Article

citation information:

Juzek, M. Analysis of the impact of

non-parallelism of shafts' axes on the contact area of cooperating teeth and

gearbox's components vibrations. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 104, 37-45. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.104.4.

Michał JUZEK[1]

ANALYSIS OF THE IMPACT OF NON-PARALLELISM OF

SHAFTS' AXES ON THE CONTACT AREA OF COOPERATING TEETH AND GEARBOX'S COMPONENTS

VIBRATIONS

Summary. In this article, the results of experimental research

and simulation studies using a geometric model made in CAD software were

presented. The aim of the conducted research and simulations was to determine

the influence of non-parallelism of shafts' axes on gearbox vibroactivity and

the contact area of the cooperating teeth. The results showed that the change

of the non-parallelism of shafts' axes significantly affects the vibrations of

selected components of the operating gearbox and the contact area of

cooperating teeth.

Keywords: non-parallelism of shaft

axes, gearbox vibrations, contact area of cooperating teeth.

1. INTRODUCTION

Gearboxes are an element of complex

drive systems used in many types of transport means, such as vehicles, trains,

aircraft or vessels [3,4]. Regardless of the purpose of the transmission, the

demands placed on them are similar. The transmissions should transfer power and

torque with minimal losses while maintaining an adequate level of reliability

[10,11]. This is particularly important considering the global tendencies to

reduce the dimensions of the transmissions and attempts to use

unconventional materials while the values of transferred loads remain

unchanged. It also imposes keeping slight deviations of the

transmission’s components and their correct assembly.

A very important

factor is the impact of the operating transmission on the immediate surroundings. The operating gearbox generates vibrations

and noise, which has a negative impact on

the users and passengers of various means of

transport. Analysing

the research works of world-class scientific centres, many concepts of

searching for vibration reduction of an operating transmission can be noticed.

It includes investigations on the shape of the gearbox housing, the study of

the influence of the type of lubricant used, the study of the influence of the

characteristics of the clutches cooperating with the transmission and many more

[1,6,7,9]. The tendency to improve the well-known models and the development of new

transmission models is also noticeable [2,5,8]. Undoubtedly, these are valuable scientific works, but it

should be noted that, in the

case of gearboxes, the main source of vibrations is the meshing

zone, which involves the issues connected with the surface of the contact area and load distribution along the line of action. These issues have a significant impact on

the level of vibrations generated during the operation of transmission. One of

the reasons for the deterioration of the value of the surface of the contact area and load distribution along the line of action is the non-parallelism of the

transmission axes, which may be the result

of deviations in the transmission components, errors during assembly or

excessive shafts deflection and housing deformation. The paper presents the results of

experimental research and simulation made in CAD software showing the effect of

non-parallelism of the transmission axes and change of the value of this

phenomenon on the surface of contact area of cooperating gears and vibrations

of selected transmission components.

2.

EXPERIMENTAL STUDIES

2.1.

Experimental studies – description of test stand

In

order to evaluate the impact of non-parallelism of gearbox’ axes on the

vibrations of its components, experimental studies were conducted using a

specially modified back-to-back test stand. The test stand modifications included

disassembly of the closing gearbox and its shafts in order to eliminate

additional sources of undesired disturbances. In the tested transmission, the

shaft of the driven gear was replaced by a stationary axis. The bearings of the

stationary axis were fixed by eccentric bushings whose rotation enabled the

mutual position of the transmission’s axes to be changed. One full

rotation of the eccentric bushing was divided into 24 positions in intervals of

15 degrees. Because of made modifications, during the tests, the transmission

operated without load. Table 1 presents selected parameters of the used

transmission.

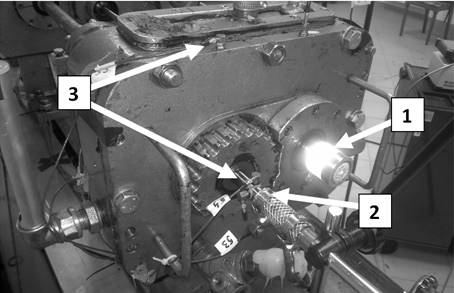

Piezoelectric

sensors were used to measure vibrations accelerations. The sensors were placed

on the gearbox’s housing and on the stationary axis of driven gear (Fig.

1) to obtain the smallest distance between the meshing zone and the sensor. The

tests were carried out for various rotational frequencies of the drive gear.

During the tests, the mutual position of the transmission’s axes was changed

by rotation of the eccentric bushing.

Tab. 1

Selected parameters of tested

gearbox

|

Parameter |

Value |

|

Number of teeth – driven gear z1 [-] |

16 |

|

Number of teeth – drive gear z2 [-] |

24 |

|

Module mn [mm] |

4,5 |

|

Helix angle β [o] |

0 |

|

Face width b [mm] |

20 |

|

Axes distance [mm] |

91,75 |

|

Profile shift

coefficient – driven gear x1 |

0.864 |

|

Profile shift

coefficient–

drive gear x2 |

-0,5 |

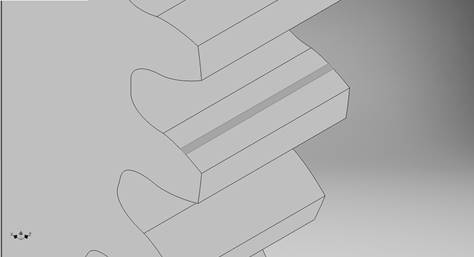

Fig. 1. Modified back-to-back test stand. 1- shaft of drive gear, 2 - stationary

axis of driven gear, 3 -vibration sensors

2.2.

Experimental studies – obtained results

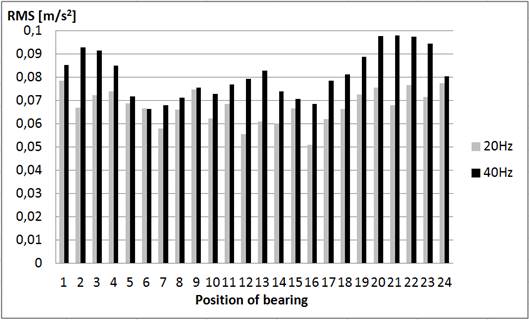

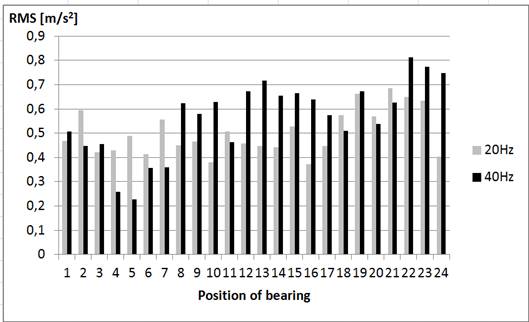

Based

on the vibration signals recorded during the tests, their relative mean square

(RMS) values were calculated. The obtained values are shown below in the

function of bearing position of stationary axis. The results are presented for

two selected rotation frequencies of the drive gear.

Fig. 2. RMS values of vibration signal measured at gearbox’s

housing for two selected rotational frequencies 20Hz and 40Hz in function of

bearing position

Fig. 3.

RMS values of vibration signal measured at stationary axis for two selected

rotational frequencies 20Hz and 40Hz in function of bearing position

3.

SIMULATION TESTS USING THE AUTODESK INVENTOR SOFTWARE

3.1.

Description of developed 3D model

The geometric 3D model

of the gearbox was created using the Autodesk Inventor software. The model

reflects all important parameters of the actual transmission used during

experimental research. In addition, it is also possible to change the

non-parallelism of the gearbox’s axes. The created model was used to

determine the surface of the contact area of cooperating gears. The measurement

was made for 24 positions reflecting the bearing position of the driven gear

due to use of the eccentric bushing. The tests were carried out for two

selected values of solids penetration, which simulated flattening of the flank

of the teeth because of the transferred load. The created transmission model is

shown in Fig. 4.

Fig. 4. Developed

3D model of tested gearbox

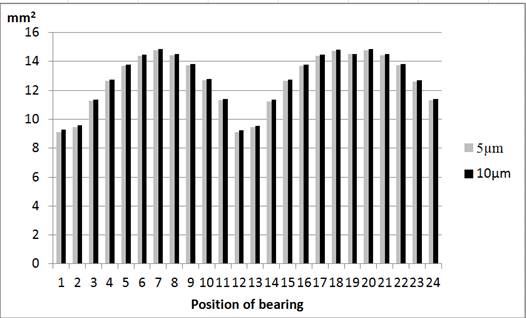

3.2. Simulation tests – obtained results

Using the developed

model, the analysis of the change of surface of the contact area of cooperating

teeth depending on the position of the driven gear bearing was made. The results

are presented for two selected tooth flattening values: 5 and 10μm. An example of the obtained

surface of the contact area is shown in Fig. 5. Area of contact of cooperating

teeth in function of bearing position for two selected values of tooth

flattering is shown in Fig. 6.

Fig. 5.

Example of obtained contact area

Fig. 6. Area of contact

of cooperating teeth in function of bearing position for two selected values of

tooth flattering

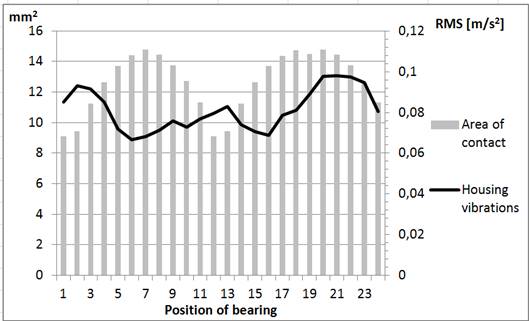

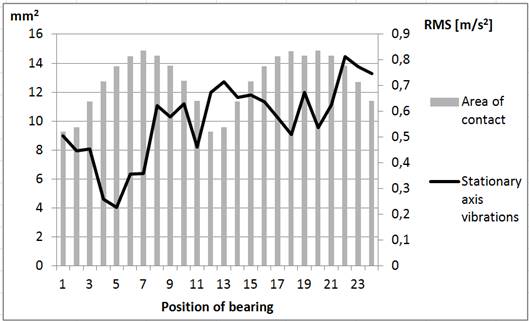

3.3. Comparison of

experimental studies results and simulation studies results

Figures 7 and 8 present

the course of changes in the values of surface of the contact area and obtained

RMS values of recorded signals as a function of the bearing position of

stationary axis. The values presented in the diagrams, in the majority of

analysed cases, confirm the relationship between the change in the surface of

contact area of the cooperating teeth and the level of vibrations recorded on

selected elements of the transmission.

Fig. 7.

Area of contact of cooperating teeth and RMS values of vibration signals in

function of bearing position

Fig. 8.

Area of contact of cooperating teeth and RMS values of vibration signals in

function of bearing position

4.

CONCLUSION

Based on analysis of results obtained during

experimental studies, it was discovered that the occurrence of the non-parallelism

of the gearbox shafts’ axes and its change during test significantly

affects the level of vibrations measured at transmission’s components.

Differences of vibration signals’ RMS values, depending on the position

of the stationary axis’ bearing, was even tens of per cent.

Using the geometrical model made in the CAD software

of the gearbox, the change of contact area of cooperating teeth was presented

for two selected tooth-flattening values. Results obtained during simulation

show dependence of the contact area of cooperating teeth and non-parallelism of

the gearbox shafts’ axes. The change of non-parallelism of the gearbox

shafts’ axes significantly affects the size of the contact area, which

changes reached several dozen per cent.

Comparatively,

changes in the RMS values of vibration signals and values of the contact area

of cooperating gears were found to be in majority of analysed cases of

stationary axis’ bearing positions, the increase surface of contact area

resulted in lowering the level of recorded vibrations. This phenomenon confirms

the relationship between the surface of contact area of the cooperating teeth

and the vibrations generated by the operating transmission.

References

1.

Figlus Tomasz, Andrzej Wilk, Henryk Madej. 2010. ,,A study of the influence of ribs

shape on the gear transmission housing vibroactivity”. Transport Problems 5 (1): 63-69. ISSN

1896-0596.

2. Guo Yi, Scott Lambert, Robb Wallen, Robert

Errichello, Jonathan Keller. 2016. ,,Theoretical and experimental study on

gear-coupling contact and loads considering misalignment, torque, and friction

influences”. Mechanism and Machine

Theory 98: 242-262. ISSN: 0094-114X. DOI: http://dx.doi.org/10.1016/j.mechmachtheory.2016.11.014.

3.

Łazarz Bogusław. 2001. Zidentyfikowany model dynamiczny przekładni zębatej jako

podstawa projektowania. [In Polish: Identified

dynamic gear model as the basis for design]. Katowice-Radom: Wydawnictwo i

Zakład Poligrafii Instytutu Technologii Eksploatacji. ISBN 83-7204-249-7.

4.

Madej Henryk. 2003. Minimalizacja

aktywności wibroakustycznej korpusów przekładni zębatych.

[In Polish: Minimization of vibroacoustic

activity of gear body]. Katowice-Radom:

Wydawnictwo i Zakład Poligrafii Instytutu Technologii Eksploatacji.

ISBN 83-7204-360-4.

5.

Ristivojević Mileta, Tatjana Lazović , Aleksandar Vencl.

2013. ,,Studying the load carrying

capacity of spur gear tooth flanks”. Mechanism

and Machine Theory 59: 125-137. ISSN:

0094-114X. DOI: http://dx.doi.org/10.1016/j.mechmachtheory.2012.09.006.

6.

Shen

A., R.B. Randall. 2008. ,,Optimal rib stiffening for noise reduction of

constant speed gearboxes”. In 15th International Congress on Sound and Vibration: 1-8. International

Institute of Acoustics and Vibration. 6-10

July 2008, Daejeon Korea, 2008. ISBN 978-89-9612-841-0.

7.

Shuting

Li. 2007. ,,Effects of machining errors, assembly errors and tooth

modifications on loading capacity, load-sharing ratio and transmission error of

a pair of spur gears”. Mechanism

and Machine Theory 42: 698-726. ISSN: 0094-114X. DOI:

http://dx.doi:10.1016/j.mechmachtheory.2006.06.002.

8.

Wei Li , Pengfei Zhai, Jingyun Tian, Biao Luo.

2018. ,,Thermal

analysis of helical gear transmission system considering machining and

installation error”. International

Journal of Mechanical Sciences 149: 1-17. ISSN: 0020-7403. DOI:

https://doi.org/10.1016/j.ijmecsci.2018.09.036.

9. Wieczorek

Andrzej. 2010. ,,Rola smarowania w

ograniczeniu hałasu towarzyszącego eksploatacji przekładni

zębatych”. [In

Polish: „The role of lubrication in reducing noise associated with the

operation of gears”]. Mechanizacja

i Automatyzacja Górnictwa 478(12): 34-39. ISSN 2450-7326.

10.

Wilk Andrzej, Bogusław Łazarz, Henryk Madej. 2009. Wibroaktywnośc przekładni

zebatych. Wpływ cech konstrukcyjnych i zużycia elementów na

wibroaktywność układów napędowych z

przekładniami zębatymi. [In Polish: Gear vibroactivity. Impact of design features and wear of elements on

the vibroactivity of drive systems with gears]. Katowice-Radom: Wydawnictwo Naukowe Instytut

Technlogii Eksploatacji. ISBN 978-83-7204-875-2.

11. Wojnar Grzegorz. 2010. ,,Minimization of

dynamic forces in gear meshing by selection of the flexible couplings

parameters”. Journal of Kones.

Powertrain and Transport 17(3): 497-504. ISSN 1231-4005.

Received 12.05.2019; accepted in revised form 17.08.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License