Article

citation information:

Kolesnikova, T., Mischenko, N.,

Sakno, O., Suprun, V., Filipova, G.A., Nikitchenko, I. Gorpyniuk, A.,

Nazarenko, M. Theoretical research response time of the mechanism for compression

ratio changing of the conrod-free engine. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 104, 69-83. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.104.7.

Tatiana KOLESNIKOVA[1],

Nikolay MISCHENKO[2], Olha SAKNO[3],

Volodymyr SUPRUN[4],

Galyna A. FILIPOVA[5], Igor NIKITCHENKO[6],

Andrii GORPYNIUK[7],

Mykola NAZARENKO[8]

THEORETICAL RESEARCH RESPONSE TIME OF

THE MECHANISM FOR COMPRESSION RATIO CHANGING OF THE CONROD-FREE

ENGINE

Summary. The mathematical model for calculating the response time of the compression

ratio of the mechanism for compression ratio changing (MCRC) is presented in

this article. This revealed the influence of various engine factors with the

connecting rod and crank mechanism (CRCM) on the operation of the MCRC (for

example, the rate of the compression ratio change). The results of the study of the operation of the MCRC

indicate a strong influence of the values d (relative area of flow passage of channels) and р (pressure) on the response time τ

in the field of their small values. This indicates that with insignificant

changes of the area of

flow passage of channel of the hydraulic lock and the minute oil pressure in the

cavities, a significant response rate of the MCRC is ensured. The results

demonstrate the possibility of speedy compression ratio change in the engine

with the MCRC.

Calculation studies showed that the mechanism full operation occurs quickly (0.02 s per unit εx), which indicates the

expediency of using such a high-pressure pump in a four-stroke gasoline engine

with CRCM. The mechanism movable body complete movement (S = 4 mm) at the oil temperature in the

hydraulic system of 45°C and pressure on

the body of p = 60 bar are stated to occur for 0.2 s.

Keywords: mechanism for compression ratio

changing, connecting rod and crank mechanism, conrod-free engine, response

time, pressure, oil temperature.

1. INTRODUCTION

Substantial progress in fuel

efficiency improvement and exhaust gas toxic components reduction in automobile

engines have become topical issues in recent times [1-3]. Increased state

control over environmental cleanliness and the economic use of nonrenewable

natural resources favoured it [4-6]. Key automotive companies participate in

the state standards development and compete for consumers; they have to improve

their engines and use up-to-date design and technology solutions [7-11].

Innovations are implemented in

up-to-date engines [12,13]. They focus improvements in the engine systems and

mechanisms and transmission units. Fuel equipment elements that improve

operating procedures play a special role in the engine design perfection. In this case, the piston motion law is push-type and depends only on the

connecting rod and crank mechanism (CRCM) constant parameters [14-16]. This circumstance does not allow

the use of compression ratio regulation being a powerful reserve to optimise

engine operating parameters in its running regimes range [17-19].

The compression ratio is believed

to be the internal combustion engine (ICE) constant design parameter as, for

example, the cylinder diameter is. The compression ratio quantity is definitely

determined by the CRCM dimensions and the cylinder head location relative to

the crankshaft axis in the conventional ICE [20,21].

The ICE power and fuel efficiency

are known to rise with the compression ratio growth due to the indicated

efficiency increase. The ICE performance improvement breaks off when the

compression ratio reaches 13...14 due to increase in the mechanical losses.

Therefore, the compression ratio values are optimal.

The compression ratio value is

built into the engine design and differs from the optimum value. The

compression ratio in gasoline engines is limited by detonation. It is less than

optimal and, as a rule, does not exceed 10.

Numerous calculations and

experimental studies show that the compression ratio regulation can ensure 20%

of fuel economy improvement.

The boost pressure in the gasoline

engine can be increased without detonation when the compression ratio is

reduced, and the power-to-volume ratio is increased with a positive effect

along with it. The fuel economy improved under light-load conditions with the

compression ratio increase [22,23].

The compression ratio maximum value does not exceed ε = 14 in most ICE designs with

variable compression ratio. The frictional losses increase with the further

increase of the engine compression ratio. The indicator efficiency, in this

case, does not compensate these losses, so effective efficiency decreases as a

result.

2. THE CONSTRUCTION OF THE CONROD-FREE ICE

The conrod-free ICE (CFICE) is given realisation of a

change compression ratio more than ε = 14. This is one of the ICE possible

designs. The crank and rocker arm mechanism (CRAM) is used in the engine

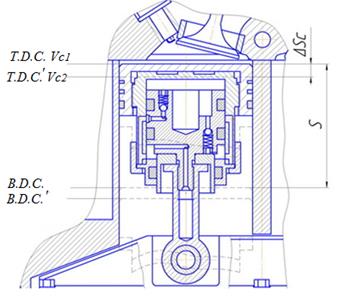

instead of the traditional CRCM (Figure 1).

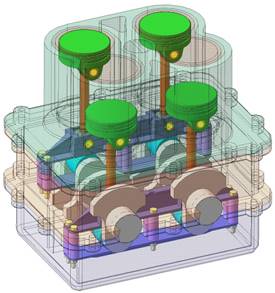

a)

b)

Fig. 1. The graphic presentation of

the conrod-free engine: (a) general view; (b) diagram of the conrod-free engine

with the MCRC; 1, 2 – piston;

3, 4 – MCRC; 5, 6 – piston rod;

7, 8 – crosshead; 9 –

rocker arm; 10, 11 – crankshaft;

12, 13 – crankcase

counterweight; 14 – gear

Experimental design efforts to create conrod-free

engines are carried out in Germany, the USA [24,25], Ukraine [26] and other

countries [9,18,27]. The engine distinctive features are as follows:

·

low friction losses in the entire load range and shaft speed

·

full dynamic balance and stroke uniformity

·

compactness and low specific gravity

The piston strictly rectilinear

motion ensuring absence of lateral loads is the advantage of the CFICE.

The analysis of the CFICE with a

CRAM shows:

·

increase effective efficiency at ε > 14 small mechanical

losses

·

constructively is implemented variable compression

The mechanism for compression ratio

changing (MCRC) was designed in the CFICE. The mechanism has to be studied

theoretically to identify the engine rational parameters.

2.1. The construction of the

mechanism for compression ratio changing

The MCRC is located in the engine

piston.

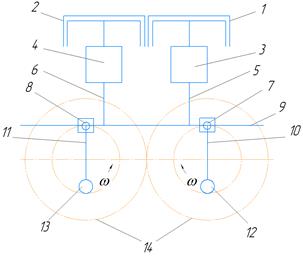

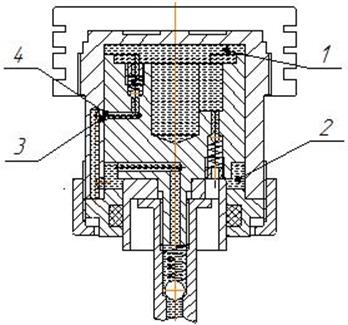

The MCRC construction diagram is

shown in Figure 2.

Fig. 2. The

construction diagram of the MCRC: 1 – sealing; 2, 10, 16 – oil

channel;

3, 11, 14 –

hydraulic lock; 4, 12, 15 – check valve; 5 – moving body; 6 –

piston in moving body; 7 – top oil cavity; 13 – bottom oil cavity;

8 – emergency valve; 9 – engine piston;

17 – piston

rod; 18 – rocker arm

Heater was installed on the experimental model of the

engine, which allowed investigating the operation of the mechanism at different

oil temperatures (the oil temperature changed from 20 to 70 degree Celsius).

This allowed us to provide realistic conditions for the MCRC operation.

A valve was installed in the oil supply line to the

mechanism that performed the function of a check valve. The check valve

prevents the creation of loads on the oil pump shaped like overpressure when

the mechanism responds. Experiments were conducted on the mechanism with an

open and closed crane. Oil was fed into the mechanism from the oil pump through

a connecting pipe. The oil pressure in the bottom oil cavity was controlled by

a manometer and maintained at 4.0 atm. In an automobile engine, an oil

lubrication system pump creates such pressure. The turn of the moving body of the mechanism to activate the hydraulic lock was

carried out using an electromagnetic relay. Due to this, the MCRC response time throughout the experiment remained unchanged.

Displacement of the moving body

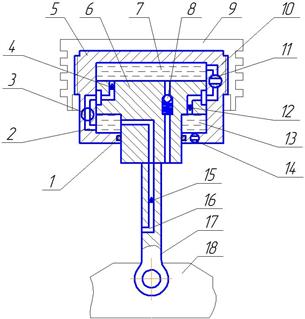

(Figure 2) occurs under the influence of applied gas forces ![]() and inertial forces

and inertial forces ![]() , and frictional forces

, and frictional forces ![]() between the piston rings and the

cylinder walls and the oil pressure

between the piston rings and the

cylinder walls and the oil pressure ![]() .

.

The

signal from the detonation sensor reaches the MCRC control

mechanism when detonation combustion in the engine cylinder appears. This

causes the turn of the hydraulic locks 3 and 11. The engine piston together with the mechanism moving

body moves down under the force ![]() . The

compression ratio decreases until the hydraulic locks return to their original position (position

in Figure 3) and the cycle is repeated.

. The

compression ratio decreases until the hydraulic locks return to their original position (position

in Figure 3) and the cycle is repeated.

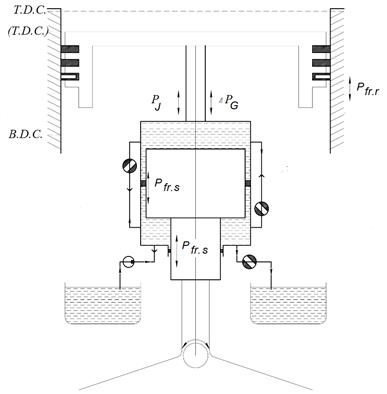

Fig. 3. The scheme

of forces operating

in the MCRC

The compression ratio change occurs

in the engine successive cycles until force closure between the body and the

movable thimble occurs with the help of the hydraulic lock upon the signal from

the detonation sensor.

3. CALCULATION OF THE MCRC RESPONSE TIME

The MCRC response time t is determined according to the

dependence:

![]() (1)

(1)

where ![]() is MCRC

moving body relative movement or, as a consequence, the engine combustion

chamber height change [m] and

is MCRC

moving body relative movement or, as a consequence, the engine combustion

chamber height change [m] and ![]() is MCRC moving body average

speed [m/s].

is MCRC moving body average

speed [m/s].

The compression ratio current value

is determined by the formula:

![]() (2)

(2)

where ![]() is cylinder

volume [m3] and

is cylinder

volume [m3] and ![]() is combustion

volume [m3].

is combustion

volume [m3].

The compression ratio rate change

per second is determined with regard to the Equation (2):

(3)

(3)

where ![]() is a

combustion volume 1 [m3] and

is a

combustion volume 1 [m3] and ![]() is

combustion volume 2 [m3].

is

combustion volume 2 [m3].

Taking into account the fact that

MCRC moving body relative

movement (Figure 4) is determined by:

![]() (4)

(4)

where ![]() is

an engine piston area [m2].

is

an engine piston area [m2].

Fig. 4. Engine diagram to determine

the combustion chamber height change:

S

is a piston stroke; ![]() is MCRC

moving body relative movement; TDP is top dead point; BDC is bottom dead centre; TDP' is piston position at the top dead

point under the compression ratio change; BDC'

is piston

position at the bottom dead centre under the compression ratio change

is MCRC

moving body relative movement; TDP is top dead point; BDC is bottom dead centre; TDP' is piston position at the top dead

point under the compression ratio change; BDC'

is piston

position at the bottom dead centre under the compression ratio change

The compression ratio rate change is

determined with regard to the Equation (1):

![]() (5)

(5)

where S is

piston stroke [m].

The compression ratio rate change per cycle ![]() is a very important factor for

MCRC. One cycle in a four-stroke engine is known to occur in crankshaft two

revolutions. Therefore, compression ratio rate change is determined:

is a very important factor for

MCRC. One cycle in a four-stroke engine is known to occur in crankshaft two

revolutions. Therefore, compression ratio rate change is determined:

![]() (6)

(6)

where n is

Engine crankshaft speed, min-1

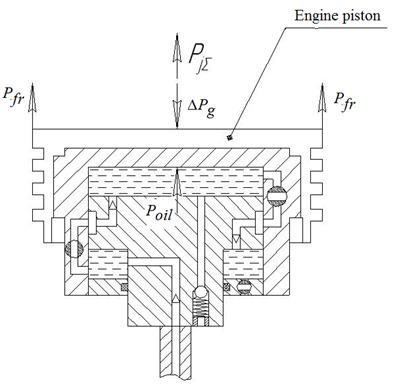

Thus, to obtain the MCRC response

time, it is necessary to determine the moving body movement speed ![]() by the

amount

by the

amount ![]() . The following MCRC motion equations (Figure 5) have

been worked out to solve this problem:

. The following MCRC motion equations (Figure 5) have

been worked out to solve this problem:

![]() (7)

(7)

where ![]() is

the mechanism moving body mass, kg;

is

the mechanism moving body mass, kg; ![]() is

the mechanism moving body movement, m;

is

the mechanism moving body movement, m; ![]() is

force of gas pressure in the engine cylinder, H;

is

force of gas pressure in the engine cylinder, H; ![]() is

total inertia force of the mechanism, H;

is

total inertia force of the mechanism, H; ![]() is

gravity force of the mechanism, H;

is

gravity force of the mechanism, H; ![]() is

friction force of piston rings, H;

is

friction force of piston rings, H; ![]() is

force, which describes hydraulic losses in the mechanism, H;

is

force, which describes hydraulic losses in the mechanism, H; ![]() is

frictional force in the seals of the mechanism, H.

is

frictional force in the seals of the mechanism, H.

Fig. 5. Scheme for

the MCRC calculation: ![]() is total

inertia force;

is total

inertia force;

![]() is force of gas pressure;

is force of gas pressure; ![]() is friction

force of piston rings;

is friction

force of piston rings;

![]() is frictional force in the seals of the

mechanism

is frictional force in the seals of the

mechanism

The mechanism moving body mass is

determined:

![]() (8)

(8)

where ![]() is the engine piston mass, kg;

is the engine piston mass, kg; ![]() is

piston rings

mass, kg;

is

piston rings

mass, kg; ![]() is

MCRC moving body mass, kg;

is

MCRC moving body mass, kg; ![]() is

cover mass, kg;

is

cover mass, kg; ![]() is

nut mass, kg;

is

nut mass, kg; ![]() is

turning bushing mass, kg.

is

turning bushing mass, kg.

Gas pressure force is determined:

![]() (9)

(9)

where ![]() is

gas pressure in the engine cylinder at an arbitrary time interval, MPa;

is

gas pressure in the engine cylinder at an arbitrary time interval, MPa; ![]() is

atmospheric pressure, MPa.

is

atmospheric pressure, MPa.

Total inertial force ![]() is determined:

is determined:

![]() (10)

(10)

where ![]() is inertial force from the MCRC

moving masses, H;

is inertial force from the MCRC

moving masses, H; ![]() is inertial force from oil in

the MCRC, H.

is inertial force from oil in

the MCRC, H.

The inertial force from the MCRC moving masses is

determined:

![]() (11)

(11)

The conrod-free engine design

characteristics (the connecting rod coefficient λ, the crank radius R

and the connecting rod length L) are

the following:

![]() (12)

(12)

The inertial force from moving

masses of the MCRC is determined:

![]() (13)

(13)

where R is crank radius, m; w is the crankshaft angular

velocity, s-1

The inertial force from oil in the MCRC is determined:

![]() (14)

(14)

where ![]() is

oil mass in the mechanism bottom cavity, kg;

is

oil mass in the mechanism bottom cavity, kg; ![]() is

oil mass in the mechanism top cavity, kg.

is

oil mass in the mechanism top cavity, kg.

The piston ring set frictional

force is determined:

![]() (15)

(15)

where ![]() is pressure at the end of inlet, MPa; с is the constant coefficient; v is

piston speed, m/s;

is pressure at the end of inlet, MPa; с is the constant coefficient; v is

piston speed, m/s; ![]() is

reduced temperature, °C (

is

reduced temperature, °C (![]() [28]);

[28]); ![]() is

cylinder wall temperature, °C; σ is the

ring radial stress, MPa;

is

cylinder wall temperature, °C; σ is the

ring radial stress, MPa; ![]() is

the ring reduced radial stress, MPa (

is

the ring reduced radial stress, MPa (![]() [29]);

[29]); ![]() is

reduced cylinder diameter, mm (

is

reduced cylinder diameter, mm (![]() [29]).

[29]).

The hydraulic losses force ![]() takes into account the loss of oil flow

through the channels

takes into account the loss of oil flow

through the channels ![]() , back-pressure valves

, back-pressure valves ![]() and

hydraulic lock

and

hydraulic lock ![]() that

occur when the oil moves in the mechanism body. The force is formed as:

that

occur when the oil moves in the mechanism body. The force is formed as:

![]() (16)

(16)

where ![]() is

oil density, kg/m3;

is

oil density, kg/m3; ![]() is

free fall acceleration, m/s2;

is

free fall acceleration, m/s2; ![]() is

the direct or backward channel hydraulic resistance, s2/m5;

is

the direct or backward channel hydraulic resistance, s2/m5;

![]() is

oil consumption under the direct or backward mechanism body motion, m3/s;

is

oil consumption under the direct or backward mechanism body motion, m3/s;

![]() is

active area of piston in moving body, m2

is

active area of piston in moving body, m2

The rubber seals frictional force

under the mechanism moving body motion is determined by the Equation (9):

![]() (17)

(17)

where µ is friction

coefficient of the pair of steel-rubber in oil, µ = 0.4 [30]; ![]() is

pressure in the MCRC top oil cavity, MPa;

is

pressure in the MCRC top oil cavity, MPa; ![]() is

pressure in the MCRC bottom oil cavity, MPa;

is

pressure in the MCRC bottom oil cavity, MPa; ![]() &

& ![]() is

gasket ring area, m2

is

gasket ring area, m2

Total calculated force is formed as:

![]() (18)

(18)

4. THE DESIGN-THEORETICAL RESEARCH RESULTS

The MCRC operation speed was

determined to be affected by the following parameters:

·

pressure on the mechanism on the side of the springing attachment

·

oil temperature

·

channels flow passage area δ

·

the MCRC moving body rotation angle when the hydraulic lock is turned on

·

back pressure in the mechanism bottom oil cavity

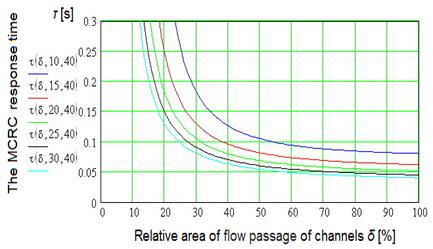

The dependence of the MCRC response

time on the relative area of flow passage of channels δ of the hydraulic lock, pressure p and oil temperature t

were obtained experimentally (Figure 6).

The empirical dependence of the response time of the MCRC

is determined:

![]() (19)

(19)

Fig. 6. The MCRC channels scheme for increasing the compression

ratio:

1 – top cavity; 2

– bottom cavity; 3 and 4 – channels

The MCRC response time τ

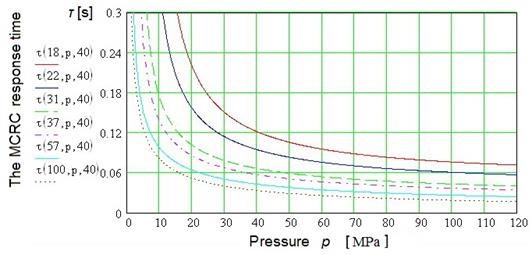

calculated dependencies on values (d, р, t) were built in Figures 7 and 8.

Fig. 7. Dependence of the response time

τ [s] of MCRC on the relative area of

flow passage of channels δ [%]

of the hydraulic lock at different pressures p [MPa]: t = 40°C

The mechanism operating conditions investigation shows that

the MCRC response time τ

decreases under the increasing values (δ, p, t). The

response time τ decreases

sharply over the range from 0 to 40% (value d) and pressure p

over the range 0 to 30 MPa

(Figures 7 and 8). Further increase of values d

and

p has little effect on the response time t. Therefore, when the MCRC

is running in the engine, it is not necessary to turn on the hydraulic lock on

100% when the compression ratio is reduced. This enabled reduction of the MCRC

response time t and the compression

ratio. The hydraulic locks are to be 100% turned on with the compression ratio

increase in order to increase the compression ratio rapidly. Consequently, the

engine operated less under nonoptimal conditions. The compression ratio

increase is the result of the inertia forces action from the body and oil

pressure in the mechanism cavities and the compression ratio change. Therefore,

the mechanism response time t for the compression

ratio rise will be less than that for the value e decrease.

Fig. 8. The MCRC

response time τ [s] dependence on pressures

p [MPa]

in the oil cavity at different relative area of flow passage of channels δ [%] of the hydraulic lock: t = 40°C

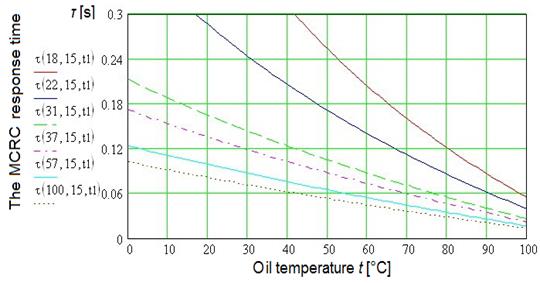

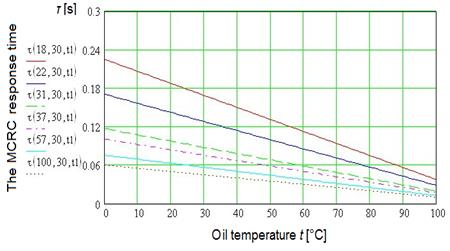

Depending on oil temperature t (Figures 9 and 10) has a different character. The curves slope

indicates significant effect of the temperature t in the whole range of its values. The relation between the value t and value t

varies greatly depending on the MCRC operating conditions (values d and р

change). The response time t increases under low

temperatures (0...40°С) and especially at the hydraulic lock small flow passage. Nevertheless, this occurs during engine

warm-up.

Fig. 9.

Dependence of the

response time τ [s] on oil

temperature t [°C] in the oil cavity 1 (Figure 8) at different relative area of

flow passage of channels δ [%]

of the hydraulic lock: p = 15 MPa

Fig.

10. Dependence of

the response time τ [s] on oil

temperature t [°C] in the oil cavity 1 (Figure 8) at different relative area of

flow passage of channels δ [%]

of the hydraulic lock: p = 30 MPa

The MCRC operation study results indicate strong influence

of the values d and р on

the response time τ in the field

of their small values. This indicates that the MCRC significant response rate

is ensured under insignificant changes in hydraulic lock

flow passage area and little oil pressure in cavities.

Empirical dependence of the oil temperature t (see Figures 9 and 10) on the response

time τ is determined:

![]() (20)

(20)

A graphical method was used to determine the Equation (20). The empirical dependence of the

response time of the MCRC is determined by the Equation (19).

The oil pressure in the bottom oil cavity was

controlled by a pressure gauge and maintained at 4 atm. In an ICE, the pressure

can be generated by an oil pump of a lubrication system. The oil temperature

was controlled by an electrical thermometer.

In the experiment, the MCRC response time was tested at

different section of canals and at different viscosity engine oil. Full

operation time is influenced by section of canals, channel form and viscosity

oil. The larger-section channels and the lower the viscosity oil the 0.2 s

of full operation time is enough.

The results demonstrate the possibility of compression

ratio change in the engine with the MCRC.

5. CONCLUSIONS

Theoretical studies were conducted.

These studies were aimed at improving the MCRC for a gasoline four-stroke engine.

The developed mathematical model of

the MCRC calculation revealed the influence of various factors of the engine

with the CRCM on the MCRC operation (for example, the compression ratio rate

change). The experimental data corroborates with the compiled mathematical model

operation.

Calculation studies show that the

mechanism full operation takes place quickly (0.02 s per unit εx), which indicates the

expediency of using such a high-pressure pump in a four-stroke gasoline engine

with CRCM.

The mechanism movable body complete movement (S = 4 mm) at the oil temperature in the hydraulic system

of 45°C

and pressure on the body of p =

60 bar are stated to takes place 0.2 s. The MCRC

response time is average time 0.23 s. An important parameter for the MCRC

response time is the response time until the appearance of detonation

combustion with increasing motor load.

Heat losses in the CFICE are less than in a classical

engine since the piston of the CFICE is shorter than in a classical engine, it

is cut to piston rings.

Currently, the patent application of the MCRC is being

considered in the patent office for the grant of a patent for the invention,

hence, the description of the mechanism is not in full detail.

The mathematical model of the MCRC and the design-theoretical research results can be

used to calculate engines of the same type in order to obtain optimal

parameters for further design or improvement of engines of similar structures.

CFICE can be used as an internal combustion engine for

motor vehicles and other mobile and fixed users as well as a pump or compressor

for creating the working fluid and transport excess pressure (pumping) of

gases, liquids, suspensions, mixtures, suspensions and other agents in various

industries and farms.

Acknowledgements

The authors would like

to express their gratitude to the team of researchers under the leadership of

Dr. Nikolay Mishchenko of the Motor Transport Department of the Automobile Road Institute (Ukraine) for the

design-theoretical research. Also mechanical engineer, Mr. Ruslan Sakno

for the MCRC prototype production, and the referees for their constructive and

valuable suggestions.

References

1.

Mickevicius

T., S. Slavinskas, S. Wierzbicki, K. Duda. 2014. „The effect of

diesel-biodiesel blends on the performance and exhaust emissions of a direct

injection off-road diesel engine”. Transport 29(4): 440-448.

2.

Mikulski M., S. Wierzbicki, M. Smieja, J. Matijosius. 2015. „Effect of CNG in a fuel dose

on the combustion process of a compression-ignition engine”. Transport 30(2): 162-171.

3.

Puškár M., M. Fabian, T. Tomko. 2018.

„Application of multidimensional statistical model for evaluation of

measured data obtained from testing of the HCCI engine prototype”. Diagnostyka 19(1): 19-24. DOI:

http://dx.doi.org/10.29354/diag/78349.

4.

Booto Gaylord Kabongo, Giuseppe Marinelli, Helge

Brattebo¸ Andre Bohne. 2019. “Reducing fuel consumption and

emissions through optimization of the vertical alignment of a road: A case

study of a heavy-duty truck on the Norwegian Highway Route E39”. European Transport/Trasporti Europei 71

(paper 4): 1-33.

5.

Hemisha Makan, Gert J. Heyns. 2018. “Sustainable

supply chain initiatives in reducing greenhouse gas emission within the road

freight industry”. Journal of

Transport and Supply Chain Management 12(a365): 1-10. DOI: https://doi.org/10.4102/jtscm.v12i0.365.

6.

Jacyna M., M. Wasiak, K. Lewczuk, G.

Karoń. 2017. "Noise

and environmental pollution from transport: decisive problems in developing

ecologically efficient transport systems". Journal of Vibroengineering 19: 5639-5655. DOI:

doi.org/10.21595/jve.2017.19371.

7.

Gopal G., L. Suresh Kumar, K.

Vijaya Bahskar Reddy, M. Uma Maheshwara Rao, G. Srinivasulue. 2017. „Analysis of Piston, Connecting rod and Crank

shaft assembly”. Materials Today: Proceedings 4(8): 7810-7819. DOI: https://doi.org/10.1016/j.matpr.2017.07.116.

8.

Islam M.A., K. Heimann, R. J. Browna.

2017. „Microalgae biodiesel: Current status and future needs for engine

performance and emissions”. Renewable and

Sustainable Energy Reviews 79: 1160-1170. DOI: https://doi.org/10.1016/j.rser.2017.05.041.

9.

Rimkevičienė J., V. Ostaševičius, V.

Jūrėnas, R. Gaidys. 2009. „Experiments and simulations of

ultrasonically assisted turning tool”. Mechanika 1: 42-46.

10.

Ubartas M., V. Ostaševičius, S. Samper, V.

Jūrėnas, R. Daukševičius. 2011. „Experimental

investigation of vibrational drilling”. Mechanika 4: 368-373.

11.

Zhang S., C. Zhao, Z. Zhao, D. Yafei, F.

Ma. 2015. „Simulation study of hydraulic differential drive free-piston

engine”. SAE Technical Paper

2015-01-1300. DOI: https://doi.org/10.4271/2015-01-1300.

12.

Czech P.

2012. “Determination of the course of

pressure in an internal combustion engine cylinder with the use of vibration

effects and radial basis function - preliminary research”. TELEMATICS IN

THE TRANSPORT ENVIRONMENT. Edited by: Mikulski J. Book Series: Communications

in Computer and Information Science. Vol.: 329. P. 175-182. Conference: 12th

International Conference on Transport Systems Telematics, Katowice Ustron,

Poland, Oct 10-13, 2012.

13.

Czech P.

2011. “Diagnosing of disturbances in the

ignition system by vibroacoustic signals and radial basis function -

preliminary research”. MODERN TRANSPORT TELEMATICS. Edited by: Mikulski

J. Book Series: Communications in Computer and Information Science. Vol.: 239.

P. 110-117. Conference: 11th International Conference on Transport Systems

Telematics, Katowice Ustron, Poland, Oct 19-22, 2011.

14.

Krajňák

J., J. Homišin, R. Grega, M. Urbanský. 2016. “The analysis of

the impact of vibrations on noisiness of the mechanical system”. Diagnostyka 17(3): 21-26. ISSN

1641-6414.

15.

Sága M., L. Jakubovičová. 2014.

“Computational analysis of contact stress distribution in the case of

mutual stewing of roller bearing rings”. Applied Mechanics and Materials 474: 363-368.

16.

Urbanský M., J. Homišin, P. Kaššay, J.

Krajňák. 2018. “Measurement of air springs volume using

indirect method in the design of selected pneumatic devices”. Acta Mechanica et Automatica 12(1):

19-22. ISSN 1898-4088.

17.

Haag J., F. Kock, M. Chiodi, O. Mack, M.

Bargende, C. Naumann, N. Slavinskaya, A. Heron, U. Riedel, C. Ferrari.

2013. „Development approach for the investigation of homogeneous charge

compression ignition in a free-piston engine”. SAE Technical Paper 2013-24-0047. DOI: https://doi.org/10.4271/2013-24-0047.

18.

Reis V.L., G.B. Daniel,

K.L. Cavalca.

2014. „Dynamic analysis of a lubricated planar slider-crank mechanism

considering friction and Hertz contact effects”. Mechanism and

Machine Theory 74: 257-273. DOI:

https://doi.org/10.1016/j.mechmachtheory.2013.11.009.

19.

Xu Z.P., S.Q. Chang. 2013.

„Simulation of an opposed-piston four-stroke free-piston

generator”. Applied Mechanics and

Materials 336-338: 585-589. DOI:

https://doi.org/10.4028/www.scientific.net/amm.336-338.585.

20.

Yan H.,

D. Wang, Z. Xu. 2015. „Design and simulation of opposed-piston

four-stroke free-piston linear generator”. SAE Technical Paper 2015-01-1277. DOI: https://doi.org/10.4271/2015-01-1277.

21.

Zhu X.,

J. Xu, Y. Liu, B.

Cen, X.

Lu, Z. Zeng.

2017. „Failure analysis of a failed connecting rod cap and connecting

bolts of a reciprocating compressor”. Engineering

Failure Analysis 74: 218-227. DOI: https://doi.org/10.1016/j.engfailanal.2017.01.016.

22.

Kojima S., S. Kiga, K. Moteki, E.

Takahashi, K. Matsuoka. 2018. “Development of a New 2L Gasoline VC-Turbo

Engine with the World’s First Variable Compression Ratio

Technology”. SAE Technical Paper 2018-01-0371. DOI: 10.4271/2018-01-0371.

23.

Zhang S.,

Z. Zhao, C. Zhao, F. Zhang, Y. Liu. 2016. “Design approach and

dimensionless analysis of a differential driving hydraulic free piston

engine”. SAE Technical Paper

2016-01-8091. DOI: 10.4271/2016-01-8091.

24.

US4013048: F02B 75/28. Bourke type engine. Reitz D.M. (USA). 22.03.1977.

25.

Yuan S.

2010. “Compression stroke characteristics of single piston hydraulic

free-piston engine”. Journal of

Mechanical Engineering 46(18): 134. DOI: 10.3901/jme.2010.18.134.

26.

UA106090C2. Crank-less

engine with link mechanism (variants). Krasnikov A.V., Vetrova O.A., Vetrov

E.A. Ukraine. 25.07.2014.

27.

RU2476700C2. Con-rod-free

ice, device to convert reciprocation into rotation and vice versa. Fedorov

V.F. Russia. 27.02.2013.

28.

Edwards J. 1983. “Ceramics and the

swing beam 2 stroke diesel for the automotive engine”. SAE Technical Paper 830315: 47-54. DOI: 10.4271/830315.

29.

Kolchin A.I., V.P. Demidov. 1980. Расчет

автомобильных

и тракторных

двигателей. [In

Russian: Calculation of

automobile and tractor engines]. Moscow: High School. ISBN 978-5-06-003828-6.

30.

Geyer V.G., V.S. Dulin, A.G.

Borumensky, A.N. Zarya. 1981. Гидравлика

и

гидропривод. [In

Russian: Hydraulics and hydrodrive]. Moscow: Nedra. ISBN 5-247-01007-8.

Received 18.05.2019; accepted in revised form 19.08.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License