Article

citation information:

Čuboňová, N.,

Dodok, T.. Ságová, Z. Optimisation of the machining process using genetic

algorithm. Scientific Journal of Silesian

University of Technology. Series Transport. 2019, 104, 15-25. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.104.2.

Nadežda ČUBOŇOVÁ[1],

Tomáš DODOK[2],

Zuzana SÁGOVÁ[3]

OPTIMISATION

OF THE MACHINING PROCESS USING GENETIC ALGORITHM

Summary. This paper deals with genetic algorithms as an

optimisation method and its use for optimisation of the machining process in

the CAM system. Tool path verification and optimisation are two best ways of dramatically improving manufacturing operations while

saving money with relatively little work. Genetic algorithms can be used for

improvement of these operations and considerably reduce length of tool paths

leading to the reduction of machine times and optimisation of cutting

parameters. Provides the software application created to optimise processes of

boring and local milling (Incomplete sentence; what or who provides).

Keywords: optimisation, genetic

algorithms, CAM system

1. INTRODUCTION

Preparatory activities

of the pre-production stage and their importance in terms of affecting the

quality and price of produced parts constitute a huge space for the application

of the philosophy of optimisation.

The problems associated with optimisation of technological processes are

increasingly relevant given the opportunities of accessible solutions and use

of computer technology [4,11]. Automated plants with deployed CNC technology

utilise PC at the design stage, with subsequent transition to technology, using

the CAD/CAM software. When solving optimisation tasks related to technological

processes, it is necessary to optimise not only operations but also the used

technological devices defined within the technological process operation

segments to ensure maximum labour productivity and minimum costs or maximum

profit. The modern concept of CAD/CAM systems enables optimising the process by

a number of criteria. Optimisation can be based, for example, on a semi-finished product. The

semi-finished product in a CAD/CAM system is gradually updated (modified)

during the design and simulation of the machining process [10]. Each following

operation includes machining of the remaining material only. This means

elimination of unnecessary and inefficient movements and actions [12]. Computer-aided

optimisation of machining processes (CAM – computer-aided manufacturing)

utilises software applications where the method of performance is usually

carried out using additional modules (optimisation programs). Optimisation

programs enable maximisation, in the machining process, especially tool paths,

cutting parameters, NC programs, etc., [13]. However, the tool path generated

from CAD/CAM systems is not guaranteed as the optimal tool path and there are

possibilities that the tool path distance is longer in order to complete each

drilling process. Therefore, optimisation of the CNC machine tool path should

be done before starting a machining process to ensure the tool path taken will

produce the shortest path of cutting tool travel [1].

Optimisation of machining processes

plays a key role in meeting the demands for high precision and productivity.

The primary challenge for machining process optimisation often stems from the

fact that the procedure is typically highly constrained and highly non-linear,

involving mixed-integer-discrete-continuous design variables. Additionally,

machining process models are likely discontinuous, non-explicit, or not

analytically differentiable with the design variables. Traditional non-linear optimisation techniques are mostly

gradient-based, which poses many limitations on their application to

today’s complex machining models. Mathematic analysis disposes of a

large variety of mathematic models for solving a large variety of optimising

problems. Nevertheless, many real-world tasks cannot be solved by these techniques,

or their solutions, which are not as good as those of some other special

nonlinear optimisation techniques. Therefore, some special optimisation

techniques were designed as solutions close to the optimal one but search only

in a very little fragment of the solution space. One of such optimisation

technique is the Evolution Programming (EP). EP is the name of a large variety

of optimisation techniques based on evolution principles. Genetic algorithms

(GA) is one of these evolution techniques, which mostly imitate principles of a

natural evolution process. GA presents itself as a very strong optimisation

technique capable of solving very complicated task with large search space in a

very short time with very good results. There is a lot of application, wherein

any optimisation technique was used or another whose results can be improved.

The field of application of genetic algorithms towards solving optimisation

problems in engineering is almost unlimited. [2]. Prediction

solutions optimisation problem depends on the correctness of the proposed

action solution to a specific optimisation task. This involves determining the

optimisation criteria and restrictive conditions, relating to the case and

knowledge of the issue of genetic algorithms, which outwardly look like a

universal solution, but requires an individual approach to each case.In

conjunction with the Genetic Algorithm (GA) method, Kumar and Pacahauri [5] and

Nabeel et al. [9] also used the Travelling Salesman Problems (TSP) to reduce

the total time and distance of tool travel for drilling sequence. Finally,

genetic algorithm is presented in this paper as an optimisation method with its use for the

maximisation of the machining process in the CAD/CAM system. It is a software

application with the possibilities of crossing methods especially with TSP,

created to optimise the processes of boring and local milling.

2. GENETIC ALGORITHM (GA) IN BRIEF

Concisely stated, a

genetic algorithm (GA) is a programming technique that mimics biological

evolution as a problem-solving strategy. The evolutionary program is a probabilistic algorithm which manages

the population of "n" individuals (chromosome) for "t"

iterations. Each individual represents a potential solution to the problem and

within the evolutionary program, it is presented as a data structure. Each

solution is evaluated, and the result of the evaluation is a degree of

suitability (fitness). The new population is then created selecting the most

suitable individuals. Some of the individuals undergo the transformation using

genetic operators and generate new solutions. There are single-transformations

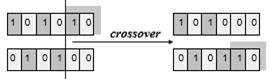

of mutation type (Fig. 1a) which will

create a new individual through a small change in the structure itself and

transformations of higher-order of crossover

type (Fig. 1b), which will create a new individual combining parts of two

or more individuals. After a certain number of generations, the program

converges supposing that the best individual represents a nearly optimal

solution [7].

|

|

|

Fig. 1. Scheme of

mutation (a), and single point

crossover (b) [6]

For a specific task,

several evolutionary programs can be proposed. These can differ in many ways.

Different ways of the individual´s

inscriptions can be used, genetic operators of individuals´

transformation can also differ similarly as methods of creating the initial

population or management methods of restrictive conditions and parameters

(population size, the probability of using genetic operators, etc.). However,

all of them share basic principles, for example, the population of individuals

undergoing some transformations (changes) and the individual struggle for

survival during the process of evolution.

The best-known techniques

among evolutionary algorithms are the

climbing technique also known as local or neighbouring search, the simulated annealing technique and genetic algorithms that truly mimic

evolutionary principles in nature. Before a genetic algorithm can be put to work on any

problem, a method is needed to encode potential solutions to that problem in a

form that a computer can process. These are the most common methods for

solution encoding: binary string

(0’s and 1‘s), string of

values (integer, real, letter...), string

encoded as permutation (every value can appear in the string only once), branching data structures (trees), and matrix encoding. It must be taken into

consideration that solution strings of evolutionary algorithms need not have a

fixed length. Then, a selective mechanism would be applied to decide which

individuals will be fit for selection for reproduction and which, on the other

hand, will be discarded as unfit. There are many different techniques which can

be used when creating a genetic algorithm for selecting the individuals to be

transferred to the next generation; Elitist selection, Fitness-proportionate

selection, Roulette-wheel selection, Scaling selection,

Tournament selection, Rank selection, Generational selection, Steady-state

selection, and Hierarchical selection. Some of these methods are used

individually, while others can be and are often used in combination.

Population size is a very important factor that

influences the function of genetic algorithms. If the population is too small,

the genetic algorithm can converge very quickly. However, if is too large, the

genetic algorithm may require too much computational time, which makes it

inefficient. In addition, the population diversity and selection pressure are

influenced by the population size. An algorithm with varying population size

does not use any of the earlier mentioned or similar selective mechanisms,

rather it evaluates individuals by age.

Age of the individual is equivalent to the number of

generations during which the individual will be in the population managed

by the algorithm. The individual´s age is proportional to its fitness and

replaces thereby selective mechanisms. However, it also directly influences the

population size in every step of the evolutionary process. This method

describes the real natural selection in the most convincing manner. Lifetime

(or age) is assigned to each individual at its origin and remains constant

during the evolutionary process until its extinction. This means that the

individual´s age is no longer recalculated. There are many ways of

assigning age to individuals. It is obvious that the assignment of a constant

value (greater than 1) would result in the population exponential increase.

Equally, as there is no selection pressure on individuals, the assigning of

constant age would result in a low-efficiency algorithm. Several strategies for

the calculation of the age of individuals have been proposed and tested

experimentally, for example [8]:

Proportional allocation:

![]() (1)

(1)

Linear allocation:

![]() (2)

(2)

Bi-linear

allocation:

![]()

![]() (3)

(3)

![]()

![]() (4)

(4)

Fitness (i) - fitness of the

individual

AvgFit - average fitness in

the current population

MinFit - minimal fitness in

the current population

MaxFit - maximal fitness in

the current population

MinLT - minimal lifetime value

MaxLT - maximal lifetime

value

LT - lifetime value

![]() (5)

(5)

Proportional evaluation - This originated from the idea of

roulette selection; the age of the individual is proportional to its fitness.

However, this evaluation has one great shortcoming; individuals, whose fitness

greatly exceeds the average fitness, can be evaluated by very old age. Linear evaluation - the life of

individuals is recalculated to the best suitability in the population. If,

however, many individuals have the same rate of fitness, or near the maximum,

this leads to a high evaluation and rapid expansion of the population. Bi-linear evaluation is a compromise

between the previous two. It highlights the differences between the life

expectancy of the best individualswhile taking into account the maximum and

minimum length of life [8].

When selecting suitable

individuals, they must be randomly modified in the hope that the fitness of the

next generation will increase. Two methods are used for searching the problem space,

namely: exploitation

- when creating a new generation, it makes use of the "experiences"

of previous generations to determine areas promising success in searching

optimal solutions; but it carries the risk of being trapped in a local extreme;

exploration - when creating a new generation it ignores the

"experiences" of previous generations. The browsing process is

conducted in unexplored areas thus avoiding deadlocks in a local extreme, which

eventually slows down the process. During the browsing itself, the main function of the

algorithm is to find the global extreme of hypersurface and not get stuck in any

of the local extremes during the searching process. Local extremes usually work

in parallel with several individuals making up the population. This is a

discrete time process – individual generations gradually take turns. The

process is repeated until the terminating condition is fulfilled. It may be the maximum number of

generations or other acceptable limit. The fundamental principle of the

genetic algorithm activity is shown in the flowchart (Fig. 2):

Fig.

2. Flowchart of genetic algorithm [7,14]

Genetic algorithms are

highly effective means of optimisation and are applied mainly for the solution

of problems with large or infinite number of solutions. Such a problem may be,

for example, the determination of an optimal drilling path when the tool path

passes through n points. Similar tasks can be found in many optimisation

techniques called Travelling

Salesman Problems (TSP) [7], a special type of problem, which evolutionary

algorithms deal with. Definition of this task is very simple: the salesman has

to visit each place within his trading area once and then return to the

starting city. If he knows the cost of travelling among individual cities, how

should he plan the tour for minimal costs? The search space is then the

permutation of n cities; every

permutation is then one possible solution and the optimal solution is the

permutation with minimal travelling costs. Size of the search space is then n! TSP is a relatively old problem:

Euler first described it in 1759 (under a different title). The name

“Travelling salesman” was first used in 1932, in a German book: Travelling salesman, how and what to do in

order to obtain commission and be successful in his trade [8]. The RAND

Company presented TSP in 1948. The good reputation of this company helped the

TSP become a famous and popular topic. In recent times, many algorithms have

been designed for TSP solution using different methods and strategies.

TSP problem can be

applied for optimisation of some technological processes such as drilling and

local milling operations. Most of the common CAM and CAD/CAM systems use none

or only some type of linear mathematics

for the solution of similar tasks due to long computing time [3]. Due to its

efficiency, GA can solve the mentioned problems within few minutes with

brilliant results. Thanks to their fundamental functions and characteristics as

parallelism, schema theorem and crossing,

it is possible to create various optimisation applications.

3. GA APPLICATION IN OPTIMISATION

OF MILLING AND DRILLING PROCESS IN CAD/CAM

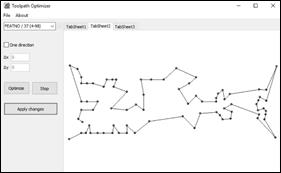

The Toolpath Optimiser

application was designed for the best use of tool paths of drilling and local

milling based on GA. During the design and creation of the genetic algorithm

for the Toolpath Optimizer application, it was necessary to choose among many

techniques and settings (for example, a problem inscription, method of

crossover, selection and mutation, setting the probability of crossover and

mutation, setting the size of population), by means of which the genetic

algorithm could be assembled. Incorrect set up of a genetic algorithm could

lead either to a too long optimisation process or to an unsatisfactory result

of the optimisation process. The set-up genetic algorithm was implemented as an

optimisation instrument for particular inputs and outputs (CL data from Creo

Parametric 5.0) for created Toolpath Optimiser applications. The application

was developed in the programming environment Borland Delphi, supplemented by

the module for reading and writing of CL data, and finally experimentally

validated on concrete examples of drilling and local milling. It also includes

a function for the movement of the approaching point before drilling, which

reduces inaccuracies of tool positioning caused by a backlash in the slides.

Input and output data of the optimisation module are CL data of CAD/CAM system

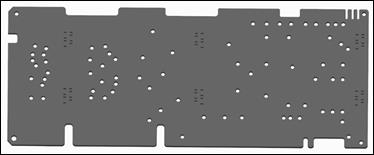

Creo Parametric 5.0. The experimental verification of the created optimisation software was applied to

maximise the creation of the technological process of the parts shown in Fig.

3a, b.

The problem of drilling optimisation can also be found

in the electrotechnical industry in the production of circuit boards, and many other areas. The reason this

problem is often solved in the production of circuit boards is that the

drilling process itself is very short. Movement of the tool out of contact with

the machined surface presents an essential part of the production time. The second

reason is the number of holes, that is, to find the optimal path for more than 20

points (Fig. 3a) becomes an almost unrealistic task under conditions of common

practice [13].

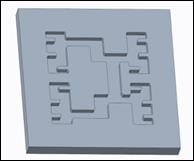

Local milling is an operation that is performed

after a previous operation of volume milling with a larger diameter tool (Fig.

3b). In places where a larger diameter tool could not remove the material, a

smaller-diameter tool is used; this operation is called local milling. High

requirements demand precision, and in drilling, the moving towards the centre of holes under the same vector is often

applied. This helps eliminate inaccuracies caused by changes in the slides

movement or movement of a machine table from positive to negative and vice

versa. The application controls the tool path so that the tool approaches the

positions of all holes under the same vector.

|

a) |

b) |

Fig. 3. Illustrations a) of printed

circuit boards for holes manufacturing by drilling operation, b) of local milling operation

A non-optimised tool

path for the drilling process is generated with the system Creo then

transformed into the CL data file and, subsequently, loaded into the Toolpath

Optimiser application. Fig. 4a shows a tool path of the drilling process

generated by the system Creo and Fig. 4b shows the non-optimised tool path

loaded into the Toolpath Optimiser application.

|

a) |

b) |

Fig. 4. a) non-optimized tool path of the

drilling operation generated by the system Creo b) non-optimized tool path

loaded in the application Toolpath Optimizer

Optimisation process in

the application starts with the confirmation of the selection sequence. Its

graphical flow is shown in two tabs (Fig. 5). One shows the best path in each

step of the evolutionary process (Path

length) and the other gives graphical information about the evolutionary

process (GA process). GA process

shows the dependence of the found shortest path on the number of generations (Length min). It also shows the

dependence of the average path length of all individuals from a particular

generation on the number of generations (Length

avg) and the dependence of the found longest path in the generation on the

number of generations (Length max). Path

length graphically displays the original length of a toolpath generated

from the CL data file (Length init)

and a new optimised path length (Length

new) generated by GA. When the evolutionary process is completed, it is

possible to compare the length of the new and original path, to compare the

optimised path (Fig. 5), to decide whether the result meets the requirements or

to repeat the evolutionary process.

|

|

Fig. 5. Graphical flow

of the optimisation process at the drilling operation

Having accepted the

optimised path (Fig. 6a), the CL data file is edited. The optimised tool path

can be loaded and displayed in Creo (Fig. 6b) and consequently processed by the

post-processor to NC code for a particular CNC machine.

|

a) |

b) |

Fig. 6. a) optimised tool path generated by

the application Toolpath Optimiser, b) optimised tool path of

the drilling operation loaded in the system Creo

|

|

|

||

|

a) |

b) |

|

|

Fig. 7. Tool path of

a local milling operation.

a)

non-optimised

tool path generated by system Creo,

b) optimised tool path loaded in the application Toolpath Optimiser

From the point of view

of tool rapid traverses, the local milling process is similar to the process of

drilling. Both processes use the same genetic algorithm, the only difference is

in the work of CL data field. Fig. 7 shows a simple example of tool path optimisation

process using the Local Mill sequence

in CAD/CAM system Creo, at Fig.7a is an original non-optimised tool path

generated by the system Creo; Fig.7b shows the same tool path optimised by the Toolpath Optimiser. The graphical flow

of the optimisation process at the milling operation is depicted in Fig. 8. The

genetic algorithm which forms the core of the Toolpath Optimiser proved to be a

highly effective means of optimisation. The result may be considered highly

satisfying. With smaller optimisation tasks - about twenty points - the

optimisation process takes only a few seconds [6].

|

|

Fig. 8. Graphical flow

of the optimisation process at the milling operation

4. CONCLUSION

To successfully address

an optimisation problem, we must know optimisation methods and appropriately

select the method we want to deploy to solve the problem in question. Although

some methods resemble one another due to their work processes, they may not be

equally suitable for solving the given task. Improper use of a method can

reduce the resulting effect of its work; it can even lead to obtaining false

results. TSP

problem can be applied for some of the technological processes such as

drilling, boring or local milling operations. Most of the common CAM and

CAD/CAM systems do not use any optimisation technique or use some kind of

linear mathematics based technique for solving this task due to the computing

time [7]. GA due to their

efficiency can solve the mentioned problems in a few minutes instead of a long

time (hours, days) with remarkable results. This article details optimisation

of machining processes using out of the CAD/CAM system environment. This

optimisation module may be used either directly or it can easily be modified in

compliance with the users´ requirements. For example, it is possible to

change the module of input and output data, which currently works only with the

CL data field of CAD/CAM system Creo. The experiments were created to optimise

processes of both boring and local milling. The results of these experiments

show that genetic algorithm is a simple and effective method for solving

complex optimisation problems. From the practical point of view, the

application Toolpath Optimiser can be used in the pre-production phase with the

aim to increase productivity and reduce production costs.

References

1. Abdullah

Haslina, Ramli Rizaudin, Abd Wahab Dzuraidah, J.A. Qudeiri.2015. “Simulation

approach of cutting tool movement using artificial intelligence method”. Journal

of Engineering Science and Technology 10 (Spec. Issue on 4th International

Technical Conference (ITC) 2014): 35-44. ISSN: 18234690.

2.

Bhoskar Trupti, Omkar K. Kulkarni, Ninad K. Kulkarni, Sujata L. Patekar,

G.M. Kakandikar, V.M. Nandedkar. 2015. „Genetic algorithm and

its applications to mechanical engineering: a review”. In: Materialstoday

Proceeding, 4th International Conference on Materials Processing and

Characterization 2 (4-5): 2624-2630. ISSN 2214-7853. DOI: https://doi.org/10.1016/j.matpr.2015.07.219.

3.

Jakubovičová Lenka, Milan Sága. 2014.

“Computational analysis of contact stress distribution in the case of

mutual stewing of roller bearing rings”.

Novel Trends in Production Devices and

Systems, Applied Mechanics and Materials 474: 363-368. Zürich: TransTech Publications. ISBN

978-3-03785-944-5. ISSN 1660-9336.

4. Karpavičius

Paulius, Vytautas Ostaševičius, Vytautas Jūrėnas, Jolantas

Baskutienė. 2017. „Self-powered wireless sensor system

application for cutting process control”. Mechanika 23(3): 456-461.

5. Kumar Abdhesh, Pachauri

Praveen. 2012. „Optimization drilling sequence by genetic

algorithm”. International Journal of Scientific and Research Publications 2(9): 1-7. ISSN 2250-3153.

6. Michalco Miroslav. 2009. “Implementácia

genetických algoritmov pri riešení

optimalizačných úloh technologických procesov”.

PhD.thesis. ŽU

v Žiline, SjF, KAVS. [In Slovak: Implementation of genetic

algorithms into solving of optimization task. PhD.thesis.

University in Žilina,Faculty of Mechanical

Engineering].

7. Michalco Miroslav, Nadežda Čuboňová. 2009.

“Computation methods for travelling salesman problem”. In: TRANSCOM 2009. 8th European

Conference of Young Research and Scientific Workers: 141-144. University of

Žilina, Mechanical Engineering Technologies, Žilina, Slovakia. 22-24

June 2009, ISBN 978-80-554-0042-6.

8. Michalewicz Zbigniew.1999. Genetic Algorithms+Data Structures=Evolution

Programs. Berlin: Springer. ISBN 3-540-600679-9.

9. Nabeel Kadim Abid Al-Sahib,

Abdulrazzaq Hasan Fahad. 2014. „Tool path optimization

of drilling sequence in CNC machine using genetic algorithm”. Innovative Systems

Design and Engineering 5(1): 15-26. ISSN 2222-1727.

10. Náprstkova Nataša.

2010.“Students connecting to production problems resolutions in CAD/CAM area”.

In: 9th International Scientific Conference:

Engineering for Rural Development: 310-314.

Jelgava, 27.-28.05.2010. ISSN 1691-5976.

11. Ostasevicius V., V. Jurenas, A.

Juskevicius. 2014. „Modified tool structures for effective

cutting”. Mechanika 2:

171-176.

12. Sága Milan, Roman

Bednár, Vaško Milan. 2011.

„Contribution

to modal and spectral interval finite element analysis”. In: 10th Biennial International Conference on

Vibration Problems (ICOVP). Prague, Czech Rep. Book Series: Springer Proceedings in Physics 139:

269-274. DOI: 10.1007/978-94-007-2069-5_37.

13. Sága Milan, Milan Vaško, Nadežda

Čuboňová, Wiesława Piekarska. 2016. Optimisation algorithms in mechanical engineering applications.

Harlow: Pearson. ISBN 978-1-78449-135-2.

14. The TalkOrigins Archive.

“Genetic Algorithms and Evolutionaty Computation”. Available at:

http://www.talkorigins.org/faqs/genalg/genalg.html.

Received 19.05.2019; accepted in revised form 18.08.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License