Article

citation information:

Malakova, S. Kinematic properties and

meshing condition of elliptical gear train. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 104, 95-105. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.104.9.

Silvia MALÁKOVÁ[1]

KINEMATIC PROPERTIES AND MESHING CONDITION OF

ELLIPTICAL GEAR TRAIN

Summary. This paper presents

the concept of eccentric elliptical gear train able to generate a variable gear

ratio law. The first step in the noncircular gears virtual design process is

the generation of the conjugate pitch curves, starting from a predesigned law

of motion for the driven element or a predesigned geometry for the driving gear

pitch curve. By designing a pair of non-circular gears, which are able to

perform a proper gear ratio function, the output member of a mechanism can be

effectively forced to move according to a prescribed law of motion, when

operated at a constant input-velocity. This mechanism is designed to obtain a

specific motion law. Detailed knowledge of meshing conditions is a prerequisite

for studying kinematic conditions in gearings, as well as the strength

calculation of gearing.

Keywords: non-circle

gear, elliptical gear, kinematic conditions, meshing conditions.

1. INTRODUCTION

The idea of non-circular gears

originates from the precursors of the engineering thought. These gears were

sketched by Leonardo da Vinci, and found their application in many types of

mechanical devices, like locks and toys. In the late 19th century, Franz

Reuleaux ordered at Gustav Voigt Mechanische Werkstatt in Berlin, a series of

non-circular gear models to help study kinematics. The gears made at those

times had simplified tooth shapes and, for this reason, the meshing conditions

were not always correct [1].

Several mechanical devices can be

designed to obtain a prescribed motion law of output element. When a mechanical

system is used to obtain a required motion of the output link, non-circular

gears are another possible choice. In spite of their poor diffusion, the

non-circular gears can be in a variety of mechanical systems. In fact, since

the gear ratio function they generate is variable, a purely mechanical control

can be performed on the input/output relationship. For this reason, non-circular

gears are useful in those mechanisms whose task is to force an output element

to move according to a specific law of motion. Automatic equipment in printing

presses, textile industry, packaging machines and quick-return mechanisms

represent the most diffuse applications.

A common challenge in the design of

mechanical systems is the kinematic synthesis of a mechanism in order to

satisfy a set of motion characteristics [2, 3]. Frequent requirements are to

guide a rigid body through a series of specified positions and orientations

(rigid body guidance), to force a coupler point to move along a prescribed

trajectory (path generation), or to cause an output member to move according to

a specific function of the input motion (function generation) [4].

The application of non-circular gears in function generating mechanisms has been

proposed and discussed in [5, 6]. By designing a pair of non-circular

gears, which are able to perform a proper gear ratio function, the output

member of a mechanism can be effectively forced to move according to

a prescribed law of motion, when operated at constant input velocity [7].

In typical arrangements, a pair of variable radius pitch curves are synthesized

to drive a slider-crank mechanism according to prescribed motion law. For many

applications, non-circular gears provide some benefits over cams, although they

are more difficult to design and expensive to manufacture. The main advantages

are the lower weight-to-strength ratios and the absence of gross separation or

decoupling of moving parts [8].

The

gearing with changing transmission gear ratio is used in the practice, even

though the "standard" gearing with constant transmission gear ratio

is used more often. This article examines the mesh conditions proposed in

elliptical gears, as I speed and power ratios in this proposed gearings. The

work is devoted to the analysis of these kinematic conditions in the proposed

gearings and examines their differences from "standard" ring gear

transmission with a constant transference number. The problem is solved for

elliptical, eccentric gear with a continuously variable gear ratio.

2. DESIGNED NON-CIRCULAR GEARING

Generation of this

noncircular gear was developed starting from the hypothesis such as the law of

driven gear motion, variation of gear transmission ratio and design of driving

gear pitch curve [9, 10]. This model of non-circular gear was designed for

variable gear ratio to a range from 0.5 through 1 to 2. This transfer should be

formed by two identical wheels with the number of teeth z1 = z2

= 24 and gearing module mn = 3.75 mm, the axial distance

a = 90 mm and for a one direction of rotation.

Given that each gear

must satisfy the conditions of proper meshing, it was necessary to determine

the geometric shape of the wheels. The pitch curve corresponded to the pitch

circles in regular gears. They represent a non-circular gear as two rollers

rolling together without slip, provided there is no addendum modification and

the nominal axle distance is used.

The gearing is designed

such that the pitch curve is composed of an ellipse formed with the basic

parameters shown in Figure 1. A geometric centre of the gear is not the centre

of wheel’s rotation. The centre of gear’s rotation is in the focus

point of the ellipse.

The pitch ellipse has a

large half-axis x = 45 mm, which is half of the axial distance. The second

half-axis is determined by the distance from the focus point 45 mm (Fig.1),

whose position is determined by considering the desired gear ratio.

Fig. 1. Pitch ellipse for designed gearing

In

pursuit of the kinematical conditions of the proposed gearings with

eccentrically selected centres of rotation, we start from one of the conditions of a correct mesh,

which states that the circumferential velocities in the pitch point are equal

and their projections into the profile normal line are the same.

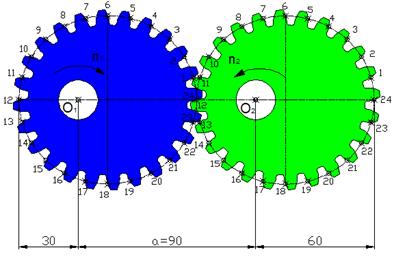

Fig. 2. Designed eccentric elliptical gear train

The conventional gearing involute starts from the base

circle, in which case, it is the base of the evolute of the ellipse. The

evolute for the left and right side teeth is not the same. Each of the twelve

teeth is different; the next twelve teeth of the same wheel are the same. The

side curve is the involute, and is different for the active and passive side of

the tooth; the teeth are asymmetrical. The gears for a given variable

transmission have been proposed as elliptical - eccentrically placed, so that

conditions were right shot. The geometric model of the proposed gear is shown

in Figure 2. Teeth of gearing are numbered; the picture depicts the mesh of the

tooth No. 24 and No. 12.

3. MESHING CONDITION OF DESIGNED ELLIPTICAL GEARING

Detailed knowledge of

the meshing conditions is a prerequisite not only for solution of the

deformation of the gearing but also for the research of speed, power and energy

conditions and for the strength calculation of gearing [11-13]. The

characteristic points of meshing in the frontal plane of the spur gear are

shown in Figure 3.

Fig. 3. Characteristic points of meshing

For the sense of

rotation shown in Figure 3, the energy is transmitted from the gear pinion 1 to

the gear wheel 2 (the gear 1 is the drive and the gear 2 is driven) and the

meshing proceeds from point A to point E. Points A, E are the outer or end

points of the pressure line AE. The sections AB and DE are sections of two-pair

of meshing teeth, that is, when two pairs of teeth meshing the gears are in

contact. When there is meshing point in these sections, so this pair of teeth

is always considered with the meshing of the adjacent pair of teeth in the

second section. The line section BD is a single-pair section, that is, there is

only one pair of mating teeth on this section of the pressure line.

Involute gear is characterised

by rectilinear pressure line [14]. This is true even for the designed

elliptical gearing. The result of the examination for teeth 24 - 12 in meshing

is shown in Figure 4.

Fig. 4. Face of pressure line for designed gear train

The characteristic points A, E are the end

points of the meshing line AE, which is component of pressure line τ, in

the meshing line is realise meshing of teeth of gearing.

The length of meshing line for spur gears is

calculated by equation:

![]() (1)

(1)

where ra1,2

is radius of addendum circle, rb1,2 is radius of base circle, a is

axial distance and α is pressure angle.

The expression of meshing

properties is used coefficient of meshing εα, calculate by

equation:

(2)

(2)

where ptb is base pitch.

The value of the coefficient of meshing for spur gears with straight teeth is

in the range 1<εα <2.

Fig. 5. The meshing line AE for teeth 24 - 12 in meshing

The length of meshing lineaof

designed eccentrically elliptical gearing cannot calculate by equation for the

circular involute gearing. Therefore, they are intended of graphic for each

pair of teeth of meshing (for example, Figure 5 and Figure 6).

Fig. 6. The meshing line AE for teeth 4 - 8 in meshing

The

measured value of length of meshing line AE and calculated value of meshing coefficient εα for

designer elliptical and spur gearing are shown in Table 1.

Tab.

1

Coefficient

of meshing εα and length of the meshing line AE

|

Elliptical gearing |

Spur gearing (mn=3,75mm) |

||||||

|

Meshing teeth input - output |

AE (mm) |

εα |

r1-i (mm) |

r2-j (mm) |

Transmission ratio ui=r2/r1 |

AE (mm) |

εα |

|

24 - 12 |

14.406 |

1.222 |

60 |

30 |

0.5 |

17.527 |

1.488 |

|

01 - 11 |

14.412 |

1.223 |

59.458 |

30.541 |

0.5136 |

17.542 |

1.489 |

|

02 - 10 |

14.436 |

1.225 |

57.891 |

32.108 |

0.5546 |

17.583 |

1.492 |

|

03 - 9 |

14.503 |

1.231 |

55.449 |

34.550 |

0.6230 |

17.636 |

1.497 |

|

04 - 8 |

14.52 |

1.232 |

52.338 |

37.663 |

0.7196 |

17.686 |

1.501 |

|

05 - 7 |

14.548 |

1.235 |

48.779 |

41.221 |

0.8450 |

17.721 |

1.504 |

|

26 - 6 |

14.594 |

1.239 |

45 |

45 |

1 |

18.235 |

1.647 |

There is greatest value

of length meshing line AE for a one pair of teeth in designed non-circular

gearing, which in meshing have a gear ratio equal value 1.0. The designed

eccentric elliptical gearing has different profiles for all teeth, the gearing

is comprised of teeth with different profiles. The coefficient of meshing

εα and the length of the meshing line AE for each pair of

teeth in meshing are not constant for this designed gear train. These values

are constant for standard circular spur gear.

Necessary detailed

knowledge of meshing condition is mandatory for solution deformation and

stiffness of gearing as well as for the strength calculation of gearing. There

is a rectilinear pressure (meshing) line for involute gear. For a standard

circular involute gearing the length of meshing line is the same for all teeth

pairs in the meshing. For designed elliptical gearing with variable gear ratio,

the length of the meshing line and coefficient of meshing for each pair of

teeth in meshing are not constant.

4. KINEMATIC CONDITION OF DESIGNED ELLIPTICAL GEARING

Kinematic conditions of

designed elliptical gear train were processed for gear No. 1 (with the rotation

centre at point O1) and gear No. 2 (with the rotation centre at

point O2). The kinematic dependences for both designed gear wheels

are shown in one graph together. There are teeth of the first gear wheel on the

horizontal axis.

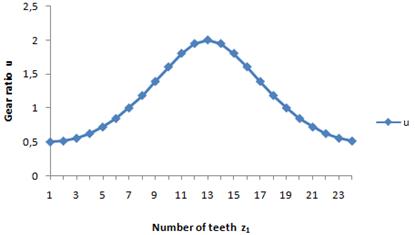

There is a continuously changing

gear ratio for designed non-circular gear train in Figure 7, during one

rotation of the drive gear wheel. Thus, the gear ratio changes over the time of

one rotation of the drive gear wheel, from u=0.5 through u=1.0 until u=2.0 and

back. If the value of gear ratio less than 1.0, this is an overdrive. The gear

ratio value greater than 1.0 signifies a speed reduction.

Fig. 7. Gear ratio of designed non-circular gear train

Fig. 8. Rotational speed of designed non-circular gear

train

The standard spur gears

have a constantly rotational speed on the drive wheel gear and on the driven

wheel gear. This non-circular gearing with variable gear ratio has a not

constant of rotational speed for the driven gear wheel. Figure 8 shows the

change of the rotation speed on the driven gear wheel (ω2) at a

constant rotation speed for the drive gear wheel, for value ω1

= 100 s-1.

The movement of spur

gear is defined in the face plane, therefore, kinematics of this motion is

planar [16]. The points of gear are moved along a circular path at a

circumferential velocity at the image central point C determined by equation:

![]() (3)

(3)

where r1,2 is radius of

pitch circle, ω1,2 is a rotational speed.

Figure 9 shows the speed

ratios for the meshing of the teeth No. 4 (drive wheel) and teeth No. 8 (driven

wheel) at the central point.

Fig. 9. Circumferential velocity for teeth 4 - 8 in meshing

in the central point

In the case of the

designed elliptical gearing, the size of the circumferential force in the

central point of the shot is different for each pair in the meshing. The

direction of the circumferential velocities of the individual pairs of meshing

teeth is the same (Fig. 10).

The graph of

circumferential velocity in the central points for the pairs of teeth in meshing

is presented in Figure 11.

The circumferential

velocity for designed non-circular gearing is not constant but changes

continuously, depending on the number of gear ratio.

Fig. 10. Changing the size and position

of the circumferential velocity at the central points of the pairs of

teeth (u - is gear ratio)

Fig. 11. Circumferential velocity in the central point

5. CONCLUSION

The

examined eccentric elliptical gear train with continuously varying gear ratio

is based on the requirements, for particular gear transmission parameters.

These are gears with asymmetric tooth profile. Properties of this gearing are

different from the properties of standard circular gears – spur gear. The

gear ratio of this elliptical gear train is not constant but fluidly varies

from 0.5 to 2.0 and back. In this way, the gear ratio changes during one

revolution of the driven gear. For a standard circular involute gearing, the

length of meshing line is the same for all teeth pairs in the meshing. For

designed elliptical gearing with variable gear ratio, the length of the meshing

line and coefficient of meshing for each pair of teeth in meshing are not the

same. There, the size of the circumferential velocity in the central point for

the pairs of the teeth is different for each pair in the meshing. The direction

of the circumferential velocities of the individual pairs of meshing teeth is

the same, the position of these circumferential velocities change with respect

to the centres of rotation.

This

paper was written within the framework of Grant project VEGA 1/0290/18

and APVV-16-0259.

References

1.

Zarebski Igor, Tadeusz Sałacinski.

2007. „Designing and WEDM manufacturing of

non-circular gears.“ In: Advances

in production engineering. APE'2007.

Warsaw.

2.

Litvin

Faydor L., Ignacio Gonzalez-Perezb, Alfonso Fuentesb, Kenichi Hayasakac.

2008. „Design and investigation of gear drives with non-circular gears

applied for speed variation and generation of functions”. Computer Methods in Applied Mechanics and

Engineering 197: 3783-3802. DOI: https://doi.org/10.1016/j.cma.2008.03.001.

3.

Žuľová Lucia, Robert Grega, Jozef

Krajňák, Gabriel Fedorko, Vieroslav Molnár. 2017.

„Optimization of noisiness of mechanical system by using a pneumatic

tuner during a failure of piston machine”. Engineering Failure Analysis 79: 845-851. ISSN 1350-6307.

4.

Tong Shih-Hsi, Yang Daniel C.H. 1998. „Generation of

identical noncircular pitch curves”. Journal

of Mechanical Design 120: 337-341.

5.

Litvin Faydor L., Fuentes Alfonso. 2004. Gear geometry and applied theory. Second edition. Cambridge

University Press, New York. ISBN-100-521-81517-7.

6.

Dooner David. 2001. „Function

generation utilizing an eight-link mechanism and optimized non-circular gear

elements with application to automotive steering“. Proceedings of the Institution of Mechanical Engineers, Part C: Journal

of Mechanical Engineering Science 215(7): 847-857.

7.

Doege Eckart, John Meinen, Tobias Neumaier. 2001. „Numerical

design of a new forging press drive incorporating non-circular gears”. Journal of Engineering Manufacture 215:

467-471.

8.

Dooner David, Seiger Ali. 1995. The kinematic geometry of gearing: a concurrent engineering approach.

Wiley Series in Design Engineering. ISBN-13:

978-0471045977.

9.

Krajňák Jozef, Jaroslav Homišin, Robert Grega,

Matej Urbanský. 2016. „The analysis of the impact of vibrations on

noisiness of the mechanical system”. Diagnostyka

17(3): 21-26. ISSN 1641-6414.

10.

Kapelevich Alexander. 2000. „Geometry and design of involute

spur gears with asymmetric teeth”. Mechanism

and Machine Theory 35(1): 117-130.

11.

Bošanský Miroslav, Miroslav Vereš. 2012. Neštandardné ozubené

prevody. [In Slovak: Non-standard

gears]. STU, Bratislava. 159 p. ISBN 978-80-227-3717-5.

12.

Medvecká-Beňová Silvia. 2015. „Properties

of eccentric elliptical gearing”. Pomiary

Automatyka Robotyka 20(2): 17-20. ISSN: 1427-9126. DOI:

10.14313/PAR_220/17.

13.

Urbanský Matej, Jaroslav Homišin, Peter

Kaššay, Jozef Krajňák. 2018. „Measurement of air

springs volume using indirect method in the design of selected pneumatic

devices”. Acta Mechanica et

Automatica 12(1): 19-22. ISSN 1898-4088.

14.

Liu Youyu. 2015. „Study of optimal strategy and

linkage-model for external non-circular helical gears shaping”. Proceedings of the Institution of Mechanical

Engineers, Part C: Journal of Mechanical Engineering Science 229(3):

493-504.

Received 11.05.2019; accepted in revised form 17.08.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License