Article

citation information:

Urbanský, M.,

Kaššay, P., Vojtková, J. New design solutions of tangential

pneumatic torsional vibration tuners. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 103, 183-191. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.103.14.

Matej URBANSKÝ[1],

Peter KAŠŠAY[2],

Jarmila VOJTKOVÁ[3]

NEW

DESIGN SOLUTIONS OF TANGENTIAL PNEUMATIC TORSIONAL VIBRATION TUNERS

Summary. The optimal tuning of a mechanical system in terms

of torsional dynamics is a very important function of the flexible shaft

coupling, built in the system. Therefore, a flexible coupling with suitable

dynamic properties has to be carefully chosen for each specific application.

The main advantage of the pneumatic flexible shaft couplings, that is,

torsional vibration tuners, developed at our department, is that we can easily

regulate their dynamic properties, particularly their dynamic torsional

stiffness during the operation of a mechanical system. In order to improve our

pneumatic tuners in terms of better utilisation of their pneumatic flexible

elements and achieving specific operational properties, two new pneumatic

tuners with tangential arrangement of their pneumatic flexible elements were

designed. The aim of this article was to introduce these new pneumatic tuners,

protected by means of utility models, namely a tangential pneumatic flexible

shaft coupling with axially deformed flexible elements and tangential pneumatic

flexible shaft coupling with serial arranged flexible elements. Due to the fact

that both mentioned pneumatic tuners are not yet manufactured, this article

deals mainly with the principles and expected advantages of the pneumatic

tuners.

Keywords: tangential pneumatic torsional vibration

tuners, new design solutions, utility models, properties

1. INTRODUCTION

Nowadays, the reduction of

vibration and noise of machines is a very important task, mainly in terms of

human health, comfort and the lifetime and safety of machines, for example [6, 9, 14, 12]. Great emphasis is

placed on the use of modern progressive technologies in order to improve

electric and combustion engines for efficiency, better emissions and dynamics,

for example [4,

5, 10].

Flexible shaft couplings are the most utilised machine parts for the flexible

transmission of load torque in machines with rotary power transmission. A flexible coupling with

suitable dynamic properties, particularly dynamic torsional stiffness, has to

be carefully chosen for each specific application, otherwise dangerous

torsional vibration can occur in a mechanical system, for example [1, 7].

Flexible elements of flexible shaft

couplings are made of various materials, mainly of rubber, plastic and metal.

During the operation of mechanical systems, it is subjected to fatigue, ageing

of rubber and plastic flexible elements and ageing and wearing down of the

metal flexible elements of applied flexible coupling, for example [2, 8]. Consequently, the

applied flexible coupling loses its original dynamic properties and thus, the

ability to carry out its important functions in a torsionally oscillating

mechanical system, mainly, the tuning of a mechanical system in terms of

torsional dynamics. The disadvantages of the mentioned flexible elements can be

eliminated using pneumatic flexible elements (air-springs). The flexible

transmission of torque is ensured by a compressed gaseous medium, which does

suffer from fatigue or ageing. The main advantage of pneumatic flexible shaft

couplings (for example, couplings according to granted patents:

SK 288455 B6, SK 288344 B6, SK 288341 B6,

SK 278750 B6, SK 278653 B6, SK 278152 B6) is the

possibility to change their torsional stiffness which depends on the gaseous

medium pressure value in its pneumatic flexible elements. This makes it possible

to suitably adapt the dynamic torsional stiffness of a pneumatic coupling to

the actual operating mode of the mechanical system.

At our department, we dealt with

the development, research and application of pneumatic flexible shaft couplings

into mechanical systems. We focused mainly on continuous tuning of mechanical

systems during their operation in terms of torsional dynamics using pneumatic

flexible shaft couplings as active torsional vibration tuners. For continuous

tuning, we use electronic control systems developed by us. Our extensive

research in the field of pneumatic torsional vibration tuners and torsional

dynamics led to improvements in our pneumatic tuners and control systems. In

order to improve the tuners for better utilisation of their pneumatic flexible

elements and achieving specific operational properties, two new pneumatic

tuners with tangential arrangement of their pneumatic flexible elements were

designed. The aim of this article was to introduce these new pneumatic tuners,

protected by means of utility models, namely:

1. Tangential pneumatic

flexible shaft coupling with axially deformed flexible elements[4].

2. Tangential pneumatic

flexible shaft coupling with serial arranged flexible elements[5].

Because both mentioned pneumatic

tuners are not yet manufactured, this article deals mainly with the principles

and expected advantages of pneumatic tuners. We are going to manufacture and

research given pneumatic tuners within our next grant project.

2. NEW PNEUMATIC

TORSIONAL VIBRATION TUNERS

2.1. Tangential

pneumatic flexible shaft coupling with axially deformed flexible elements

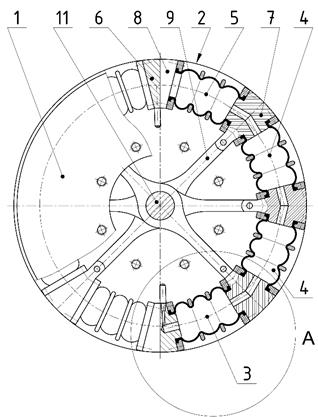

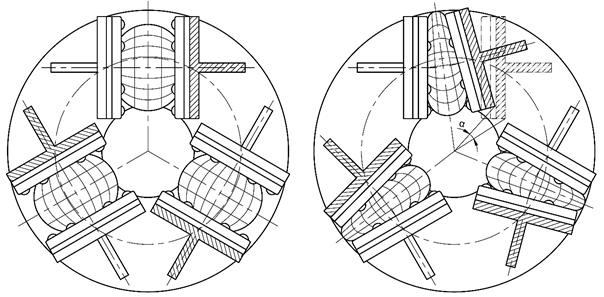

Proposed tangential pneumatic

flexible shaft coupling with axially deformed elements (Fig. 1) is made up

of a driving (1) and a driven hub (2), flexibly connected by pneumatic flexible

elements (3). The pneumatic flexible elements are attached to support bodies

(4), which are rotatably mounted on pins (5). These pins are solidly connected

to the corresponding hub. The axes of the pneumatic flexible elements are

perpendicular to the axes of the pins. The support bodies (4) are fixed to the

pins with washers (6) and split pins (7). The rubber shells (8) of the flexible

elements are firmly connected to the support bodies with flanges (9).

A compressed gaseous medium (most

commonly air) is fed into the fuel space of the coupling via a filling valve

(12). The compression space of the coupling consists of inner spaces of the

pneumatic flexible elements, mutually interconnected with the inner spaces of

the support bodies. The pressure of the gaseous medium holds the unloaded

coupling in neutral position (Fig. 1). Under load by torque, it comes to

angular deflection between the driving and driven hub and consequently to axial

deformation of pneumatic flexible elements (Fig. 2).

Fig. 1. The

tangential pneumatic flexible shaft coupling with axially deformed flexible

elements in unloaded state (neutral position)

The angular twist causes the

gaseous medium compression so the load torque can be transmitted flexibly. The

support bodies of the proposed coupling are automatically turned to the

equilibrium position so that only axial deformation of the elastic elements

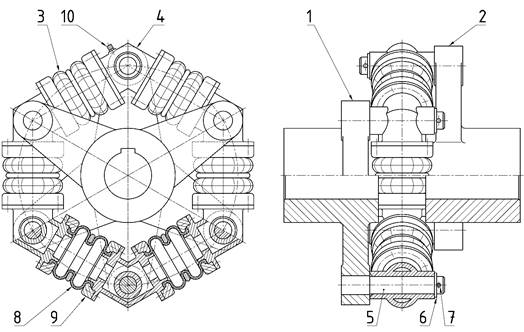

occurs. In Fig. 3, we can see that in the case of conventional tangential

pneumatic flexible shaft couplings (with fixed support bodies), the flanges of

the elements are tilted during twisting.

Fig. 2. The

tangential pneumatic flexible shaft coupling with axially deformed flexible

elements in fully loaded state (at maximum twist angle α)

Fig. 3. A

tangential pneumatic flexible shaft coupling

a) in basic

position, b) in fully loaded state (at maximum twist angle α)

Since the flanges of the pneumatic

flexible elements are parallel in the full extent of the coupling’s

twist, it is possible to fully utilise the stroke of the pneumatic elements

given by their manufacturers, for example [2, 110]. Therefore, the

pneumatic flexible elements are deformed in the most suitable way with respect

to their design and lifetime. Another advantage of this type of coupling is

that the entire assembly of flexible elements connected by the support bodies

can be easily withdrawn from the pins, which allows easy and quick assembling

and disassembling of the whole coupling.

2.2. Tangential

pneumatic flexible shaft coupling with serial arranged flexible elements

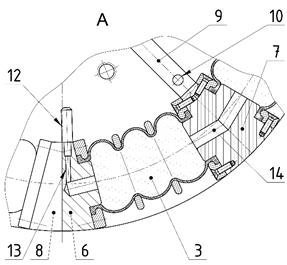

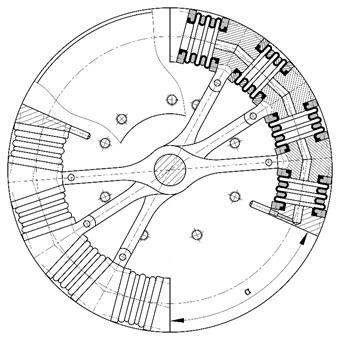

Proposed tangential pneumatic flexible shaft

coupling with serial arranged flexible elements (Fig. 4) contains a driving flange (1)

and a driven flange (2). Between the flanges, the compression space of the

coupling is situated. The compression space of the coupling is comprised of

pneumatic flexible elements (3), (4), (5), which are arranged in a circle so

that they are connected and create a “flexible chain”. The flanges

of the pneumatic flexible elements (3) are fixed to rigid parts (6) of the

driving flange and to support bodies (7). The flanges of the pneumatic flexible

elements (4) are fixed only to the support bodies (7). The flanges of the

pneumatic flexible elements (5) are fixed to rigid parts (8) of the driven

flange and to the support bodies (7). The support bodies are fastened to

rotatable floating bodies (9) by pins (10). The rotatable floating bodies are

rotatably mounted on a pin (11). The pin (11) is coaxially embodied in the driven

flange (2).

|

|

|

Fig. 4. The

tangential pneumatic flexible shaft coupling with serial arranged flexible

elements in unloaded state

Mutual interconnections of the

pneumatic flexible elements (3), (4), (5) are done by ducts (14), which are

created in the support bodies (7). The compression space of the coupling can be

filled with gaseous medium through valves (12) and valve ducts (13). If there

is overpressure of the gaseous medium in the pneumatic flexible elements

(compared to the atmospheric pressure) then the rigid parts (6) of the driving

flange and the rigid parts (8) of the driven flange are in contact, then the

unloaded coupling is in basic position (Fig. 4). Under load by torque, it

comes to an angular deflection between the driving and driven hub and

consequently to a deformation of the pneumatic flexible elements of the

pneumatic coupling. The angular twist causes the gaseous medium compression and

then the load torque can be transmitted flexibly in mechanical systems

(Fig. 5). The shape of the support bodies (Position 7 in Fig. 4)

can be adjusted so that the bearing surfaces of the pneumatic flexible elements

flanges are parallel at the maximum twist angle α of the coupling (Fig. 5), in order to maximise the

effective area of the compression space of the coupling and hence increase the

maximum load torque of the coupling.

Fig. 5. The

tangential pneumatic flexible shaft coupling with serial arranged flexible

elements in fully loaded state (at maximum twist angle α)

The function of the support bodies

(7) in connection with the rotatable floating bodies (9) (Fig. 4) is to

ensure the stability of the “flexible chain” of pneumatic flexible

elements in the radial and axial direction (referred to the axis of rotation of

the coupling) when the coupling is twisted. In this way, much higher values of

the maximum twist angle α of the

coupling (Fig. 5) can be achieved (for example, compared to the tangential pneumatic

flexible shaft coupling shown in Fig. 3).

The high value of the maximum twist

angle of the coupling is one of the prerequisites for creating a high-flexible

coupling, which means flexible coupling with very low value of relative

torsional stiffness k0, can be expressed as follows:

![]() . (1)

. (1)

The k0 is defined as the ratio

of the nominal dynamic torsional stiffness of a flexible coupling kDN (at MN) to the nominal torque MN of the coupling. Common flexible couplings have the

relative torsional stiffness value in the range of

10 ÷ 30 rad-1. Shaft couplings marked as

high-flexible have the relative torsional stiffness value lower than

10 rad-1. Therefore, with respect to physical principles, a

flexible coupling with a low torsional stiffness must have a large twist angle in

order to transmit high load torque.

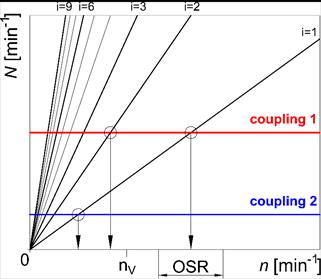

By the application of a

high-flexible coupling in a mechanical system (coupling 2 in

Fig. 6), the resonances from the individual harmonic components of a

torsional vibration excitation can be moved from the operating speed (n) range (OSR) of the system to the

lower speed area far enough under idle operating speed nV, for example [142]. This lower speed area

can be quickly run across at the start-up of a mechanical system, as shown in

the general Campbell’s diagram of a mechanical system (Fig.6), where i stands for the order of the

harmonic component of torsional vibration excitation.

Fig. 6. Campbell’s

diagram of a mechanical system

3. CONCLUSION

The tangential pneumatic

flexible shaft coupling with axially deformed elements and the tangential pneumatic

flexible shaft coupling with serial arranged flexible elements can be applied in the

systems of mechanical drives. They allow flexible torque transmission and due

to the ability to change their torsional stiffness, ensure the tuning of these

systems at various operating conditions.

In the case of the tangential

pneumatic flexible shaft coupling with axially deformed elements, the pneumatic flexible

elements are deformed in the most suitable way in terms of their design and

lifetime and the

stroke of the pneumatic flexible elements is allowed to be fully utilised.

Regarding the tangential pneumatic

flexible shaft coupling with serial arranged flexible elements, the design is

focused on creating the high-flexible coupling, which means flexible coupling

with very low value of relative torsional stiffness. The current trend in the

field of flexible shaft couplings, which is the most noticeable in the

automotive industry, is the development and utilisation of high-flexible

couplings (dual

mass flywheels). Because gaseous media throughout its lifetime is not subject to ageing,

resultantly, pneumatic couplings do not lose their initial positive dynamic

properties, it would be of better advantage to develop flexible couplings with the

advantages of both pneumatic and high-flexible couplings.

On the above-mentioned grounds, we

suppose that both proposed pneumatic couplings are able to increase the

technical level and reliability of the mechanical systems in which they will be

applied. Therefore, we are going to research and manufacture the prototypes of the given

pneumatic couplings under the terms of our next grant project. Our research

will be focused on the following activities:

·

designing and manufacturing of specific

prototypes of the pneumatic couplings using the principles of presented utility

models,

·

measuring static [11] and

dynamic operating properties of the prototypes,

·

creating the mathematical and physical models of

the prototypes,

·

applying the prototypes into torsionally oscillating

mechanical systems, in order to do a tune and continuous tune the mechanical

systems during their operation in terms of torsional dynamics using pneumatic

flexible shaft couplings as active torsional vibration tuners and electronic

control systems developed by us,

·

creating the mathematical models of the torsionally oscillating

mechanical systems,

·

comparing the results of measurements with

results of the simulations of the torsionally oscillating mechanical systems

with the applied prototypes,

·

improving the mathematical and physical models

of the prototypes, if necessary.

Acknowledgement

This paper was written within the framework of the

APVV-16-0259 grant project entitled, Research and development of combustion

technology based on controlled homogenous charge compression ignition in order

to reduce nitrogen oxide emissions of motor vehicles.

This paper was written within the framework of the KEGA

041TUKE-4/2017 grant project entitled, Implementation of new technologies

specified for solving questions concerning the emissions of vehicles and their

transformation in educational processes in order to improve the quality of

education.

This paper was written within the framework of the VEGA

1/0473/17 grant project entitled, Research and development of technology for

homogeneous charge self-ignition using compression in order to increase engine

efficiency and to reduce vehicle emissions.

References

2.

Gurský

Pavol. 2011. „Influence of working cycles identification on

characteristics of flexible couplings and their comparison”. PhD thesis,

Košice, Slovakia: Technical University of Košice.

8.

Maláková

Silvia, Jaroslav Homišin. 2018. Defining of material characteristics for

flexible element in pneumatic flexible coupling. In Projektowanie, badania i eksploatacja. Volume 1, edited by

Jacek Rysiński, P. 277-282. Bielsko-Biala: Scientific Publisher of the

Academy of Technology and Humanities in Bielsko-Biala. ISBN 978-83-65182-93-7.

12.

Singhal

V., Jain S.S., Parida M. 2018. “Train sound level detection system at

unmanned railway level crossings”. European Transport/Trasporti

Europei 68(3): 1:18. ISSN 1825-3997.

13.

STN 011413:1992.

Mechanické

kmitanie – Pružné hriadeľové

spojky – Všeobecné požiadavky na

skúšky. [In Slovak: STN 011413:1992. Vibration – Resilient shaft

couplings – General requirements for tests]. Prague: Publisher of standards.

Received 10.02.2019; accepted in revised form 30.04.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License