Article

citation information:

Hajdučík, A.,

Škrabala, J., Medvecký, Š., Brumerčík, F. Kinematic analysis of

trapezoidal suspension. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 104, 27-36. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.104.3.

Adrián HAJDUČÍK[1],

Jozef ŠKRABALA[2], Štefan

MEDVECKÝ[3], František BRUMERČÍK[4]

KINEMATIC ANALYSIS OF TRAPEZOIDAL SUSPENSION

Summary. This article deals with the kinematic analysis of

trapezoidal suspension. Specifically, it focuses on the behaviour of the

chassis when obstacle crossing was monitored. Our team is developing an

autonomous mountain vehicle that will be equipped with different working

adapters such as a cutter bar and a picker. The device was designed for work on

slopes, hence, must be able to overcome certain natural obstacles. This implies

the need to analyse the wheel suspension kinematics. The vehicle was built on a

trapezoidal suspension, which has proven to be the most suitable option with

respect to operating conditions. From the results obtained, it was possible to

analyse the driving characteristics of the obstacle, track the rollover limits

and overall safety of operation.

Keywords: mountain mower,

trapezoidal suspension, obstacle

1. INTRODUCTION

The comfort of driving a car

depends on the road surface, road condition and the construction of the car

itself [14,18,19,21]. The last of these factors can reduce the adverse effects

of the other two. There are many types of constructions. The axles are the

vehicle structural elements, which connects the vehicle frame and the wheel [1,3].

The axle consists of the wheels, wheel suspension system, wheel bearing system

and optional systems: suspension, steering, drive and wheel braking [5,8,15,16].

Division of the axles:

1. Solid axles

2. Swinging (independent hanging)

axles

Fig. 1. a) solid axle,

b) independent hanging axle [1]

The dependent suspensions consist

of a rigid element - a beam at the end of which the wheels are attached. Hence,

the movement of the wheels is dependent as the movement of one wheel is

transmitted through the beam to the other. Thus, they are mainly used on the

rear axles of trucks and on the axles of vehicles designed to work in tough

terrains and difficult conditions [2,4,6,20]. The vertical movement of the

wheel with independent suspension does not affect the direct movement of the

opposite wheel. The advantages of independent suspension are vibration

resistance and simpler influence of vehicle properties by changing geometry, smaller

space requirements and lower weight of unspring parts [10].

Kinematic analysis was used to

calculate the positions, velocities and acceleration points of the mechanism,

regardless of the load. The design and calculation works were done with the use

of the Creo Parametric CAD system and the ADAMS system.

2. BASIC REQUIREMENTS

The proposed axle is

based on the following requirements:

• forwards /

backwards

• turning wheels

• turn around the

centre of the mower

• walk in

The following

requirements were observed as well:

• work on slopes

with a slope of up to 45°

• overcome terrain

inequalities and obstacles

• correct

positioning of the mowing device

• maintaining

agrotechnical requirements

• dampening dynamic

effects from wheel drive

• use of suitable

tires for a given use

• use of passive

suspension

• points of

attachment of the arms on the chassis

Based on these

requirements, the trapezoid axle type (two-armed) was selected. The advantages

of this type of suspension are mainly the variability in the choice of

geometric parameters, the possibility of attaching the shock absorbers and the

load distribution on the two arms. The rotating unit was above the wheel,

allowing the wheel to rotate by 90°. The advantage of the position of the

servomotor [9,10] above the wheel was to reduce the load on rotation. This

"relieving" of the servomotor was ensured by moving the axis of the

servomotor through the centre of gravity of the wheel. We tried to distribute

axle weight to the centre of gravity of the wheel, which helped to use full

tires. Other components and construction were significantly easier, making the

axle centre position in the direction of the horizontal axis y approaching the

centre of gravity of the wheel. In the direction of the axis z, from the

position of the centre of gravity, the servomotor with the gearbox was

affected. A schematic sketch of the axle can be seen in Fig. 2 [11,12,17].

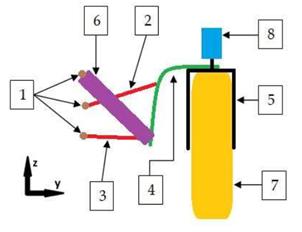

2.1. Elements of the

mechanism

The main axle parts

(Fig. 2) are the chassis attachment (1), upper suspension arm (2), lower

suspension arm (3), suspension body (4), wheel attachment (5), air damper (6)

and a servomotor (8).

Fig. 2. Schematic sketch

of the axle [17]

To suspend the axles,

the air suspension was selected as it is more suitable for the needed application

because it has adjustable stiffness. We were able to adjust the stiffness of

the dampers by the means of the pressure in the rolls. These shock absorbers

have the possibility of complete shutdown and a choice of jump in the event of

an obstacle. Communications between the shoulders and the brick, as well as the

shoulders and the frame, are pivotable. Therefore, each joint had one degree of

freedom, which was ensured by the roller bearings [7,8].

The choice of the

geometric dimensions of the trapezoidal suspension was based on the concept of

the mower, the size of the reaction forces at the pivots of the suspension pins

and the kinematic analysis of the suspension mechanism.

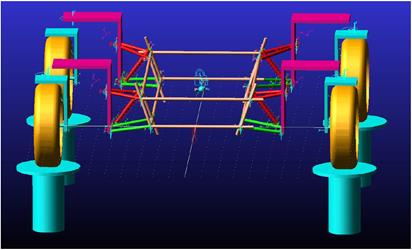

Fig. 3. Geometrical 3D

model of the axle [17]

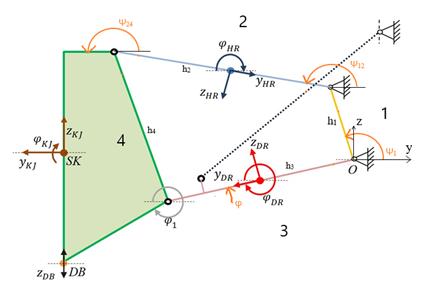

3. KINEMATIC ANALYSIS OF

THE TASK

Before performing the

analysis, it was necessary to define the mechanism itself, create a kinematic

scheme, determine the number of degrees of freedom of the mechanism, the

correctness of the mechanism, as well as the number and type of links in order

to create a mathematical model. The input parameters of the model were the

geometric coordinates of the significant points and the suspension parameters,

which formed a set of all permissible solutions. The created kinematic model of

the mechanism has one degree of freedom. The remaining degree of freedom was

taken by defining the displacement of the DB (wheel / terrain) contact point in

the z-axis direction (Fig. 4) [17].

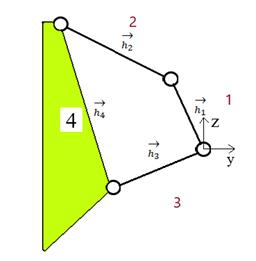

Fig. 4. Kinematic scheme

with reference points [17]

This kind of mechanism

has been analysed by different authors in various publications [3,4,13].

However, it is obvious that the mechanism of this suspension is four-element,

closed and single-loop. The Gruber's rule determines that real mobility is the

same as the theoretical one, consequently, the system is correct.

3.1.

Mathematical model

Mathematically, the

motion of a mechanism is described by nonlinear algebraic equations (NAE). Fig.

5 demonstrates that it is a closed-loop mechanism. We determined the number of

vector loops from the formula [5]

![]() . (1)

. (1)

Fig. 5.

Single loop mechanism

The vector loop is then

written as the equation

![]() . (2)

. (2)

The input values were

based on the dimension requirements of a customer. The formulas derived for the

mechanism kinematic loop are defined as

y

axis: ![]() , (3)

, (3)

z

axis: ![]() . (4)

. (4)

3.2.

Solution in ADAMS

The model used for ADAMS

simulations has been adapted to suit the optimised number of moving parts,

hence, the inertia of the mechanism itself. The simplified model of a mountain

mower was developed in the Adams MSC software (Fig. 6). The input parameters of

the model were the geometric coordinates of the significant points and the hanging

axle parameters that created the set of all acceptable solutions.

Fig. 6. Model in Adams view environment

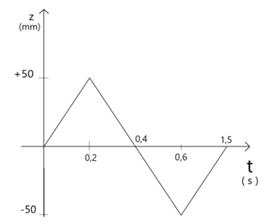

As mentioned above, the

remaining degree of freedom was removed by defining the displacement of the

wheel contact point and the ground in the z-direction. Simulations that

represented the crossing of the mower over the obstacle were performed. The

simulation consisted of a displacement of 100 mm in the z-direction, that is,

50 mm in the positive direction and 50 mm in the negative axis direction (Fig.

7).

Fig. 7. Graph of actuating process (right side)

4. RESULTS

The actual

implementation of input variables was evaluated by monitored parameters /

outputs from the simulation. The outputs were specific characteristics or

features of the model that delimited a set of permissible solutions. Many

outputs were monitored for simulations. We have selected the following outputs

for this article.

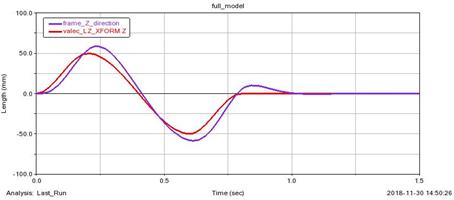

The following selected

graphs reflect the behaviour of a specific point on the frame, depending on the

change of path, speed and acceleration when crossing the obstacle.

Fig. 8. Graph of track

dependence on time

The red colour curve in Fig. 8 shows dynamic excitation (by

displacement). The total displacement was 100 mm in the z-axis direction, 50 mm

in a positive and 50 mm in a negative direction.

The purple colour

illustrates the response of the vehicle gauge in the direction of z-axis.

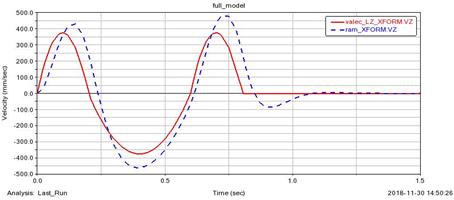

Fig. 9. Time - velocity dependence

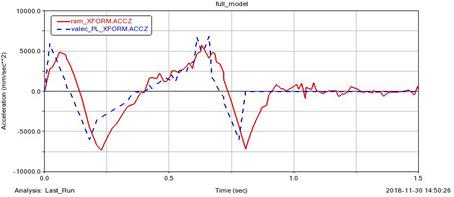

Fig.

10. Time - acceleration dependence

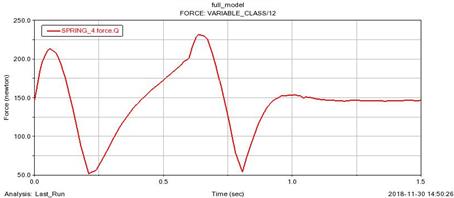

Figure 11 shows the maximum compression

or stretching of the spring. During the passage of the wheel through the

obstacle, the force effects on the springs were monitored.

Fig. 11. Spring force

during simulation

5. SUMMARY

The kinematic analysis

in MSC Adams demonstrates the possibilities of applying different types of

suspension. Extreme conditions for safe operation when crossing obstacles were

identified. Solution results were verified on a second mower prototype (MM2).

All tests were successful. Furthermore, other tests are ongoing at the time of

preparation of this article.

The first part of this

article provides information on axle types and the choice of the appropriate

axle type. The selected axle appears to be the most appropriate for (MM2) as

confirmed by tests. The initial conditions that influenced the formation of the

suspension were defined. In the next section, the principle of creating a

mathematical model was presented. Thereafter, an overview of some test results.

Acknowledgement

The

research is supported by the Cultural and Educational Grant Agency of the

Ministry of Education, Science, Research and Sport of the Slovak Republic under

project No. 046ŽU-4/2018.

References

1.

Amirouche

F. 2007. Fundamentals of Multibody

Dynamics: Theory and Applications. Springer Science &

Business Media. 684 p. ISBN 08-1764-406-7.

2.

Avesh

Mohd, Rajeev Srivastava. 2018. “Parametric optimization to design a

passenger car suspension system for better dynamic performance”. European Transport/Trasporti Europei

71(paper 1): 1-14.

3.

Bulej V., J. Stanček, I. Kuric, I. Zajačko. 2017. „The space distribution and transfer of

positioning errors from actuators to the TCP point of parallel

mechanism”. Machine Modelling and

Simulations 2017 (MMS 2017). ISSN 2261-236X. London: Édition

Diffusion Presse Sciences, 2018. Available at:

https://www.matec-conferences.org/articles/matecconf/pdf/2018/16/matecconf_mms2018_02006.pdf.

4.

Caban J., P. Drozdziel, J. Vrábel, B. Šarkan, A.

Marczuk, L. Krzywonos, I. Rybicka. 2016.

„The research on ageing of glycol-based brake fluids of vehicles in

operation”. Advances in Science and

Technology 10(32): 9-16.

5.

Caban

J., A. Marczuk, B. Šarkan, J. Vrábel. 2015. „Studies on

operational wear of glycol-based brake fluid”. Przemysł Chemiczny 94(10): 1802-1806.

6.

Dahil

L. 2017. “Effect on the vibration of the suspension system”. Metalurgija

56(3-4): 375-378.

7.

Faturík Lukáš, Libor

Trško, Slavomír Hrček, Otakar Bokuvka. 2014. „Comparison of structural design in high and ultra-high cycle

fatigue regions”. Transactions of

FAMENA 38(4): 1-12. ISSN 1333-1124.

8.

Figlus

Tomasz, Mateusz Koziol. 2016. „Diagnosis of early-stage damage to polymer - glass fibre

composites using non-contact measurement of vibration signals”.

Journal of Mechanical Science and

Technology 30(8): 3567:3576. ISSN 1738-494X. DOI: 10.1007/s12206-016-0717-1.

9.

Glowacz Adam, Zygfryd Glowacz. 2017.

„Diagnosis of the three-phase induction motor using thermal

imaging”. Infrared physics &

technology 81: 7-16. ISSN 1350-4495. DOI: 10.1016/j.infrared.2016.12.003.

10.

Glowacz Adam, Zygfryd Glowacz. 2017.

„Diagnosis of stator faults of the single-phase induction motor using

acoustic signals”. Applied acoustic

117A: 20-27. ISSN 0003-682X. DOI: 10.1016/j.apacoust.2016.10.012.

11.

Kelemen

M., I. Virgala, T. Lipták, Ľ. Miková, F. Filakovský,

V. Bulej. 2018. „A

novel approach for a inverse kinematics solution of a redundant

manipulator”. In: Applied

Sciences-Basel (Special Issue "Advanced Mobile Robotics") 8(11),

2229: 1-20. ISSN 2076-3417. Available at: https://www.mdpi.com/2076-3417/8/11/2229.

12.

Kohár

Róbert, Slavomír Hrček. 2014. „Dynamic analysis of a

rolling bearing cage with respect to the elastic properties of the cage for the

axial and radial load cases”. Communications

– Scientific Letters of the University of Zilina 16(3A): 74-81. ISSN

1335-4205.

13.

Koziol

Mateusz, Tomasz Figlus. 2017. „Evaluation of the failure progress in the

static bending of GFRP laminates reinforced with a classic plain-woven fabric

and a 3D fabric, by means of the vibrations analysis”. Polymer Composites 38(6): 1070-1085.

14.

Krayushkina

Kateryna, Olegas Prentkovskis, Andrii Bieliatynskyi, Raimundas Junevičius.

2012. “Use of steel slags in automobile road construction”. Transport 27(2): 129-137.

15.

Palčák

František. Theory of mechanisms.

Bratislava. SVŠT, 1993. 168 p. ISBN 802270-531-4.

16.

Skrúcaný Tomáš, Branislav

Šarkan, Tomasz Figlus, František Synák, Ján

Vrábel. 2017. „Measuring of noise emitted by moving vehicles”. MATEC Web of Conferences 107: 00072.

ISBN: 978-1-5108-4114-7. DOI: https://doi.org/10.1051/matecconf/201710700072.

17.

Škrabala

Jozef. 2018. „Design of the remote controlled mower“. Diploma

thesis. Bratislava: Slovak University of Technology in Bratislava.

18.

Sobota Aleksander, Renata Żochowska, Emilian

Szczepański, Paweł Gołda. 2018. „The influence of tram tracks on car

vehicle speed and noise emission at four-approach intersections located on

multilane arteries in cities”. Journal

of Vibroengineering 20(6): 2453-2468.

19.

Staniek

M., P. Czech. 2018. “Self-correcting neural network in road pavement

diagnostics”. Automation in

Construction 96: 75-87.

20.

Thomas

D.G. Fundamentals of vehicle dynamics.

society of automotive engineers. 1992. 495 p. ISBN 1560911999.

21.

Valaskova

V., D. Papan, R.C. Barros. 2016. “Assessment of the roadway dynamic

response due to the tatra 815 lorry excitation and experimental

verification”. Komunikacie 4.

ISSN: 2585-7878.

Received 03.06.2019; accepted in revised form 19.08.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License