Article

citation information:

Mantič, M., Kuľka, J.,

Faltinová, E., Kopas, M., Lumnitzer, J. Simulation analysis of rope

belaying system. Scientific Journal of

Silesian University of Technology. Series Transport. 2019, 104, 107-117. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.104.10.

Martin MANTIČ[1],

Jozef KUĽKA[2],

Eva FALTINOVÁ[3],

Melichar KOPAS[4],

Ján LUMNITZER[5]

SIMULATION ANALYSIS OF ROPE BELAYING SYSTEM

Summary. This article

describes a technical proposal of anchoring determined for a horizontal

belaying system, which was developed to increase the safety of crane operators

and maintenance staff in their movements and work at heights. This belaying

system can be installed either on the common, already existing footbridge of

the overhead travelling crane or on the crane track. Loading of the steel wire

rope was investigated by the simulation figurines during various assumed

loading regimes. The figurines were attached to the rope belaying system by

means of the standard personal protective equipment and the calculation process

was realised using the non-linear dynamic FEM analysis.

Keywords: rope, safety, non-linear dynamic FEM analysis,

simulation.

1. INTRODUCTION

Technical solution of the problems, which were presented in

this article, resulted from a requirement concerning safe entrance to the

crane-operator’s cab of a bridge crane as well as safe maintenance of the

crane and crane track. It is necessary to emphasise an important fact that

entry into the crane-operator’s cab, which is usually situated at a

height, as well as maintenance activities performed during the winter period

are especially dangerous with regard to the possibility of injury. Taking into

consideration the above-mentioned facts, it was developed in an original horizontal

rope belaying system, which is presented and analysed in this article, in the

form of a created simulation model. Under real conditions, this horizontal

belaying system (HBS) should be anchored using one of the three possibilities:

a)

anchoring between the

steel columns

b)

anchoring between the

concrete columns

c)

anchoring without the

columns by means of own supporting structure

Bearing capacity of the anchorage equipment of type C (this

is the category of the proposed equipment), which is considered as the value of

dynamic force, has to be 12 kN at least in accordance with the technical

standard STN EN 795. It was necessary, as the first step, to investigate what

heavy loading of the rope and joining elements corresponds to this force. There

were calculated reactions in the connecting points of the horizontal rope,

forces in the rope and deflection of the rope during loading by the vertical

force 12 kN, which is acting in various distances from the supports, using a

pre-load in the rope with the values from the interval 0.2 kN ÷ 20 kN.

At the same time, it was calculated as change of the rope pre-load value due to

an increase or decrease of the ambient temperature. The value of the anchorage

rope diameter, which was used for the calculations and also in the simulation

model, was 14 mm.

Various relevant aspects of the steel wire ropes were

presented in the corresponding literature. The publications [1, 2, 3] dealt

with steel wire ropes, taking into consideration the general principles of

their operation and safety. Possible causes of rope damage are described in

professional works [4, 5, 6, 7, 8]. Similarly, analyses of the stress state and

operational loading, as well as failure analyses of the steel wire ropes, are

shown in publications [9, 10, 11, 12]. Described in these papers [13, 14, 15],

are the mathematical and geometrical models developed for a computer simulation

of the steel wire ropes. The dynamic non-linear simulations, which were

performed using the Finite Element Methods (FEM), are presented in the articles

[16, 17, 18, 19, 20].

Original methods developed for the solution of questions

concerning mechanical vibrations and detection of failures occurring in the

mechanical systems are illustrated in the publications [21, 22].

2. MATERIALS AND METHODS

There are two possibilities in the case that the rope

belaying system is anchored along the crane track:

- anchoring to the steel columns of the hall (the

distance between the columns was 12 m and 18 m)

- anchoring to the supporting concrete columns of

the hall (the distance between the columns also was 12 m and 18 m)

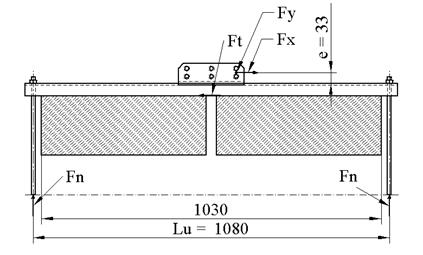

Connection of the steel wire rope to the steel column of

the hall was achieved by means of the anchorage point, which was fixed to the

sidewall of the column, according to Fig. 1.

Fig. 1. Connection of the horizontal belaying

system to the sidewall of the column

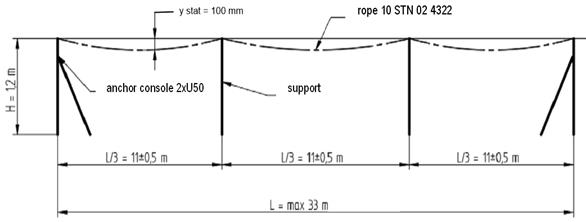

Connection of the rope to the concrete column of the hall

(two concrete pillars arranged side-by-side) was realised by means of the

connecting bolts with the thread M12 in order to tighten the auxiliary

construction of the anchorage point, according to Fig. 2.

Fig. 2. Anchorage to the double concrete

column

There was a proposed new, own-developed supporting

structure determined for movement of the crane operating personnel or maintenance

staff on the crane, whereby the distance between the neighbouring supports was

5 m (Fig. 3).

The technical standard STN EN 795 defines the bearing

capacity for the analysed anchorage equipment of type C as the dynamic force

with the minimal value 12 kN. Other conditions, which must be fulfilled

according to Chapter 4.3.3 from the given technical standard, are as follows:

- the minimal strength of the rope has to be

two-times higher than the highest acceptable force, which occurs during

the capturing of a fall

- all other supporting components and anchorage

guide have to be dimensioned with regard to a double-value of the force,

which occurs in these parts during the capturing of a fall.

Fig. 3. Own-developed construction situated on the walkway

of the crane

The individual loading-level values, which were applied in

the strength calculations, respected the above-mentioned technical standard.

2.1. Simulation of loading for the HBS during fall of

persons – computational model

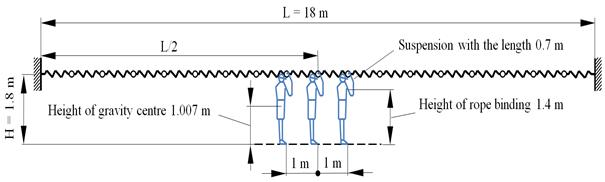

Calculation of loading for the HBS was realised according

to the crane user requirement, taking into consideration the real loading

conditions, that is, maximally 3 persons are moving on the walkway at the same

time and the maximal weight for each of them is 100 kg. The calculation

procedure was performed for the most unfavourable arrangement of the HBS, using

the steel wire rope with diameter Æ14 mm [21] and with span 18 m, whereby there is a

possibility that several workers are moving together within one section. The

computational model was created using the MSC Motion software, which is

specified for the solution of dynamic systems.

Mechanical characteristics of the belaying (anchoring) rope

and suspension component were simulated by a system of individual mass points

that represents the weight of the ropes and connecting elements. The stiffness

characteristics of the ropes are represented in the model by means of the

springs with the stiffness values corresponding to the applied components,

obtained by measuring. The persons (their human bodies) are simulated by means

of the anthropometric figurines. The complete computational model is

illustrated in Fig. 4.

Two stereometric computational models with different

simulation of figurine properties were created to represent a real situation.

Both models were investigated for various pre-load values of the belaying

ropes. The individual computational models are marked as follows:

o La14-18m-XXkN-LZ

– model with the stiff figurines

o Lb14-18m-XXkN-LZ

– model with the flexible figurines

where:

L means

application of the rope belaying system

a or b means

the method, which is currently used for simulation of the figurines (a - stiff,

non-flexible figurines, b - flexible figurines)

14 is

the belaying rope diameter (given in mm)

18m is

the belaying rope span (in m)

XXkN is the rope pre-load value (there were used the values 5,

10, 15 and 20 kN),

LZ means

the rope suspension component

Fig. 4. Model of the belaying system with the figurines

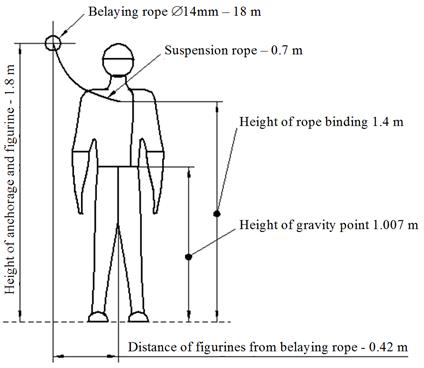

These are the defined geometrical parameters of the

analysed belaying system:

- anchorage height of the belaying system above

the base is 1800 mm

- length of the rope suspension components is 700

mm

- the free length of the suspension rope before a

fall of the figurine is 120 mm + overhang of the rope ystat, max caused by

the own weight of the rope

- point of connection of the suspension rope to

the figurine is situated 1400 mm above the base

The stiff figurines used in the models “La...”

with the weight 100 kg were situated in the middle of span and with the mutual

distance 1 m. The height of the figurine is 1800 mm and the height of the

figurine gravity point is approx. 1007.3 mm. The distance of the figurines from

the belaying rope in the horizontal plane was 0.42 m (Fig. 5).

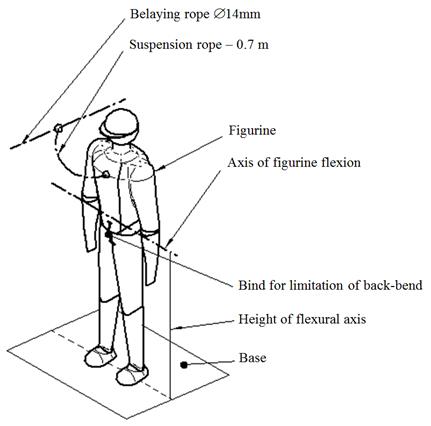

The figurines used in the models “Lb...”

are flexible in the waist around the transversal axis. The figurine waist is

positioned in the height 0.98 m from the figurine foot. A possible back-bend of

the figurine was eliminated using a bind between the bottom part of the

figurine and the figurine body (Fig. 6).

The calculation process considered such sequence of the

occurrences, by which the middle figurine was falling as the first and the

other figurines were falling gradually in the time interval 0.2 s. The most

unfavourable situation assumed a free movement of the figures without mutual

collisions during a falling.

2.2. Elaboration of the calculated

results

Considering the fact that eight (8) computational

models were investigated, the elaborated results of the performed computational

analyses are summarised in Tables 1 and 2, using the undermentioned designation

of the individual values.

Fig. 5. Model of the stiff figurine

Fig. 6. Model of flexible figurine

The designation of the

used input parameters is:

G

[kg] weight

of the figurine

n

number

of the figurines

lz [mm] length of the

suspension component

hz [mm] height

of free figurine movement (free fall)

kz [N/mm] stiffness

of the suspension component (obtained from measurement in rope test-room)

Fo [kN] pre-load

of the belaying rope

The

designation of the calculated values is:

lzmax [mm] maximal

prolongation of the suspension component

Fz1 [kN] the

first dynamic response of tensile force in the suspension component at

beginning of the figurine fall (after tension of the suspension component)

Fzmax [kN] maximal dynamic

force in the suspension component (mostly the second response)

Fomax [kN] maximal

force in the belaying rope (pre-load + dynamic response)

ystat,max [mm] maximal

static overhang of the belaying rope (in fact, it is the first dynamic

deflection of the rope caused by its own weight; the figurines are motionless)

ystat+dyn [mm] the

highest calculated deflection of the belaying rope after fall of the figurines

It is possible to state, according to the results presented

in Tables 1 and 2, as well as after comparison of the forces Fomax with the

total deflections ystat + dyn that if the pre-load value is less than 20 kN.

Hence, the maximal dynamic force (occurring in the belaying rope) does not

exceed the value 30 kN, which is the maximal value of a force that is

acceptable with regard to the anchorage of the belaying rope.

Tab. 1

The results obtained

and elaborated from calculations for the models

La14-18m-XXkN-LZ

|

Model |

Load - stiff figurines |

Suspension component - rope of personal protective

equipment |

||||||

|

G [kg] |

n |

hp [mm] |

lz [mm] |

kz

[N/mm] |

lzmax [mm] |

Fz1 [kN] |

Fzmax [kN] |

|

|

La14-18m-5kN-LZ |

100 |

3 |

120 |

700 |

85,7143 |

38,14 |

1,35 |

3,26 |

|

La14-18m-10kN-LZ |

100 |

3 |

120 |

700 |

85,7143 |

39,9 |

1,17 |

3,47 |

|

La14-18m-15kN-LZ |

100 |

3 |

120 |

700 |

85,7143 |

41,438 |

1,28 |

3,57 |

|

La14-18m-20kN-LZ |

100 |

3 |

120 |

700 |

85,7143 |

36,3 |

1,33 |

3,13 |

|

Model |

Load – stiff figurines |

Belaying rope d = 14 mm, L = 18 m |

||||||

|

G [kg] |

n |

hp [mm] |

k [N/mm] |

Fo [kN] |

Fomax [kN] |

ystat,max

[mm] |

ystat+

dyn [mm] |

|

|

La14-18m-5kN-LZ |

100 |

3 |

120 |

214,5615 |

5 |

21,53 |

98,62 |

806,15 |

|

La14-18m-10kN-LZ |

100 |

3 |

120 |

214,5615 |

10 |

25,13 |

45,00 |

708,00 |

|

La14-18m-15kN-LZ |

100 |

3 |

120 |

214,5615 |

15 |

25,26 |

33,80 |

632,39 |

|

La14-18m-20kN-LZ |

100 |

3 |

120 |

214,5615 |

20 |

28,61 |

25,39 |

531,51 |

Tab. 2

The results obtained and elaborated

from calculations for the models

Lb14-18m-XXkN-LZ

|

Model |

Load - stiff figurines |

Suspension component- rope of personal protective

equipment |

||||||

|

G [kg] |

n |

hp [mm] |

lz [mm] |

kz

[N/mm] |

lzmax

[mm] |

Fz1 [kN] |

Fzmax [kN] |

|

|

Lb14-18m-5kN-LZ |

100 |

3 |

120 |

700 |

85,7143 |

37,86 |

1,35 |

3,23 |

|

Lb14-18m-10kN-LZ |

100 |

3 |

120 |

700 |

85,7143 |

32,31 |

1,88 |

2,76 |

|

Lb14-18m-15kN-LZ |

100 |

3 |

120 |

700 |

85,7143 |

30,67 |

1,718 |

2,64 |

|

Lb14-18m-20kN-LZ |

100 |

3 |

120 |

700 |

85,7143 |

33,99 |

1,658 |

2,90 |

|

Model |

Load – flexible figurines |

Belaying rope d = 14 mm, L = 18 m |

||||||

|

G [kg] |

n |

hp [mm] |

k [N/mm] |

Fo [kN] |

Fomax

[kN] |

vstat,max

[mm] |

vstat+

dyn [mm] |

|

|

Lb14-18m-5kN-LZ |

100 |

3 |

120 |

214,5615 |

5 |

21,38 |

98,62 |

802,42 |

|

Lb14-18m-10kN-LZ |

100 |

3 |

120 |

214,5615 |

10 |

24,645 |

50,55 |

755,00 |

|

Lb14-18m-15kN-LZ |

100 |

3 |

120 |

214,5615 |

15 |

28,383 |

33,80 |

733,12 |

|

Lb14-18m-20kN-LZ |

100 |

3 |

120 |

214,5615 |

20 |

30,054 |

25,39 |

634,16 |

Figures 7, 8 and 9 illustrate the time behaviours of the

calculated values F0, Fz and y for the model

“La14-18m-5kN-LZ” (stiff figurines, pre-load level 5 kN).

Fig. 7. Time behaviour of the tensile force in the belaying

rope

Fig. 8. Time behaviour of the tensile force in the

suspension rope

Fig. 9. Time behaviour of the overhang for

the belaying rope in the middle of span

4.

CONCLUSION

The analyses presented in this work were performed based on

information obtained from measurement of the stiffness characteristics

concerning the steel ropes or suspension components of personal protective

equipment used in the horizontal belaying system and from measurement of the

samples provided from the submitter of the given task. According to the

calculated results, it is possible to conclude that the dynamic loading, which

occurs during stoppage of the fall of two or three persons, is less than the

values determined by the technical standards [23] and [24]. If the pre-load

value is less than 20 kN, then the dynamic force, which is arising in the

belaying rope, does not exceed the value 30 kN, which is the maximal acceptable

force with regard to the anchorage of the belaying rope.

In view of the above-mentioned facts presented in the form

of the results obtained from the performed simulation process, it is possible

to point out that the analysed horizontal belaying system is a suitable

technical equipment that increases the safety of the crane service and

maintenance.

Acknowledgements

This article was elaborated in the framework of the Grant Project VEGA 1/0110/18.

References

1.

Boroška Ján, Jozef

Hulín, Oldřich Lesňák. 1982. Oceľové laná. [In Slovak: Steel ropes]. Bratislava: Alfa.

2.

Boroška Ján. 2000. „Činitele ovplyvňujúce životnosť a bezpečnosť prevádzky oceľových lán”. In: Výskum, výroba a použitie oceľových

lán: 15-21. [In Slovak: “Factors affecting the service life

and safety of steel wire ropes”. In: Research,

production and use of steel ropes: 15-21]. Faculty of Mining, Technical

University, Kosice, Slovakia. ISBN: 80-7099-592-0.

3.

Molnár Vieroslav. 2006. Oceľové

laná. [In Slovak: Steel ropes]. Kosice: Fakulty BERG, Technical University, Kosice,

Slovakia. ISBN 80-8073-629-4.

4.

Molnar Vieroslav, Gabriel

Fedorko, Beata Stehlikova, Peter Michalik. 2011. „Statistical

comparison of rope strands by ANOVA test and Kruskal-Walis test”.

Technics technologies education

management-TTEM 6 (4): 1121-1126. ISSN 1840-1503.

5.

Torkar M., B. Arzenek. 2002. „Failure

of crane wire rope”. Engineering

Failure Analysis 9(2): 227-233. ISSN 1350-6307.

6.

Costello George A. 2003. „Mechanics

of wire rope”. In: Wire & Cable Technical Symposium: 73rd annual

convention: 56-63. Wire Association International, Inc. May 2003. Atlanta,

Georgia, USA.

7.

Costello George A. 1997. Theory of Wire Rope. New York. Springer.

ISBN 0-357-98202-7.

8.

Chaplin Christopher

Richard. 1995. „Failure mechanisms in

wire ropes”. Engineering Failure

Analysis 2(1): 45-57. ISSN 1350-6307.

9.

Peterka Pavel, Jozef Krešák, Stanislav Kropuch, Gabriel Fedorko, Vieroslav Molnar, Marek Vojtko. 2014. „Failure analysis of

hoisting steel wire rope”. Engineering

Failure Analysis 45: 96-105. ISSN 1350-6307.

10.

Velinsky

S.A. 1985. „General nonlinear theory for complex wire rope“. International Journal of Mechanical Sciences 27(718): 497-507. ISSN0020-7403.

11.

Giglio Marco, Andrea Manes.

2005. „Life

prediction of a wire rope subjected to axial and bending loads”. Engineering Failure Analysis 12(4):

549-568. ISSN 1350-6307.

12.

Imrak C. Erdem, Erdönmez Cengiz. 2010. „On the problem of wire

rope model generation with axial loading”. Mathematical and Computational Applications 15(2): 259-268. DOI: https://doi.org/10.3390/mca15020259.

13.

Stanova Eva, Gabriel Fedorko,

Michal Fabian, Stanislav Kmet. 2011. „Computer modelling of wire strands

and ropes Part I: Theory and computer implementation”. Advances in Engineering Software 42(6):

305-315. ISSN 0965-9978. DOI: https://doi.org/10.1016/j.advengsoft.2011.02.008.

14.

Molnár Vieroslav,

Gabriel Fedorko,

Jozef

Krešák, Pavel Peterka,

Jana

Fabianová. 2017. „The influence of corrosion

on the life of steel ropes and prediction of their decommissioning”. Engineering

Failure Analysis 74: 119-132. ISSN 1350-6307. DOI: 10.1016/j.engfailanal.2017.01.010.

15.

Stolle Cody S., John Douglas Reid. 2011. „Development of a wire rope

model for cable guardrail simulation”. International Journal of Crashworthiness

16(3): 331-341. ISSN 1358-8265. DOI: 10.1080/13588265.2011.586609.

16.

Velinsky

S.A., G.L. Anderson, G.A. Costello. 1984. „Wire rope with complex cross

sections“. Journal of Engineerig

Mechanics 110(3): 380-391. ISSN 0733-9399.

17.

Imanishi Etsujiro, Takao

Nanjo, Takahiro Kobayashi. 2009. „Dynamic simulation of wire rope with contact”. Journal of Mechanical Science and

Technology 23(4): 1083-1088. ISSN 1976-3824.

18.

Paris

A.J., C.C. Lin, George A. Costello. 1992. „Simple cord composites“.

Journal of Engineerig Mechanics

118(9): 1939-1948. ISSN 0733-9399.

19.

Rudawska Anna, Hubert Debski.

2011. „Experimental and numerical analysis of adhesively bonded aluminium

alloy sheets joints”. Eksploatacja i Niezawodnosc – Maintenance

and Reliability 1(49): 4-10. ISSN 1507-2711.

20.

Gajdoš Ivan,

Ján Slota, Emil Spišák, Tomasz Jachowicz, Aneta Tor-Swiatek.

2016. „Structure and tensile properties evaluation of

samples produced by fused deposition modeling”. Open Engineering 6(1): 86-89. ISSN 2391-5439. DOI: https://doi.org/10.1515/eng-2016-0011.

21.

Zul'ová, Lucia, Robert

Grega, Jozef Krajňák. 2017. „Optimization of noisiness of

mechanical system by using a pneumatic tuner during a failure of piston

machine”. Engineering

Failure Analysis 79: 845-851. ISSN 1350-6307.

22.

Product catalogue of steel

wire ropes. Wire and rope production factory DRÔTOVŇA a.s.,

Hlohovec, Slovakia, 2001.

23.

STN EN 795: 1996. Osobné ochranné

prostriedky proti pádu z výšky. Kotviace zariadenia.

[In Slovak: Personal

fall protection equipment. Anchor devices]. Bratislava.

Slovak

Office of Standards, Metrology and Testing.

24.

STN EN 364+AC(832622):

1997. Osobné

ochranné prostriedky proti pádu z výšky. Kotviace

zariadenia. [In Slovak: Personal fall protection equipment. Testing methods].

Bratislava. Slovak Office of

Standards, Metrology and Testing.

Received 11.05.2019; accepted in revised form 17.08.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License