Engineering

Failure Analysis 79: 845-851. ISSN 1350-6307.

Received 19.05.2019; accepted in revised form 11.08.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License